-

Posts

1201 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by duragg

-

THanks. Stuck waiting for the hone-tank to open up after some other cylinders are done. Then blow another .030 out of the bores. Pistons here Friday. Total Seal will make the rings next week. Cam shipped to ISky. Credit Card raped (again). Beer cooler empty (again). Time to order my tranny kit and start pushing bearins and lapping syncros. I wanna drive this motor sometime soon. Need to do some port-matching too. What is that exactly, making the transition between intake manifold and head smooth? TJ

-

Just today I shipped an A grind Japan cam to Isky for an L490 regrind on my new F54/N42 buildup. The motor I pulled from my 240 was an L24/E88 with some kind of aftermarket cam. Has CWC stamped on it. The car also had .030 tower shims and heavier springs with aftermarket valves. I am staling the shims and springs for my N42. Leaving the good valves, this relatively unknown but decent shape cam and whatever else is left from that E88 cranium I suppose. Its all surplus to my needs, if you can use any of it please let me know. Tj

-

Wish I knew exactly what to tell you but I am in your same position (1 month behind...). In one of my 3 heads I scavenged parts I found an MSA Spring Kit, Cam and Pads. The pads were 160s, 170s and a 190. It would be a simple thing to take 10 thou off a 170 with the right equipment.

-

Grainger has M8 x 1.25 x 50 Studs. Suitable for studding intake and exhaust manifolds? What is a double end stud? Just means it has a "grip" in the middle? http://www.grainger.com/Grainger/TECO-Double-End-Threaded-Stud-1DV83?Pid=search

-

Give Tony my flywheel and this handy drawing... http://www.datsport.com/Flywheel.html

-

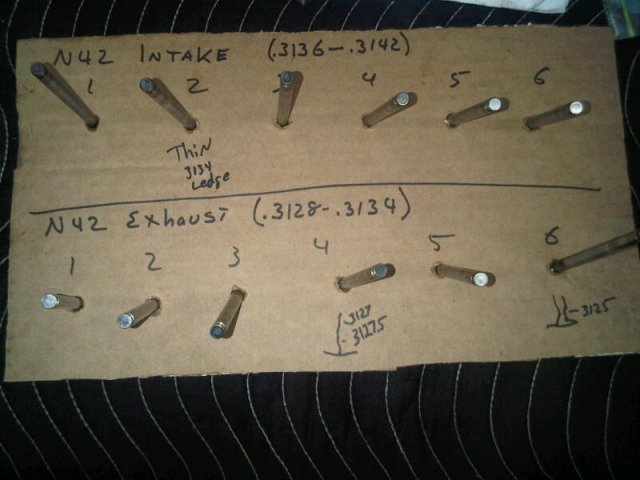

Head lapped up nicely. A few small scratches I will let Mike look at (www.sf2racing.com) Valves dimensionally are so-so. A few have some thin spots. Replacement SI plain valves maybe at $7 each? Or Replacement SI fancy valves at $15 each? Or just run these biches again. TBD. Let Mike call that too. I was pretty worried about the guides - I hate pulling and replacing guides. It takes time and patience to do it right. Book specs are .3150 to .3157 for both intake and exhaust. I pulled Mikes pin gauge cabinet open and got a .3150 and a.31565 pin. The .3150 is perfectly snug on all of them. One guide is a bit tight at the top so I will have him take a half out of that one. The guides are surprisingly tight. What next. Guess I can lap the side of the N42 head for the intake manifold. But thats a messy job. Port match the Triple Weber intake to the N42. Type random **** on the internet that nobody reads in an Air Conditioned room with an Ice-Tea? Worthy goal for a Sunday.

-

Saturday May 28. Got the N42 head cleaned and on the lapping table. Took about 40 minutes in various steps to get the cylinder side perfectly flat. Back-breaking work! Trying to hold that head on the big table even at moderate RPMs. Wants to run off the side. Disassembled my other heads and found more goodies. * P79 head spit out some pefect valves, but they are the shorter kind. Cant be used in N42? * E88 head spit out an MSA spring kit that is going in the new N42.Plus a bunch of different height lash pads. Along with these... Rockers and MSA Stage 1 cam on the E88 are toast. Rockers and stock "K" cam on the P79 are toast. Rockers on the N42 and "A" cam are just pristine. Moving all the good parts to the N42 build box. Monday will order stones and pistons for the F54 block job along with gaskets and such. Stupid question.. but do I order the Head Gasket for the F54 block or the N42 head? I think F54?

-

ITM RY6134-040 should be the +1mm replacement piston. Total Seal T2416 +.1mm

-

Delicious. Which cam are you using? Looks like the base circles are min'd out at the shaft diameter. Know the specs? TJ

-

Sitting here realizing I am already buying new pistons, rings and what for an LD28 crank I'd be strokin. But the whole project scope / time and budget gets wonky. Either leave the 87mm bore, or blow out to 89mm? Can an F54 block be safely blown out to 89mm? Since I am getting free machine shop time asking my friend to blow out to 89 may be greedy. Seems with many of these mods you have to go to a VERY expensive head gasket ($300-$400 bucks)? Eh. Next time will do a Stroker. Aint no deals on LD28 cranks out there now anyways.

-

Pistons are +.5mm measuring 3.405" Cylinder bores are 3.409 Piston to wall clearance is supposed to be .001 to .0018. So we are blowing the bores out to the next size and order new pistons. Bigger is better.

