-

Posts

473 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by inline6

-

Hi Leon, I see from previous posts, John has mentioned "SPD, Burns, and others"... You might want to look at this: SPD PDF Is your car race only or on the street? I have a nice dual 2" system on the car right now... What is the reason you are thinking about going to 3" from your dual 2's?

-

John, I'm struggling a bit with the thought of extending 3 cylinders about 6 inches more than the other three... I mean, if equal length primaries are important, it can't be good to run one half of the header an extra 6 inches or so than the other and then merge... What is the best way to deal with this? It's probably really tight in that area of the tunnel, so running some kind of S pipe off of the one collector and a laser straight one off of the other and then trying to merge where they become equal distance is not looking possible... plus the distance to the merge is then lengthened considerably... Thoughts?

-

So, I have my engine back from the builder, and now am working on getting it back in the car. I bought this Nissan Motorsport header off of ebay for it. It has the 1.75" primaries. I'm looking at the outlets and wondering what the best way to go from there is. They are 2.5" OD. I've been searching the forums and reading about merge collectors... I guess my question is how do you incorporate merge collector(s) with this header? The outlets are offset from each other so that the exit for one is quite a bit further back than the exit for the other. Do I run some 2.5" pipe off of the one to get to the same location as the other, and then "y" down to a single pipe? I was running a Clifford Research header and two completely separate 2" pipes - and those pipes are still in the car. I've read many of the posts comparing one exhaust vs. two... I guess, going with an all new exhaust is an option, but I like the existing 2" pipes quite a bit. If I want to stay with two, 2" pipes for now, should I just skip the merge collector? Having owned one of these chrome plated headers for my 510 years ago, I know the chrome isn't going to last. In fact, there are a couple of tiny rust spots on the back of this one already. I'm going to ship it off to Jet Hot, where they will strip the chrome and ceramic coat it. In preparation for that, I bolted it on the motor today to check fit. I'm glad I did, as I needed to grind on the flange reinforcement bar that goes under the primary inlets so it would clear the block where the vent is. I also need to determine what kind of hook up I am going to use from the collector to the next piece. And I need to weld in some oxygen sensor bungs before shipping the header off to be coated... Garrett

-

So, the rods in this motor are Toyota 3SGTE (89 and later Celica All-trac, 91-97 MR2 Turbo) with 3/8" ARP 2000 Bolts. Haven't mentioned this fact yet: The rod bearings are those of a Toyota Camry 2VZ-FE 2.5 V6... they are narrower than the 4 cyl rod big ends. They are centered as in this pic (not my motor): Less friction supposedly frees up power - I wonder if it is more than 1 hp! Both mains and rods are Clevite 77 with Calico coatings. Orig Post containing the pic above: http://forums.hybridz.org/index.php/topic/100748-rod-bearing-question/page__p__944414__fromsearch__1#entry944414

-

I thought it was 8 quarts, but you already have more in it than that!

-

I considered them, but I recall my machinist being surprised by how low the torque setting was on them... and he didn't feel the ARP would provide any improvement. So, we reused the stock main bolts. He said that when he final torqued them, there was no stretch. No stretch translates to no need to replace for the most part... unless you want to get crazy and think about how much wear they had from being installed and removed several times during mock-up/pre-assembly. Evidently, he can easily detect stretch when torquing typical "stretch" bolts to spec. If I recall correctly, they are only like 40 lb-ft. or is it ft-lb?

-

-

I looked back through emails going back and forth with him... The aluminum slug we started with -- the dish was .148 deep. If memory serves correctly, JE pretty much ignored that dimension and we decided to cut the dishes further ourselves after we had them in hand from JE. Then, we had to cut the intake another .065 (probably at the angle the of the valve) and another .038 on the exhaust. So, that is going to be ballpark. But, obviously, you'll want to measure your engine to account for your unique situation.

-

Comp oil pan from Design Products has come in. Also, the pistons were modified in yet another round as the PTV wasn't sufficient on mock-up. The note from Bryan was: "After cutting the valve pockets deeper; the pocket edges were radiused with 100 and 120 grit cartridge rolls. I then re-polished the whole dish area with the 120 grit rolls. After this the pistons were masked with duct tape except for the tops and then the tops glass beaded at very low pressure. Then the tops were soda blasted." Looking sweet, I must say It's crunch time now... I go to pick up the motor on Sunday. Looking forward to it.

