-

Posts

301 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by dapiper

-

Ophier claimed supplier sent long shaft, now waiting for short shaft replacement. I thought after mkt only fabbed short shaft, otherwise use stock

-

Thanks to all for info. Will try Joe

-

Finally got thru to Ophier(??) who assured me he will research and call me back. More later

-

GTECH, Thanks for details your experience. Wow, 6 months, Summer will be over Wonder if Checkered Flag is their fabricator?

-

Any one know source? Whitehead Performance has had my 300ZX Turbo driveshaft for 6 months. Repeated attempts to get status have failed. Take care, beware.

-

Excellent build very similar to mine. Need your Z31 axle shafts. Please advise availability. Thanks

-

Just found another fabricator who quoted $2500 off the bat in single lots using sked 10 304SS including water cut head flange. Any chance of sourcing head flange here? Wud save $200.

-

Changed using Stone gasket with no coatings applied. Did not fire yet, but after a few weeks noticed beads of coolant and block moist. Appears to be leaking at block side interface on both sides of block, but primarily on plug side near middle. Suspected condensate, but weepage stopped after coolant drained. Both head and block are straight. Using ARP studs. Gasket lifted off block and stuck to head. Have tried FelPro and stock graphite gaskets and they both weeped. The FelPro actually dripped coolant. Never had problems with previous design asbestos gasket. It had a pressure sensitive coating that adheared well and did not weep. I suspect the composite material is not water proof (paper) or does it require heat to seal? Block scraped, scottbrited and wiped with mineral spirits and acetone to dry as prep. Survey of posts had one where thin film of RTV was applied around coolant passages. Never heard feedback on that procedure. This seems to be a common problem with the new composite gaskets. Head and block is N42 from '76 280Z 1 What is best gasket to use? Some have thin fire rings which would not match my o-rings on block (ITW) Others don't have the metal seal for the oil galleys. Have not tried the Beck-Arnley, since both were damaged. 2 What is best coating, if any? Tried Hylomar with some success. Have not tried Permatex Copper Cote.

-

Solution to last my last post found. Austin Hoke may be able to fab CNC flange with integral transition.

-

Fabricator challenged at adapting round tube to square port. Is there a header flange available here? I thought I recall someone had fabricated one for use in building a tube header.

-

Getting another estimate for custom fab tube header using 304SS sch 40 fittings for divided turbine and external wastegate to accommodate TO4 or GT35 tangential turbine. Please advise interest.

-

Where did you get that Cometic MLS? thought they couldn't make due to lack of volume sales. What is bore? How much $? Heard Kaminari makes one but 89mm bore.

-

I hope this thread continues. I have an L28 N42 custom turbo that just got reincarnated from a bad cam regrind. Nice to get the other one grafted back on. Nevertheless, still tired of the limitations and really want more power, but don't want to invest any more in the old dog. The motor has limitations that can't be easily resolved. The availability of aftermarket parts is non-existent IMHO. Try to source a tube header or intake plenum. Last quote was $3500. Just put the Z32 train and 300ZX TT CV joints in my '77. Got tired of blowing trani's I am preaching to the choir, I know. The 2JZ makes sense or even a 1JZ. I know guys who have the 1J and are making over 400 RWHP and 600 is within reach. I figure, get the 2J and keep the boost below 20 psi and get 550 RWHP easy. Guess I'll find out how much the R200 can stand. Guess we all need another project., but n the end, I just want to drive.

