-

Posts

180 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by HLS30-08077

-

So. After reading everything possible on the subject, studing the FSM's, diagrams, drawings and anything I can get my hands on...... Here's what I've done to my 2/74 260Z........ I completely rewrapped the engine harness and removed every un-needed wire. Those included the EGR wires, red foglight wires, added a 10 gauge ground wire in the middle of the front core support to be bolted to the support, The A/C compressor blue wire, small white and w/r wires from the shunt, the shunt, ALL A/C wires (yellow pressure switch wires, mag valve wires and A/C relay) Emergency switch and it's wires, etc, etc. Interlock Module... (Located in the uppermost area of the passenger side kick panel w/ 2) 6 pin connectors, I completely disconnected it. Seat contacts and seatbelt contacts... Disconnected because I will have aftermarket seats and a different model or style seatbelt system AND the wires all go to the now-disconnected interlock module (it'll have a roll bar and 4-point harness's) Interlock Relay... Located on the firewall and had 1) 2 wire connector and 1) 3 wire connector. The Black/yellow and the yellow/black (or solid yellow) need to be cut from the relay and connected to each other. The other wires are a ground and 2 control wires. I cut mine and fed them back thru the firewall. Emergency Switch... Located near the battery on the fender, 4 red associated wires, I disconnected the switch, cut the Y/B and the B/Y from the connector and connected them to each other. The black wire is a ground and not needed, the blue is connected to the B/W ign. wire inside the harness. The dreaded SHUNT... Since I won't have an AMP gauge, the shunt is pointless, as that's the only purpose I have found it to serve. The shunt's W/R 8ga wire is a tap from the Alternators 8ga wire. The alt wire goes to the green fusable link on the firewall, but not before it's split again and goes thru the firewall. After it's fused on the firewall, it's now a 10 gauge W/R that also goes thru the firewall as well. The White 8ga wire from the shunt, goes to the Black fusable link on the firewall. After it's fused, it goes to the starter. There is an 18 gauge tap on the White wire, before the fusable, that goes to the VR. SO, I cut the 2 large wires from the shunt and connected them to each other. Reason for this is simple, they are already connected inside the Shunt via a large peice of wavy metal. Which I felt could only inhibit amperage, so one less connection. The 2 small wires from the shunt were cut and fed back thru the harness and the firewall, to be cut off. They go directly to the Amp gauge, which I will toss and replace with a very small LED face volt meter, from a bad Car stereo Capacitor. The only thing left is the Voltage regulator. If I had a question for the pros, It would be this.... Does the VR have anything to do with the Fuel Pump relays? I know it has an alt. sense wire but wondered, if I connected the B/W and the W/B together as well as the W and Y together, tossed the black ground wire, what wires are left and where or what should I do with them. Below is the remainig crap, you should have seen all the old tape, wires, connectors and crap that removed. Filled a grocery bag with junk. Dave

-

Good to know. I did the non-vented rotors and Toyota 4-piston calipers up front but still have the stock MC and drums brakes in the rear on my 70' and everything is well balanced. And the pads are your everyday regular pads. But the 260Z has the 15/16" MC, S12-8 4-piston calipers and non-vented rotors up front, and the rears are the 79' to 81' 280ZX rear disc brake set-up, with regular bendex pads and rotors. Nothing slotted or drilled, no special compounds or anything like that. It's just a basic set-up for now. I can't even tell you how it performs until next spring when it hits the road for the first time in 2 years. But I will definately give updates and progresssive reports on the pros and cons of this set-up. Thanks again Jon, you da man! as always, Dave

-

Well, my son is 6'2" and he has head clearance and says the sits are awesome. but he's also a broomstick so width is not an issue for him. I'm 5' 7" and barely 135 lbs soaking wet. They fit me but there's room to spare. if you're height/weight proportionate, @ 6'4" they would be snug but fit you. I don't know the exact manufacturer but they say NISMO (Nissan Motorsports International) on the headrest. sorry I don't have more info for ya. Dave

-

So I bought a brake line with ends on it and started bending. Foound some of the OE brackets and tried this out...... Below. Also ordered my Stainless Steel Brake lines and clutch line. Should be here by thursday, so I can see if the mod will work with full suspension travel. Cause this WILL be a driver, not some show peice, taking up space in some dark garage. I hate that. Oh Ya, I used the old ratty line for mock up but it's out of here on thursday. I'm thinking maybe a long soft spring for any hang over issues, similar to the ebrake line over the diff.

-

So here's my Progress so far. This is all on an early 260Z (2/74) I got the mount and POR15'd it after media blasting it to help the POR stick better. I went to go mount it and found that the 260Z's exhaust hanger is in the way. 4 spot welds, an air hammer and large mallet later, the hanger is gone and I'm ready to slip the RT in place. Of coarse, the fuel lines and the rubber bracket are in the way. So I move the bracket forward and gently push the brake and fuel lines upward to clear the R/T. After that, the instal was smooth. Couple smacks with the plastic mallet to align the bolt holes and we're good to go. Had to lift the diff into place and ballance it on my shoulder while I was bolting it to the Mustache bar, then lifted the front to bolt up the poly to the R/T. In the 4th pic, you can see that I tightened the Poly so much (to make sure it was tight) that the inner plate started to twist. I fixed it shortly after the picture was taken. Here's the pics.... Dave.

