-

Posts

476 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by inline6

-

JE pistons - Need contact info of someone knowledgable

inline6 replied to inline6's topic in Nissan L6 Forum

This would be extremely helpful - as your pistons will certainly be close to what I need. G -

Anyone know of someone at JE that is knowledgable about L series pistons? As with many things, it would be very helpful to talk to the right person who has actual knowledge, instead of doing the best that I can with whoever answers the phone. My thinking is that, if this person exists, they will know what blank to start with and a lot of the parameters that I need not rethink (don't want to reinvent when what has been done before works). Would be great to start there instead of from scratch. Alternatively, if you have a JE job number and can describe what you ordered in detail, that could be good info. A job number is a good place to start if you know all the info that was specified for the pistons. Thanks for any help you can provide.

-

Hi Zack, Your bearings look like the ones that are going into my motor. They center up into the bearing bore just like your pic. My rod bearings are from a Toyota Camry 2VZ-FE engine (same as Lexus). I am building a 3.0 liter with a reground stock L-28 crank, Toyota Celica rods (See John's note about non-Nissan rods) and custom pistons. I was able to order rod bearings (Clevite 77 with coating) from Calico Bearings. Garrett

-

Do you recall the name of the place that did the welding work for you? Pistons are anything from ~$850 from Rebello to $1200 or $1300 direct from JE. If I send it out for welding, I'm thinking new guides and seats all around, in addition to the welding, plus head gasket resurfacing and combustion chamber shaping. Most of that my engine builder could do... I'd like to estimate these costs vs. doing a P90 from scratch I guess. My engine builder did one of those recently, and he didn't care for the shorter valves - which put the exhaust port turn even sharper... Plus, he said something about not being able to get good quality valves for that head. He ended up having to get a custom set I believe. And then, there is the option of a welded N42...

-

I WISH I had those chambers... G

-

This car has only been driven to and from and during autocrosses and track day events for the last 4 or 5 years (when running). I'd like to be able to fire it up and drive it down the street if I want without getting tickets... but, it by no means is driven on the street with any regularity. I have an M3, an S2000 and a C6 Corvette Z06 which are all bone stock that I drive around for transportation (yeah - no wife).

-

The stroke is 3.165 (80.39 mm). I was shooting for 81 mm using the stock crank (79 mm), but this is the most the crank grinder could get out of it. I am using Toyota Celica rods... They are 5.430 (measured) center to center, which is about 8 mm longer than stock. Cam redline is 7700 RPM with the springs that came with it. Stock flat tops wouldn't have taken those revs... and of course, I will be using the Toyota rods. So, custom pistons are a requirement now. The E88 head has had the seats replaced with hardened ones, intake seat and valve is now 280z size. I just did a ton of port work and combustion chamber work, put in new maganese bronze guides, had them sized to fit and refaced the Manley valves (tuliped ones sourced from Nissan Comp back in the day). If horsepower is in the heads on these cars (and the money), I really hate to start over with another head. I talked to my engine builder about the three options I mentioned in the post above. He suggested another option... Ordering flat-top pistons that will pop above the deck by .095". I know of no one who has done this. But, he makes some good arguements. Looking at my combustion chamber, he says that he could stick the head on his mill table, and then remove material from each chamber... But, he says we'd only have to remove a little bit from say, 11:00 to 1:00 (on driver side of the chamber), and cut back the edge of the chamber a bit along the 5:00 to 7:00, or 4:00 to 8:00 locations (passenger side of head) to make room for the piston. The other locations around the chamber are already cut back enough for the 88.5 mm piston to come up into the chamber - because of the unshrouding work I have done. If you look at this pic, you can see the chambers as they are now. Note the little shelf at 12:00. That shelf is about .080" stepped down from the head gasket surface. Cutting another .080" off of the head (.017" has been cut so far from stock) will give me a flat area for quench that will be about the size of that little shelf. But, add flat top pistons to this mod, and I will probably be somewhere between 11.5:1 and 12:1 based on my calculations. With the pistons in hand, we could mill a small dish as necessary under the exhaust valve area to fine tune the compression - bring it down to 11:1. Another benefit is that the chambers would be modified identically across the six where material is removed instead of any casting irregularity that I might have now. I'm chewing on it.

