Sam280Z

Members-

Posts

395 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Sam280Z

-

I'm running 229.3 deg. 350 was ~120 deg off. Only matters for coil on plug ignition and sequential injection. See my thread here: http://www.msextra.com/forums/viewtopic.php?f=131&t=45296&p=323787#p323787 Sam

-

Carbon Hood - how much shaking is acceptable

Sam280Z replied to RebekahsZ's topic in Body Kits & Paint

I'd re-install the springs. They take up the slack in the hinge linkage. Also, run the bumpers at the rear corners up to put a small amount of tension on the hood back there. You can use a piece of paper to gauge when the bumper is contacting the hood. It should take a tug to get the paper out. Sam -

Just cannot get a seal at the cast iron flange

Sam280Z replied to BlueStag's topic in Nissan L6 Forum

True. It sounded like you were trying to move it a more substantial amount -

Just cannot get a seal at the cast iron flange

Sam280Z replied to BlueStag's topic in Nissan L6 Forum

Biasing the flange might not be the best idea. Your studs will not be perpendicular to the flange surface. This will cause the nuts to seat at an angle and the load will be at a single point. This will cause the metal to deform there and the nuts will not stay tight. You could source some self aligning washers to prevent this, but it may be easier to just have the exhaust pipe bent out of the way a bit. Sam -

Did it start after sitting and drying out?

-

I seriously doubt that welding on the diff would damage the computer. it's possible, but unlikely. where did you connect the welder's ground strap?

-

Ben, You probably didn't damage anything with the welding. It sounds like it is just flooded. What were you welding? If it won"t start tomorrow after the plugs are dry, give me a call tomorrow. Sam

-

"car has not been driven for close to a year" old gas can varnish and be like glue on the valve stem - making the valve hang open and/or close too slowly... Sam

-

OK. So you re-calibrated LC-1 input to the MS. Which user? What voltage curve? How do you know it is correct? The programmed output curve from the LC-1 has to match the curve in the MS. You still have not said if you have addressed the grounds. Until you do this, we are wasting time. If the LC-1 voltage curve was incorrect, the log you provided is useless - definitely need a new log. If you haven't already, I would recommend purchasing tunerstudio and megalog viewer. Sam

-

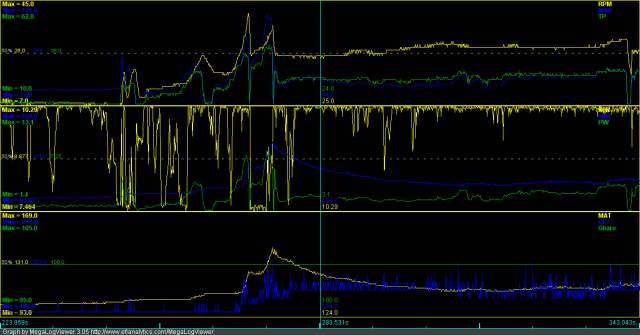

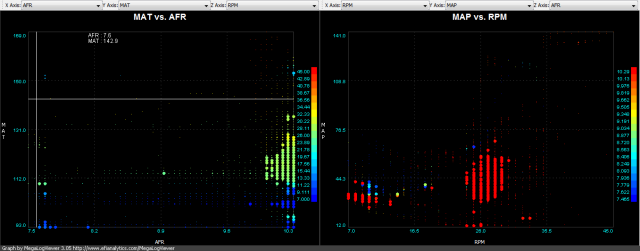

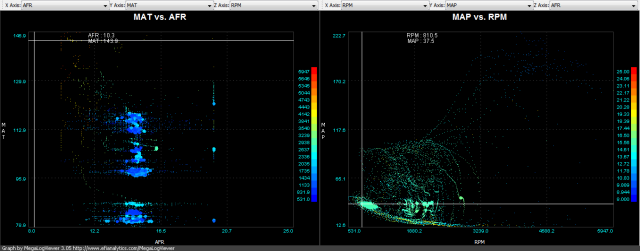

I don't want to come across as harsh, but you are making it difficult for me to help you. I assume that the last post was 78zstyle posting from MadMaxDallas' account. I have no idea what "I got my wideband to read correctly now.. I had to mess with the LC 1 output." means. The wideband doesn't "read". It outputs a programmable voltage that the MS, gauge, or other device uses. I still do not know if you have a gauge or if the incorrect AFRs were showing up in the tuning software. I apologize... the graph I showed was not from your log - I edited the post above. The attached graphs are yours: Assuming the wideband is correct, which i doubt, you are rich. You need to fix your grounds. How are you triggering the MS? There is a lot of jitter in the RPM signal. Can you attach your MSQ file?

-

Can you point me to a time in the log when it is behaving correctly and also when it is behaving incorrectly? I don't see any big issues in the attached scatter plots. **Edited: because I grabbed the wrong log file from my download folder*** I assume you have a turbocharger and are running about 15lbs 5 lbs of boost? If either is incorrect, your MAP sensor needs to be calibrated. Are you seeing the problem in a AFR gauge or in the tuning software interface? It is not hard to get the gauge to read differently. Make sure the LC-1 output to the gauge is configured correctly (if you have a gauge - which on is it?) You really need to ground everything at the same location. Otherwise, you will be chasing your tail. Also, be sure to run all sensor grounds back to the same place as well. Sam

-

The forum software usually tells you why it won't let you upload. You may have to change the file extension to something like .xxx. I can change it back to .xls after it is downloaded. What about your grounds? Sam

-

The link you provided wants me to install 3rd party download software which I do not want. Attach the log to a post in this thread. Which O2 sensor / WB controller are you using? The MS, AFR gauge, and AFR sensor controller should all be grounded at the same location.

