-

Posts

473 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by inline6

-

Time for an update on the 3" exhaust. I have been working on it when I have time, fitting it all together. This past weekend I finally got to start welding the stainless stuff together with my little MIG welder. It is difficult to make the welds anything but fugly. The tip isn't welded on yet... I think I like it the way it is (length of it that is), but I'm going to look at it each time I walk by for a few days before I make up my mind. This 6" round Magnaflow fits nicely: Rear hanger isn't supporting the weight of the exhaust at the moment. I purposely located the stainless wire here at the bottom of the pipe going under the diff... in the case the pipe drags on the road at any time, this will act as a "pad" to keep the pipe from getting scraped up. I'm thinking the exhaust will drop about an 1/8th once all the joints are tightened up and I remove the jack stands: Trying to keep the pipe as close to the car as possible... My ugly welds... I tried practicing on some more scrap tonight. 5" muffler located in the driveshaft tunnel: Merge collector fitted as close to the header as I could get it: Lots of pieces necessary here to fit the header to the merge collector: I hope to finish all the welding this week/week end. Now if I could just locate an LD28 water pump, I could get this thing started.

-

These are all gone. Not at RockAuto, ebay, Partstrain, Auto Parts Warehouse,etc.

-

I did find one. Thank you for replying though. I appreciate it.

-

Still looking for one of these. Willing to pay $50 delivered to 30115.

-

L series head getting CNC'd:

-

Yeah, it has gone quiet. I've been working on the exhaust for a while now. The Nissan Motorsports header that I bought (1.75" primaries) hit the driver's floor. Evidently, that is a common problem with it. To fix that, I ended up cutting off the collector and using some 1.75" mandrel bent pipe to change the direction a bit. I also shortened these three pipes as they were about an inch longer than the other three. Header mods: Merge collector: 3" stainless pipe: Fitting the exhaust: I hope to finish up the exhaust this weekend. Then it's just a matter of last minute checks before the first fire up...

-

Check the pic at the link I provided above... I am looking for the all metal transmission crossmember. It goes underneath the transmission and has a rubber isolator between the tranny and it. When you say "pinion", it makes me think you are thinking of a differential crossmember, but I'm really not sure. My car is a series one. Thanks.

-

I am still in need of one. When I made my last custom exhaust system, I modded mine a bit so I included it with the exhaust when I sold it a couple of weeks ago. Looks like mine is 70-72 specific. Garrett

-

-

It's a 12/70... which is a 1971. VIN is HLS3016511. Two bolts screw in vertically to secure it to the body. Thanks. Garrett

-

Sorry... I wasn't clear. I need the metal mount, not the rubber one. Garrett

-

Let me know. Thanks. Garrett

-

Hmmm. Even without the three beers, I don't think I'd follow this without spending a whole lot of time with it. I will say, that my Honda S2000 clearly has a side branch resonator in the factory exhaust. Always wondered why that dead end pipe was there. My theory was it was there to make the two lengths of pipe after the Y the same length... making the tonal quality or pitch of the sound the same for both.

-

I think all the parts are here. Wondering if this will be enough "muffling"... --- I kinda doubt it. 3" mandrel bends and straight pipe: Mufflers, exhaust tip, band clamps, 3/8" rod (to make hangers), and rubber strap hangers: The Nismo header (1.75" primaries) that needs to be "modified": The "Merge Collector": Once the header has been modified to clear the existing floor, I'll be making some connectors to the dual inlets on the merge collector. The header, fabbed connectors, and merge collector are all made out of mild steel. They will be sent off to be ceramic coated. The rest of the system is stainless.

-

I looked at many glasspacks because I really like the sound of that one video linked to above. I was going to copy the setup as best as I could based on the owner's descripton, but I couldn't find any glasspacks that I thought would be suitable/durable. I have run them before (a four pack) on a true system, and I liked the sound of it until the fiberglass burned out of them. And they were at the back of the car... Most are not stainless (one from Magnaflow was but it had a 2.5" core - so wasn't 3" all the way through) and I came across your post, John, about the Dynomax during my research. I wasn't sure if that one was stainless, but even so, they use fiberglass in theirs... So, I'm going to try putting the Magnaflow 14867 (5" Dia.) in the tunnel just after the SPD merge collector that John helped me with. At the back, I'm going to try the Magnaflow 12619 (6" Dia.). Both are 100% stainless with no fiberglass to burn out and have 3" cores with straight through perforations. Got a couple of of 3" stainless mandrel J bends, some stainless straight pipe, stainless rod hangers, and stainless band clamps etc. also. The header and the SPD merge collector are both mild steel and are going to be sent off for ceramic coating after I complete the the fitment of the whole system to the car. I'll snap pictures of the construction and put up a video when it is complete. Have no idea what it is going to sound like... just have to wait and see. G