-

The diff is in GA now. 30115 is the zip. Let me know if you still have interest. Garrett

-

Not together yet. Hopefully not too much longer.

-

I'll check with my engine builder. As recent as a week ago, final assembly hadn't been started, so I may still be able to use it. Garrett

-

Well, this engine build thread has been going on a long time, so it is fitting that we take a short ""vacation" to France before getting back to work. Thanks for the info.

-

Looks like there are a couple available: Page 14: http://www.nissanusa.com/nismo-web/Nismo-Motorsports-Catalog-2010.pdf 11044-E4620 ALL 1 NISMO composite head gasket for L-Series. 85mm bore, 1.2mm compressed thickness. 11044-E4621 ALL 1 Head gasket for use with O-ring type head sealing above. L-Series 6-cylinder. 11044-E4623 ALL 1 NISMO head gasket for L-Series 91mm bore, 0.6mm compressed thickness I've got the E4623 version. G

-

Very cool. I see you are in Paris, France. Can't help but think your 240z is extremely rare there. I bet you have some interesting stories to tell... about how you got possession/delivery of the car, about Parisians reaction to it, etc. Yes?

-

Thanks for the compliment. Almost every last bit of credit goes to Bryan, my engine builder. I do research... decide what I want, and then pay the bills. He has been the one to point out several of the mods and the one making everything fit together. From swapping around engine bearing shells to achieve optimal bearing clearances, to further machining the pistons to achieve the correct, desired compression ratio and to provide adequate PTV (taking into consideration the adjustment available via the adjustable cam gear), to determining how much the pistons stick up out of the bores when "rocking" them, and oil flow modifications, cooling flow modifications, the additional coolant holes above exhaust ports #5 and #6, machining the vent hole in the block for a fitting, etc. etc. etc. He is doing a stellar job. I wish I could have been present in his shop to learn even more than I have via phone calls from working with him.

