-

Posts

473 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by inline6

-

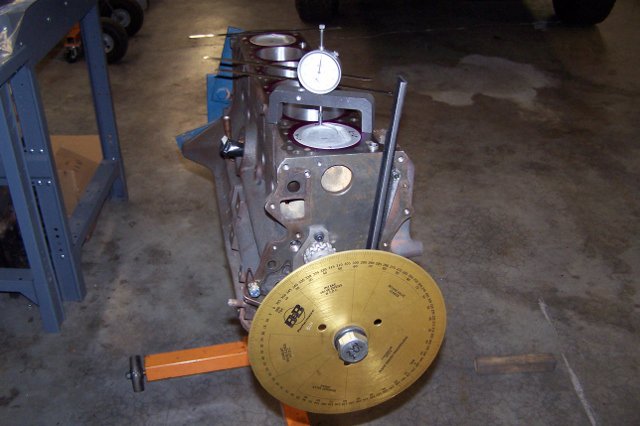

Another update... I am just about out of tensioner travel due to surfacing what I calculate to be .107" off of cylinder head since it was virgin. The bolt washers are hiding the remaining slot clearance - about .080" to .100". Also, I had to use up almost all cam gear adjustment to get the cam to 100.5 Intake Center Line. Cam degreed in/checked out as: Intake- 281* @ .050 valve lift (Cam/follower lash .010) .549 net lift at valve 100.5* Intake centerline Exhaust- 267* @.050 valve lift (Cam/follower lash .010) .542 net lift at valve 108.5* Exhaust centerline Cam measures 104.5* Lobe seperation. Cam is advanced 4* from "straight up". PTV on the exhaust is only .082"... and on the intake is only .002" More machining of pistons to add PTV is necessary!

-

Do you still need one? I have some extras. Question for you: What is the intended use, street or racing? The reason I ask is, I have one body that I had to remove some burrs from the bores... The previous owner managed to forceably shut the butterflies hard enough (beat on them?) so that the throttle plates dug into the aluminum bores and left some ridges. I carefully removed the ridges and then spun some fine sandpaper strip on a die grinder to polish the bores. Basically, the bores are probably a few thousands oversize right where the throttle plates shut. If racing - then you'll mainly be at full throttle operation, and I doubt seriously it a few thousandths bigger bore only where the plates are would matter one bit. For steet, achieving smooth idle adjustment could be an issue. If interested in that one, obviously it'd be cheap. If not, I could sell you one of the others. They are in great shape. Let me know.

-

I have 4, 12" long, 2.5 ID Eibach springs in almost new condition. 2 are 200 lbs and the other 2 are 175 lbs. I don't recall what stock rates are, but these are a lot stiffer. I ran Suspension Techniques springs (popular kit from Motorsport Auto) back in the day for many years. These are stiffer than those too. Then, when I put in ground control coil over kits, I went to the 2.5 ID springs. I ran the 175, 200 combo for a short period of time, but that was when I was transitioning the car to mainly autocross and little street driving. So, I went even stiffer. I'm running 250 lbs front and 275 lbs rear. My car has pretty much been an autocross and track car for like 10 years now. PM me if interested in the springs.

-

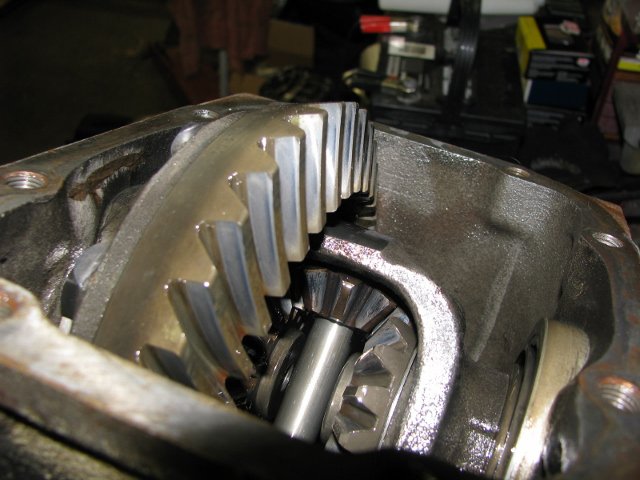

Here are the pics. I do not know what it would cost to ship to you at the moment. If you aren't in a big hurry for this, I should be able to disassemble it and ship only the ring and pinion gears to you towards the end of May, as I am planning to be in VA for a few days then and I do have a hydraulic press. Or I could bring it back with me as you said. If you would rather get it now, then provide your zip code (maybe it is already in the thread?) and I'll see what kind of estimate I can get for you. G

