-

Posts

314 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by jpndave

-

It was cool checking out your project. Always great when the parts measure out correct! I have a set of Manley H-Beams here as well as stock Gen 4 rods if you want to check them out. These photos belong over here now...

-

Brake and clutch master cylinders and balance bar. Not sure if I will use this or just buy a set of pedals, leaning towards the "buy pedals" option.

-

-

-

You should be able to pick up a Sweet or similar rack off of eBay for a decent price. Just will take some patience to get the right ratio and width. That's the direction I'll go. I haven't nailed down all the geometries yet. Debating on hubs, etc. I'll probably use the late Mustang parts just because that will make the rear half-shafts easier and cheaper as well as a really common bolt pattern, brake availability, etc.

-

Thanks for the reply Chris. I don't dare go any lower in the rear and it is already starting to push economy at cruise. I don't think gearing will be a limitation on acceleration, should be traction limited even with sticky 295 tires. Top speed will be power limited with a teoetical of . 200mph would be at hp peak in 5th. The I am certain will be pushing it. Here we have several "legal" choices to use that speed. Salt flats are a few hours away. Road course at Miller Motorsportz Park about 1-1/2 hrs and the run outside Vegas as well as their track about 6hrs. I wouldn't mind just seeing what it will do at least once. Got to get it built first which is proving to be a very slow process. 4130 is stronger but definatly needs to be welded properly. I already have the tubing from an abandoned project. I'm also planning on 4130 in the supports, floors, suspension and scattershield for the tunnel. Trying to save weight wherever remotely practical while increasing strength. I have Miller 200DX TIG and 350P MIG to weld with. Proper prep, back purging and post weld normalizing will be in order. I know the A-arms are adding some work but the end result is much superior and I'll regret it if I don't being as far down as I am on metal replacement now is the time. I'll take a look at your project for ideas there. Stock rack is aluminum but I have two concerns with it: Width, It will need to match the suspension pickup points for bumpsteer, and Strength. We'll see how it matches up. I really appreciate the comments on getting it on a rack. Been worried about that. One of the front rails is buckled and pushed slightly back. I think I need to get those sorted out first then up on the rotisserie. Not sure how to make a rotisserie work without the rails there unless I weld in a temporary support in the engine bay which might be a good idea actually. I have seriously gone back and forth on the engine. I am intimately familiar with the LS family. That route would be cheaper and easier, no contest. Lighter than a Coyote (LS is ~430, Coyote ~444, heavier than Voodoo, no specific #s I have found overall but the crank alone more than makes up the difference). However, I love having a high revving exotic sounding engine in that car. The LS can be made to rev at an exponentially higher cost the higher you go. But, by camming it to do that you lose the smooth bottom end so at highway cruise it would be loping which doesn't work even using their VVT. My Jeep is right at the cam limit for keeping the cruise and it's more than 1000rpm off on the top end. There is no way to get an exotic BRAPP sound out of it, destinctive and cool? Yes! But not the same spine tingling sound. It would sound just like my 6.8 in the Jeep. Also, power delivery is much better to avoid wheelspin. Not quite as strong on the bottom but more on top, very progressive build of power and tons from about 4k to the 7200 peak and on up over 8200. Coyote will just be a stopgap if necessary. I'm rambling, thanks again for your comments. I'll look into that suspension and rotisserie info.

-

Happy to oblige Sirpent. Just wish it was more often/more progress faster. Labor of love though. I need to unload a few other projects so I can get my body parts coming from John Washington. Snagged that 2nd rear so looks like we're building two sets of brackets!

-

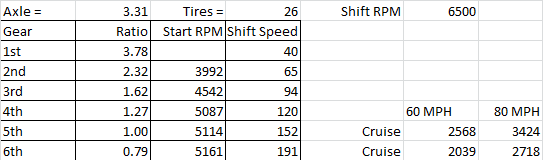

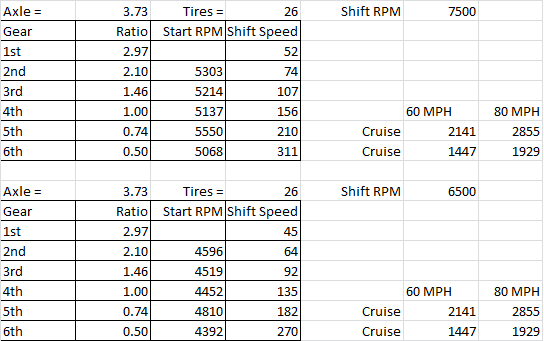

I don't think you would want much lower than that or you'll just spin. I'm concerned I might be too low with the 3.73 rear and 2.97 first. You would end up with this (not sure what your power band would be like, best shift point).

