-

Posts

317 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by T-Bone028

-

I know this may be a little bit pre-mature, or possibly give away the "secret sauce" ahead of time, but CAD drawings or something similar would be cool to see as you continue through the prototyping phases. Personally, I would like to see something modular, whereas intake runner with bolt on TB (weber dcoe pattern), bolt on air horns, and bolt on airbox options. You could potentially sell more given some peoples disappointment with their canon intake manifolds (& knock-offs) for webers. Just a thought.

-

Given your two engines L24 & L28, this might be an interesting read: http://www.classiczcars.com/forums/engine-drivetrain-s30/42488-new-engine.html Essentially he built a L28 block, L24 crank and rods, with flat-top pistons. Another useful link as you ponder your engine combo might be: http://www.ozdat.com/ozdatonline/enginedesign/ Regarding 200hp...you should read the thread "Max N/A hp, no shortcuts" in the FAQ section, under the L6/engine sub-forum. That might give you an idea of what goes into a N/A build...Zredbaron went a lot further than what you're talking about, but it should still give you some insight. 200hp isnt a super lofty goal, but there are certainly cheaper ways to get there...and I know after I finished school, money wasnt something I had a lot of. I would disagree with triples being a racing specific set-up...they work fine for me on the street. However, it wasnt exactly the cheapest project...with all the "while I'm at it" side projects, I spent quite a bit of money. My triple install thread is here: http://forums.hybridz.org/topic/112810-weber-dcoes-installed-initial-impressions/ Good luck and happy reading.

-

Weber jets??All who live for their triples please read this

T-Bone028 replied to datfreak's topic in Nissan L6 Forum

Standard stroker build: F54, P90 head, L24 rods, KA pistons about 10.5:1 compression ratio with a 470 lift 270/280 duration cam, 280ZX distributor with MSD 6a, header, exhaust, electric fan, etc. R200 3.7 LSD rear end. My order for the 36mm's should come in on Thursday, so I'm hoping to do quite a bit tuning this coming weekend. I ended up paying $85.50 including shipping via PierceManifolds ebay store. Their ebay store is probably 25% cheaper than their website pricing. -

Weber jets??All who live for their triples please read this

T-Bone028 replied to datfreak's topic in Nissan L6 Forum

HAHA damnit Steve. I just purchased a set of 36mm chokes. I was happy with the 33's and I was already losing traction with 33mm chokes on 245/55/15 Dunlops...hopefully my experience will be similar with the change to 36mm!!! -

Weber jets??All who live for their triples please read this

T-Bone028 replied to datfreak's topic in Nissan L6 Forum

Hey Steve, a F11 idle jet should be slightly richer than a F8, but not quite as rich as a F9 as a lot of other people on Hybridz seem to run (FYI, I use a 55F9, might switch back to a 50F9). However, I'm not sure if a 55F11 idle jet will be richer than a 60F8. An F2 emulsion tube should be about right given its range is for 450-575cc's. Regarding the switch from 34 to 36 main venturi's...thats really interesting that you saw such a difference! Which is awesome btw. Could you tell me more about how it "felt"? I know the butt dyno lies sometimes, but how did it feel? Like a very noticeable difference? Like much more top-end at the expense of low-end? Any descriptors of how it felt with the 34's in comparison to the 36's would be appreciated. And nice work on the ebay deal! $30 is super cheap!!! -

For replacement parts on the DCOEs try piercemanifolds.com This should be a fun project for sure, I would be interested in the difference in dcoe jetting for the change from NA to turbo.

-

Weber jets??All who live for their triples please read this

T-Bone028 replied to datfreak's topic in Nissan L6 Forum

My idle screws are set 1 - 1.25 turns out from fully seated using the older style coarser screw. What I found when I went leaner/turned-in was spitting/coughing from the front carb. I'm planning on spending saturday and sunday tuning and swapping jets and e-tubes to play around. From a driveability standpoint, I find nothing wrong with how it feels running in idle, cruise, partial throttle, and WOT. Just experimenting at this point and trying not to get caught up in "perfecting" my AFR's. At the end of the day, as long as it drives well and consistently is all I'm really concerned about...until I bump up in size on the main venturi's...then I get to do it all over again! Speaking of which, if anyone has 34 - 36 chokes for 40's, let me know! -