-

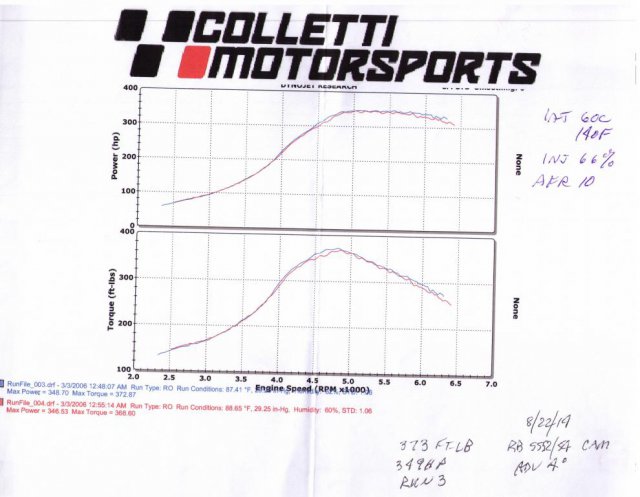

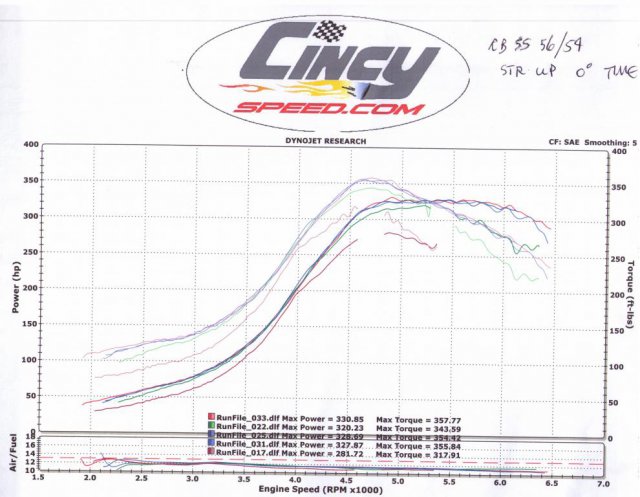

Just replaced Schneider regrind with Delta cam one and wow, what a difference. More mid range torque, smoother idle, more idle vacuum 14 "Hg, grabs revs better, just more enjoyable to drive. Was out all afternoon taking the long way home. Was running lean in mid range 16:1 which shows pumping 10 % more air. Spent a lot of time and effort fighting this problem. Wish I had some recourse. It's a jungle out there and things are not quite what they used to be, so take care, beware. Will get dyno sheet soon, but AFR and inj duty confirm increased power.

-

Thanks for chiming in. Appreciate your suggestions. Misery loves company. Tried Schneider 270 but too much cam for me, low vac and soft below 3K RPM. 260 similar to RB SS56/54, but didn't try that one. You should be OK for non turbo. Keep me posted.

-

Yeah, all that. I been doing this for 35 years. Understood about accuracy, but verified within a degree or so or enough that it's not way off. Just checked blow off valve, looks ok. Getting ready to change cam AGAIN to Delta regrind before I pull the motor

-

Using Autronics aftermkt ECU with DIS ign LS1 coils. Timing and fuel map same as b4. Tried tuning (33 pulls) to no avail. Unless you mean the LS1 igniters. Using 4ms dwell and 27 deg total at 6K RPM with dip to 25 deg at peak torque, 4600 RPM. Did not check all other cam timing events, since did not install the degree wheel. Did not want to remove rad and all the other to get to the crank nose. Using timing marks on harmonic bal. I can verify other events now, since adding complete degree label to balancer. Will advise.

-

It all started with a cam regrind from Schneider, the Racer Brown SS56/54 turbo grind. They took 2 months. When reinstalling, had to turn up idle screw 2 turns and only got 10" Hg vac at idle. Used to get 12-13". On the Dynojet 248H t got 325RWHP at 18 psi boost. Used to be 410. Ran cam straight up as before. Degreed cam to be sure. Just checked Intake open event which matched cam card. Tried adv cam 6 deg, but just reduced top end range. HP curve flattens out at 5k to 6K RPM and does not even equal peak torque. Motor leak down is 2-4%. Tried another milder RB regrind from Schneider the SS54/52 which always had about the same top end power before and exceeded the hipo cam power to 350 RWHP. The idle vacuum was 12 inHg, much smoother. I've missed the whole Summer with this regrind issue. I did send the original RB cam, which Schneider refused to regrind because they claimed the metalurgy was compromised. It had 0.030" pitting on the #6 cyl lobe nose. I just got it back from Delta. Will install and compare. Extensive datalogging history substantiates the big disparity of over 80 HP. For example the fuel flow and AFR figures show the regrind cam motor is pumping less air. Inj duty is high 60% vs high 70%. Did change to Z32 tranny and CV joints in rear axles, but this can't equate to overall loss. Meanwhile, thoughts and experiences anyone?+

