-

Posts

1568 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Zmanco

-

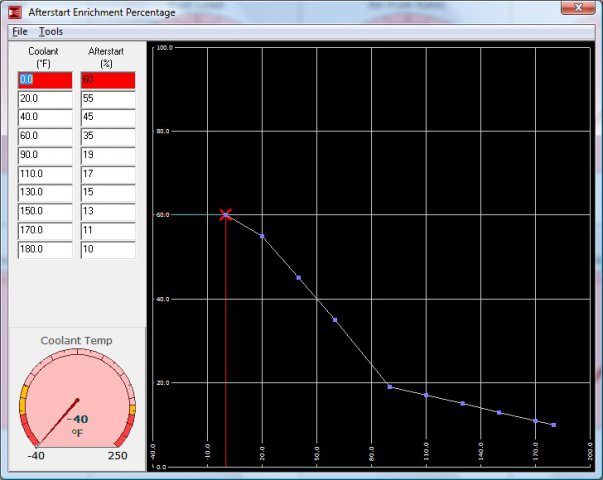

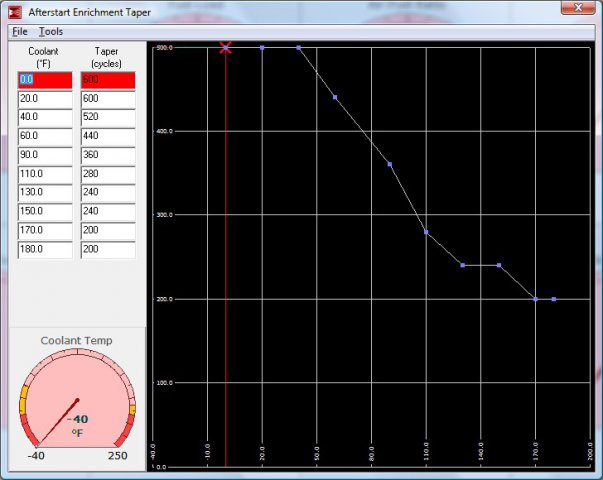

No problem Nigel, just wanted to make sure you weren't headed in the wrong direction with your tuning strategy. Dave, I've noticed the lean condition at start when the engine is warm and your explanation of warm fuel in the rail makes sense. With the MSII/extra code there's pretty fine grain control of ASE so I give it about 5 seconds (assuming an idle of 850 rpm) of +10% which seems to help.

-

Noddle, please re-read Ron's and my previous posts. MS will take the change of temperature from morning to afternoon (and summer to winter as well) into account and automatically adjust the amount of fuel delivered without needing the IAT correction table. The formula it uses to calculate how long to fire the injectors is the ideal gas law: PV = nRT where T = IAT and n = the amount of air in the cylinder. Check out wikipedia to learn more: http://en.wikipedia.org/wiki/Ideal_gas_law. You should also read some of the MS manual as they do a good job of explaining this as well. Note to the MS purists: I'm leaving off the affect of VE and other inefficiencies here on purpose. You can see that as T goes up n must go down if all else remains unchanged. You do not need to use the IAT correction table to achieve this. As Ron and I said earlier, this is already built into the way MS calculates how long to fire the injectors before each squirt. My engine is NA like yours and I do use the IAT correction table to take into account heat soak of the IAT sensor when idling in summer traffic. But it doesn't even begin to kick in until 110F at which point it's only +1%, and then it grows slowly from there. And when I tune, I set those values back to zero to make sure they're not having any effect. Otherwise you'll find yourself tuning AROUND the IAT table which is NOT what you want.

-

MS calculates how much fuel is required before every squirt using the ideal gas law which takes into account the temperate of the incoming air. Hence in theory it will lean out the mixture as the air temp goes up, all else being equal. In practice there are a host of issues that can cause the IAT sensor to heat soak to some degree so the system tends to be less accurate at low air speeds (light throttle) and more accurate at WOT (where the air flow is greatest). If you're interested, search on IAT in the MS section and you'll find many discussions on the best place to mount the sensor etc.

-

Airplane on a conveyor belt debate settled, now...