Weber jets??All who live for their triples please read this

T-Bone028 replied to datfreak's topic in Nissan L6 Forum

AZGhost, Larger pump jet should provide bigger shot, shorter duration...or smaller pump jet; smaller shot but longer duration. Conversely, you can just change the exhaust valve at the bottom of the carb. Only need to change 3 jets instead of 6 = less money. Smaller bleed-back/exhaust valve should provide longer duration. I currently have 45 pump jet with 55 exhaust valve installed, with a "0" exhaust valve that I still have yet to test. I believe the pump jet circuit was intended to provide the extra gas needed at sudden throttle opening, not necessarily to tweak idle circuit AFR at cruise. From what I recall when I was watching the pump jet arm on the bench, even at partial throttle plate movement, the pump jet would depress all the way to bottom (albeit slower than at sudden WOT). So I would agree with Duragg, progression hole placement is contributing to the lean condition your experiencing at 2500-3000...and the common "fix" is to bump up the idle jet. FWIW, Im experiencing the opposite, with a 50F9 idle jet it gave me about 12 - 12.5 AFR at cruise. However, I was experiencing a bog at sudden WOT at <2000 RPM. I went to a 55F9 idle jet and that mostly fixed the stumble/bog, but it gave me a rich idle cruise of 11 AFR's. Thinking back on it though, I could have gone with a bigger AND longer pump shot to reduce the stumble and could have kept the idle jet size the same to have better cruise AFR's. Disclaimer: I'm new to DCOE's, and my rambling is based off some reading/research I've done over the past few weeks. I could be completely wrong, but as I write it out it seems to be correct in theory. -

Just a couple of shots. Under the hood: 3.1L with 40 DCOE's Wheels: 3 piece BBS 15x9 rear, 15x8 front. Inside: Autometer gauges, paint matched roll-bar

-

From the album: T-Bone028's 1972 240Z

-

.....IM SORRY WHAT?!?!?! That track video shot by Josh Clason/Depth of Speed with JDM Legends was the SINGLE biggest push to install the triples I had sitting around!!!!! I wanted that sound, singing through the rev range and classic nostalgic power. Unfortunately, I cant help with advice on degree'ing the cam...but congrats on a BEAUTIFUL car. Hope you get it running again soon...and please feel free to take gratuitous pics of anything/everything!

-

Weber jets??All who live for their triples please read this

T-Bone028 replied to datfreak's topic in Nissan L6 Forum

I mounted the AFR gauge on the clamshell cover in between the speedo/tach using one of the universal gauge mounts. I'll try to snap a pic tomorrow. Edit: here is the picture. I think you can buy the mount for like $10 (also from Amazon) and its just 2 small holes drilled into the top clamshell cover and barely "screwed" in (threads barely go through the cover and are basically flush to the underside). I'm sure it could be mounted elsewhere. Wiring was a breeze. Just power and ground needed to get it running. -

Weber jets??All who live for their triples please read this

T-Bone028 replied to datfreak's topic in Nissan L6 Forum

Folks, joining this thread to consolidate notes/experiences. Here's my install thread: http://forums.hybridz.org/topic/112810-weber-dcoes-installed-initial-impressions/ And here is my current jetting with 40 DCOE's on a 3.1L (I find my current jetting to be pretty fun, but still testing) 33 main venturi 4.5 Aux 130 Main 170 Air 55F9 idle F11 emulsion 45 pump jet, 50 exhaust valve Steve, regarding W/B, maybe I'm not familiar with a W/B that doesnt require a laptop or some other tool to datalog, but with the AEM, you essentially have to wire in a 9-pin serial cable to one of the wires coming off the guage and then use a serial-to-USB adapter to record data onto a laptop. If you do a google search on data-logging with the AEM UEGO, there should be a couple of hits on how to do it. Never bothered to look it up for the Innovate. However, with just the in-car W/B gauge and checking it as I drive, I still find it to be a pretty useful tool. I will eventually wire in the serial cable though to study logs/runs once I finalize on what direction I want to go with upgrading my ignition. -

Weber DCOE's installed | Initial impressions

T-Bone028 replied to T-Bone028's topic in Nissan L6 Forum

Steve, If you dont mind I'm going to move our conversation to the Weber sticky (listed under FAQ -> Engine Components -> Fuel Delivery -> "All who live for triples"). My initial impressions of my DCOE install is now over (they are awesome) and tinkering for fun has now begun! -

Weber DCOE's installed | Initial impressions

T-Bone028 replied to T-Bone028's topic in Nissan L6 Forum

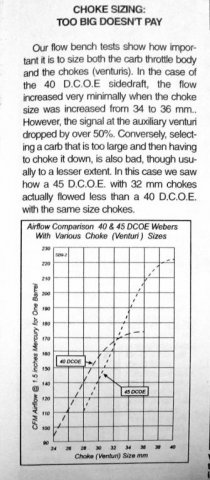

I went with the AEM UEGO, but I know another popular option is the Innovate motorosports MTX-L (at least that is what seems to be the most comparable to the AEM UEGO). I went with the AEM due to the reviews I read regarding inconsistent quality of the Innovate, and AEM being pretty dependable. I think the main benefit of the Innovate is their data-logging interface and wider range of AFR. AEM goes from 10 - 20 AFR. Innovate goes 7.35 - 22.4 AFR. I havent been outside of 10.5 - 13.8 AFR's so I dont really see the range issue being applicable. Both are pretty much the same price on Amazon...$150-ish. As far as my jetting: 33 main venturi 4.5 Aux 130 Main 170 Air 55F9 idle F11 emulsion 45 pump jet, 50 exhaust valve I'm going to try F16 e-tubes with 135 main and 180 or 185 airs this weekend and bump timing from 13 to 15 degrees advance. As I make changes, I think thats where the W/B pays off. I also may try larger chokes in the near future. Let me know how the 36 chokes work out...I posted this graph on the Weber sticky, but essentially the author's findings point to the 34's being a better choice over 36mm chokes for 40 DCOE's...but I guess everyones experience is different and the only way to find out is test! -

