-

Posts

473 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by inline6

-

Hey Pete, any update?

-

Ok, an update: Block (N42) is back from the machine shop. They left about 4 thou for final honing (final sizing). Also, the main caps were ground a touch and the crank main bore was align honed - probably overkill. I am looking for a torque plate... If I can't find a suitable one to use then I will just have the final hone done without it. Head bolt/stud hole location is such that the distortion on these blocks (when compared to many) isn't a big issue. Anyway, happy to pony up money to rent one, if that is what it takes. The fun stuff, (actual assembly) is not too far off!

-

Hey Pete, let me know what your machinist says... or point me in the direction of McKinney (how to contact), and I'll check that out. Probably looking at doing final hone in the next couple of weeks or so. Thanks much!

-

Time to hone the cylinders... Anyone have a nice torque plate they are willing to part with for a couple of weeks? Looking for a nice quality one for 88 mm bore on the L motor. Rental is fine. Please let me know - shop is in VA. Thanks.

-

Oops. My bad. I stand corrected.

-

Those are 280zx ones. These are z31: z31 axles

-

I worked for a long time Nissan engine builder for one summer when I was in college. He uses an air hammer just like Josh said. No heat, no lube. I even used it once to drive some guides out and put new ones in. Is very easy. I don't think you can drive them out a bit and back in and use them though. All kinds of problems with that.

-

Got it. Well, my motor is no longer... I'm building the 3.0 stroker with Toyota rods and offset ground crank, etc. with the e88 head... you commented on the build thread about welding up the cyl head chambers... Anyway, with the right needles and those big bore SU's, and further timing tweaks as necessary, it will be interesting to see how much more you can get out of your motor. I'm thinking lots.

-

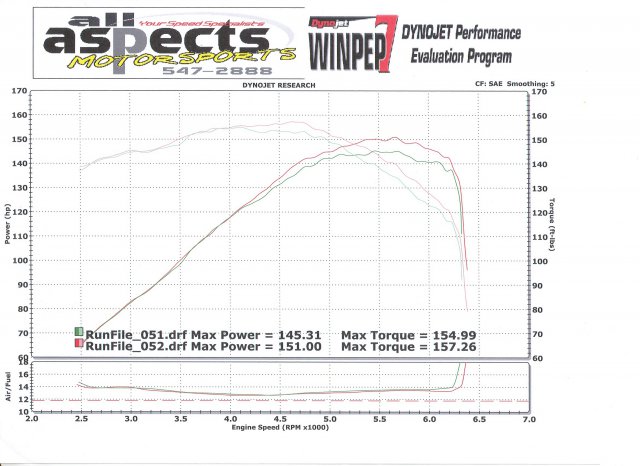

What needles are you running? Are the SU's modified or stock? I was running SM needles with my stock SU's, manifold, and air cleaner... flat top f54 block and e88 head and stock cam but with bigger valves and some port work, header, etc. As you can see, the ratio looks decent across the range here. Maybe the motor is too apples to oranges, but wondering if the SM needles would be a good choice for that cam... The stock N27s were no good for my combo. Dog rich at idle to be decent at high revs.

-

My custom JE pistons have arrived... Now we have to see if they were made to the correct specification. If so, we should be able to start building the thing in earnest now.

-

Well, you need to do another video so we can all hear the latest

-

What MLS did you use Pete? Also, don't forget about putting up a sound clip. I'd like to hear it!

-

Hi Tony, When you say 'this is the same cam', do you mean it is identical to the cam and valve springs from Kinetic Sunbelt that I have?

-

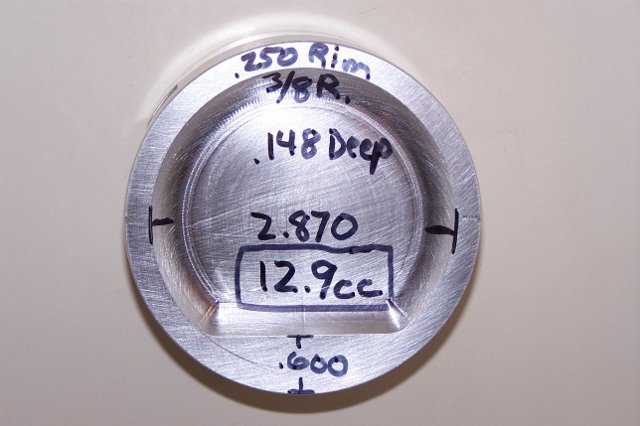

I think I am doing what you and NewZed describe with the piston and dish area... it's just that the "quench pad" is quite small. Note that the piston is marked as .600" - for the distance from edge of piston to end of flat area, and the rest is dished. That .600" matches the flat portion of the combustion chamber in that pic. Also note that the piston has a .250" flat shelf running all the way around the perimeter. The idea is to have this work with the flat area on the spark plug side of the chamber... as well as the flat edges that are near the "main" quench pad. The flat areas of the piston will be put right at TDC and I am using a .6 mm (.024") thick head gasket. When the valve reliefs are cut, I'll see if there are any other options to improve the quench (maybe a slight raised area on the piston to match the slant of the combustion chamber until the valve reliefs are encountered). Does this make sense?

