-

Posts

145 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by tioga

-

Did anyone look closely at the pics? The 4th pic down looks like shit. It's also forged, cast and billet.

-

Twin cam head for the L6 from Derek at Datsunworks

tioga replied to Derek's topic in Nissan L6 Forum

Are you line boring the cam towers once the head decks are machined? I can see why you would not have with your head using the old Honda cam towers but with the new machined towers you made it would make since to do that when the rest of the head work was getting done as a final step. You post that you had to turn your cams with a wrench worries me. Maybe it took no effort and was a 2" wrench but it did make me wonder. With no rockers I would want the cams to turn easily by hand. -

Twin cam head for the L6 from Derek at Datsunworks

tioga replied to Derek's topic in Nissan L6 Forum

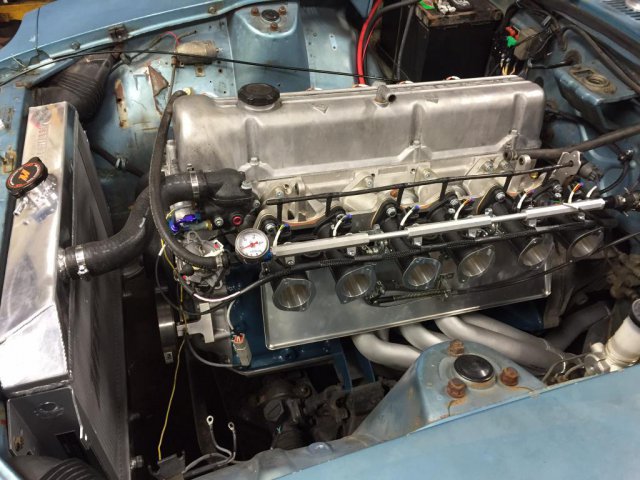

I liked the clean hidden look of the interconnects. It seems to be how the manufactures do it like the M motors and old Mercedes. I have had it both ways and don't think one is better than the other as long as your links and rose joints are tight. It would seem the number of joints in a crossbar setup would be more susceptible to slop. Some manifolds with only two crossbar supports and oddly placed ones at that bother me. The TWM manifold on my car now is guilty of that. Shorty before I did my itb's I did a set of Weber's for a customer and did a interconnect setup and liked it so I did the same on mine. Seems easy to get balanced and have not changed over time. -

Twin cam head for the L6 from Derek at Datsunworks

tioga replied to Derek's topic in Nissan L6 Forum

Looks like if you run the short 37mm o-ring to o-ring injectors it will not interfere with the air box. I have the Bosch ev14 short in mine. What fuel system will this be running? I have been extremely happy with the AEM Infinity I am running. The tuning softwhere is extremely easy to use. When you drag the timeline through a log it highlights the cell or cells responsible for that moment in time and will suggest a new VE to correct. It should also have auto-tune within the next update or two and correct for you. -

Twin cam head for the L6 from Derek at Datsunworks

tioga replied to Derek's topic in Nissan L6 Forum

Have you bought them yet? Strong dollar right now. I just ordered a mangoletsi intake for 150.00 dollars less than last week. One thing that I did wrong was use all right hand lever interconnects. What I should have done is on the center body put a right and left master lever on. Then the center body would open the left and right body. As I have it I open number one body with a link and it opens #2 and #3 this puts the load of two return springs on one interconnect tab. I think during rapid throttle opening it flexes. You should order light weight return springs with the bodies. The ones they come with once you tie three together plus the cable return spring are heavier than necessary. Does the fuel-rail overhang the inlet of the body with the short body THS52i? -