-

So here's my Progress so far. This is all on an early 260Z (2/74) using the 79' to 81' rear disc brake conversion brackets from JOE and 79' 280ZX rear calipers. The Ebrake mounting tab is too low and has clearance issues with the control arm. My fix is in the pics. The early 260Z's brake line mount is in direct line with the large caliper plate and will need to be removed and a new one place farther back towards the rear of the car to clear the plate. I crossed the Ebrake cables to take up the slack and they work great. I can operate them by hand, pulling the "Horse-shoe bracket in front of the diff. Now I gotta change the brake line bracket to clear the caliper plate. Then order the Stainless brake lines to mock up the hard line from the calipers. Dave

-

Disk Brake Upgrade Ideas for 77 s30

HLS30-08077 replied to Zerocell5688's topic in Brakes, Wheels, Suspension and Chassis

OK, so here's what I did.... Took a while but I got the OEM bracket off, loaded the ebarke cable onto the stock bracket and figured out where I wanted it. I went for the old 2 finger spacing and it looks and operates properly. I should have the rotors in by friday and we'll see how they look. But I still gotta order the stainless lines to mock up the calipers hard lines and see if the banjo is an option or a better bet. Also crossed the E-Brake cables over to take up the slack. I can pull the cable by hand, from in front of the diff, without it binding. So pulling the handle should be very affective. On the 4th picture, the suspension is fully dropped and when it comes back up, will hit the stock brake bracket. So I need to cut it off and move it back towards the rear of the car so the SS line and the caliper will clear the bracket. Dave. -

Disk Brake Upgrade Ideas for 77 s30

HLS30-08077 replied to Zerocell5688's topic in Brakes, Wheels, Suspension and Chassis

OK, here's what I got. I bought the 79' to 81' 280ZX adaptors and picked up the 79' 280ZX calipers from the Pull-A-Part for $6.50 each (love pull-a-part) pads were $12 for the rears and the adaptor I got for $90 cause someone changed their mind. Here are the pictures. You can see on the last pic that I obviously need a 90* to aim the line upward towards the main brake line on the body. I'm thinking, maybe a plate weded to the top of the brake bracket to hold the hard line, then the SS flex line from there to the body. Maybe? Opinions? So do I need to cut off the ebrake bracket and weld on the stock one in that place to get it to correctly and at the correct angle? The cut/bent line is just to keep the inlet clean and dirt free. just temporary. Dave -

Disk Brake Upgrade Ideas for 77 s30

HLS30-08077 replied to Zerocell5688's topic in Brakes, Wheels, Suspension and Chassis

Thanks George, That's a start. Dave -

Does any one on here have pics of their 79' to 81' 280ZX rear disc brake swap into an S30. I need to see the Stainless brake lines you used and how they fit. Can I just buy the regular Earls SS lines from Motorsport for my 260Z and still use them with the ZX rear disk brakes??? I need pics people, Please!!! I'm a visual kinda guy. Dave

-

Disk Brake Upgrade Ideas for 77 s30

HLS30-08077 replied to Zerocell5688's topic in Brakes, Wheels, Suspension and Chassis

Does any one on here have pics of their 79' to 81' 280ZX rear disc brake swap into an S30. I need to see the Stainless brake lines you used and how they fit. Can I just buy the regular Earls SS lines from Motorsport for my 260Z and still use them with the ZX rear disk brakes??? I need pics people, Please!!! I'm a visual kinda guy. Dave -

I know, I just keep thinking of the stock mount and keep forgeting about the interlocking (failsafe) feature of the GM mount. Thanks guys, I can never be too informed. The more answers I get, the more informed I am, the more info I can give when someone asks me. You get the idea. Dave

-

All good questions and I considered that after I hit the "Submit" button. I just like that "Bullet-Proof" idea before the wheels even hit the ground. I won't have that much HP to the wheels but it's always nice to know that it'll never fail under "Dumb ass" conditions. Thanks again Jon, Dave P.S. That 79' 280ZX at the Arlington Pull-A-Part has a complete rear in it. (Diff, Mustache Bar, extra diff in the hatch area, etc, etc.) Just FYI. It's in Isle I-2 in the middle and the 78' 280Z is in Isle G-1 toward the back fence.

