-

Posts

9963 -

Joined

-

Last visited

-

Days Won

74

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by Tony D

-

-

Bo,

I PM'd about that "shell swap"...

Seriously, let me know.

-

"To make matters worse, I found out that my wife changed my policy on the Z to liability only......."

Oh, how those words ring true...turbo makes a squeal at MSA, call AAA for a tow "no sir, you have standard towing"

Wife changed policy in October without consultation "to save money" ($100 a year vs $68 a year???)

Hello, new turbo $795....goodbye simple cartridge swap at $275!

That sucks!

Cut the front off, get it relatively straight and run a modified strut bar near core support... Channel mount your radiator and run a G-Nose up,front.

Back on the road and Stylin'!

-

What does it matter?

As stated, buy blank to reproduce and you have become a "company" making them...which classifies most parts like this for 40 year old cars.

-

Onto the standard triple manifold as a plenum?

Or on the carbs/ITB's?

Either is easily accomplished with a 25mm touch spacer plate using both flange patterns as an adapter plate.

Inlet will point wrong once you have inverted it.

-

The standard feed size is A/N-3, the -4 is needlessly big, and a restrictor will be necessary, for sure.

-

Get Defog working. I made that mistake ONCE, and won't make it again.

Hot air blowing only on the window doesn't necessarily keep your tootsies warm, but it DOES. Warm the cabin and DOES keep the windscreen so you can see!

Something the heater does not necessarily accomplish!

My Suzuki Super Carry Van has had the Defog vents torn out in the conversion from RHD to LHD, and It drives me batty! Sure I can turn on AirCon to dehumidify the interior...but having functioning Defog (and the ability to push dehumidifies air into the windscreen) is more important than just two center vents blowing ice cold air to the cabin!

-

Era is late, if I'm not mistaken the FJ24 for the 240RS was well after production of the L-Series had ceased. I went to look at the new for 87 or 88 FJ-Powered 240RS at Naha Prince when it came out.

The DR30 Skyline had the FJ20, and I think was (?) 81 maybe 82... But that's not an FJ24. Which, oddly, was carbureted. The turbo FJ20's were stick running 250+ BMEP as I recall, with the N/A FJ24 right near that at around 200. The early FJ20s were well below that for use in the Gazelle and Sylvia. It was the DR30 Skyline where the Turbo FJ made the most power. Those rods were...800gm? 740 or 840 sticks in my mind... Beefy-heavy,

They were not Nissan-Produced Rods in the Nissan L28 making 1,000 rods. They had a Nissan part number, but you couldn't by any car anywhere where those same rods were installed into an engine at the Nissan Engine Assembly Facility.

-

Most I personally saw with an HKS Box was RS OKI on their Dyno eddy-current verified (and likely from an early tuning run) was 444kw on 50's driven on the street, twin turbo (hey, it was the 80's!) and a 125mm exhaust in an S30.

There were those who made more, and likely that sticker was low for ultimate development given it's performance. Real racers don't usually put their real HP on the back window...a good example is Electramotive back then with "750 HP@7,500 rpm @ 20.6 psi boost" huh uh, huh huh huh, yeah, right! Considering they boosted to 30+, and revved same as the N/A guys to 9,000+ those were good "keep 'em guessing and smile for the reporter, guys" numbers!

-

Yeah, the numbers looked right to me but that card freaked me out. VW grinders do that all the time sending you a 1.00 gringos what you specified a 1.25, 1.5, or 1.7 rocker grind (ramp rate varies greatly...)

I think looking at the guys from OZ on that small port head would net an equivalent combo.

-

I would call your cam grinder and VERIFY that the cam card is not a simple typo...otherwise....

The Rocker Arm Ratio on a Nissan L-Series is 1.5 (1.48, meh) and NOT 1.00! If they REALLY DID MEAN "1.00" then the cam is going to act significantly different at 1.5 ratio.

After Peak-Torque you pull fuel. On JeffP's turbo engine we were pulling fuel after peak torque and stopped at 13.8 AFR simply because we were seeing minimal increases in HP, no change in EGT, and didn't feel the need to push it further.

We started at the Paradigm of 11:1 for turbos, passed thorough the Paradigm for N/A, and didn't see the need to go,further as stated above. Prior to that time, had you told me a 400 hp turbocharged engine under boost would run at 13.8:1 AFR at 7,000 rpms I would never have believed it, much less one making half again as much HP!