-

Which intake air temp sensor are you using? Where is it located? Sensor heat soak can make the ECU think the air is hotter than it is - therefore less dense than it is- and it will pull fuel accordingly. Sam

-

I have my LC-1 powered from a relay that is turned on by the ignition relay - signal taken from the stock ignition box. It is on while cranking, which is technically not a good idea, but usually the sensor is not hot yet (except in the case of starting after a stall). I have had it like this for over a year with no issues. I also recommend getting the wire harness from DIY. It will save you hours of work. I use the MS3X for ignition, so take the following with a grain of salt... You should be able to use the fidle output to control a fan relay. Be sure you have a way to control ignition - it requires a high current driver. I recommend you email the guys at DIY with your questions. They are extremely helpful and will make sure you get what you need. Sam

-

I used part # BK104WS when I rebuilt my 5 speed (1978 280Z). I'm pretty sure it is the same kit for the 280ZX.

-

Missing tooth trigger wheel for the optical dizzy

Sam280Z replied to letitsnow's topic in MegaSquirt

DIYAutotune ended up producing one with excellent instructions. This is what I'm using now. http://www.diyautotune.com/tech_articles/using_diyautotune_nissan_trigger_discs.htm -

MS3 w/ MS3X Install - L6 turbo, sequential injection & boost control

Sam280Z replied to Sam280Z's topic in MegaSquirt

The large cap is what was recommended by Crane when the power lead on the Hi-6 is extended. It is a Crane part. It also came with some MOVs to install on solenoids. Where would the smaller cap go? On the battery, MS power, other? Thanks, Sam -

From RockAuto ( I included the front dimensions as well for future reference): 1971 NISSAN 240Z 2.4L L6 : Engine : Crankshaft Repair Sleeve Wiki TIMKEN Part # KWK99189 Min Shaft Dia: 1.887"; Max Shaft Dia: 1.893"; Installation Depth: 0.984"; Width on Shaft: 0.551"; Overall Sleeve Width: 0.668"; Flange Dia: 2.205"; Sleeve Material: Steel Optional; Front National Part # 99315 Redi-Sleeve; Shaft Size Min=3.146", Shaft Size Max=3.153", Width=0.827", Overall Width=0.945", Flange Outer Diameter=3.543", Installation Depth=1.375" Rear Not the same brand, but dimensions should be similar. Sam

-

Is that tube hollow? And does it connect all the runners to each other internally? If grretc is not interested, I may be. Sam

-

MS3 w/ MS3X Install - L6 turbo, sequential injection & boost control

Sam280Z replied to Sam280Z's topic in MegaSquirt

FIXED!!! Tried everything I could think of. Re-routed wires, re-did ignition wiring, consolidated even more grounds, upgraded chassis ground strap, turned off the multi-spark, and did innumerable fiddling with conditioning circuit pots. Did everything one at a time. Some had no improvements. Others had minor improvements, but none completely eliminated the sync loss. Finally, I replaced the sparkplug wires with the old magnacores and lo and behold - no sync loss for 3 days. Yesterday, I put on a set of NGK wires. Again, no sync loss. I have reset the pots to the recommended settings with no issues - even with the multi-spark back on. I have a large capacitor (28 f) coming that I am going to put on the power supply and I will retest the MSD wires. Thanks to everyone who tried to hep out with this. Hopefully the issue is gone permanently... Sam -

MS3 w/ MS3X Install - L6 turbo, sequential injection & boost control

Sam280Z replied to Sam280Z's topic in MegaSquirt

Pretty sure I'm dealing with a noise issue. Switching the Crane HI-6 to single spark has helped a lot, but I'm still getting sync loss at weird times. It seems to happen most often if I run the car for a while, turn it off for a few minutes, then get going again. After a while of more running it starts up again. I'm playing with the pots per: http://www.diyautotune.com/tech_articles/vrsensor/megasquirt_vr_index.htm Problem is, it is so intermittent, I can't be sure of any changes' effects immediately. Sam -

Who'd be interested if we made a L28ET trigger wheel?

Sam280Z replied to Matt Cramer's topic in MegaSquirt

Use the sync loss logger. You can datalog at the same time. It only records a tooth log when a sync loss occurs. -

http://www.msextra.com/doc/general/ms2external.html

-

MS3 w/ MS3X Install - L6 turbo, sequential injection & boost control

Sam280Z replied to Sam280Z's topic in MegaSquirt

MAP sensor problem fixed. MapDaddy surface mount IC detached from PCB. New one installed and it is working again. Still fighting sync loss. It comes and goes. See my thread at MSextra: http://www.msextra.com/forums/viewtopic.php?f=131&t=43936 It seems to happen at the same place on the trigger wheel almost every time.