-

Posts

353 -

Joined

-

Last visited

-

Days Won

25

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Ben280

-

315/30r18 rear and 295/30r18 front. I think the rear wing is 72" wide with a 13" chord length. I wanted the wing to match the rear track width which is quite a bit wider than factory. Got the airdam painted and mounted this weekend, and finalized the splitter wire mounting positions. I have to fiberglass up the blending piece, but that should be pretty speedy once I get material. A couple photos of the mounting/airdam fixed on: I have a radiator to hood duct/extractor that i'll throw glass up while I'm at it in the next few days.

-

Well, winter was quiet! Spent most of the winter skiing, rather than being cold in the shop, but spring has sprung and we have some exciting progress on the car. Since the car is in good mechanical shape, the big to-do's have been cosmetic. Mainly the air dam! It's such a cobbled together thing that I knew I had to make some improvements. To that end, I bought a 3d printer, whipped out my iphone and got to designing some new end areas. I'm keeping the same spirit of the airdam as before, but symmetrical sides (just flipped this piece and printed again) meant that I can be confident in the tolerances that I'm working with on both sides of the car! Pretty impressed how well this lined up fresh off the printer, and from a medium quality iphone photogrammetry scan of the front end. I opted to use the PLA as a core for the fiberglass layup, we'll see how that does long term. People have issues with PLA as a finished surface as the "glass transition" temperature is pretty low, and normal temps for sunny car parts will result in significant softening. I think inside 5 layers of fiberglass it should be just fine. (Glassed, sanded down and filler primer. It's easily the nicest part of the airdam at this point!) There is a pretty good gap between the bottom of the air dam and the splitter, so I printed up another whole piece that I will use to pull a direct positive part from. I don't want this to be super heavy duty, so I'm not going to encase the PLA core. (printed and glued) This piece had some scaling issues, even though I modeled it from the same references as the airdam pieces. Oh well! Final bit was that I really needed to make the car all one color again, and install some of the fun stuff I had made up before the winter. I had aspirations of painting the car, but when that plan met with the reality of budget, I opted to go back and vinyl wrap the front end again. The hood might get a re-do, but otherwise I'm rather happy with how it all turned out! Hoping to have the car mostly back together this weekend, and then aiming for an auto-x event at the end of June to shake out the cobwebs from car and driver!

-

The Megasquirt wasn't wrong. It was working well enough, but it wasn't able to provide any higher level diagnostic functions, effectively run the IAC valve, run drive by wire, or integrate a comprehensive traction control strategy. My tuner was also moving away from tuning megasquirt, and as someone who relies on a tuner, I figured giving him want he needed to succeed was important. The Megasquirt is a powerful computer than can do a lot, but I was running into those limits. The Haltech also provides a lot more I/O functionality, which I was out of on the Megasquirt.

-

Hijack away Cary! I like the Howe Racing as i knew it would work with the balljoint I wanted to use, and it had the correct thread for an inboard heim joint. I had to modify it enough at this point, I think next time I'll have some fully custom ones bent up, and use a spherical bearing on the inboard side.

-

If you are near a SCCA/NASA group that runs the "Track Night in America" or whatever the NASA equivalent is, I HIGHLY recommend it! Much more laid back, and geared towards beginners. If you apply mechanical sympathy to your car you'll be in great shape. Big braking zones are the hardest thing with these cars initially, so just go out, take it slow, and enjoy hearing that straight 6 roar! Thanks man! There are a handful of builds on here that have been going on long before I started and are still far from done. I have a newfound respect for the patience those folks have. For the Howe Racing arms, they are extremely not for the Z platform. haha. They are for the Trans Am cars (tube chassis) but they manage to utilize a similar lower arm configuration. I had to add some additional brackets to mount the tension rod in the right spot, remove some "stock" brackets, and design a sway bar attachment point (still not 100% happy with that one). Was hoping I had a photo, but no such luck! I'll do a photo dump here shortly!