-

Oh, if you want to be like that, then....

http://losangeles.craigslist.org/ant/cto/4739422471.html

Maybe buy this one as well, since it's "Big Tank" and swap the five speed in from the one above?

http://losangeles.craigslist.org/sgv/cto/4738461877.html

I don't know, that's $4,500, plus $2,200 to ship... I don't know if that leaves enough to get inspection registrations, and all that done compared to that Dutch Frau Xander found!

Bah! I'll just get the one by my house in Riverside...it looks just like what he wants anyway...what did this take? Three minutes on SoCal Craigslist to find it?

http://inlandempire.craigslist.org/cto/4719746443.html

Xander will look at the Map in that last advert, recognize street names, and go "DAMN TONY D!" ;P

I'm not sure how or where you were searching on Craigslist... These were just basic quick searches I did and found almost the exact car you say you want within a 5 minute drive from my house, WITH a spare high performance engine thrown in!

Then again, as Xander can attest..."I'm like that!"

-

Hot feet, cold windshield in "Heat"

Now put into "Defog" position, get confused more!

-

My car runs consistent 15.50's at 89....

A 14.0 at higher trap speed would tend to indicate more torque and therefore more horsepower.

Dyno numbers, unless strictly defined are pretty much useless one to another. Stick with the same Dyno for relative performance quantification change.

A stock 76/77 Coupe will run (as evidenced by my foul-mouthed companion...) 16:47 or slightly slower in the real world. Mine was quicker by a full second, and you're a good 1.5 faster than me...

I know I've been on three different metered quantifiers, A G-Tech, A Dynojet, and A Mustang traceable to SAE J Whatever it is... And they all come in within 20 (+\- 10 HP of median) and they all correlate to the 1/4 mile trap speed and weight as tested the day of the runs, on the return road of the track.

Dyno testing isn't IR the faint of heart, fact of the matter is if it won't pull on the Dyno it's not making power regardless of what it feels like. My biggest help in getting good shift points was using an old G-Tech on "Instant G's" that tells you how hard the car is REALLY pulling. Regardless if it's sounding better, if the G's drop, you're loosing time! Unlike Obiwan, my post death haunting will be "Use your Instruments,

-

I had people with headers, TB, chrome and bling swear at me because my stock Z whipped ther modded one by a full second EVERY TIME we ran the 1/4 mile. It's variability and attention to detail, 150 is about where a properly tuned stock L28 should be, it's where mine is, and the 1/4 mile times confirm the Dyno slip (if anything they make the Dyno low

-

From the port of LA it's $1,100 if you drop it at CFR Rinkens on the way to LAX...

If you book ahead of time in Germany, it's €1,100.... What a deal, ja?

Driving across the USA can be done leisurely, it will cost you (brace yourself) around $600 in fuel costs to take a roundy-bout journey of 3,600 miles and suck down around 170 gallons of petrol at say, $3.50 a gallon (€0.77 per liter) premium 91 petrol is much higher, around €0.79 so nobody wants that extravagance...

In several months, you could easily drive 30,000 miles! I did so in the Midwest from June to November, around 6,000 miles per month. In my Z I would regularly dash to ZCONs and stick 15-18,000 miles on the car in three weeks!

Advice: buy your car, then buy your parts and install EVERYTHING then and there. New Ball Joints, Tie Rods, Brakes, EVERYTHING. The car WILL NOT pass TÜV as you buy it even from the most reputable dealer or individual in the USA.the parts are cheaper here obviously, and your invoiced price on the purchase does not need to mention the several thousand in new parts you put on it in the week after you got it! Saves on import taxes if applicable...

The biggest issue you will have is finding a place to do the mechanical work yourself. If you pay a shop to do it the costs increase quickly. A rental in LA, and a good international data roaming plan will get you your car within a week or two if you do groundwork beforehand and BRING CASH. That leaves you a week to bring the car underneath up to,proper specification, and then plenty of time for a leisurely drive through the countryside!

Pack it on a boat in Bayonne NJ, should be slightly less shipping from there, and in a couple of weeks go be reunited at the port again with your purchase!

-

"So rev limiter at 6500"--that is your personal choice.

That conclusion did not get get extracted from the above statements.

I have L20B rids that equal Xnke's experience in terms of RPMs in an L6.

Horsepower N/A and RPM capability are completely different discussions.

