-

Posts

314 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by jpndave

-

It shouldn't affect the width. If anything might be more compact. These engines are wide on the top. If I could get my hands on one of these, I would make it fit! Maybe I should do a Coyote now and swap one of these in a few years. Hmmmm

-

I think this would be the best way to go. We use a Camaro factory cable or sometimes the Lokar on our drive by cable Jeep swaps. If I don't do drive by wire I'll go this route. I can post the Camaro number if anyone would like it when I get to my computer.

-

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

So this looks like a T56 Magnum (which is all T6060 internals) and additional upgrades depending on what options you selected with a Camaro T56 tail for fit. It looks like they all get upgraded bronze shift pads and carbon blocker rings 1-4. The level 5 gets a cryo treatment and REM polish. Does that sound about right? -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

Thanks for all the advice. Phantom, that's a good perspective to keep. It's easy to get caught up in trying to get everything and lose focus on what the primary goal is. This will be on the street 90% of the time. I'd like to be able to take it to Miller Motorsports track a few times a year and maybe to the dragstrip a couple of times. I just want to enjoy the car. That doesn't mean it can't be an extreme build, just need to stay focused. So Pro-Touring type build with some limited track time. Engine will be a slightly built LS3 (I'm also considering an LS7 or the new LT1) planning on 500 RWHP or a little more. That should be fairly easy to obtain with any of those combinations. I like the 6.2L in my Jeep and want just a little more on the top end with this car, otherwise I would be happy with that. I'll probably lighten up the rotating assembly wherever I can to let it wind up faster and rev higher. I am in the process of putting a 4.0" crank in the Jeep. I don't think that I will go that route on the Z to let it wind up faster. I'll be focusing on the lightweight parts wherever is reasonable without using unobtainium, probably bump the compression slightly, clean-up and polish the heads, free flowing exhaust, high lift on the cam would be good and a little cam timing change but don't want to go too far to have things lumpy, needs to stay really streetable. On the gearing, just want to make sure that everything will work out well with the combination I am planning. Good spacing for the gears, not too low on the bottom to be roasting tires everywhere but low enough I'm not riding the clutch all the time at slow speeds. In 6th, great fuel economy and low rpms for cruising comfort but not so low that it's causing problems with the cam. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

Is this what you have here? http://www.tickperformance.com/t56-magnum-tr-6060-conversions/ -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

I can just laser out what I need for the mounts so I'll do them here. Heater outlets won't be an issue, I'll be replacing that with a new HVAC unit. The bellhousing will need to be accessible so that will be my rear positioning limit. What did it take to make the T56 tail work with your 6060? Do you retain all the strength and better shifting of the 6060? -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

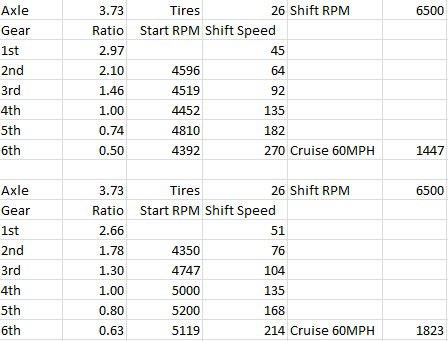

I'm still trying to make the best decision on the transmission ratios. I may be overthinking this a bit, but, don't want to get the wrong box and regret it. Notice on these that all of the 1st and 3rd gear overall ratios are the same. With 3.31 on the low 1st set and 3.73 on the taller 1st, 1st and 3rd are exactly the same. The RPM drops 1-4 seem to be more even and consistent on the set with the lower 1st gear. Not so sure on the two overdrives. The 2.97 first gives ~2000RPM per shift drop. The 2.66 set goes more like 2200, 1800, 1500. BTW, I would prefer that 6th is a cruise gear for mileage and lower revs on the engine. Thanks everyone for the input. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

I found the length answer on SUNNY Z's thread. Looks like it is pushing it for being long enough but doable. Some of this will depend on how far back the engine is set. I'm not sure if all the kits position it the same. I'll be fabricating mounts and will set as far back as is possible. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

Will the 26.6" at dimension "A" work with an LS into my 240 or do I need a different length? I am concerned that the shifter on these may be too far forward. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

I just read up on that thread and it sounds like he is largely headed in the right direction. It was a good read other than the drama over demanding pictures on page 2 and 3. I'll try and chime in over there. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

This car will stay independent in the rear. I want to keep the handling. It will be strong enough to take whatever the engine can dish out. I plan on 300m stubs and shafts. We did a run of shafts for a cobra kit car company a while back so we should have the tooling. We run 300m for parts regularly. I'll use 930 or 935 CVs, and thinking a 8.8 for the center. If anyone is interested in upgrading I can run additional parts. I'm open to suggestions on that as well. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