-

Well, I checked out Kakimoto... I'd love to hear it. I just bought a whole bunch of stuff from Amazon - about $570 worth... I ended up picking Magnaflow over Borla. Just haven't historically cared for Borla sound much on the cars I've heard it on and am convinced it would be louder than the "equivalent" Magnaflow unit. So, a bunch of stainless steel is on the way... It's going to be quite the project, starting with mods to the 1.75" primary Nissan Comp header. One of the collectors hits the floor (driver side). Been thinking and thinking about how best to resolve. I've finally decided. I'm going to weld a plate onto the collector end (shutting it) and fill primaries 4, 5, and 6 with sand - packed really tight. Close off the primaries with another plate (can bolt that one on)... and then take the header to an exhaust shop and have them heat the primaries just before the collector to red hot, so it can be bent a bit away from the floor. I did this with my roll bar when I made it as it needed a bit of tweaking after being bent by the shop I used. The sand packed tight keeps the tubes from kinking or distorting. Yeah... what a pain! Garrett

-

I've spent a rediculous amount of time researching choices of mufflers for a new 3" exhaust I will be making. I've listened to tons of videos, but it seems there are practically no 3" systems on normally aspirated L-28s out there, or next to no video's of them anyway. Basically, I don't want to spend a bunch of money and time building a custom system that ends up sounding "ok". I have heard some great sounding z cars and some not so great sounding ones. I'd sure like this one to fall into the first category. I've found a couple on YouTube that I like: Since the car is mainly a track toy at this point, I can take it being loud, but not so loud that I can't drive it without my ears bleeding when I am keeping my foot out of the throttle. I've already got some hearing loss, most certainly from a Datsun 510 that I had a 2.5 inch system on it years ago... I used to drive 1.5 hours each way every weekend to see my girlfriend. Anyway, I plan to drive this car to and from the track and on the road every now and then. Has anyone here run just a single Borla XR-1 like this: Borla 40944 on a three inch system? Can it be driven without ears bleeding? With both of the video's above, the owners are running a combo of mufflers/reasonators. Since the 2.5" system in video #2 is "too loud" for the owner (he added a dynomax bullet), then I'm thinking my 3" with the 40944 will more likely be too loud for me (unless at the track). His motor, by the way, is quite similar to mine. Video 1 has a three inch pipe, and an interesting configuration - a Magnaflow muffler "near the diff" and a two foot glass pack mounted at an angle after that. Definitely like that the "rasp" is not present with this setup. I wonder if that is the configuration though or maybe 3" pipes reduce that in general. Here is what I am thinking about right now: Tunnel Options: Borla 5" round Magnaflow 4" round Section of pipe that can be substituted in with band clamps. Rear Muffler: Borla Oval 40944 Anyone have a 3" system on a NA Z? If so, can you post a video so I can hear it?

-

I just went to my car and replicated what you did. I grabbed the first u-joint down from the steering wheel with my left hand and with my right hand, rotated the steering wheel one direction, then the other, and measured the free-play movement. I put a piece of tape on the steering wheel rim and used the edge as reference. It's exactly 1/8th of an inch of free-play allowed by those splines on my car. The steering wheel is a 13.8 inch diameter MoMo, so if yours is bigger or smaller diameter, take that into consideration. I can easily feel when the joint in my left hand starts to move, so that measurement is accurate - it should be a good reference for you. And my shaft easily has over 200k miles on it. It feels darn tight to me. I've got perhaps tad more than a quarter of an inch of play before the wheels visibly move. With the worn spot in the rack and the worn u-joints, it was easily over a half inch of play, and was very noticeable. Garrett

-

Ooops. I didn't read your full post before responding. 30k miles... and you seem to have eliminated U-joints as the problem. Interestingly, you mention that the problem is when the steering wheel is dead center. You should try rotating the wheel like one revolution in either direction off of dead center and checking to see if the same amount of looseness is there. If it is looser at dead center, then there is likely to be some wear in the rack itself. The rack does have some adjustment available to account for wear. Check the Factory Workshop Manual for info. My car had a shimmy for a number of years that I couldn't track down and with the steering jumping back and forth at dead center, I ended up accelerating wear there... It ended up creating a spot at dead center that was "too loose" - both before and after I figured out the problem. The problem? "New-ish", after-market lower ball joints. They were obviously cheapies, but I overlooked them for a long time because they had been replaced "recently". I ended up buying new OEM ones, and another rack, unfortunately. Again, with 30k, these issues seem kind of unlikely... If the wear is where you say it is, I don't know how to fix it. I will say that now that my car has a good rack, urethane rack bushings, new u-joints in the shafts, and a new urethane coupler, I have next to no play at all. I can see my wheels move with the slightest movement of the steering wheel.