-

Howdy HybridZ! Seems like the trend, y'all get an update at the beginning of the year and at the end of the year! Might need to reframe my temporal perspective and do every 6 months. This was a slow year for the car and myself. First year since I've owned the car that it hasn't gone to any events! Wish I could say it was because I was doing a bunch of sweet mods and we're hitting the track hard next year, but that's not how it went. Overall, since 2020, the "smiles per $" has been way down, and I think I probably burnt myself out doing the V8 swap as quickly as I did it. Combined with the wreck, I felt like I really needed to step back, re-evaluate and take the year off to figure out how I want race cars to fit into my life! A big thing I've found is that since this just isn't a street car, and has no ability to be a street car, it's tough to get that "just gonna go drive the dang thing" and get excited about the project. Starting to find motivation again, which is nice, and I'm aiming for an event or two next year. That's not to say I didn't get ANY mods done this year! I got the Haltech 2500 into the car, and got it tuned. That was a fun small project, with a bigger price tag, but I'm hoping that it solves a lot of problems moving forward. It did reveal that some of the problems with this current engine are just that. The current motor is a L33 aluminum 5.3, but it's just not making great power. Compression and all that looks fine, but it's only putting down 330hp, when we'd expect closer to 400. Putting that out of my mind for now, and going to run it like this. A new engine is just not in the budget right now. I also did quite a bit of work on the front suspension. I've been running the Apex Engineered arms up front, and have been happy with them. Full disclosure, Ohm is a supporter of the build, you may have seen the car on his page! After running a handful of events, I felt like I had 2 problems to resolve. 1) I needed more track width. I have a 1" spacer in the front, and it's just another thing to check on the car, also while making scrub radius work. 2) I needed a beefier ball joint. The Apex arms use a factory sized ball joint, that is a better material, but after running a few track events, getting up on curbs and getting pretty spicy, they were just not up to the task. Bigger is better, so I went and upgraded to a Howe Racing TA2 front control arm, with their thread in ball joint. The arm is 2" longer than factory, and allows the use of an improved ball joint, the design of which is derived from a 3/4 ton truck. I feel pretty good about this mod! I got some work done on managing airflow on the front of the car. With the freshly chopped fenders, I needed a way to get air out of the wheel well, and made up some Kevlar pieces to help with that. I also made a plug for a radiator extractor vent that will help direct air out the hood, rather than spilling around inside the engine bay. I'll need to snag one more fitting for the dry sump, but otherwise, things are looking in good shape. I'm excited to let the car be "done" for a little bit this year.

-

@walkerbk Sorry for the necrobump, but any updates on this? I'm particularly interested in how the rear fit up!

-

This has been such an exciting build to watch! Parts are looking spectacular, looking forward to seeing progress continue.

-

Yup! Still available. Sent you a DM.

-

Still Available everyone!

-

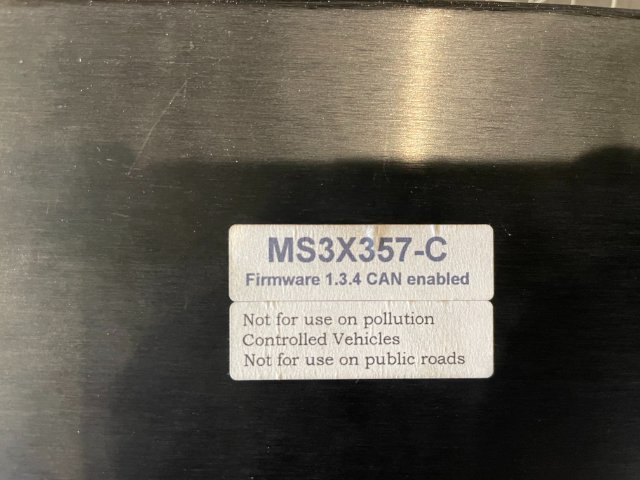

SOLD!!!! Selling my ECU! This has successfully run 2 versions of my L28 (one with ITB's) and a LS V8. Megasquirts are known for being very powerful for the price and have a huge community behind them. Lots of details, here's a link to the data sheets: https://www.diyautotune.com/product/megasquirt-iii-ems-system-with-ms3x-expansion-v3-57-assembled/ New is $700, I'm asking $500 shipped. Sold!!!!

