-

Posts

317 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by T-Bone028

-

I've actually been searching for similar answers on and off all day...unfortunately I've been looking for information about timing marks on the pulley as it relates to ignition timing so I cant give a direct answer. Regarding the rubber deteriorating, I've read in a couple of various posts on Hybridz, Zcar, and ClassicZcars about it possibly going bad, giving inaccurate measurements as it relates to timing. I believe the suggestion was finding TDC on cylinder 1, and making a new mark on the pulley. Also, anyone want to tell me what the 5 timing marks on the pulley indicate in an L24 style pointer and marks? (single pointer on timing chain cover, 5 grooves on pulley) I believe they are 5 degree increments, but is it 0, 5, 10, 15, 20 as viewing from the front of the car facing the engine, increasing left to right? Or is it something different (5, 10, 15, 20, 25)? BUMP for some knowledge bombs! Sorry to hijack IncompetentOne, but I believe (hoping) answers may be interrelated.

-

Weber DCOE's installed | Initial impressions

T-Bone028 replied to T-Bone028's topic in Nissan L6 Forum

I believe my pump jets are 40 or 45, but from what I understand, it can be more cost effective to play with the exhaust valve at the bottom of the bowl, since there are only 3 of them. I purchased "0" exhaust valves, but decided to wait on messing w them. After being honest with myself, the car is slower w the webers in it's current state of tune (which is untuned) compared to the SU's. So, bought a timing light and going to try and see where I am this week. Hopefully, my timing isnt advanced enough and that's why it feels a little sluggish. Got to check for vacuum leaks too just in case. After that, I'll get back into jetting. Let me know how your endeavor turns out! Could be fun to compare notes. -

Weber DCOE's installed | Initial impressions

T-Bone028 replied to T-Bone028's topic in Nissan L6 Forum

I wonder if the lean sneeze is due to the brake vacuum assist valve being place on that runner...I would imagine no, since it's not really pulling extra air from the vacuum canister, but maybe I'm wrong? Any thoughts? 310z...Regarding the anti-vibe mounts, i would have liked to put them on, but short of going to stack filters or a lower profile aircleaner, paper gaskets will have to do until I figure something else out for clearance. Your Z build looks great btw. Bludestiny...couldn't agree more about the sight of triples. With a stroker, I just didn't have the bling bling vroom vroom impression with the SU's. Don't get me wrong, I was happy w the SU's...but triples are just the wow factor I wanted from an aesthetics standpoint. Here's to hoping that the performance is as awesome as I've read! Day 1 of tuning starts today! -