-

I don't know how to calculate dynamic compression, if that is what you call it. But my cam has more aggressive specs than the Schneider stage IV: Intake Seat duration 320 degrees .050" duration 290 degrees Valve lift with zero lash .565" Hot valve lash .015" Net valve lift .550" Exhaust Seat duration 315 degrees .050" duration 274.8 degrees Valve lift with zero lash = .565" Hot lash = .015" Net valve lift =.550" I've got three options in mind for how to proceed now... 1. Send the head off to have the combustion chambers welded up. I guess I'd put modeling clay in one of the chambers and sculpt it to fit (represent the finished chamber) - so they can see where to weld. If I do this twice, I can calculate the finished chamber cc volume (immerse the finished piece in water and measure the volume), which will allow me to calculate final compression ratio before getting the work done. This would be nice - so as to confirm that I am going to land at the 11:1 I am shooting for. 2. Tell Dave Rebello I need domed pistons - something with a 12:1 compression ratio with my E88 with 45.6 cc chambers... specify the pin height I need, and diameter... And then when I get them, machine them as necessary to fit my chambers. 3. Mill the head a bunch - order flat top pistons (with adequate valve reliefs) and see if it runs worth a damn on 93 octane with this radical cam. This last option will sacrifice HP (without quench) I'm fairly certain. And, it may detonate, requiring the use of racing gas. Not cool because that stuff is expensive.

-

Hi Pete, What you say makes a lot of sense... I was talking with Dave Rebello yesterday and he we saying pretty much the same thing. But, I was running a F54 flat top block with the head previously (something like about 10.1:1, right?), with a Euro distributor - the Euro distributor advance spring(s) and the vacuum advance (in combination with a Crane Hi 6 Capacity Discharge ignition) with 17 degrees initial, and 36 total, and I had no detonation on the 93 octane we have around here. That was with a stock cam... Now I have this monster cam I'm about to use (HUGE overlap)... which is the same one Zredbaron is using. I dunno. Seems like I should be able to run 11:1, but I'd like to have some quench. Rough measure of the combustion chamber says that .080" off the head surface still won't give me any quench (squish) to speak of, yet the compression ratio looks like it goes up to near 11.5:1 at that point. I'm thinking 11.5:1 with no quench is going to be trouble. Ughhh. Why am I finding out now that the E88 is not the best head to use? Because of this, I am toying with the idea of creating a mold of the cyl head combustion chamber and seeing if JE can make something from it. Welding the head is another option, but my engine builder doesn't want to send the head off for welding... According to him, there is all kinds of badness that can happen: valve seats loosening, guides loosening, head shrinking, warping in all kinds of directions... If I had a job number for a JE piston that would give me some quench with an E88 head, I'd sure be happier. I'll be using the Kameari chain tensioner, so I shouldn't need to put shims under the towers. But that is a minor point. Rod stretch... I was planning to run .024" piston to deck. Yeah. That is what reading the forums here and having no real world experience of my own with building these engines will do for you. I'll be running about 7700 RPM max. Gotta make some decisions soon. G

-

Did a sonic test on my block and we won't be able to go to 89 mm as I had hoped. Based on the numbers, I'm looking at 88.5 mm max. That means the compression ratio is going to be too low for the cam (~ 10 to 1). So, I need to put a dome on the pistons. So, how do I do that? I can easily calculate how much of a dome I need (in cc's)... But, how do I specify such a thing? I'd like to go with JE... Have no clue how to proceed. I'm guessing that they have several L series pistons in their database, but I really have no idea how to specify exactly the contour that I need with valve reliefs, etc. Shooting for 11:1 compression ratio... Anyone know how I should proceed? How do I specify what I need to JE? Garrett

-

Still have this? Garrett

-

Any idea of approximate cost? I'm thinking the block would have to be shipped there (where the machining and liners can be done) and back? Am I better off (time and cost) searching for another N42 block... say from 75? Theory being that with production variances or more regular changing of coolant, perhaps I can find one with thicker (enough) walls? G

-

I dropped off most of the engine parts with my engine builder today. The block is an N42 from a 77 Z (had round port head). Quick measurements on the bore thickness in a couple of accessible areas make me think I won't be able to do the 89mm overbore. This is going to be a NA engine... but we measured .175" in one spot on the front cylinder (freeze plugs are removed). Back cylinder, where accessible was in the .2 something territory. It will be sonic tested in the coming days. From some threads I found here, the guidance seems to be .125" thickness for cylinder walls. Anyone have thoughts on this? I hoped to go 89mm on the bore with this block. Now, I'm thinking 88.5 will be more likely. And that might put me at .115". G

