Chris83zxt

Members-

Posts

102 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chris83zxt

-

My MS3/MS3X full sequential spark/fuel settings

Chris83zxt replied to Chris83zxt's topic in MegaSquirt

Looking back at my OP I have not updated that I relocated my IAT to the outlet end tank of my intercooler. Heatsoak was just causing too many issues with it mounted inside the engine bay in the intake piping. I'm content that its done right now that it's on the IC. I would recommend that anyone just starting to research their megasquirt setup plan on getting it outside of the engine compartment if at all possible, it'll save you idle tuning headaches at the very least.- 17 replies

-

- megasquirt

- ms3

-

(and 3 more)

Tagged with:

-

Very clean engine bay. Hope I can get mine looking that organized at some point

-

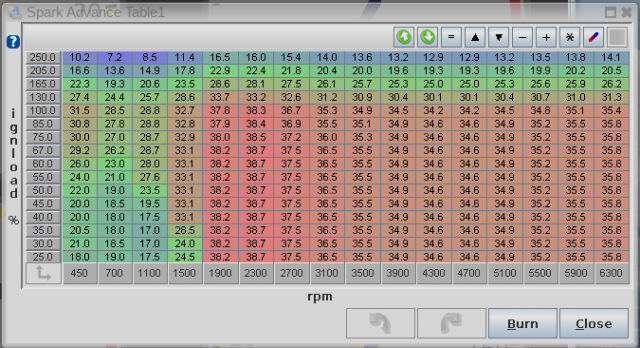

I've been doing some research and after looking at a couple of N/A timing tables and reading some threads with people who have turbo'd NA motors I think I'll start with multiplying the bottom 4 rows by .85, the next four up by .825, the next four by .8, and the boosted areas by .66 I'm pretty confident that'll get me into a safe enough area until the motor is broken in enough for me to feel comfortable loading it up on a dyno.

-

Because I'm dropping it off at a shop and having a full rebuild done. I've got a spare block and spare p79 head if stock parts are needed (I intend to stay with a stock crank and connecting rod setup). I have a big cone filter that sits behind and beneath my driver's side headlight (pointing downward).

-

No I think 400-450whp in a Z will get you into the 10's as long as you're hooking.

-

So my car was running pretty great for about 2k miles on the setup below: http://forums.hybridz.org/topic/116315-my-ms3ms3x-full-sequential-sparkfuel-settings/ Unfortunately in late March we had a couple of very rainy days and I ran through a giant puddle and hydrolocked the motor. Even though I was able to get it restarted something is definitely broken inside the motor so it's been sitting since. I've been collecting parts and I'm about to take it into a local engine shop to have work done. I'm going to be going .030 over with the ITM flat-top pistons. Also I'll be having some mild head work done and a little bit of porting done on the turbo inlet. Some other miscellaneous stuff like a Fidanza flywheel to help pep things up a little. My compression will be going up to about 8.6:1. As you can see in the above timing tables I've got mildly aggressive timing in place (~40 degrees in a lot of spots). I figure I'll need to drop timing down and also boost at least during the break-in period on the new motor. Does anyone who has made similar modifications to their turbo motor have any suggestions on timing adjustment? I figured multiplying the entire table by .5 would probably be pretty safe but might be leaning too far on the side of safety. Any opinions are welcome and appreciated.

-

My MS3/MS3X full sequential spark/fuel settings

Chris83zxt replied to Chris83zxt's topic in MegaSquirt

It's the "Toyota style" that's diagramed on the megasquirt forums and a few other places. I used an O'Reily relay modified per the diagram all taped up and mounted to the driver's side strut tower in the engine bay. I ran the MS tach wire out to it and then ran the signal back in through the stock tach wire that comes out next to where the stock coil is mounted. I'm looking for advice on the timing table since my engine is about to be rebuilt with some major internal changes: http://forums.hybridz.org/topic/117932-timing-advice-needed/- 17 replies

-

- megasquirt

- ms3

-

(and 3 more)

Tagged with:

-

It'll probably just work. I have my pwr grounds grounded to the intake manifold and all my sensor grounds tied into the ground reference going back to the MS3 unit. I've put a couple of thousand miles on it now with no sync issues at all.

-

I couldn't find a definitive answer when I was rewiring my car but FYI for anyone stumbling upon this the toyota tach relay mod works fine with our stock tachometers.