-

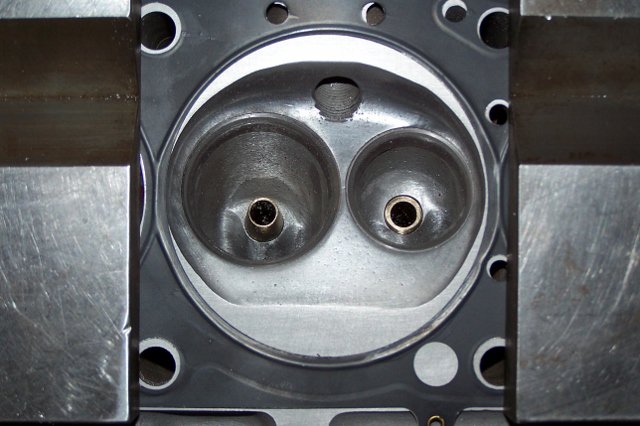

It's been a while and I have an update that is worth sharing. Some more chamber mods have been roughed in, and I have a chunk of aluminum that my engine builder has made to hopefully provide guidance to JE for the custom pistons. With my E88 head cut about 110 thousandths, and valve unshrouding done, the chambers look quite a bit different than stock. Milling the head this much was done to try to get some quench. Welding was not a viable option because I had done all of the valve and valve guide work already. Looking at the pictures, you can see that cutting this much off of the head does in fact give it some quench, but nothing like some of the other L heads. The chamber is at 33.2 cc at the moment. I am shooting for 11.0:1 compression and will be attempting to run 93 octane. It you've read the previous posts, you know I've got a big cam, which will help... and I'll eventually be running EFI. To get the compression down from where it would be with a flat top piston, I'll need a piston with about 12.75 cc's of dish. We still have to add valve reliefs, which should add some more cc volume. So, the finished pistons will likely have a shallower dish than this blank:

-

Nissan dealer can order you one. Take the tensioner to the parts counter (sometimes helps to have the item in hand as they are looking at pictures) and they can look up the bolts for it. Other option is to determine metric thread size and length and see if your local parts store has metric bolts that are close enough... or go looking online - Amazon comes to mind.

-

Yes, you also have to use an adjustable cam gear and time the cam because although the Kameari unit takes up the slack, the distance between the cam and the crank gets shorter. And this alters the cam timing in relationship with the crank. Xnke, I'm not sure where to do more unshrouding work. The Nismo gasket is 91mm wide at 3:00 and 9:00 if I recall correctly. As you can see, the gasket is right at the edge of the intake valve. There is a little room left on the exhaust, but my bores are only going to be 88mm... As it is, I'll need to eyebrow the block for flow reasons. Should I take the exhaust valve area out to the edge of the gasket like on the intake side? Or, are you talking about more unshrouding elsewhere in the chamber?

-

So, I have been held up with the decision of what to do about my head. It is a late style E88 and I didn't realize the lack of quench issues with it. I explored all kinds of options, popping a flat top piston up out of the deck, welding chambers, etc. After chewing on it for some time, I decided to mill the heck out of it. At this point, it has had .107" taken off of it. Here is a pic of one of the chambers. The .6mm Nismo gasket is laying on it. Chamber size is 33.2 cc. So, the idea now is to order custom JE pistons that will work with this chamber. I'll be running zero deck. Based on some earlier mocking up and measuring of piston to valve clearance, my valve reliefs will need to be around .160" intake and .180" exhaust. Piston to deck clearance will be the Nismo gasket = .024". I calculate that between valve reliefs and a dish in the pistons, I'll need to find 11.75 cc's to bring the compression ratio down to 11.0 to 1. I could also open up the chamber a bit on the spark plug side, but I'm thinking it would be good to have the flat area there for quench. I am hoping to run this thing on 93 pump gas with 35-36 degrees advance. If I can't do that with the Mikuni set up, maybe the Tec GT fuel injection setup can make it happen.

-

duplicate

-

I'm interested in the 81-83. I'm in central VA as well. Just north of Charlottesville. Garrett

-

I found two for you that might be possibilities in Rhode Island: 1982 Transmission Nissan 280 ZX STOCK NO. #34108 $200 Kingstown Auto Recycling USA-RI(North-Kingstown) 1-401-295-9400 1983 Transmission Nissan 280Z/280ZX MIGHT BE 4 SEATER Stock No. 45776 $ Call Woonsocket Auto Salvage USA-RI(Woonsocket) 1-401-769-2323

-

JE pistons - Need contact info of someone knowledgable

inline6 replied to inline6's topic in Nissan L6 Forum

This would be extremely helpful - as your pistons will certainly be close to what I need. G -

Anyone know of someone at JE that is knowledgable about L series pistons? As with many things, it would be very helpful to talk to the right person who has actual knowledge, instead of doing the best that I can with whoever answers the phone. My thinking is that, if this person exists, they will know what blank to start with and a lot of the parameters that I need not rethink (don't want to reinvent when what has been done before works). Would be great to start there instead of from scratch. Alternatively, if you have a JE job number and can describe what you ordered in detail, that could be good info. A job number is a good place to start if you know all the info that was specified for the pistons. Thanks for any help you can provide.

-

Hi Zack, Your bearings look like the ones that are going into my motor. They center up into the bearing bore just like your pic. My rod bearings are from a Toyota Camry 2VZ-FE engine (same as Lexus). I am building a 3.0 liter with a reground stock L-28 crank, Toyota Celica rods (See John's note about non-Nissan rods) and custom pistons. I was able to order rod bearings (Clevite 77 with coating) from Calico Bearings. Garrett

-

Do you recall the name of the place that did the welding work for you? Pistons are anything from ~$850 from Rebello to $1200 or $1300 direct from JE. If I send it out for welding, I'm thinking new guides and seats all around, in addition to the welding, plus head gasket resurfacing and combustion chamber shaping. Most of that my engine builder could do... I'd like to estimate these costs vs. doing a P90 from scratch I guess. My engine builder did one of those recently, and he didn't care for the shorter valves - which put the exhaust port turn even sharper... Plus, he said something about not being able to get good quality valves for that head. He ended up having to get a custom set I believe. And then, there is the option of a welded N42...