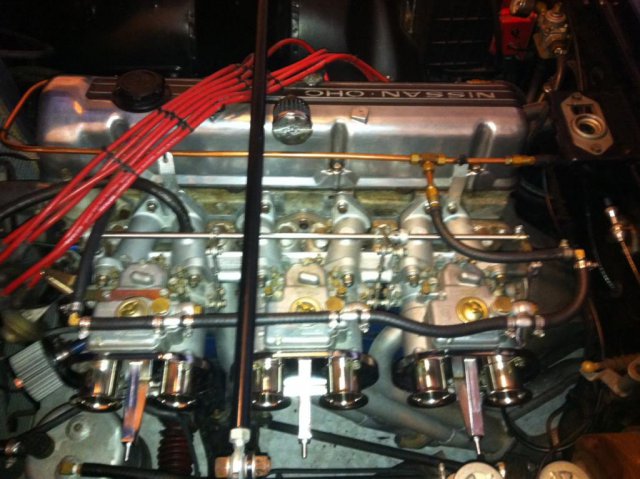

Finally made the switch from SU's to triple webers. Here's the basics: 3.1L with 470/280 cam,header, exhaust, MSD, etc. 40 DCOE 2's: 33 main venturi 4.5 aux venturi 130 main 180 air 50F9 idle F11 emulsion 55 exhaust bleed Here's a before pic with the SU's Started rebuilding the carbs roughly a month ago with a couple of mis-steps here and there. The carbs looked like they hadnt been touched in over 20 years, and they were filthy with dirt and dried gas. Between the 3 carbs, I went through about 6 cans of carb cleaner and I still thought they were dirty. Bought almost all of my replacement parts from Pierce Manifolds...great vendor. For those who have never rebuilt a DCOE, heed the advice you've read....take your time and dont force anything. I broke a pump rod due to trying to force a stuck accelerator piston and as I was checking my floats I noticed one of the support arms that holds the pivot pin was cracked. It broke off completely shortly after. Hopefully the gas proof "JB Water-Weld" I used to put it back in place will hold over time. As far as the actual rebuild, it was pretty easy. Just matched up where the gaskets should go, and referenced the Weber manual. I took my time to set the floats per spec to 8.5mm/15mm, turned out all of the idle screws to 1.5 turns from fully seated, and lined up the throttle plate edge with the first progression hole on each carb. Regarding the actual installation, sprayed all the manifold bolts with PB blaster over the past 3 days and went through the tedious process of undoing all of the bolts. I couldnt see a way to get them all out with anything other than a wrench and 1/8 inch turns at a time...there just wasnt any room! That or I need better tools. Got the SU's out and put in a new intake/exhaust gasket and put the redline intake manifold on. After getting all of the bolts torqued down, things started moving a lot quicker. I bought the plastic anti-vibration mount with O-rings, but after getting the 3rd carb on, I realized that it would be impossible to actually run the air cleaner I planned to use due to interference with brake fluid reservoirs. So had to take all the carbs off and put on paper gaskets and re-install. Hopefully it wont be an issue. Ran the fuel lines, re-attached hoses, temporarily mocked my throttle cable set-up, and crossed my fingers. Primed the fuel pump and started checking for leaks. Found leaks and tightened everything back down, and started cranking. It took about 4-5 minutes of cranking the engine before it wanted to fire up. Kept at it and she came to life! couple of blips of the throttle and it quickly settled to a steady 1000 RPM's. Success! Watched it smoke off all of the PB blaster and let it run for about 15 minutes. Checked my fuel pressure gauge and was at 3.5 psi, and my AFR was fluctuating at about 10.5 - 11 at 1000 RPM idle (using an AEM UEGO w/b). Revved her a few times to hear the glory, and noticed that I was occasionally getting what sounded like a misfire. A couple of other blips, and I would get a backfire out of the front carb, on the rear barrel. It happened twice, and was something I couldnt replicate consistently. I'm going to try replacing my spark plugs in the next few days and start paying attention to how they look. Hoping to actually drive the car tomorrow. I still have yet to sync the carbs, tune anything, or completely address my throttle linkage...I probably should do all of those things...but I just want to actually drive her and see what its like under load! My initial impressions, this is gonna be a hell of a "project" with a lot more work to go!. I was hoping I could get the carbs on the car for about $500. I got the carbs, manifold, and linkage from the PO with the car...with all the other misc pieces and "while I'm at it" stuff...so far I'm about $1600 in! A lot of the cost came from air horns and new main venturi's (carbs came with 30's), but there were a lot of little odds and ends that added up quick! I still have to install my heat shield, dial in my throttle cable / linkage, and figure out my ignition timing. For those thinking about going to triples, you have to admit they look awesome. Now back to re-reading the Weber FAQ for the 15th time.

-

If the shell is as mint as you say for $450, buy buy buy!!!! Powerplant scheming can wait until it's safely secured in the garage!

-

And to clarify my statement about degrees, certifications, and internships not meaning anything, they do. They help get your resume from the recruiters desk, to the hiring managers. If you get called in for an interview, then it's up to you to demonstrate how you would apply the knowledge you've gained. If you can't, then it's meaningless. Best of luck.

- 44 replies

-

- Mechanic

- Summer Job

-

(and 1 more)

Tagged with:

-

Before you dismiss working in a office doing CAD all day, every step in life is just that. A step. Working for a company that does stuff you want to do, and starting out doing something you dont want to do, is a good start. Degrees, certifications, and internships don't mean anything. They are all just another step closer to getting your foot in the door. Once your inside, you'll realize there's a whole lot of doors left to open and you can make latteral changes towards your desired career. Your willing to sweep floors at a garage in hopes of learning something useful....same thing applies to an entry-level job in your industry.