-

Hi HybridZ universe! Been taking a break from the car for a bit, but starting to get more motivated here. Let's do our quick catch up first. ORP was an interesting event. We had positives, but the issue that wrecked the car in July surfaced it's head again. Turns out the ABS was overpowering the master cylinder seals on the front circuit and causing massive pressure losses. I had more pronounced but less consequential failure out there, but had good data to show what was wrong. I got my hands on some Tilton Type 79 master cylinders, developed specifically for the Audi LeMans teams who were seeing a similar failure in their master cylinders. I also had to upgrade the pedal box as these are bearing mount master cylinders. The plan was to run the car again at PIR, but that event ended up getting canceled, and so the car has sat since September. Slowly getting poked at, and trying to figure out where I wanted things to go. I made some aero mods to the fenders, and have been slowly cleaning up the firewall and some other areas. The big change I'm in the middle of here is with my ECU. I'm ditching the megasquirt and going Haltech. The LS never really ran right on the megasquirt, and when I started seeing some odd stuff starting it up for the first time this year, that was all the impetus I needed to ditch that. It'll be for sale shortly, expect to see it soon. Hoping to get to an event this year with the car, but really not sure when or where. For now, here's where we sit. I put it down on the ground for the first time since August last year.

-

Hey man! Yes, if listed, it's available.

-

Going to agree with @AydinZ71 on this one and recommend you get a new factory style tank and external pump. A fuel cell used to be the "easy" route, but if you want one with proper baffling, pumps, surge tanks etc, you are looking at double the cost of a factory style tank, and that doesn't include the fab work to make it fit. Fuel cell's also require semi frequent inspection which is unnecessary on a OEM style tank. If you DO want to use a fuel cell, the Radium FCST setups are the way to go, and is what I have in my car. I have 2 AEM 50-1200 pumps in there. They were great with the old L series motor and are doing just fine with the LS. When you do the AN lines, be sure to get ones that are rated for ethanol. A lot of the rubber in the standard lines isn't designed for any amount of ethanol, so the E-10 in typical pump gas will make them rot out.

-

Updated ITB price! It's build season, who wants em!

-

Oh my! Those brake kits are both amazing, I have a soft spot for the radial mount one though.

-

As a side note, if anyone wants to support myself and the car, check out this sticker pack from my BFF Jake at Aerowolf https://www.aerowolfusa.com/products/team-stickerpack

-

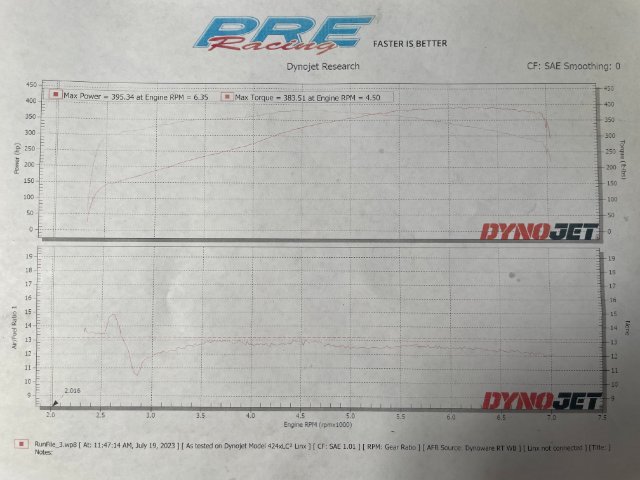

PRE uses a Dynojet. Can't remember if those are supposed to read high or low, but it's a good metric if you always use the same one! I'd have liked a bit more power, but I think ~400hp is more than enough to get into trouble. (clearly!) So far the repairs are minor, and the trick has been sourcing panels. A PNW local reached out and had a set of fenders and headlight buckets he sold me for a song, and I'm taking a trek up north on Saturday to pick up a new hood. I think the airdam is mostly savable, but the old headlight covers and flares are toast. Working to get a new set of flares from Japan, and another instagram follower was super kind and sent me some replacement headlight covers! Planning to have the car back out August 19/20 at ORP. We'll have some crazy mis-matched body work and a plywood splitter, but I think we should be in decent shape for continuing to shake the car down!