For a low revving, boosted engine only making 400HP, the track record for the stock unprepped rods is clear: ARP Bolts & Run It.

I can't think of the last time I disassembled the rods on any L-Series and used stock bolts. Had to be back in the 80's when I couldn't get the 396 Chevy Bolts easily in Japan. Since ARP started making them for the L-Series, I haven't ever bought a stock new rod bolt!

Development on the turbo Z in the early 80's resulted in the dropping of the Nissan Rod on anything approaching or over 600HP. The car tested in Road and Track did not have stock Nissan Rods, Prepped Nissan Rods but they did have a Nissan Part Number and were available to anybody from any Nissan Dealership in the world, so they were technically in the eyes of the sanctioning body "Stock Nissan Rods"---were they in ANY engine from Japan, in ANY production car for sale on ANY lot in the world? Not on your life! Today you would refer to them as "aftermarket" rods...Carrillo, Metchart, Cosworth, etc... Not "prepped Nissan-Produced Rods" by a longshot! By the rule, though, they were "Nissan Production Rods", there is a BIG difference in the terminology. This is actually in the FH book in part...

-

On the cams note, something I have considered while dreaming up stuff in my head that I have no money for.... How about a modular camshaft like Ford used on the 4.6s? cut the lobes and bearings out of whatever material you want and use an EDM to slice them like loaves of bread. Maybe an indexing keyway cut into the cam and lobes to make sure everything lines up right, bingo.

This was discussed as my experience with stationary engines was the same. Chill the core in LN2, heat the lobes in hot oil and have the press ready to push stuff on using long pieces of tubing!

-

1

1

-

-

Can it be melted down and turned into a DOHC L-Head?

-

1

1

-

-

I've got one of these. It's incredibly well made. And not very expensive either.

Haha! For Americans...that's a gold brick kind of price.

I agree, for the build quality, I see no issue with it, but the majority of S30 guys in the US are complaining about a secondhand manifold at $300!

-

100 per hole.

After that, you're on borrowed time,

I don't know who was making 1000+ at 9500+ on them, but it wasn't the boys at Electramotive,

-

You Bastard Son-of-a-Bitch! AAAAAUUUUGH!

You Baaaaaaaaaaastard!

Getoutofmyheadgetoutofmyheafgetoutofmyhead...

-

Pre - 6/76 280Z 2+2

The larger tank kills the spare tire well, the post-6-76 have a raised floor above the metal floor...lots of wasted space inside.

Have you spoken to Jochaem Kaphengst or Frank Poll?

They are usually shipping cars in April from SoCal...

-

eBay is your friend, Kunigawa makes some nice Nissan turbo feed/drain parts kits.

-

I'm with Xnke in this one - same as the L-Engine. I've grabbed towers from a box where they were all mixed (4 & 6 cylinder sets just thrown together) with a mandrel to assemble them, they go together fine if the head is flat. The issue comes from guys who warp a head and ONLY mill the HG Surface...and not the top side. I was planning on mandrel assembly. The SPC Machining tolerances on Honda Parts are insane. You have a 0.003" oiling clearance, with a line-to-line fit on the split towers it will be more than tight enough. The issue is parallelism and square to all valve stems. You could even make an assembly mandrel to locate that, as well. Then match mark and pin them.

IMO, line boring will screw up the Honda tolerance and require an expensive machine.

If you are considering a poorman's line-boring setup like they use on VW Type 1 cases that locates on front and rear towers as a sliding bearing, with the remaining caps cut at the parting line and then cut to match the end two bearings....you could run that with a 1/2" air drill.

But given Honda Tolerances....I'd mandrel assemble them.

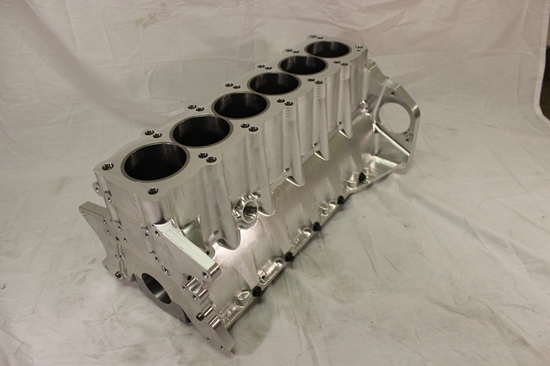

what is this plenum

in S30 Series - 240z, 260z, 280z

Posted

Yep, intake manifold...S20!