-

I got it from Kinetic Sunbelt in GA. It has a lot of duration. Based on some info in the forums here, Sunbelt was one of the last who did any L series development with the cams. That lobe profile is assymetrical, and designed to work with valve springs that only have 190 lbs at .550" (max) lift. At installed height, spring pressure is only 56 lbs. Less spring pressure (if adequate) should translate to more power and less stress on the valve train. Max rev dictated by the springs is 7700 RPM. Intake Seat duration 320 degrees .050" duration 290 degrees Valve lift with zero lash .565" Hot valve lash .015" Net valve lift .550" Exhaust Seat duration 315 degrees .050" duration 274.8 degrees Valve lift with zero lash = .565" Hot lash = .015" Net valve lift =.550" G

-

***********Edit: Moved the following post to a separate thread... I dropped off most of the engine parts with my engine builder today. The block is an N42 from a 77 Z (had round port head). Quick measurements on the bore thickness in a couple of accessible areas make me think I won't be able to do the 89mm overbore. This is going to be a NA engine... but we measured .175" in one spot on the front cylinder (freeze plugs are removed). Back cylinder, where accessible was in the .2 something territory. It will be sonic tested in the coming days. From some threads I found here, the guidance seems to be .125" thickness for cylinder walls. Anyone have thoughts on this? I hoped to go 89mm on the bore with this block. Now, I'm thinking 88.5 will be more likely. Garrett

-

Looks like I only have one of them. Pretty good shape. Painted with epoxy primer and then black back in 1994. Both pins are perfect and there was little if any metal corrosion. Garrett Edit - by the way, I think they are side specific. This one has an R on the backside.

-

Yes they say "240z", came from my 12/70 car. I believe all of the pins are there. Let me see if I can find them. Garrett

-

What condition is acceptable? I think I have some of the quarter panel ones, but the chome is maybe not there anymore. I painted them black and used them for a while before I bought and used new plastic ones.

-

Yeah, spensive. A little less than my first car cost me. Which is really insane... Took my N42 block to be cleaned and sonic tested last week. Should get it back this week. Still looking for some Glyptal if anyone has some sitting on a shelf. Otherwise, I guess I'll have to buy some new and then what is leftover will sit on my shelf... probably until I'm dead.

-

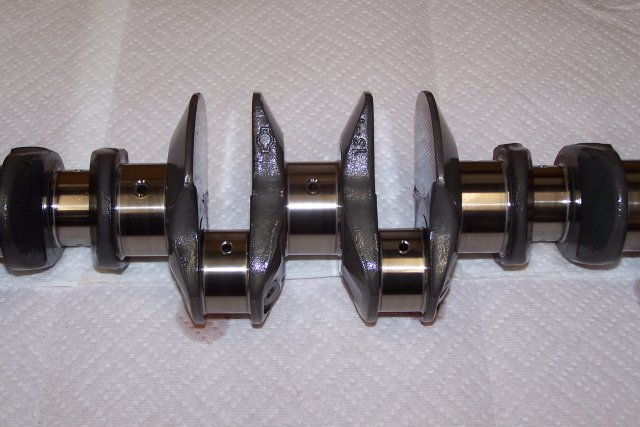

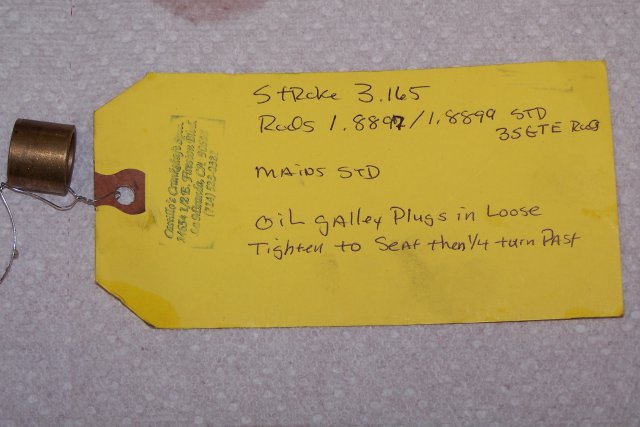

The crankshaft has arrived from Castillo's! Stroke came in a little less than I had hoped (3.165 instead of 3.188), but it was dictated by the factory stroke being a little under spec as well as tolerances when stress relieving the crank which happens during rod journal resizing. As was mentioned before, it probably isn't worth the bucks spent for the small amount of stroke increase I have ended up with. However, those of you buying Rebello 3.0 liter stroker motors are pretty much doing the same thing. Here are some large pics:

-

I took these off of my L28 with E88 head very recently... They are quite nice. They are the 4 screw (early) version that is desired. I had them rebuilt in 1994 with new Nissan OE: thottle shafts, thottle plates, throttle shaft bushings, jet nozzles, screws for domes, screws for float covers, and the hoses that go from the float chamber to the nozzles. I replaced the stock N27 needles with the "SM" needles which are the hot ticket for the L28 engine. I put some attention to polishing the domes some time ago. That is why they look pretty good. They could use a maintenance polish to make them really shine again. While replacing one of the shaft bushings during the rebuild, the aluminum around it broke. This was expertly tig welded (and run on the car since 1994 with no issues). Also, one of the air filter tabs was tig welded and redrilled at the same time. They do have some miles on them - probably 70k since the rebuild, but they work great. I have the heat shield also... If you think you are interested, I will post a few more pics. I was getting ready to sell them on eBay... I'm not sure on pricing because I haven't looked to see what they are worth yet. I know that Ztherapy ones are like $600, and these obviously aren't anything near that nice. My rough guess is $250, but let me look around and see...

-

Did you get some of these? I have a nice set of L-28 stockers from an N42 motor. Let me know.

-

I took these off of my L28 with E88 head very recently... They are quite nice. They are the 4 screw (early) version that is desired. I had them rebuilt in 1994 with new Nissan OE: thottle shafts, thottle plates, throttle shaft bushings, jet nozzles, screws for domes, screws for float covers, and the hoses that go from the float chamber to the nozzles. I replaced the stock N27 needles with the "SM" needles which are the hot ticket for the L28 engine. I put some attention to polishing the domes some time ago. That is why they look pretty good. They could use a maintenance polish to make them really shine again. While replacing one of the shaft bushings during the rebuild, the aluminum around it broke. This was expertly tig welded (and run on the car since 1994 with no issues). Also, one of the air filter tabs was tig welded and redrilled at the same time. They do have some miles on them - probably 70k since the rebuild, but they work great. I have the heat shield also... If you think you are interested, I will post a few more pics. I was getting ready to sell them on eBay... I'm not sure on pricing because I haven't looked to see what they are worth yet. I know that Ztherapy ones are like $600, and these obviously aren't anything near that nice. My rough guess is $250, but let me look around and see...

-

Hmmm. Hadn't thought to use the carbide cutter... Thanks for that. A great example of when two heads are better than one. As for the rods, I am using Eagle brand for a Toyota Celica. My engine builder says they are ok, but not as 100% ready to go as others. That is probably why they tend to be more affordable. I forget the weight, but something like 560g vs. 710g stock - I think? I will be taking the block to my engine builder after I finish removing the casting flash. I don't anticipate any issues with the block... I better not have any that is, because it would be wasted time and effort to remove the flash only to find out that I should find another block. He'll spec out the block, proceed with mocking up crank and rods to see what we need spec-wise for the pistons.

-

Crankshaft should be arriving any day now. Can't wait... In the mean time, I've learned from reading the forums that combustion chambers should be polished - not glass beaded! So, I did that. You can see the undercut on the side of the chamber here. I was copying a 510 head I had done by Malvern racing long ago. I also learned from the forums that the N42 block is the one to use for 89 mm bore. Wow. I was going to use my F54 block. Luckily, I still have my N42 block from an earlier motor. How about this casting flash??? I spend a couple of hours with an air powered hand held belt sander... belts are 3/8" wide by 13" long, one of my latest tool aquisitions. Going through belts rather faster than I had hoped. I am using Norton 60 grit. Looks like it is going to take about 5 to do most of the inside of the block. Anyone have some left over Glyptal on the shelf? I don't think it takes a full quart to do one block, but that is the only quantity I can find for sale.