- 44 replies

-

- Mechanic

- Summer Job

-

(and 1 more)

Tagged with:

-

While I appreciate your desire to learn, I would highly recommend looking for a job that will give you experience that will directly translate to your future career choice. I.e if you want to work for acme aerospace company, try to find a summer job that is as close to 100% applicable as you can find. Save the automotive know how and learning for the weekends. With that being said, if you really want to pursue work at a garage, you may not get much more than oil changes and the like for at least 2-3 months. I also would be doubtful that a garage would want a short-term mechanics apprentice. If you have a family friend that has a project, I think that's your best bet for learning. Sorry if I sound like Debbie downer, but the older you get and the more money you make, you will always wish you ha a little bit more.

- 44 replies

-

- Mechanic

- Summer Job

-

(and 1 more)

Tagged with:

-

Thoughts on triple weber fuel line routing

T-Bone028 replied to T-Bone028's topic in Nissan L6 Forum

I have a sychrometer and I just replaced my narrowband with a AEM wideband last week. Hopefully, the 30 chokes won't be too restrictive for the street with my 3.1L (though I think they will). -

Thoughts on triple weber fuel line routing

T-Bone028 replied to T-Bone028's topic in Nissan L6 Forum

Thanks for the input fellas. Though I would like to eliminate the hardline and replace with braided lines and AN fittings, my "cheap" spring project has already surpassed $1000. I already had the carbs, manifold, and part of the linkage. It's the small stuff that adds up quick! Hopefully, I will have it all on the car and running by next weekend. -

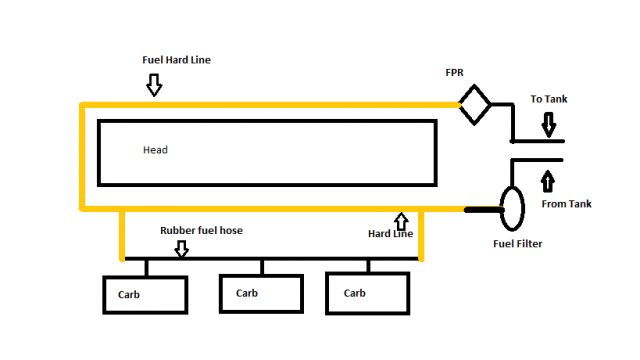

Folks, looking for some feedback on my planned fuel line routing for my triple weber install. Currently, my set-up with SU's is as follows: Tank > fuel filter > fuel pump > fuel filter > custom fuel hard line with two T's that feed the SU's > fuel pressure regulator (3.5 PSI) > return to tank. My question is, would it be feasible to plumb the triples in-between the two T's on the current fuel hard line? Right now, the existing 2 T's feed 1 SU each. My triples have T fittings on all 3 carbs. Pictures are worth a thousand words, so first picture is my current plumbing with SU's, and then the beautiful and very professional MS Paint picture is what I was thinking I could do without having to change too much to my current system. Thoughts on why it would or wouldnt work? Any risk of fuel starvation? Thanks in advance.

-

I can't point you to definitive information, because I don't know what you mean by tuning s.u.'s as it relates to airboxes. If you are talking about performance airbox options, I would suggest either getting a stock airbox with the integrated air horns, or buying air horns from MSA and putting on their K&N filters.

-

Actually just installed the AEM UEGO wideband this afternoon. Very simple to install. I would say the hardest part was figuring out how I wanted to secure the cable from the O2 sensor before it went into the cabin. Was immediately able to see I go lean at mid-throttle. Great informational tool and showed up 2 days after I ordered it from Amazon...I didn't even choose expedited shipping!

-

Triple webers 40dcoe or 45dcoe? And muffler question.

T-Bone028 replied to Sotenacious's topic in Nissan L6 Forum

Duragg, PM sent -

Triple webers 40dcoe or 45dcoe? And muffler question.