Check the turn signal sockets themselves.

-

Weber jets??All who live for their triples please read this

T-Bone028 replied to datfreak's topic in Nissan L6 Forum

Not sure if this helps you with the P90 CFM answer, but might be of some use to everyone following this thread. I dont recall seeing this picture/graph in any of the other pages, but I came across it in a post on side draft central. The graph compares 40's vs 45's CFM's for multiple venturi sizes. According to the chart, 45 DCOE's with 36 venturis should be flowing roughly 205 CFM's @ 1.5 inches of mercury per barrel. -

Weber DCOE's installed | Initial impressions

T-Bone028 replied to T-Bone028's topic in Nissan L6 Forum

I would say those plugs look pretty good to me, I believe they should be a light gray to tan color when running right. And I know its easy for me to tell you how to spend your money, but...invest in a wideband! $150 to take the guess-work out is worth it to me. What is your jetting? -

Thank you Domz and Noelawinslow, you both helped me think through my issue which is now solved! Didnt even think to check running/parking lights and side markers, turned the switch on and...nothing. Disconnected the parking light relay harness and re-installed as per factory, and parking, dash, and side marker lights started working again...this lead me to checking a fuse I forgot about for the parking light relay harness (which was blown). Checked my turn signals and brake lights, and they started working again as well. Started to close back up the clamshell, and poof...no lights. Started jiggling wires, and ta-da, lights work! Started individually jiggling wires till I found the culprit. One of the pigtails had a wire that was not securely seated in the connector. Re-seated the wire, made sure it was secure, and lights are now all 100% operational. Glad the problem wasnt too involved and thanks again!

-

Typical Z issues that I thought I resolved 3 years ago... Entire car was rewired 10 years ago with Painless/EZ wiring harness kit. 3 years ago I rebuilt the combination switch, installed both headlight and parking light relay harnesses via "Zsondabrain" from ClassicZcars. And for a while, life was good. Recently noticed the driver side rear brake light, turn signal, parking/running light, and reverse light all stopped working. Passenger side lights all work fine and all lights/signals in the front work fine. I replaced bulbs and checked fuses just in case with no luck. Interestingly enough, Hazard Switch is lighting up all 4 corners correctly. What am I not thinking about? Why would only one corner of the cars lights all stop working? Only other thought is that a wire came loose under the clamshell cover while I was in there doing something else for my Wideband O2 mounting. Any other thoughts while I try to keep hunting down the issue?

-

Missing parts on my weber dcoe 40 Need help

T-Bone028 replied to Sotenacious's topic in Nissan L6 Forum

Also, I must have missed it...but why are you removing the butterfly and shaft again? Those screws should be staked in and can't be removed without drilling...you also should avoid removing the butterfly and shaft unless you either 1) know exactly what your doing, and 2) you absolutely have to. At least that's what all the books/articles I've read say... -

Missing parts on my weber dcoe 40 Need help

T-Bone028 replied to Sotenacious's topic in Nissan L6 Forum

Piercemanifolds.com -

Weber DCOE's installed | Initial impressions

T-Bone028 replied to T-Bone028's topic in Nissan L6 Forum

Congrats Steve, sounds good! And great work on your stroker build...just read your build thread. Now break that motor in so you can really open her up! -

Weber DCOE's installed | Initial impressions

T-Bone028 replied to T-Bone028's topic in Nissan L6 Forum

Also..Without going into detail, I came across some classic detroit muscle today.... I love these triples! -

Weber DCOE's installed | Initial impressions

T-Bone028 replied to T-Bone028's topic in Nissan L6 Forum

I would say that's tremendous progress! Nice work. I'm no expert, but this is how I set them. Speed screws turned in to move the trottle plate edge to just before uncovering the first progression hole. Sychrometer to measure flow, and bring the highest flowing carbs to the lowest by very small adjustments to the idle speed screw. Bench set idle mixture screws to 1.5 turns out from lightly seated, and make small adjustments using best-lean method while monitoring wideband and using sychrometer. Sounds like she's almost ready for the road! I'm hoping to do some more tuning in the very near future with F16 e-tubes instead of F11 and slightly larger mains and airs.