Thanks for the input alainburon. So that would look like the lower one here: Axle = 3.73 Tires = 26" Shift RPM 6500 Gear Ratio Start RPM Shift Speed 1st 2.97 45 2nd 2.10 4596 64 3rd 1.46 4519 92 4th 1.00 4452 135 60 MPH 80 MPH 5th 0.74 4810 182 Cruise 2141 2855 6th 0.50 4392 270 Cruise 1447 1929 Axle = 3.36 Tires = 26" Shift RPM 6500 Gear Ratio Start RPM Shift Speed 1st 2.66 56 2nd 1.78 4350 84 3rd 1.30 4747 115 4th 1.00 5000 150 60 MPH 80 MPH 5th 0.80 5200 187 Cruise 2315 3086 6th 0.63 5119 238 Cruise 1642 2431 -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

OK, I made up a chart to show shift and start RPM for each gear with the listed specs. I can manipulate this as needed. What do you think? Axle 3.73 Tires 26” Shift RPM 6500 Gear Ratio Start RPM Shift Speed 1st 2.97 45 2nd 2.10 4596 64 3rd 1.46 4519 92 4th 1.00 4452 135 5th 0.74 4810 182 6th 0.50 4392 270 Cruise 60MPH 1447 Axle 3.73 Tires 26” Shift RPM 6500 Gear Ratio Start RPM Shift Speed 1st 2.66 51 2nd 1.78 4350 76 3rd 1.30 4747 104 4th 1.00 5000 135 5th 0.80 5200 168 6th 0.63 5119 214 Cruise 60MPH 1823 edit: I'm not sure how to make this spreadsheet display correctly, I'll try again. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

RebekahsZ, My experience with cams in an LS has been the opposite. The L92 in my JK is very driveable and a beast when on the cam. I used this Comp Cams profile: HYDRAULIC ROLLER-Substantial power and torque gains across the board. Hyd. Hyd. 1600 to 6700 156-401-13 267PHR14 267 281 214 228 .559 .571 114° I have polished the heads (just smoothed everything up), decked to give 1/2 point more compression (making it the same as an LS3), the Phaser limiter, modified shorty headers w/merge collectors 1 3/4" primaries and the stock LS3 intake. That goes through a mildly built up 6L80E and 242 AMG transfer case. 4.10 gears and 37" KM2 tires. It runs very well both mild mannered and a beast when you stand into it. Some of that I am sure is due to the VVT changing timing on the cam. You can feel when it advances, almost like a 2 stroke engine hitting the powerband. I'd like a similar feeling in the 240 without the VVT, maybe a little more on the top. I have driven a lot of different vehicles with LS swaps because of my exposure to it where I work, from 4.3L V6, 4.8, 5.3, LS1, 6.0 of many configurations (LQ4, LQ9, LS2, L76, etc.) and the LS3/L92. I have not been impressed with the 6.0, especially the LQ4 (sorry) they just feel, I don't know, they aren't at all snappy. There is definitely more torque there but the power just feels flat, stifled. They feel like an old low compression big block. Now, throw some compression, heads and a cam at them (LS2, L76) and they wake up. Honestly, my favorite engine, the sweetheart of the line is the L33. I want more power than it produces but they feel great! Basically it's just an aluminum 5.3 with LS6 heads, a compression bump and more aggressive cam that really comes alive. Every one I have driven puts a smile on your face, even in a Wagoneer. They are lively and just crisp, right there whenever you ask something of them. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

The five speed would be lighter ~ 100lbs as apposed to 135lbs for the T56 Magnum. Strength and shift quality not so much. The T56 Magnum is a basically TR6060 in the T56 case. The shift quality comparison would probably be valid compared to the earlier T56. Thanks for the input. At this point I just really want to find the best solution. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

I'm thinking 295/35-18 so 26" with maybe 3.73 gears but that can change as needed. Shift points would be a little higher than that with the cam I am looking at. I'll check out the rpm modeling and see what that yields. Thanks for the input. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

Maybe a better question would be what speeds do I want to make shifts at? ON a road course? In a drag race? Autocross speeds? Road Driving? Maybe 1st to 50mph, 2nd to 70mph, 3rd to 100mph, 4th to 140? 5th and 6th for cruising at lower rpm? -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