T-Bone028 replied to Sotenacious's topic in Nissan L6 Forum

I have a 3.1L with a similar grind cam and I'm currently going through the process of rebuilding and installing 40 DCOE's. I currently have SU's with SM needles. I run out of steam around 5500 RPM. My car doesnt do any track time, and is a weekend driver...that being said, I'm more interested in street-ability with revs staying under 6500-7000 RPM. DCOE's are almost infinitely adjustable, and for a mild street motor, I'm thinking 40's will be fine, just need to play with chokes and jets if I run out of breathing room at higher RPM. But for me, I'm more interested in balance and fun throughout the entire rev range...so for MY application, the 40's will hopefully be enough until I save up enough disposable income for ITB's. -

Awesome, thanks Leon. I already have 170 airs, but will gladly take the idles off your hands. How much? Feel free to PM me or respond here.

-

Bump. Leon, any luck?

-

As a small point of reference, I've already spent +$800 on getting my triple webers ready to be installed. I already owned the triples, manifold, and linkage. The additional cost comes from the small things: carb rebuild kits, air horns, filters, heat shield, etc. I haven't even bought new jets etc. I would figure out what you really want as a goal, then start mapping out the different ways to get there. Then estimate the cost, and multiply by 1.5 or 2.

-

Looking for 32 or 33 venturi's/chokes for weber dcoe 40's, non set-screw type in particular. Would also be interested in jets. 130-145 mains 165-180 airs 50f9 or 55f9 idles Thanks in advance!

-

Savage42, PM sent

-

jtpaintballwdp's 1970 240z "resto-mod" journal

T-Bone028 replied to jtpaintballwdp's topic in S30 Series - 240z, 260z, 280z

Uhaul truck and trailer, a little sweat, and get that sucker trailered back to your house. Nothing like staring at the z to get you even more motivated. plus the truck helps with all the spares you can haul! -

One thing to add...if you're going to try to start it, might as well drain the gas tank and put in fresh gas!

-

Is your z currently running? If so, what is your current carb setup? (you mentioned you don't have efi) Before you get fixated on the sound you might get from a CAI, try going for a ride in either your car or in someone elses that has triples or su's with an opened up airbox. You'd be surprised at the intoxication of some "traditional" setups.

-

Advice/Suggestions on places to live on the East Coast?

T-Bone028 replied to EvilC's topic in Non Tech Board

If you do move to NoVA, it will be difficult to find a home with a garage (im sure just about everyone on this forum would have that as a must have requirement!) in the 200k to 250k range...at least in loudoun or fairfax county. Although the opportunity landscape is fantastic, you got to pay to play here....and commit to horrific daily commutes. Those two counties are in the top 5 highest income level averages in the nation. Prince William county is still reasonable with just a slightly longer hike in to the dc metro area. -

Has anyone ever heard of "Datsun Spirit" in VA?

T-Bone028 replied to T-Bone028's topic in S30 Series - 240z, 260z, 280z

In regards to shops in Northern VA. Autoexpectations that you mentioned is out there, and so is a shop called CreationZ, also in Sterling/Dulles. There is also a VERY recognized shop in Md called Bonzai Motorworks...havent been there though. My experiences with Autoexpectations and CreationZ are as follows. Autoexpectations, nice guy. The owner was a co-owner of Datsun Dynamics. We chatted for a while, and although they are familiar with Z's and Nissans/Datsuns, I might not go there again. I took in a driveshaft that needed new u-joints pressed in and when I got it back, they were pressed in...but he did not grease them and the u-joint was not pressed in evenly which was causing binding. I ended up greasing it myself and had to take it to a friend of mine to get it "adjusted" (one solid whack with a Big F****** Hammer). Creationz...former tech at Datsun Dynamics, and again a really nice guy. Has a lot of parts in his shop but good luck getting a hold of him though. I have no complaints about my experience with them (4 u-joints pressed into 2 halfshafts, $50 per joint). Definitely a smaller operation though. I would stop by there again if I needed work that I couldnt do myself. Topperge, If you want a hand with anything feel free to PM me. I'm in Centreville/Chantilly.