-

I chased down play in my steering... I just couldn't stand it. In my case, the u-joints were the problem. I'm betting yours have never been replaced and are certainly part of the problem. In fact, I doubt it is at the splines because that is not an area where things are typically moving/sliding, unless the pinch bolt was loose for an extended period of time. The u-joints on the other hand are wear items. Here is a post I did about replacing them: Replacing stock steering U-joints Garrett

-

Are nismo or HKS head gaskets still around?

inline6 replied to wigenOut-S30's topic in Nissan L6 Forum

Not sure why the Tomei and evidently the old HKS (there is a thread that shows they are identical) are this way unless everyone in Japan was building off the N42 block as the foundation? I haven't compared with an N42 block, but I bet that one has no issues with these gaskets. Either way, what is to keep someone from clamping some scrap eighth inch plate on both sides of the gasket and simply drilling those two locations? The new holes will be perfect. I'll do that to mine soon and put it in the for sale section. Garrett -

Are nismo or HKS head gaskets still around?

inline6 replied to wigenOut-S30's topic in Nissan L6 Forum

I bought a Tomei 1mm for my build, but didn't end up using it. I think they are still available... Here is the gasket at the Tomei site: TomeiUSA link Interestingly, Motorsport Auto is showing a "temporary replacement" for the 1 mm gasket that is 1.2mm... Motorsport Auto HG Here is recent thread where a guy bought a Kameari and a Tomei and they turned out to be identical. Tomei = Kameari I don't need the 1 mm Tomei I bought. I'll sell it for $285 plus shipping. You can pm me if you are interested. Garrett -

Are nismo or HKS head gaskets still around?

inline6 replied to wigenOut-S30's topic in Nissan L6 Forum

I was able to get a Nismo recently (.6mm) for a normally aspirated motor recently. Also, Tomei are still available. -

Thanks. When I started this project about two years ago, I was living in VA. I took a couple of attempts to find someone good - both recommendations came from folks on HybridZ. The guy that built it is out of Martinsville, VA - so not in this area. He's done lots of work on NASCAR engines and picked up this project on the side because work had dropped off at his employer. I hear there is a place around here though. Near Kinetic SunBelt from what I understand. Can't find them on Google though...

-

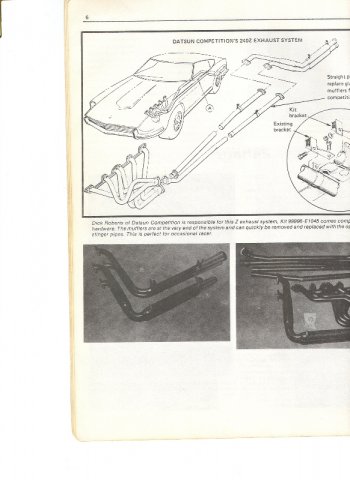

Well, the first exhaust I put on the car was an old Nissan Comp set up and the Clifford Research header. The pipes were dual 1 and 3/4" with 4 glasspacks - 2 small and 2 larger. I absolutely loved the sound especially above 4000 RPM. When the glasspacks had burned up many years lateer, it got too loud, and I was getting pulled by cops too much. Since, I had taken the glasspacks off and put a straight pipe on at a track event once, and noticed how much more power I had, when I redid the exhaust, I went with two 2" pipes. That is about the equivalent of a single 2.75" pipe flow-wise. I put a lot of time and effort into it. It has two stainless Magnaflow 4" round resonators in the driveshaft tunnel and two aluminized Magnaflow 5" X 7" oval mufflers (flipped and staggered) in the back. I put some nice stainless tips on the end. Here are some pics: I didn't like the sound as much, but it wasn't bad. Here is a dyno run... A part of me thinks that pipes that are too big in diameter for a given engine hurts sound quality, and that with the new motor, my existing pipes will sound better. I think what I'll do is go ahead and buy what I need and fab as necessary to hook up to the existing pipes... then dyno it and see how it sounds. If I am thrilled with the sound, I'll probably keep it a while, but if not, I'll move to the three inch and try to get a good merge collector or whatever the terminology is in there too.