-

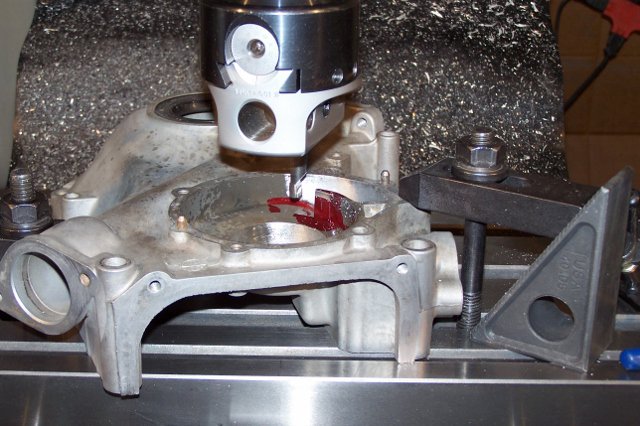

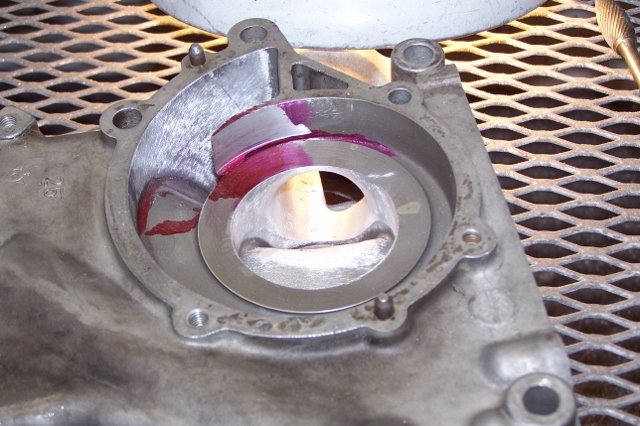

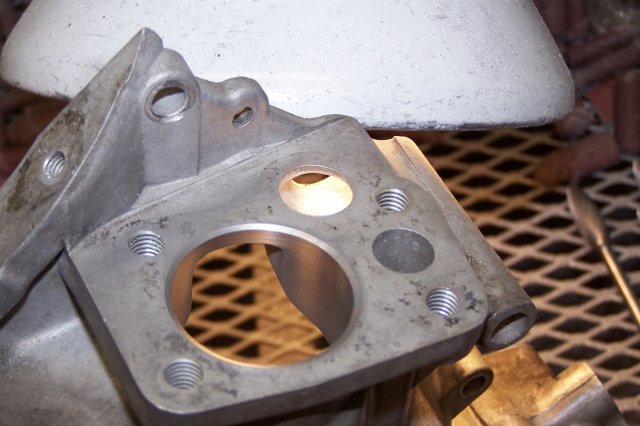

Some more progress to report... My head gasket has a 91mm bore on it if I recall correctly. The cylinder head mods I did brought the chamber edge to the bore edge of the gasket. However, the bore size ended up being 88mm instead of 89mm, as the sonic testing indicated we shouldn't go that big. So, here, the top edge of the bores is being modded to get rid of the "shelf" or lip that would otherwise be present and obstructing intake charge flow. As part of the documentation that came with the tensioner, they said that it could be modded to increase the mounting bolt size and get a bit more adjustment if desired. Doing that here. The holes in the head were drilled and tapped for 8mm bolts. And, some mods to the front cover to make the diesel water pump work well and to increase flow for both cooling and oil:

-

Kind of bizarre and interesting. An L-28 on an engine stand with various sections removed... you can see crank turning, cam turning, valves operating.

-

Yep, those are the ones I bought and they will be at the engine builder's tomorrow. They have to be turned in a lathe a touch for the springs I am using with the cam. Here's hoping that it all works and I get a bunch more hp than I otherwise would have as a result (of the light spring pressure).

-

Thanks John. I picked one up off of ebay. Appreciate your input. Garrett

-

Ancient thread... but I'm trying to track down titanium retainers for an L series. Can't find anything online about Dell Engineering... Are they defunct?

-

I've been researching through the forums and elsewhere and came across a post where someone said the Clifford Research header interferes with the Nissan Comp oil pan. If true, I'll need to find another header to use, because I plan on using the comp oil pan with my new motor. I'm not wanting to build myself one from a Stahl kit. So, I'm thinking about trying to track down a Nissan Motorsport header with 1.75 primaries. The application is an L28 bored to 88mm - 2.933L running 11.1 to 1 comp ratio. The cam is a Kinetic Sunbelt unit with the following specs: Intake Seat duration 320 degrees .050" duration 290 degrees Net valve lift .550" Exhaust Seat duration 315 degrees .050" duration 274.8 degrees Net valve lift =.550" Redline on the cam/valve train is 7700 RPM. I have a tripple Mikuni 44PHH set up with 37mm chokes in it right now, but will be switching over to a 45mm TWM fuel injection set-up a down the road a bit. The car is mainly a track day car at this point, but I still drive the car to and from - because I don't want to buy a truck and a trailer. I've been running the Clifford header and true dual 2" pipes for several years... I have 2 4" round Magnaflow's in the tunnel and two 5X7" oval Magnaflow's in the rear to keep things quiet. The main question is, are these primaries too big? If so, is what is my best header alternative?

-

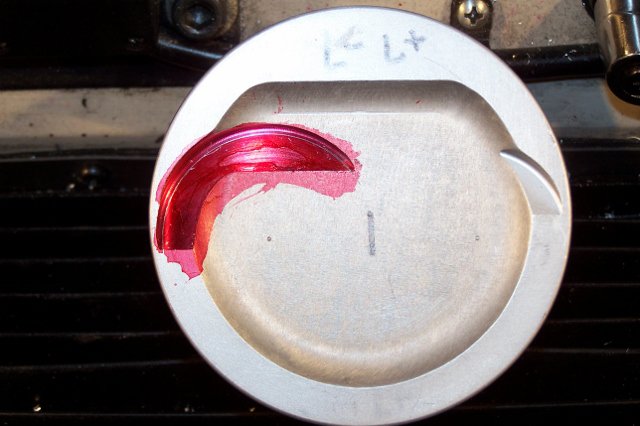

I got the cam from Kinetic Sunbelt in GA. With the springs they supplied (single - not double) they said not to run it higher than 7700 RPM, but that is close to 8k... The seat pressure (installed) was checked and found to be only 56 lbf. At ~.550" lift, the springs were only supplying 190 lbf. Because the spring pressure is so light, my engine builder is strongly recommending the use of titanium retainers. The receipts just keep adding up. Here are pictures of the work just now done to add PTV for the intake valves. Garrett

-

Let me know if you have 12 for sale (to fit L series) and the price. Thanks.

-

Ohhh... yeah, I could see that one tripping people up. Thanks for the head's up.