Zmanco replied to Globerunner513's topic in Non Tech Board

It depends if it's 33 or 45 rpm. -

New low profile tire... Has low profile been taken too far?

Zmanco replied to B00STDZ's topic in Non Tech Board

The phrase "Just because you can doesn't mean you should" comes to mind. -

There is snow on the ground today so I was watching some of my favorite videos and thought I'd share this one. I'm sure some of you have seen it before but expect you'll enjoy watching it again. I really like the box shot of him driving - he is so calm and relaxed.

-

Weber jets??All who live for their triples please read this

Zmanco replied to datfreak's topic in Nissan L6 Forum

When I rebuilt my DCOEs I installed the new needle and seat assemblies just assuming they were the same size as the old. While tuning afterward, I found that I had an intermittent lean condition that could be felt above 4k rpm, similar to what Russell described. I initially suspected I had a fuel delivery problem and swapped the fuel pump and filter with no success. Eventually I put the old needle and seats back in and the problem was solved. I don't remember what size they were, although I'm pretty sure the rebuild kits were NOT genuine weber. -

I miss Henry's ribs - I trust the building is still standing? Just barely?

-

Weber jets??All who live for their triples please read this

Zmanco replied to datfreak's topic in Nissan L6 Forum

When I had triples I did play around one afternoon with float levels and could not find any significant repeatable changes from small adjustments. I was using a narrow band O2 sensor and 2nd and 3rd gear pulls on an empty road so it was anything but scientific. But I suspect that tweaking float levels is not going to solve the flat spot issue unless the float levels are currently way out of spec. -

got my new rear brake kit

Zmanco replied to 1 tuff z's topic in Brakes, Wheels, Suspension and Chassis

IIRC from an earlier thread, aren't they from a Mustang Cobra? And since most brakes aren't made by the car manufacturer themselves, I doubt they are made by Ford. They look very similar to the calipers on my wife's Volvo which are made by Ate. -

got my new rear brake kit

Zmanco replied to 1 tuff z's topic in Brakes, Wheels, Suspension and Chassis

I had the same issue with the 240sx rear calipers and toyota vented setup in front. I eventually solved it by using a pad with a higher coefficient of friction in the rear to balance it out. But it would be better I think to be able to use the same pad material front and rear so they have more similar thermal characteristics. -

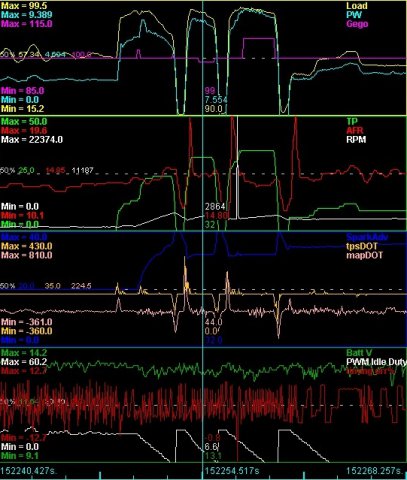

I'm trying to understand what the datalog variable "timing error" means and was looking at a few other datalogs. I found one with another RPM spike and noticed that the timing error hit its max of -12.7% at that exact moment. I've tried searching on the various megasquirt sites, but so far can't find any discussion of what timing error is referring to. Can anyone shed some light?

-

Actually I'm running with Magnecor wires. Before I installed them I had a lot of resets. Since then, except for this, I haven't had any, not even one. And I'm not sure if this is a reset or something else. Interesting thing is that I switched to the Magnecor wires a year ago but this issue has only begun to show up in the last few weeks and is beginning to occur more often. I'm not sure if something is degrading, or if I've just become more sensitive to it.

-

In the datalog I posted there were 2 known red lines - 1 where I restarted the car at a store, and the other just after the event in the screen capture which was from me hitting the space bar to mark it. Matt, did you see other resets?

-

I've been running with this beta code for about 2 months and the problem only recently surfaced. Also, I'm pretty sure that cygnusx1 is running released code so I don't think it's the beta. I'd have to retune my IAC if I switched back to the released code so probably won't do that unless everything else comes up empty. Also, how did you see the processor reset? What variable is it in the log? And what does timing error refer to?