-

Schneider cams also regrinds rockers for $10 ea

-

That you Joe?. Yeah that's the cam card for the hipo RB grind. Lot's of grinders have cams that copy that one. Joe was the original owner/fabricator of my Jim Cook chassis. Still trying to reinstall the regrind from Schneider, but lost cam trigger sensor. Went kaput when winged it with the chain block....duh. My dumb luck. I think I still have your old phone no. Will try that later. just now checking out my posts. Looking to upgrade turbo soon and setting up deal to fab equal length turbo headers for the L28. Thanks for all the CarolinaZ info.

-

You DIVIDE by rocker ratio. Do some measurements. For example, set clearance at cam to 0.010 for intake per stock spec. Measure at valve is 0.007.

-

Wow, that BC is tiny. Hope you got lots of head, manif and high CR for that cam. Schneider has 220's. I used SS feeler gage stock and cut little squares to fit under the lash pads. Lets see, calc lash pad thickness: Pad = (stock BC - cam BC) / 2 / rocker ratio + stock lash pad = ((1.3 - 1.056) / 2 / 1.5 ) + .117 = .198 Something's wrong. Is your head a P90? NewZed may be on to something re valves being trimmed too much to equalize. I NEVER trim my stem tips, cuz of loss of tip hardness. If you can, remove springs and measure inner pocket height (inner spring perch to stem tip without shims. Should be 1.610 - 1.625 on new N42. Outer pocket will be .050 more. Of course depends on if new valves, new seats or how much grinder pocketed valves into head. Normally, exh valve pocket taller by .020. Did you use any cam tower shims? My base circle is 1.25I, 1.23E and I am using 160/140 pads My SS-56-SS-54-112 RB cam used 200I/175E pads

-

Thanks for all the comments. The RB cam profile is SS-56-SS-54-110. I wud post the cam card if I knew how. Where is the insert pic command? Paste does not work either Have talked to Elgin and Isky, but went into black hole. Will try Ron again. JWT has very pricy $560 cam (with 480 lift and 256 deg (@ .025" lift at valve) duration and 32 deg overlap, P/N L6 A280Z-00C1M. This is more that the RB cam, prolly too much. This cam is a symmetric profile. MUST use their valve springs, ($130) 75 psi at stock height (1.6") and 200 psi at lift, which seems low, especially on seat at boost. The cam is a stock billet, no core reqd. They have no retainers or lash pads. The base circle is 2.3" which would call for near stock lash pads (140-150) depending if you have to shim your cam towers due to head milling or how much your valves are sunk Here is quote from Ben Phila. He has been very helpful. paste kaput The RB cam has 20 deg over lap, 480 lift, 244 I, 236 E durn at 025 valve lift, which is asymmetric. I get 12 "Hg vacuum at 800 RPM with a CR of 8:1. Peak power is 435 RWHP at 6200 RPM. I have tried the 270 and 284 Schneider grinds which were way too much cam for the street. Soggy below 3k with less power on top. All top end. The idle vac was only 6-8"Hg for the 270 and 3" for the 284. This is unacceptable. Would have to idle at 1500. Did have more area under torque curve, once awake.

-

Good luck on that one. Never even heard of ones that thick. Schneider has 220's. What is your base circle? Must be like 1.1" or less. Ensure your retainer pockets are tall enough to support those or they may pop out. I have shimmed lash pads. Put the shims on top of the valve stem.

-

My old Racer Brown grind is spitting chunks. Time for a modern grind Any suggestions for grinder and profile? Target is 6500 RPM or maybe 7K for peak power, 550 HP at 25 psig. What say all you gurus?