-

Just as well build 2 mount setups as 1. I'll see if I can lock down the second diff, I can always sell it if it doesn't work out.

-

Look at the ears on that diff, mounting it under the Z is going to be a whole lot easier than the other style. Plenty of meat to avoid the thing climbing around under the car. They run 34 spline inners stock. Mustang upgrades are all over the place and honestly, the stock parts with shortened shafts should be plenty strong for the 1000-1500lb lighter Z cars. If you are ok with an iron main housing, 3.31 gears and a limited slip I can get one for a great deal for you!

-

I decided just to start over on the front and rear suspension. I need to completely replace front subframe and floors, just as well put what I want under there.

-

That's the beauty if that transmission with an engine that has a good powerband, it's always in the power up to way past where it will go. If I could muster a 200mph run it would be right at peak HP for the Voodoo. Not sure if 500 wheel HP would pull that off though. It would be fun to try - once anyway on the flats. We should put one of these 8.8 diffs in your car. What ratio are you looking for?

-

So that will yield these results with Voodoo first, Coyote (if I can't get a hold of the Voodoo initially) 2nd.

-

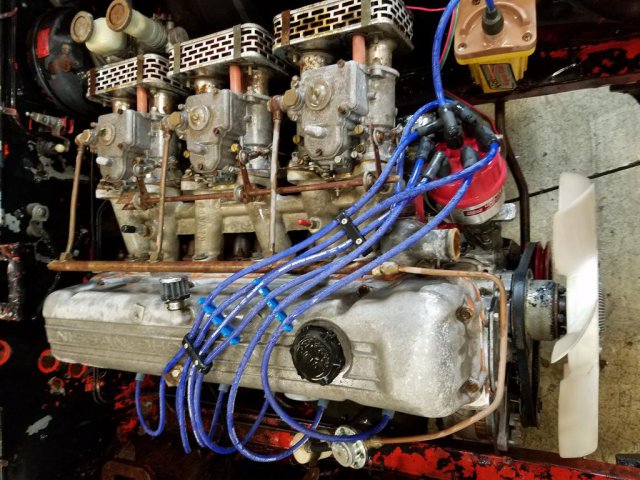

That is a 3.73 with a Torsen T2R from a 2015-16 Mustang with the track pack. I would like to get an aluminum housing to save some weight but can mock up with this one and even run it a while if necessary. Just about ready to pull the engine and transmission out. Know anyone that wants a hot stock setup? Cam, triples, balanced, 280 block, 240 crank, Tri-Y headers, unilite, etc.

-

-

I don't know about Coffey's hoods, would be interested to find out. John Washington's fiberglass skin weighs 11 lbs. not sure on the full hood. http://www.ztrix.com/hoods/hood-skin-only-no-factory-style-reinforcing.html I have planned a bunch of his parts.

-

Nice! Thanks for posting the pics!

-

Just a thumbs up for ihiryu! Purchased a set of Speedhut gauges for another project and he was great to work with. IMO they are nicer than the Pro Comp Autometer gauges I have here. Definitely will be using them in my 240Z when I get to that point. Dave

-

Send me those brake lines and I'll flare them for you, seriously if you can get them here I'll flare them for you. Or, message me and I'll let you know what flare tool to buy. There is a much better hydraulic tool available that does a cleaner job. Are they 3/16" (-3) lines? Nice work BTW, car is looking great.

-

A musician's therapist (The $300 Z)

jpndave replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

I have some electric shears that should work as well or we can just use the plasma cutter. -

A musician's therapist (The $300 Z)

jpndave replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

My brake will probably handle the floors depending on how much you need to replace. You are welcome to use it. -

A musician's therapist (The $300 Z)

jpndave replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Lunch sounds great! Have you ordered the frame rails yet? -

A musician's therapist (The $300 Z)

jpndave replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Need to assemble the rotisserie. No way am I doing all the floor work I have to do upside down. Undercoat wouldn't be horrible. Welding is doable but easier when gravity is your friend rather than fighting you. There might be a way around some of that. I have a couple of ideas that might work to help on the rails. -

I would give JE a call, they have some pretty good pricing on custom pistons and include a premium ring package. I have the same ring set here if you want to see it. Thin set, Steel top, Napier second, etc.

-

I need to come and see your project! Have you checked JE for pistons? I think they are a little more reasonable. I have a set of theirs here for my LS 6.8 going in that Jeep if you want to see them.