-

If your block has a working CHTS use it instead of a coolant sensor. It works fine and it gives you a much better idea of what the conditions are around what is typically the hottest part of the head. There's a couple of posts here with the values you need to set, or you can look at the FSM and derive your own based on the graph in there. An idle valve is not necessary for basic functionality. AFAIK there isn't any difference between how you should trigger on an NA or Turbo motor. It's probably easiest to set up on 82 or 83 l28et because of the optical dizzy. Any injectors should work provided they fit (or you can make them) and you pay attention to their impedance. Having known values for opening dead time would be beneficial but can be narrowed down to within a couple of tenths of a millisecond through trial and error.

-

My MS3/MS3X full sequential spark/fuel settings

Chris83zxt replied to Chris83zxt's topic in MegaSquirt

Here's a pic per request, though I'm a bit embarrassed at this point to show my engine bay. I'm about 1/3 of the way finished soldering connections, thus all the wirenuts. I plan on having that bracket reproduced in a thicker aluminum sheet and then mounting small bus bars on the bottom side for the grounds needed nearby (2x per coil, injectors). I'm getting about 25 highway mpg now vs. the 30 I was getting before the port work, bigger turbo and bigger downpipe. Fair enough trade off I suppose.- 17 replies

-

- megasquirt

- ms3

-

(and 3 more)

Tagged with:

-

My MS3/MS3X full sequential spark/fuel settings

Chris83zxt replied to Chris83zxt's topic in MegaSquirt

A piece of thick sheet metal on the valve cover. Much less fancy than I've seen elsewhere (including what you were working on). I am happy with the location though, and will probably pay a shop to machine a cleaner cut version out of aluminum, since my sheet metal is already rusting in a few spots.- 17 replies

-

- megasquirt

- ms3

-

(and 3 more)

Tagged with:

-

My MS3/MS3X full sequential spark/fuel settings

Chris83zxt replied to Chris83zxt's topic in MegaSquirt

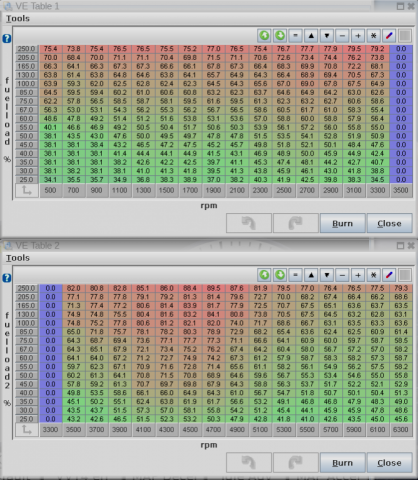

I felt I needed the higher resolutions at light and medium loads since that's where I spend most of the time driving the car and where I want the mileage paybacks for going sequential. At boost I'm just throwing a lot of fuel at the motor and it seems to be just fine with that. It might be that the linux version of TS doesn't do smoothing. I've been tuning on my win8 (blech) laptop but I didn't want to do the original post or the photo work necessary on it so I installed TS on my linux desktop (and haven't bothered entering my registration info either--that might be it). About a week ago after the tune was running well I went in and smoothed the 3d table manually and since then I've spent a couple of hours in VEAL set for very hard changes so it de-smoothed some areas, which I'm fine with since the car is running like a top at the moment. Some of the peaks and valleys I imagine are due to the transitions on the afr and spark table (and small variations within the motor itself). I'm not currently monitoring for knock at all. I did have the hardware installed in the MS3 unit. One of my next projects will be trying to make the stock knock sensor work with it. If I can't get that working, I'll switch to a Bosch wideband setup. Meanwhile I do have a spare block from an 81' if worse comes to worse. I did the majority of the early ve tuning running on 87 pump swill up to 9psi and didn't have any perceptible problems. The idle is actually quite smooth between 750-800 rpm with these settings, that might have been what I spent the most time tuning overall. You'll notice on the ve map I made a plateau in the idle region and I also tweaked the ignition advance table in the idle region to help keep it stable.- 17 replies

-

- megasquirt

- ms3

-

(and 3 more)

Tagged with:

-

My MS3/MS3X full sequential spark/fuel settings

Chris83zxt replied to Chris83zxt's topic in MegaSquirt

Here's the msq file. gypz_x.zip- 17 replies

-

- megasquirt

- ms3

-

(and 3 more)

Tagged with:

-

There's an option in your project settings that sets whether your want AFRs displayed in the traditional gas format (14.7 stoich) or lambda (1.0). Voltage might be one of the options too.