-

I'm not mistaken, I'm misinformed and confused. There are 3 holes on top of the GM mount. Should I just use the middle one? I know the mount is in compression when the car is under load (forward motion) but what about if the car is in reverse and the only thing holding the diff up is 1 bolt? Just trying to cover all the bases. For safety, clarity and peace of mind. Dave

-

OK, so here's my "Question of the Day" for any of you, Brad, BJHines, etc, etc. In the pictures on post #5, It shows 2 bolts holding the GM mount to the R/T mount. So why did my R/T mount only come with 1 hole? And which of the 3 holes on the GM poly mount should I use? Should I drill another hole? Wouldn't 2 bolts be better than one? Some one? Anyone? Dave

-

260z no charge, no shut off

HLS30-08077 replied to sqweekykneecap's topic in S30 Series - 240z, 260z, 280z

Well? did the diode work? If it did, can you documnet what you did on each wire, as if a retarded person (me) was reading it? I'd really appreciate it. Thanks in advance. Dave -

This was my solution.... I also plan on a better set for the 260Z build, and I'm also buildiong custom door panels with speaker pods as well. I'm also going to do custom rear panels to aim the rears a little closer to the passengers and not at each other.

-

The picture below is an example of a bad diff mount. You can see that the rubber is seperating from the metal. The first time you really GET ON IT (floor it or drop the clutch) the rubber will completely seperate and the diff will smack the upper diff strap (located above the diff to "Arrest" the diff under diff mount breaking conditions. You can tell if it's wearing out by dropping the four bolts that hold the crossmember and letting the diff hang by the mustache bar. While it's hanging, apply a trwisting motion to the crossmember while watching the rubber and metal area or the mount. (as shown in the picture) Dave

-

I know my 70' 240Z and my 74' 260Z are the same. but I'm gonna guess and say that all S30's are the same bolt pattern for the seats (240Z, 260Z, 280Z )

-

Flux core... should I just give up now??

HLS30-08077 replied to z2go's topic in Fabrication / Welding

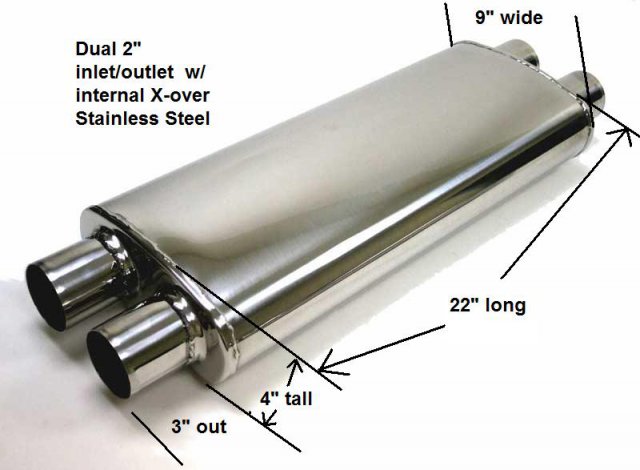

The only thing I've used on the 260Z build has been a .032?? Flux-core welder (Harbor Freight Tools Special) and it kinda sucks but at the same time, it's not THAT bad. I've learned to keep the nozzle as close to the weld (about 1/4" away) as possible. On 22 to 18 guage, I use the LOW setting and turn the speed up to 6 or 7 (On a nine scale dial) And when I welded the diff cross member peices together (pictures below) I used the HI setting and kept the speed at about 7. It welds 12 to 16 gauge beautifully, in my opinion. Especially on a tight budget. Would love to be able to afford a gas though, but I'll stick with the FC for now, it works. Dave. As you can see, the welds aren't that bad and after a little grinding and POR15, they turn out nice. ALL this in prep for the R/T mount that I'm hoping to see soon. (Hint Hint RoostMonkey) I cut out the center to make room for the dual 2" exhaust that will be added later, using the 4"x9"x22" muffler shown, which will sit hight in the tunnel due to the crossmember alteration. -

IS IT ME OR IS......... a proper statement?? Hell, Imight be real interested but I'm a "See it, Touch it, Smell it" kinda guy. I need eye candy....

-

Wish I would have come across this thread before, I could have added to it in my usual way. As an ex-Car-Toys installer, I've used the SPAL kit over 30 times. 10 of which were in 240Z's. Here's a couple shots of the instal in my own Z. I also have done power door locks in almost all of those 240Z's as well. They go well together. I charge $160 for the kit with 2 switches and another $100 to install it. I should charge way more considering the pain in the a$$ it is to drill for wiring and such, but my loss is your gain, or something like that. Here is an assortment of power window and lock instals on a few different S30's

-

Or at least that's the name on the seats headrest area. Got them for $360 off craigslist. The guy had them in his 240SX and thought they were too soft. Just right for me... And the wife. That's a plus. Just had to drill new holes 3/16" to the outer upper corner of the front stock holes, and 1/8" wider to the outer part of the rear holes. So I can go back to stock in a heart beat. Dave

-

260Z seatbelt interlock. Defeat

HLS30-08077 replied to Pharaohabq's topic in S30 Series - 240z, 260z, 280z

Thank you. I need all the help and clarity I can get. Dave