Twin cam head for the L6 from Derek at Datsunworks

tioga replied to Derek's topic in Nissan L6 Forum

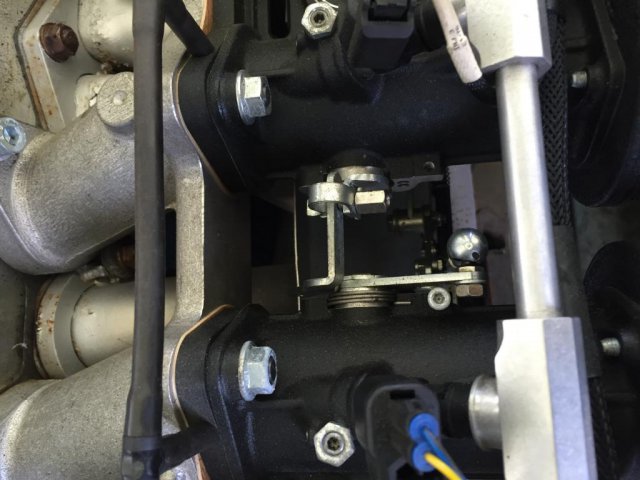

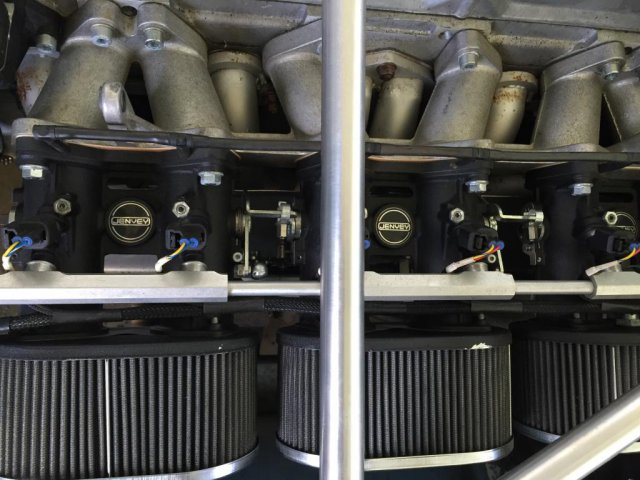

Tony, The throttle bodies are jenvey. I really like them. They are much slimmer than most of the others. The hardware, levers and fuel rail are very nice and clean. -

Twin cam head for the L6 from Derek at Datsunworks

tioga replied to Derek's topic in Nissan L6 Forum

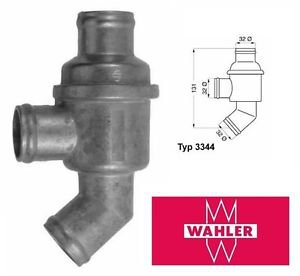

Why not put the thermostat in from the front like the OSG TC-24. You could do a ft outlet housing cover like they did (but may be harder to find a hose that fits) or just match the bolt pattern of the stock thermostat housing cover and have it point to the drivers side (left) then a 90* upper house would work. This would seem to keep it from interfering with surfacing top or bottom. I can easily run any coil with an igniter built in so k20 would be fine. -

Twin cam head for the L6 from Derek at Datsunworks

tioga replied to Derek's topic in Nissan L6 Forum

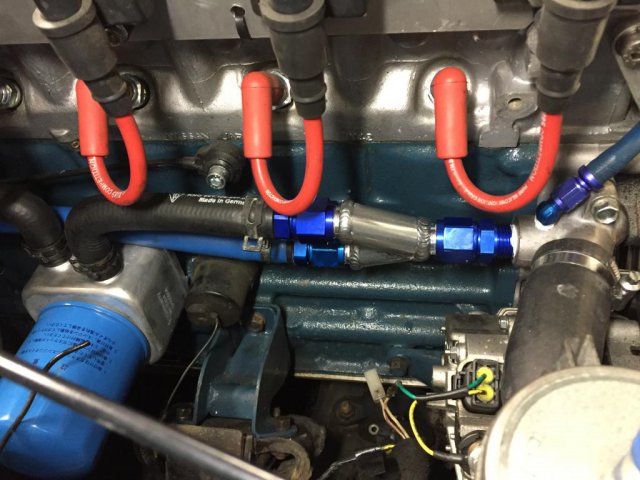

Here is my water bypass hose to the water pump. You would need something much larger for that BMW t-stat and most of the inline ones I have seen. I think a built in t-stat with at least two or three casting bosses for temp sensors & a bypass like this. I would think you would want the stock temp sensor for the gauge & a second for the fuel system. -