-

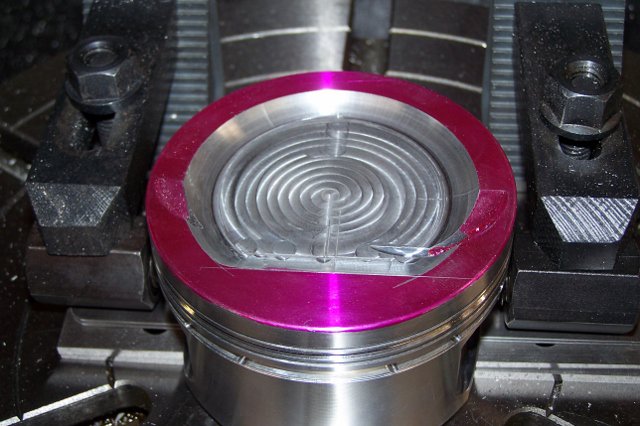

Just got some more photos from Bryan, my engine builder. The pistons have been put in the motor for the first time in order to see the relationship with the deck. Measurements are written on them. Along the pin axis, they are basically flat with the deck. One side verse the other, the variance is about one to two thousandths. The plus and minus numbers at the 6:00 and 12:00 positions are the measurements made when rocking the pistons. +7 for example is the amount that the edge of the piston rocks up and out of the cylinder bore. The Nismo gasket I am going to be using measures .025" in the non-ridged area (just the flat portion). It should not compress any during installation. Specs given by BRAAP and Brian (BandMZcars) in some posts say .022" is the minimum to run for piston to head clearance. I've not seen anything about compensating for piston rocking. So, hopefully, the .022" takes this factor into consideration. With + .000" on some of the pistons and the .025" gasket, I'll be at .025" "static" - if you will. Glad to see the pistons from JE came out to spec in this regard.

-

I talked to my Dad yesterday, and he hasn't had a chance to take the back cover off. He works at an accounting place, so they are slammed with tax preparation right now. He hopes to get to it this week. G

-

My dad stopped by the house last week and couldn't figure out which differential it was by my description. He took pics of them (I have several) and this is the one. Now he needs to go by and pull the cover off and take the pics... Sorry, this is the best I can do via long distance.

-

A few pics... Unfortunately JE did not cut the dishes in the pistons as we wished. The machinist had to remove some more material to get the piston dish cc where I wanted it. Now, they have 11cc volume including the valve reliefs. My calculations put the engine compression ratio at 11.15 to 1. Here, the pistons are all cleaned up: Bryan, my engine builder, has finished sizing the rings to the bores. The oil expander gap is too big with the expanders that came with the pistons. Bryan said they were producing only 4 lbs. of oil ring drag, so we have to go up one size. Those have been ordered. And lastly, the crank is sitting in the block for mock up. We need to put the rods and pistons in to see where the pistons are going to end up relative to the deck. Because I am trying to get as much quench as I can with my E88 head (milled lots!), I will be running piston to head clearance of the thickness of the Nismo head gasket - .6mm (.024").

-

I moved to GA 6 months ago, and the diff. is at my house in VA. I have family that can go by and put their hands on it - remove the rear cover and take pics... but not disassemble. Also, if it was me, I'd jump right on it for you, but since I am asking favors of them, I'd like to be kind enough to let them work it into their busy schedule. Might be able to have one of them do it one day this week. Again, would have to ship the whole thing... Let me know if you are still interested, and we'll get you some pics.

-

I've got a 3.7 that came from a 73 Fairlady brought to the states by someone in the military. I ran it for several years in my Z - probably from about 1994-97. Can't recall the details now, but I think the front seal started leaking... and when I replaced it, I didn't have a torque wrench that would go to the spec. Anyway, I think I torqued it on too light or too heavy because the front pinion bearing went out in short order. I didn't run it that way long because I needed a different ratio anyway. So, long story, but the diff is completely assembled and I'm sure it is a 3.7 - and 85% positive it is non "k" because it was came in the 73 Fairlady. It is in VA. Let me know if you are interested. I can't see using it again, as I now use a 4.11 lsd R200, and would like it to go to a good home. I'll refund the price of the diff if it is not useable. $100 plus shipping and it is yours. Garrett

-

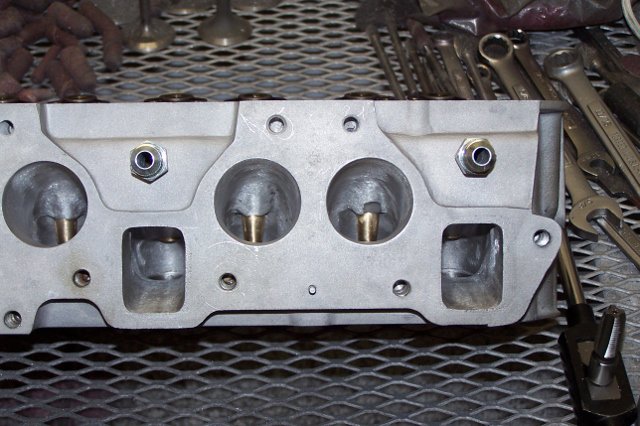

So, the machinist is working hard on my project now. He torqued the head on - I'm using ARP studs, and then measured bore deflection. The worst place only measures a total of 4 tenths out... that is 4 ten thousandths of an inch. He measured in various places and most of the deformities were 2 tenths or less. And the worst was additive - 2 tenths one direction and 2 tenths in the other (or something like that). Guess what folks? That is pretty friggin' good. Combustion pressures are what? Hmmm. Over a 1000 psi, maybe? I'm guessing that the cylinder walls might deflect a tad with that kind of pressure? Anyway, I feel pretty ok about not using a torque plate for the final hone.