-

Using the FSM specs measured the crank in all dimensions were standard. Time to order bearings. Have to hone cylinder bores next and then figure piston and ring size. These pistons already have "0.50" stamped on them which I assume is +.5mm. Shipped cam to Isky for the "490 Grind" treatment. Tj

-

Engine torn down. The good: Crank is marked "STD" in yellow paint, cylinders still show x-hatch, rear main seal is blue, rods marked 0.50, bearings all pristine. The bad: Head gasket blown at #3 and #4 with some water intrusion in the head bolt holes and minor corrosion in those holes and cylinder bores near BDC. Engine was partially rebuilt, but they must not have opened the front cover. Water passages were totally 100% blocked (Surprise the HG B?). What is that nasty crusty shart in there? An LD28 Crank would be handy right now... especially with my old L24 block sitting in the corner... here kitty kitty

-

1973 240z gets a new motor this summer. Oily plugs, 80psi compression and a tranny that is just plain beat. I have acquired the following ingredients: * L28 F54 Flattop from 1983 ZX * Tall-eared 5 speed from same 1983 ZX. * N42 head with steel seats and a pristine A-grind cam (ready for regrind). * A valve spring kit with tower shims, different lash pads, from the old L24 motor (also had a CWC cam I am throwing away). * Triple DCOE 40 151s which I've been running all along with the tired L24 Ingredients I am NOT Planning on using: * Tired L24 (P30?) block * Interesting E88 head, stainless (small) valves and cam (stealing springs, shims and keeepers and such). * P79 head * Short eared, but single hanger 5 speed. Ingredients I am still researching * A gnarly cam with a LUMPY idle and up to 7000 rpm would be fun. * Lightened flywheel I will cut down on the Lathe * A reasonable clutch Goal is a scrappy sounding old-school Ratty Z. Drivin about 3 times a month. Bottom end buildup first with new bearings and re-hone and Total-seal rings. Tranny then rebuilt with new bearings and syncros. Top end last with the best of the parts I have and decide to buy. Re-install in the car and begin the Weber dance again (with Wideband). I need to post here so I remember what I did 3 years from now... Many hours spent in the archives here. Great forum. TJ

-

Z-Ya, your question: "Where and how are you measuring length" was the answer. Incorrectly I was measuring total length and indeed the older FSMs list a spec for Total length. But they also have a drawing showing the correct measurement. The newer FSMS and the drawings of where to measure show from the base of the lapped mating surface to the tip which accounts for my rookie error. Case closed. Thank you.

-

It is possible that the 116.5 and 117.5 valves I found in this N42 head are the incorrect part. E88 spec is the 116.5 and 117.5 lengths N42 spec is the 114.9 to 115.5 and 115.7 to 116

-

Valves are removed from the head and using a digital caliper I measure from the base of the head to the top of the tip. They are all 116.5 and 117.5. My malfunction is the 1975 and 1976 FSM say the valves should be 114.9 to 115.5 Intake, and 115.7 to 116 exhaust. Question is, are their different lengths used in different years of the N42 head. Thanks in advance for taking the time to help straighten me out. Tj

-

Anybody have an FSM for a 1977 280z, in the EM section what does it show for Valve Length specification? More specifically: I have an N42 head in my lap with steel valve seats and 116.5mm Intake valve length 117.5mm Exhaust valve length. Only FSM I have is a 1975 and a 1976. Those two FSMs spec Intake valve length at 114.9 to 115.5, Exhaust 115.7 to 116. Hoping the 1977 FSM shows different values which Cant find the 77 FSM online. Thanks, TJ

-

Thanks all. Any of you drill the missing 4th Progression hole on DCOE 40 151s? The Spanish 151s have a crappy 3 progression hole setup causes lean on tip-in of throttle. I really enjoy the challenge of triples. This is NOT a DD though. Building a flattop F54, N42, cammed triples, CR5sp to replace L24.

-

Last question: What is "dd"?

-

Oh, No to the Vacuum Advance. I think I set it at a total of 35 right now. I had intake leaks so removed the manifold and lapped it flat, new gasket, reassembled, reset timing, reset and balanced flow with my German flo-thing, reset idle, reset idle needles, reset idle, reset idle needles and test drove. I don't drive the car much and am replacing the L24 with a flattop F54 and N42 head this summer. Will make a new heat shield tomorrow and zoom around some this weekend. Hope that solves my idle stalling. Thx.

-

Wandersparrow: Thanks for the pics. While we are here, could you explain your fuel delivery manifold? I need a better fuel delivery system with a proper gauge visible in the cockpit. Why not wrap headers?

-

As summer hits my DCOE 40 240 seems to idle unreliably and even quitting sometimes like it is starving for fuel. Other Triple'rs have heat soak issues? What are you using for heat shielding? Also, what impact if any does water temp have on running? Do triples prefer any particular water temp? Thanks. Tj

-

1973 240z with L24, Triple DCOE 40-151 carbs. Headers go down to a giant red glasspack Cherry-Bomb thing (looks 18" or so). Then to the exhaust tip which is split into 2 (high-low) and that seems to have packing in it also. I find the exhaust a little muffled. Doesn't have a snappy bark. Should I delete the Glasspack? Make it smaller? Too noisy? The tip? This is a weekend play car, NOT a daily driver. Going to do something today so appreciate any advice. Tj

-

I didn't have the patience to hack out the old sound deadening. I just cut out some rust spots and welded in repairs in the bad areas. I might put a carpet kit over the floorboard... Not sure (already bought it, but also already bolted seats in). Grainger has hole plugs in every size (US Sizes) so I just ordered some that are close enough. This Z (My personal race car) is half rusted out piece of ****, and half work of art (eyes of the owner). Thanks for the assist. TJ