-

My MS3/MS3X full sequential spark/fuel settings

Chris83zxt replied to Chris83zxt's topic in MegaSquirt

Yep I can post my msq file when I get home. Firmware was whatever came on it (purchased late September from DIYautotune). The advance table is a blend of what I saw from a few tunes here and I think I have mine falling off as boost rises faster than some others based on general research I did on the subject. I couldn't get the car started using the recommended settings, it didn't seem to be seeing the trigger at all for whatever reason with poll level selected (maybe a glitch in the firmware version I'm using). Having it triggered on rising edge on the other hand worked right off the bat, as did falling edge. With falling edge triggering my wheel offset was very close to your value. I chose rising edge based on something I read in the MS3X documentation, though I can't point to exactly what that was now. I might be able to find my notes from the install as they were pretty thorough.- 17 replies

-

- megasquirt

- ms3

-

(and 3 more)

Tagged with:

-

My MS3/MS3X full sequential spark/fuel settings

Chris83zxt replied to Chris83zxt's topic in MegaSquirt

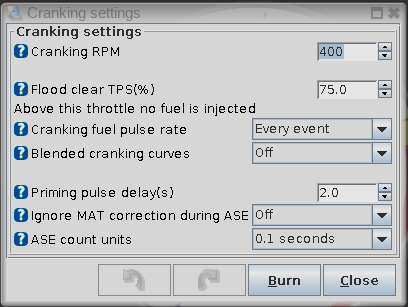

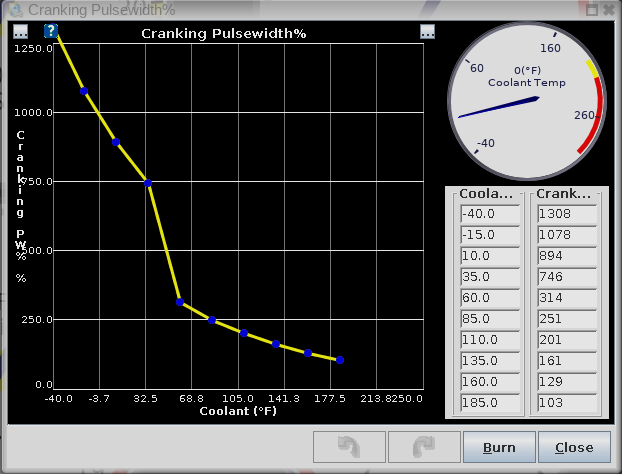

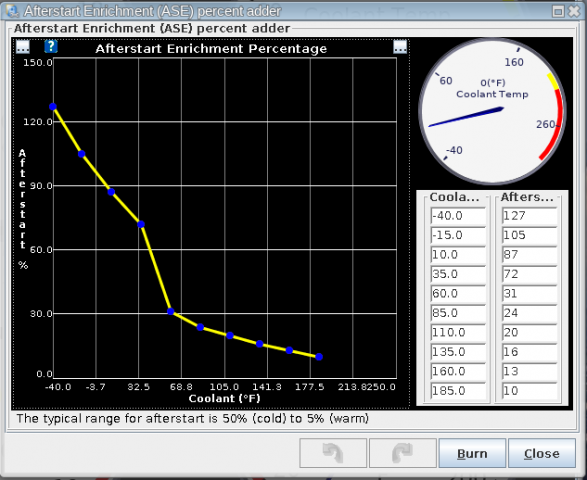

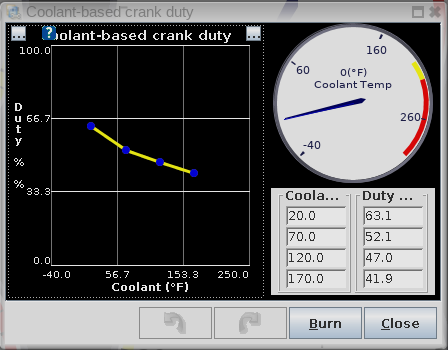

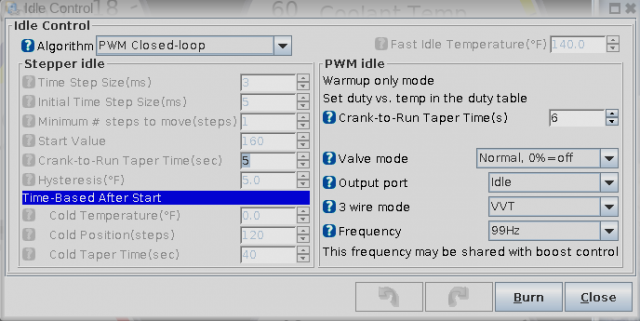

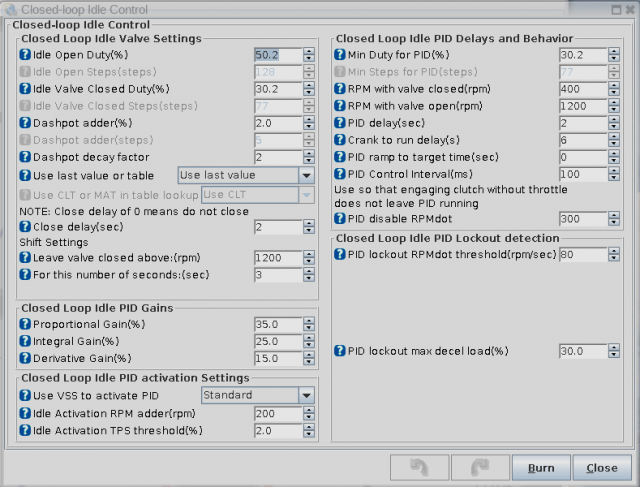