-

Ok, mini report! We made it to Global Time Attack!! It was super close, and looking doubtful at some points, but we did it. PRE Racing here in Portland was great and they really pushed to get the tune finalized before heading out. I'm still having issues with the idle, but we think that's the Megasquirts fault. The Idle motor is also probably a piece of junk, but we're leaving it alone for now. Official dyno numbers came in at 395hp/385tq. Not too shabby, but we aren't taking the timing at high RPM that we would expect. I think a ECU refresh is in the cards, but for now we have a safe tune and she RIPS. Fully loaded we are at 2500 with driver. GTA was shaping up to be a shakedown weekend. I knew there would be teething pains, things needed to be reviewed and I was pretty rusty from a year away. First session out the plan was to go out, make a couple hot laps, see how everything felt and then come in and check everything over. The car wanted to get after it! This thing is a rocketship on the straights now, i might need to swap the gears around again to make sure I have the legs! Second session was a similar plan, go out, make sure everything felt ok and then come in. I decided to lean on it a little bit and see what was what. The grip on these tires (Continental ECF) weren't spectacular, but they were solid. I think they need a full and proper heat cycle to get good. I noticed a little bit of locking into T8, which was weird because I have ABS, but didn't think much of it. In retrospect, this was a big mistake. I was able to improve, 1:52.3. 2 seconds slower than my fastest time last year, but really poor driving. I'm carrying so much more speed into the corners, and not fully trusting the car yet, it's challenging to go really fast, but going deep into the 40's at this track is certianly on the cards now. A lunch break and we jacked the car up, checked over some suspect oil leaks, moved a oil line off the header and started to make a plan of what to check over at the end of the day. First semi push lap out and a major lockup over a bump sent me head on into a tire wall. The car looks worse than it really is. The car doesn't pull, frame is still as straight as it was before this, (which is to say still a little kinked) and everything still works! No leaks or anything, which is great. Bad news is all the sheet metal is toast and the very fancy splitter took a mega hit into the wall and is a write off. Definitely a bummer, put an end to the weekend, but the car is making a quick resurgence. A lot of folks have reached out to me and offered parts. Last thing to sort out is the splitter, and I need to make a handful of parts, but overall we are looking to be in really good shape for another event in a few weeks! Onward and upward my friends.

-

240z SCCA vintage race car, restoration

Ben280 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Looking good! When choosing an ECU, I would ask your tuner what they prefer and buy that. Make sure it is compatible with all your bits and bobs. Haltech for example is notorious for keeping their CAN stuff difficult to access, similar to AIM. Tuners can work on just about anything, but what they can do and what they like to do are often different. I saved my megasquirt for the V8 conversion, but I would have been better off buying a Link or a Haltech, purefly from an ease of tuning perspective. Megasquirt idle control is finnikey at best! -

240z SCCA vintage race car, restoration

Ben280 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Very nice!! Looking A+ flakey -

A musician's therapist (The $300 Z)

Ben280 replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Have any photos of the mustache bar misadventure? Seems odd that T3 would switch to bolts, when a stud is just a backwards bolt! Studs in the diff also REALLY help when mounting the diff by your lonesome. Excited to see some photos of the car out and about! -

Instagram is @brokenjawracing (check the link in the sig of the post!) My fab buddy got real stoked about the muffler placement, I'm pretty stoked on it!

-

Small update, the car is back from my buddy getting the exhaust done, so that's great! pretty stoked how it turned out. We are using spintech mufflers, and going for the IMSA/Cup car dual center exit, while keeping things as tucked as possible. I opted for ovalized tube under the diff, really hope this gets me the clearance I want/need. . Tires also showed up! I need a seat time tire that won't kill me or break the bank. I went with the Conti Extreme Contact Force with is a 200 treadwear tire, but is endurance focused. From what my track friends tell me, it should wear like iron, and be pretty reasonable pace wise. I'm hoping to get about a season and a half out of them. I got 315/30r18 in the rear and 295/30r18 in the front. Planning to narrow up the front wheels at some point, but with the LS, there is way less weight on the front of the car to help warm stuff up. Lots of people who I've talked with say that going smaller tire up front has been real beneficial, so we'll see. Planning to set the car up for these sizes which will let me switch out easily for the Yokohama a052 or the Hoosier A7 in the same sizes.

-

I have a camshaft and towers that were in my stock of spares that I am including with the head. The towers and camshaft that were in the car when the pump failed are obviously garbage, and are currently on my wall as offerings to the gods of speed. The head casting itself appears to be in good shape. I would recommend you take it to a shop to have it dimensioned and checked over and generally cleaned up. Let me know if you are interested, I'm happy to provide additional pictures or dimensions if you would like!