Twin cam head for the L6 from Derek at Datsunworks

tioga replied to Derek's topic in Nissan L6 Forum

Derek, I am wondering what thermostat you are planning on using with v2. I know inline but my concern is getting circulation around the t-stat to heat it. Without a bypassing t-stat it seems you would get a temp spike before the thermostat heated the water around the t-stat enough to open it. I thing casting enough meat in the ft of the new water manifold to machine a t-stat right into it would be better. I am running a -4an bypass from one of the old sensor holes in my t-stat housing back into the inlet of the water pump to circulate around the t-stat. If you look at all l6's I can think of they always have some water coming out of the housing to circulate. Like with the fuel injected cars they had the heater under the aux air valve. For v2 you might look at the old bmw 4cyl. Thermostats. They were reliable and are a cheap inline with bypass. They came in a variety of temps too. I am definitely seriously considering getting on the list for one of these. Like I said before I would want to do a tall block 3.0L so I could get some rod ratio to turn this thing like it need to be turned. Seems fitting to do a 3.0 with the rod ratio Nissan would have wanted given the l20b was done this way. Would it be difficult to relocate the oil cap to the rear over one of the cams? This would give extra clearance to the hood. Also I would want coil on plug. Could we cast some meat in the valve cover for a hold down bolt or make sure the diameter fits a push in coil like the VW or BMW ones. Coming home from vacation today I told my wife I thought I was going to sell my 911 turbo. I told her I like playing with my Datsun more. This is why. I could build a serious motor, rotisserie it & still have money left over. -

Twin cam head for the L6 from Derek at Datsunworks

tioga replied to Derek's topic in Nissan L6 Forum

Derek have you checked hood clearance? I am wondering if there is room to run the tall deck ld28 block. This wold give the stroker guys a better rod ratio to twist. The ld28 is about 20mm taller. -

http://www.ebay.co.uk/itm/DATSUN-240Z-260Z-280Z-280ZX-EXHAUST-MANIFOLD-FLANGE-/291721245856?hash=item43ebf0f4a0:g:gOQAAOxy0zhTMsFS

-

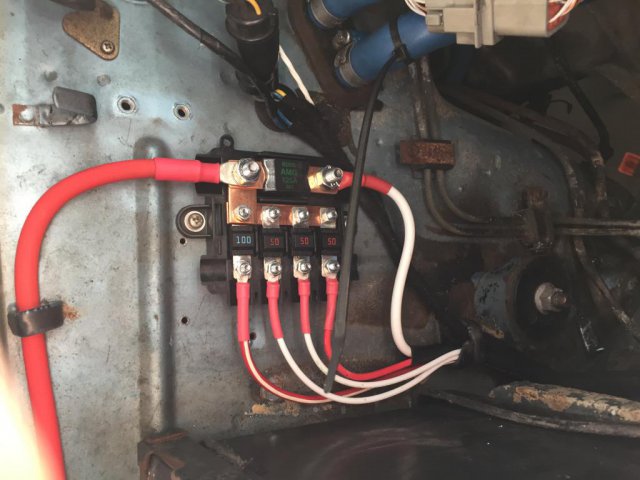

What do you think about my fuse box update?

tioga replied to tioga's topic in Ignition and Electrical

Engine bay & some interior. All old relay boxes removed, seatbelt interlock, ignition & about 100ft of miscellaneous wire removed. Still have dash & rear quarter to go but not much in rear quarter to remove.- 11 replies

-

- Fuse box

- electrical

-

(and 1 more)

Tagged with:

-

What do you think about my fuse box update?

tioga replied to tioga's topic in Ignition and Electrical

It has a cover. Why do you think I need a 80a fuse? Do you know the load on that circuit? Honestly I need to look at the load on each of them & decide what fuses to use. The ones in it I had laying around.- 11 replies

-

- Fuse box

- electrical

-

(and 1 more)

Tagged with:

-

What do you think about my fuse box update?

tioga replied to tioga's topic in Ignition and Electrical

All came from here. I could not find a US vender. http://www.12voltplanet.co.uk/fusing-circuit-protection.html- 11 replies

-

- Fuse box

- electrical

-

(and 1 more)

Tagged with:

-

Twin cam head for the L6 from Derek at Datsunworks

tioga replied to Derek's topic in Nissan L6 Forum

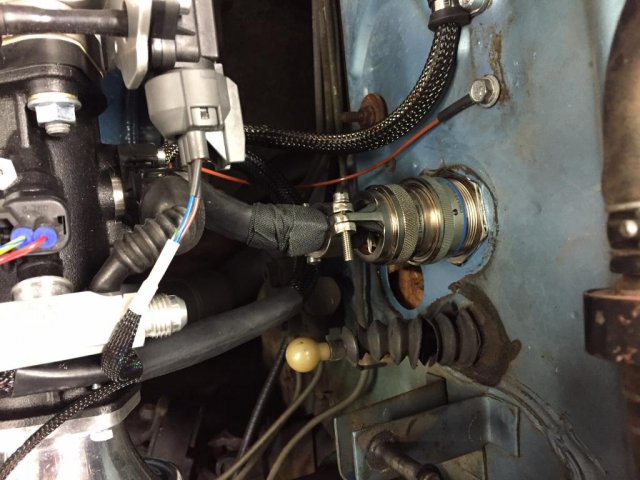

If you guys are looking for a cam sensor I used a Volvo 850 cam sensor on top of a stock distributor. Ground the top of the distributor down flat, ground off the vacuum advance boss,welded up the vacuum advance hole & attached a single window reluctor from a VW/Audi 1.8 or 2.8 to the old distributor shaft with mechanical advance removed. I actually used the end of the VW cam cut off, Drilled & tapped then screwed directly on the distributor shaft. The Volvo cam sensor fits perfectly in the inside diameter of the distributor. Here is the only pic I have on me but you can see the pickup,on the distributor. -

Is This Serpentine Belt Routing Going To Work?

tioga replied to Zzeal's topic in Ignition and Electrical

I would want more wrap. I assume you can't come off the crank & straight up to the tensioner? This would allow you to wrap around that idler after the tensioner & before the alternator giving much more wrap on the alternator. Since the crank pulley is so much larger the less wrap on the crank would not make much difference. The other way to get some more wrap would be to put a idler on that nice big upper alternator bolt. -

Interior box has all the fuel injection relays & fuses in their own section. Then normal car body fuses. Then a panel with a 50 amp accessory relay, a ignition relay, horn relay & headlight relay. The ignition switch now only carries the load of the two relays. There is a forth section with 6 micro relays that is for expansion in the future.

- 11 replies

-

- Fuse box

- electrical

-

(and 1 more)

Tagged with:

-

Thank you. Over 40 hours of strip, seal, crimp heat shrink. Each connector has a heat shrink lable on it with the device it's plugged into & the pin location at the ecu. Example (Injector 1 c1-31) the same at the ecu end. After 27 years repairing cars you have an idea what would be nice when trouble shooting a problem. It takes a lot more planing than I realized to make it really clean. The yellow wire hanging by the distributor is just temporary until I get the temp gauge wire I have in the circular connector connected to the gauge. The wire is all mil spec & the connectors are Deutsch with gold terminals.

-

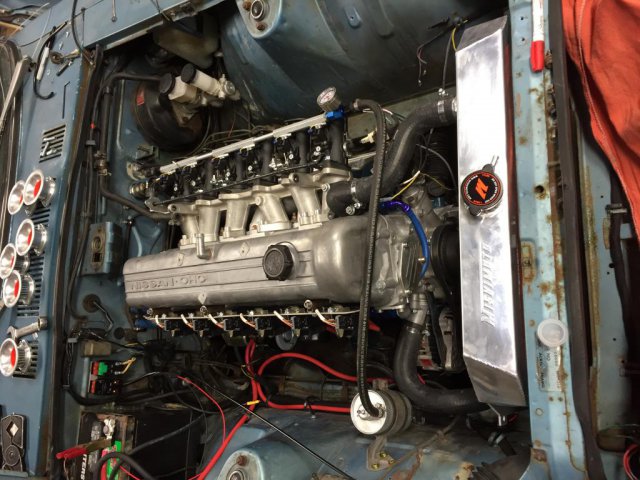

I have a 3.0l with jenvey ITB's and am running a aem infinity 6. I was wondering if anyone else was using the infinity & would share some of their maps. I just got it started yesterday & am just starting to tweak it. I would love a head start with a ignition map & fuel map start point. Once the motor is finished & kinks worked out it will be pulled back apart for full soda blast & paint. Thanks, Tioga.