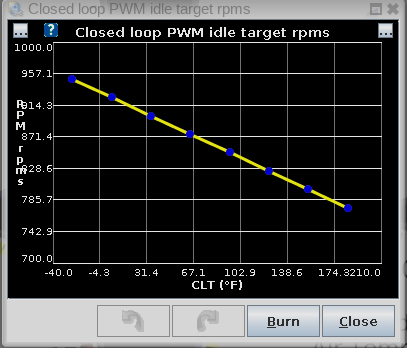

Small update after this morning's -6 ethanol starting adventure. I changed the initial pwm cranking duty from 63.1 @ 20F to 100 @ -10, the other values remained the same (and have been tested much more extensively). I also changed the crank to run 'taper' (it doesn't actually taper as far as I can tell) on the idle valve from whatever it was (5 or 6 seconds) to 15. I found that I could get the car started this morning but as soon as the valve began closing it would die immediately. Having it open for 15 seconds allowed the motor to prime up enough to stay running with only a minor hiccup as the valve closed. Ideally having the PWM valve close in a true tapering fashion would help with cold, cold starts as well as possibly having a crank to close temp/time based table. Maybe these features will be incorporated in a future megasquirt firmware.- 17 replies

-

- megasquirt

- ms3

-

(and 3 more)

Tagged with:

-

My MS3/MS3X full sequential spark/fuel settings

Chris83zxt replied to Chris83zxt's topic in MegaSquirt

Oh yeah, LWP also ceramic coated the exhaust manifold in a package deal. Probably has some small benefit to exhaust scavenging, but more importantly I've had 0 heat soak issues and also no more snap/crackle/pop from the manifold after shutting the engine down.- 17 replies

-

- megasquirt

- ms3

-

(and 3 more)

Tagged with:

-

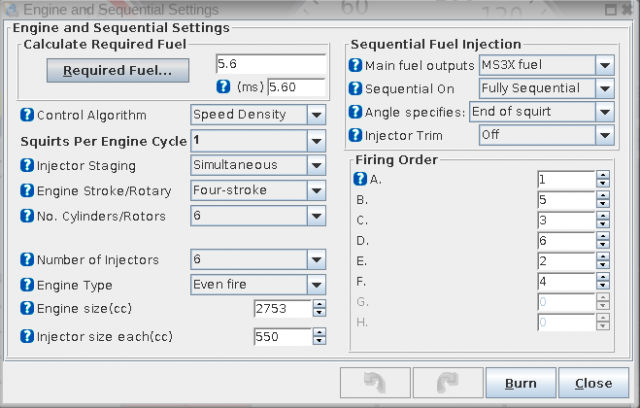

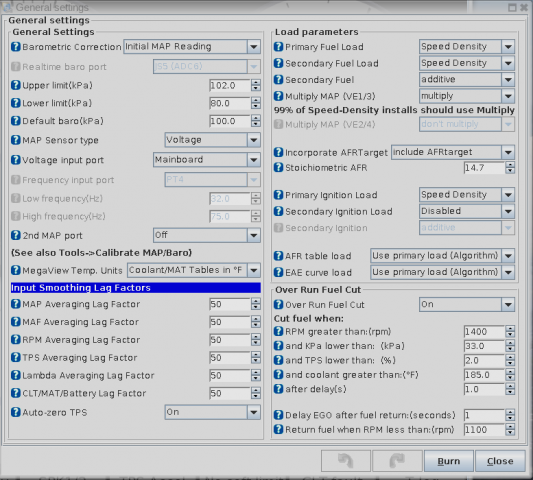

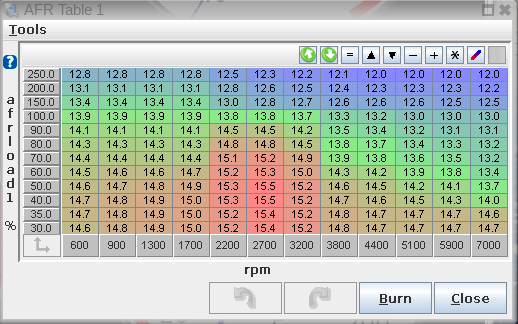

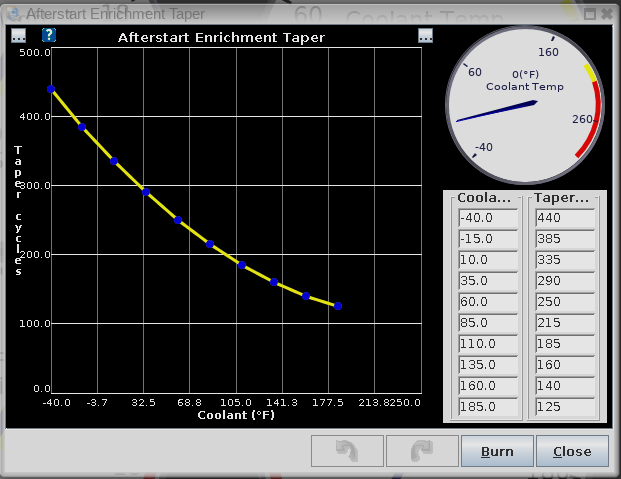

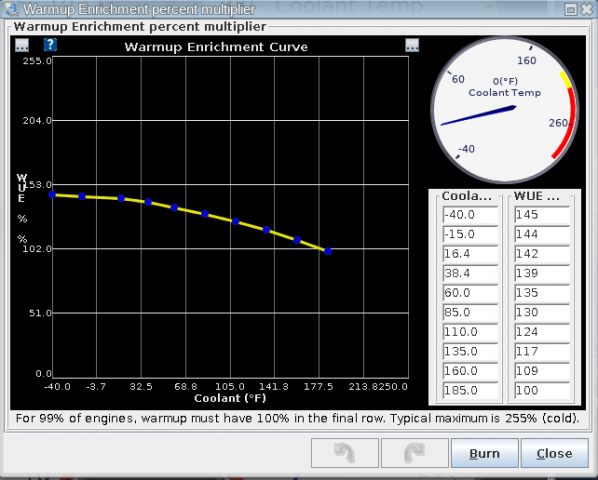

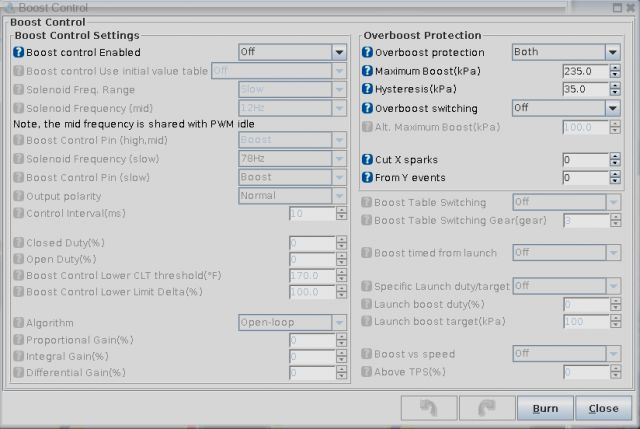

So it took me one afternoon to rip out the stock injection and get the car wired up and started on ms, it's taken me almost three months since to get things to where I'm pretty happy (one month delay thanks to the stock T3 blowing to bits). My car: 83 l28et, p90a head, stock block with at least 206k miles. Last time I tested I had low compression on #6 (110 vs. 145 on rest). My compression tester was stolen along with my truck and I haven't replaced it yet. I think I might have blown the ring back into place while letting VEAL tune the upper regions of my ve table whilst doing 3,500-5,000 rpm on the interstate in 3rd for about 20 minutes last week. It's run silky smooth since that session after the lifters quieted down (I was worried that I had done something bad until I learned that was common with hydraulic lifter setups). The non-stock stuff is: 3" K&N filter in the wheel well under the drivers side headlight, 3" piping up to turbo. same-side ebay fmic ebay type-s bov recirculated via a 1 and 3/8 line back into the intake just before the turbo. EGR is deleted and blocked off. I have had the intake and exhaust manifolds mildly ported by Lonewolf Performance. They also welded a 1/2" T3 spacer onto the exhaust manifold and a 38mm tial wastegate flange as well. I am very happy with their work. 60mm 240sx TB and TPS EM USA external wastegate set to between 15 and 18psi depending on the gear. Holset HY35 (used, fair condition) New, bigger downpipe for Holset with first O2 bung located about 1' downstream of the turbo--catback still whatever came on the car cause it's in good shape and I like the sound characteristics Ebay injectors which are supposed to be high impedance custom versions of the Bosch 403 injectors (~550cc) - so far they seem to be the real deal Palnet 14mm fuel rail Walbro 255 GM flex fuel sensor (the newer one) D585 LS truck coils (round w/ heatsink style) A set of Silverado shorty plug wires A Bosch 505 idle valve (3 wire) A homemade tach adapter Innovate MTX-L wideband and gauge Speedhut electronic fuel pressure gauge Some ebay boost gauge retrofitted in place of the stock boost gauge which is semi-accurate GM open element IAT sensor (between IC and TB) (using the CHTS as the coolant sensor for MS) DIYautotune dizzy trigger wheel DIYautotune supplied MS3/MS3X 3.57 with integrated knock sensor circuit DIYautotune MS3 and MS3X harnesses (recommended -- not a single sync problem since the first startup). I think that's most everything that's relevant to the tune. I've found the flex fuel sensor is working pretty good in tandem with MS3 and I'm able to switch to different blend ratios without it throwing the ve map off. My cold start settings are based on testing with approximately a 60% ethanol blend. There's a decent chance that at the colder temperatures