-

Posts

565 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by pat1

-

-

That would not cause the problem your having. You have a internal mafuction of the master cylinder. A seal or oring or a cup is damaged causing the internal leak in the M/C.

-

I would say the master cylinder is junk. The fluid is bypassing the seals in the master cylinder.

-

looks great man. post more pics please

-

Zreddy's pan is done here are some pics

-

I guess times must be tough. I remember when there would be a post every few min. Now it seems like a post every few days.

I know, I remember it also and it was not that long ago. This one post every few days is getting old.

-

Why can't you use the stock rb25 ecu? I have put a couple rb25s in 240sx's and never had an issue.

you can't tune them. something with the eprom.

-

I have always bought my gauges from summitracing.com. They have good prices and fast shipping. Sometimes you can find coupons on the net for them also.. Just google summit racing coupons.

-

Off the top of my head it sounds like you have everything. I would put a new timing belt, tensioner,idler pulley and a water pump. And a t-stat. I have coilovers on my car with heavier springs. I put the Toyota 4 piston calipers and the bigger master cylinder. I still have the stock rear brakes. The brakes work great for the street.

-

You will need a intercooler and piping, get a walbro inline fuel pump. As far as the crossmember goes I modified it by drilling two holes in it and grinding down the sides a bit so the z crossmember will fit right on. I had to slot the stock engine crossmember forward about 1/4 inch and the motor and trans dropped right in.

-

They raped me back when I was building my motor. They charged me $500 for a plain Nissan gasket set for my rb26. I will never buy from them, or recommend them after that...

Holy cow, 500.00 for a gasket set

-

I can tell you the difference between the series 1 and 2 motors but as far as what car it came from I don't know. I found the easiest way to tell the difference between the two is the ignitor chip on the back of the engine on the plug cover thingy. The series 2 has the ignitors built into the coil packs. I hope ths helped with something.

-

The rb20 would be easier. I used the stock skyline motor mounts and modified the stock z trans crossmember to use the rb trans mount. With the rb20 you can use the stock z driveshaft. The wiring is cake. It's less than 10 wires plus gauges. The rb25 is the same but you need motor mounts that run 475.00 from Mckenney motorsports or you can make your own. You have to get a driveshaft made which is about 250-400. The wiring is also easy. Tuning is easier with the rb20 vs the rb25. With the rb25 you can't use the stock rb25 ecu. You have to use a rb20 or z32 ECM.

All and all the rb20 is a little easier and cheaper. It's how much power you want. My rb20 is perfect for me. It hauls a$$. And revs to the moon.

-

I was trying to get paid for my time LOL

-

this guy had me help him pick this car up yesterday with a entire uhaul truck full of parts for 240z,260,280z. I was like a kid in a candy store. Stay tuned guys I going to build a killer ALL aluminum rear sump oil pan with a internal oil cooler set up. It's going to be TRICK. I can't wait. Back to the car It's in real good shape and it's begging for a rb LOL..

-

you can make you own for less than 2 bucks

-

there is a ton of info on the rb part on this forum. The swap is pretty straight forward. I did a rb20 swap in my 280z and I found it easy. I decided on the rb20 because of the cost. I have seen the rb20's produce about 400hp and that more than enough for my datsun. I have about 1500.00-1800.00 in my swap before I added everything like a bigger turbo,injectors and NIStune and etc. Thats 1500.00-1800 with it running and driving. I added everything else after the swap. The only part thats a pain to find is the rear sump oil pan which nissan does not make anymore. Thats where I can help you. I have been build custom rear sump pans for the rb swaps for the s30's (see my posts on the rb engine part on this forum) Please let me know if you have any questions about this swaps. I would be glad to answer any questions.

-

When you spin the cas by hand can you hear the injectors click? Who did your harness? I think the problem is in the wiring. You have swapped all the main sensors. I would grab a meter and check out all the wiring. There is a sticky at the top of the page. For some reason your not getting signal from the PCM.

-

I have a gianttech plasma,arc,tig machine and it works great. I don't have any complaints. It doesn't weld as good as my Miller syncrowave 200 though but it does the job. It came with a warranty for 3 years and the customer service is awesome. I had a problem with my food pedal and Larry (the Gianttech guy) fixed the problem fast. I use the plasma part all the time and it has never let me down.

-

are you getting the negitive signal to the ignitor from the pcm? Do you have power at the coils? Are you getting - signal from the ignitor to the coils? There are 3 wires going to the coils. You have a power,ground and a signal wire from the ingitor. Is you pcm a manual or a auto transmission pcm? I have a auto pcm that I used on mine and there was a wire to the pcm that had to be grounded to start. It was the wire from the inhibitor switch from the auto trans range switch. I had sort of the same problem with mine but it would happen when I was driving it and then I would loose spark and the car would stall out and not start. My problem was the PCM.

-

-

your right, it is in the stock cooler. I'm running a rb20.

-

why don't you use the stock oil pressure sending unit hole in the block. That's what I did with mine. As for the oil temp I would put it in the line to the oil cooler or in the pan.

-

looking good man. I like that color

-

WOW Pat... they are looking better and better as you build more!! Excellent local service now for the guy's needing RB oil pans.

Thanks Joel

Here are some pics of a pan that I finished tonight for Flexall..

tacho says no. 280zx

in Nissan RB Forum

Posted

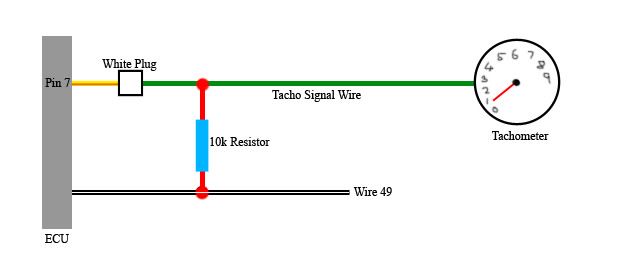

this is what I used with a autometer Gauge. I don't know if it will work but it's worth a try