-

Thanks for taking a look. datalog200811041112.zip

-

FWIW, last summer I bought mine from amazon.com. Hint: find the specific part number of the CF kit you want and then google it. That's how I found Amazon with the lowest price. Otherwise I would never have looked there for car parts.

-

In theory using the chassis would be a great idea because of the large surface area (the electrons mostly flow on the surface of the conductors, not through the center). But in practice, the chassis isn't one continuous piece of metal and over time corrosion will develop at the various seems which will add resistance. So for our old cars, as was said above, it's best to pull both +12V and ground cables to the battery wherever it's mounted and to use at least 4 gauge or larger (size, not number). That said, it's probably not a big deal if you use the chassis if the car has lived its life in a less corrosive environment (Arizona for example) and if the battery, starter, and rest of the engine are all in good condition. But separate cables would be better.

-

Don't forget slownrusty: http://forums.hybridz.org/showthread.php?t=139021 I saw it in person last weekend and it's just as impressive as in the pictures. Should be very fast once he's through sorting the engine...

-

I'll ask this question here as I think it adds to the thread (if not, sorry for the thread jack): it seems like most people find the non-webbed manifolds more desirable than the webbed. But it's my understanding that Nissan added the webbing in later years to help reduce the heat rising from the exhaust manifold and heating the fuel rail. If that's true, then wouldn't the webbed be more desirable? Or is it just that the non-webbed looks better?

-

Recently a few times while accelerating I've felt a brief "miss", sort of like a reset but not as harsh. Today I happened to be datalogging while it happened and here's a screenshot of the log. Basically the RPM spiked to 22,374 for one cycle - you can see it just to the right of the reference line on the second panel from the top - white trace. Strangely there isn't any change in the injector PW so I don't see why the engine should loose power such that I can feel it. Everything else is running great. And it's not a reset. Has anyone else experienced this or have any ideas? Perhaps it's an artifact of the RPM Lag Factor of 40? (I suggest this knowing how the calculation is done and not seeing how it could occur.) Trigger is from a ZX turbo distributor and I'm running the MS2Extra beta code on a V3 board. Initially I thought it might be an issue with the beta code, but so far no one on that forum has any ideas so I thought I'd ask here.

-

Just an fyi, my L28 with a stock starter cranks around 225 rpm. A gear reduction starter is even slower. I don't think you need to leave the L28 family of distributors, you just have a bad unit. I believe the main differences between the various flavors used in the NA ZX (80-83) is the advance curve. Some begin the advance at lower revs and/or have less/more total advance. Sorry I don't know the specifics by year and transmission, but I know there are a few threads on this site that discuss the specifics. If there's a JY nearby you might try to pick one up and drop it in just to confirm the problem. Last one I bought was only $20 IIRC. Good luck.

-

Did you bring the flywheel in as well? I'm wondering how the machinist attached the clutch cover to the machine?

-

A few things: David K, I didn't refer to their clutch using the term "stage". According to Centerforce's literature, the model I have is a Centerforce II. I agree that for the most part, a NA engine can run with a stock clutch. I've done that for 5 years now. However, as I've improved my power output, I've found that as soon as I get some heat buildup in the clutch I get slippage on the 1-2 and 2-3 upshifts. Of course, once it begins to slip at all the extra heat only makes the problem worse and the only answer is to park it or back off on the shifts. Given I like to participate in HPDEs, I figured I should look at a clutch that would have a little extra torque capacity, especially at higher revs. That's how I landed up with the CF II. For a stock NA L28 (or L24 or L26 for that matter) I completely agree that the stock clutch should be good for a street driven vehicle. As I don't know the OP's plans for the car, I was just letting him know the pros/cons I had experienced with the CF II.

-

Update: the clutch engagement is now normal and NOT near the bottom of the pedal travel. Also, the vibration issue seems to have mostly gone away with only a mild vibration around 4k left. Silver280zx: how would a machine shop balance the clutch cover since the weights are rather free to move around? It seems like the balance would change constantly - that's what I was experiencing for the first thousand miles are so.