they may foul plugs with pump gas. It started on the third try a little while ago with the block at 13 degrees so I'm pretty satisfied with the settings as they are (tomorrow morning at -10 should be interesting). I'll probably dyno it soon. You can see by my upper VE map that the porting work and bigger intake tract has shifted the peak torque region closer to 4,700rpm, if you've got a bone stock setup you might shift the fat area of the ve table a few hundred rpm to the left. Here are the settings I'm using. I hope these are useful for someone, lord knows I've gotten a lot farther a lot faster than I ever could have without the knowledge on this site and others.

- 17 replies

-

- 1

-

-

- megasquirt

- ms3

-

(and 3 more)

Tagged with:

-

By DIY trigger wheel you're referring to the disc sold by DIYautotune on an 82/83 dizzy or a true DIY wheel for the crank?

-

After looking at all of the values there are some more problems. Turn off accel and decel enrichment while tuning the VE table. Your warmup enrichment curve should end at 100% in the final row, not 96%. That is also a pretty aggressive timing table. I think by 220kpa I'm down to 14 degrees or so around peak torque rpm. My values were derived by looking at existing maps from long term users here. I do not personally know whats 'safe' to run at what kpa, but those values are definitely on the higher side of what I've seen.

-

I wonder if they'd hire me to do dash restos. My first attempt wasn't a complete success, but I rarely fail at anything twice

-

Running sequential fuel/spark I've found my tired old l28et does fine in the cruise areas up to around 15.5 afr on 87 pump gas (flex sensor bounces between 7-8% ethanol). Anything lower than 12.0 in any area and you're probably not making any extra power, just wasting gas. Looking at your ve table I'd say the surging you're experiencing is probably because you're set too rich at higher rpms. Depending on what you've done to your motor your peak torque is going to be somewhere in the 4,200-4,800 rpm range, and the ve table values will peak in that range and then start falling off again. When I started my tune off I made sure that all my upper ve table was pretty far on the rich side, and let VEAL pull fuel from the cells over numerous wot runs. I would experience bogging every time I hit a too-rich cell, but the problem would get better over repeated runs as VEAL pulled fuel to get the AFR into range.

-

Have you adjusted your lambda delay for your wideband? It defaults to something more suitable for Phil's v8 vette with headers. I used someone's settings I found on here and had more consistent results. They started at something more like 500ms at 700rpm/35kpm.

-

MS3 w/ MS3X Install - L6 turbo, sequential injection & boost control

Chris83zxt replied to Sam280Z's topic in MegaSquirt

Once I knew they were "big enough" for what I need I haven't bothered trying to figure the exact size. I also rarely have a duty cycle gauge active, though if memory serves me right they're usually 1-1.3% while idling.