Getting a starting weight is out of the question now. I well underway doing the disassembly. Final weight will be no problem. I have access to a four pad race scale set. I hope the 2300lb. range is doable. I be trimming weight anywhere it's even semi reasonable keeping in mind the final goal. This will be a cammed LS3 minimum. Should be 500, maybe even 600hp. They respond so well to a cam and some port cleaning. My Jeep engine runs very strong with similar mods. It is slightly noticeable at an idle and really comes on strong. I won't use the VVT on this project so I'm sure the idle will be quite a bit more noticeable with a similar profile. I want a faster response than the VVT/Auto will allow. Again, I'll be lightening up the rotating assembly as much as can be done semi reasonably. I'm still torn on the gearing configuration and don't want to get it wrong. The steep 6th sounds like a good choice for mileage, not sure on the rest. Does anyone know if the 26.6" back from the block face is correct for the shifter spacing? Thanks for the input, Dave -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

I updated the ratio list to show the third mixed option. I am leaning towards Autometer gauges for several reasons. The two main are a preference for the electronic speedometer and I want to lose the Amp gauge for sure. I know you can put the later 280 volt gauge in there but may just opt for a full set. I plan on keeping the car around 2300 lbs. with some lightweight pieces, such as the front clip, bumpers and hatch. The new power windows are lighter than what is in there now. The heater and aftermarket air I just removed were heavy. One piece units with the small compressor won't add more than maybe 20lbs. I have a compressor here on my desk we are designing brackets for that is very light ~12lbs if I remember correctly. I want a sound system in there too but have speakers with composite cones and neodymium magnets that don't weigh much and sound great. Same for the sub. Cruise weighs ounces with a drive by wire throttle. Lizard Skin insulation/sound proofing is very light. You can have both I think if planned correctly. Some will cost a bit more. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

Another possibility would be to go lower numerically on the rear end, say 3.08 or 3.31. If that engine can pull my 5500lb Jeep on 37" mud tires at 1500 RPM, the Z should be cake even at 1200 RPM. Then the launch would be good with the lower first and even better on mileage. The two things I would be concerned about is first that the cam wasn't wild enough to cause problems cruising that low an engine speed. Second that the gear spacing would work for performance. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

That's what I'm worried about, well that and the spacing 1st-4th or so. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

Thanks for the reply Phantom. I like the steep overdrive idea a lot. My Jeep JK cruises 1500RPM/60MPH and 2000RPM/80MPH quite nicely. The lightweight Z would be no problem at all. I am more concerned with the rest of the box as the overdrive can be changed out if needed. It will be on 17" or 18" wheels, thinking 245 up front and 295 or 305 out back. Thinking Subtle Z front and YZ rear. I'll probably go with the standard GM speedo signal and change the gauges. I'm more concerned with the 1st through 4th ratios as these are more fixed and would be extremely impractical to change. -

Which Tremec 6 Speed Ratios?

jpndave replied to jpndave's topic in Gen III & IV Chevy V8Z Tech Board

Normally aspirated at this point. -

My project is a 1973 240Z I’ve owned for 30 years, my high school car. I just brought this old girl in to give her a full makeover. The plan is a Pro-Touring/G-machine type build with LS3, Tremec T56 Magnum 6 speed and possibly a Ford 8.8 in the rear. I will be doing full upgrades of chassis, suspension, paint, the works. She needs to be comfortable so power windows and locks and a replacement HVAC including A/C that actually works. The company I am with is a conversion manufacturer for Jeeps mostly, Novak. My Jeep JK is linked below. We have all the tooling to do the swap components including manufacturing shafts, splining, etc. I may do a run of parts for the driveline if need be. Let me know if any of you have interests. Not sure where the best place to post all that up would be. I’d like to start a build thread and would appreciate input. My current question centers on the transmission selection. I have an LS3 for mock up but need to buy the transmission. I have line on a new T56 Magnum but am unsure of which ratio and model for sure. Is the shifter location in the standard T56 Magnum in the correct location (26.6” from the rear face of the block) or is the XL a better choice (34.9” seems way too long)? Which ratios are recommended? This won’t be a full time track car. I would like to be able to do some track days and maybe autocross events but primarily a driver. Rear end ratio can be whatever is best. Highway mileage and a nice cruise rpm would be a huge plus. The three ratio choices are: 1. 2.66/1.78/1.30/1.00/.80/.63 2. 2.97/2.10/1.46/1.00/.74/.50 3. 2.66/1.78/1.30/1.00/.74/.50 5th and 6th can be swapped independently if necessary and don’t have to be together, option 3 is showing that change to the taller first gear set. Thanks for any input you can offer.

-

Long Tube Headers with 3" Collector (Group Buy)

jpndave replied to datASSun's topic in Gen III & IV Chevy V8Z Tech Board

I might be interested depending on quality, fit and cost. I would want stainless and a merge collector.