-

Some manifolds are cheap. If you have to take it off to repair, and the repair is going to cost more than getting another one (factor in your time), maybe another one is the way to go? What manifold is it? 240? 280? zx turbo? I've got a low mileage 280zx NA in excellent condition that has all the factory studs and nuts even. $20 plus shipping and its yours.

-

This is the high capacity pump that I am reusing. Looks like a few nice chunks of stuff have been through here. One of them was stuck in the soft aluminum housing... was able to pick it out Raised edges were removed. Rotor polished up in the process. Also modded the inlets and outlets for better flow. More exciting stuff coming before long.

-

Some pics of crankcase vent mod - to install fitting with o-ring. I will run a hose from here and the valve cover vent into a catch tank.

-

Will be assembling my very expensive track motor soon. Stock pan is going on unless I can find some nice alternative. Anyone have a Nissan comp pan and pickup that is not being used? Garrett

-

The last of the parts I had to round up are en route... Attaching a pic of the fittings installed in new holes above the #5 and #6 exhaust ports. They are placed at the top of the cooling passages - as high as my machinist could get them without cutting threads into the top of the passage surface. Lots more pics coming soon... Stay tuned.

-

WTB: Lower Steering Joint (lower steering column) for 1971 240Z

inline6 replied to VlaDeMaN's topic in Parts Wanted

The U joints I bought are direct replacements for the stock u-joints in the steering linkage. Just remove old and replace with new. No modifications. A great option for those that want to go that route instead of welding/modifications of the the other option mentioned in the thread -

WTB: Lower Steering Joint (lower steering column) for 1971 240Z

inline6 replied to VlaDeMaN's topic in Parts Wanted

And this is another option: http://forums.hybridz.org/index.php/topic/99247-replace-your-steering-u-joints/page__p__930653__fromsearch__1#entry930653 There are two joints. One in the lower shaft, and one in the upper. -

Have you measured the ID's? If they used glass beads, I'd think there is a chance that no appreciable (measureable) amount of material was removed. I'd grab a bit of aluminum polish and a rag and polish the inside of one, then measure it. If it is within spec, I wouldn't think it would be a problem.

-

Engine assembly questions - rear main cap seals and

inline6 replied to inline6's topic in Nissan L6 Forum

Are any of yours OEM Nissan? I came across a thread in a forum where someone said the OEM ones don't have pins. -

I ordered rear main cap seals (the strips) from Nissan and they didn't come with any pins or "nails". Anyone ever seen that before? Do I use them as is? The How to Rebuild or the How to Modify book, one or the other, seems to indicate that they are not always utilized - that you can get some that don't have them. Also, on the Kameari timing chain idler, do you still run one (the straight one)of the chain guides - just not the curved one?

-

Crank, flywheel, pressure plate, and disc, etc. are being balanced. The crank was 2-3 grams out of balance... The brand new Fidanza 10 lb. aluminum flywheel was 8 grams out... Looks like I'll be final honing without the use of a torque plate. My engine builder is going to try to torque the head on and take some measurements to see the cyl wall deflection. We'll see... Should have some more pics and more frequent updates going forward as we are getting ever closer to assembly, or rather, mock-up!

-

When balancing is done, the crank is typically balanced by itself. Then the flywheel may be bolted on and the balance is checked and adjusted as necessary, next, the pressure plate... The disc is balanced by itself instead of while on the crank assembly because its relative position changes all the time relative to the other parts which are "fixed" in their position. Rods are not assembled onto the crank when it is balanced. The rods are typically weighed and each one is brought to within a certain range of the others. As long as there isn't any substantial difference in the weight of the new rod bolts and nuts from one rod to the next across the rods (1 to 2, 2 to 3, etc.) you won't harm any of the balance just by putting in slightly lighter hardware. Only if say, you ran the stock hardware in 1 of the rods and the new stuff in each of the others would you mess anything up. Make sense?

-

The block has already been bored... The equipment to hone is readily available. My engine builder says a week max. $400 deposit (you or Pete) is fine... What is this one made of? Over 70 lbs. incurs extra UPS charges, and at some point, cost inevitably will get too high. Thanks Tim, and Pete.

-

Thanks... Motor is in VA, as I just moved here recently. Do mention it (loaning it out). It would be shipped to VA and returned promptly. A deposit is fine... Garrett