Dat73z

Members-

Posts

851 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Dat73z

-

This afternoon my boost controller came in so I temporarily stuck it under the radio to see how it would look. I'm still undecided to either hide it or have it exposed. I guess at this point my car has become a restomod so maybe having it easily accesible is the way to go.

-

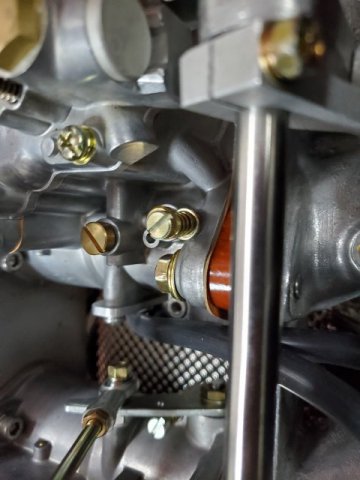

This evening I was curious and checked the plugs. It seems I got the BR8ES hot enough today to at least start self cleaning. The porcelain was all black after my mountain run on Fri. This week I'm fairly limited on time but I'd like to install the electronic boost controller and play with the jetting a bit more. I think I need to pull some fuel out since I've fixed all the leaks on the carbs.

-

Had to take the wife for an appt this AM so more shakedown boosting through the mountains. Somehow now I feel like the BR8ES are smoother through the rev range. Or maybe the cool mountain air is playing better with the turbo at elevation, not sure.

-

Also, on my drive yesterday I was cruising the freeway for a couple of hours and noticed my pan oil temps were 130 in the AM and 140 in the PM, and my oil cooler is already 2/3rds obscured with cardboard. I think I need to figure out a long term solution but I still need to do some more research and figure out what the options are.

-

@rossman it sounds like we have a fairly similar setup. Do you also have a 292-9 cam? Have you had it on the dyno? I put the BR8ES back in this AM just to be safe. Maybe when I get things dialed on the dyno the plugs will look better. @Zetsaz yeah to be honest I didn't think about it until I had installed everything lol. I'll order up a can of radiator black and maybe spray it in next weekend. Finally got notice from USPS that my electronic boost controller is coming in soon. After installing my old TurboXS controller, I think the best place to mount the solenoid and pressure sensor is behind the washer bottle where they will be hidden but accessible under the inspection cover. Inside the car I'm not sure where I want to mount the screen. I'm not a fan of having gauges and screens everywhere as I like the OE interior look. I'm thinking maybe velcro or double sided tape mounting it above the defrost/seat belt/choke lights in the center console. Or I could have it behind that panel under the pivot completely hidden since I could just pivot the panel up and hit the high or low boost setting.

-

Did another 150 miles today and the car didn't skip a beat on BR7ES and 10lbs of boost. I think I need to get new tires. I'm currently running r888s which are fairly old. My buddy hopped in for a drive and we lit up the tires in 1st gear at 30 or 40mph and spinning into 2nd as I was rolling into it on an uphill onramp. Also considering painting the intercooler black. I thought the fairlady Z grille would obscure it a bit more but at a distance it's pretty obvious, and I prefer the OE Z look with the coolers and rad support blacked out.

-

What was your engine setup? I read the same somewhere, probably here on HBZ that the projected tip mechanically advances your timing by somewhere around 4 degrees. The projected tip can get hot, preigniting the fuel. I switched over to the BR7ES last night, gapped to 0.028. The engine seems to idle a bit smoother and pulls to 6k without hesitation. The weather was cooler last night so not a great test, the outlet of the intercooler was frigid cold to the touch. Today I need to drive the car another 100 miles or so to pick up my 67.5 pilot jets and get breakfast with a friend. So I'll do some more testing on and off boost today. The main reason Im trying the 7s is I've noticed the 8s tend to get dark quickly, within a few hundred miles on my setup. This is probably because I live in one of the more densely populated parts of the US and traffic is everywhere. But I also noticed the plugs starting to get much darker after my drive yesterday where I was basically on boost for an hour in the mountains over maybe 2 hours of driving. The elevation change was also affecting my carb mixtures, Im sure. I think I'll stick to the 8s for track days, dyno or generally days when I know I'm going to be running the engine hard and at higher boost. But maybe the 7s would work better if I'm going to cruise long distance.

-

@rossman yeah that's what I've read too and what I currently run BR8ES. Some people on the FB groups were mentioning one step hotter to the 7 range would be better on the street and run the 8s on the track or dyno for detonation resistance. Maybe I should just stick with 8s unless the 7s really offer much better starts/drivability. Especially since Im 8.5:1 CR and running 91 pump gas

-

It is apparent I need to relearn how to drive my car. The way the turbo starts spooling in the 2k rpm range and peak torque is at 4k means I don't really need to rev it to the moon to approach high speeds, and response is really good. Corner exit is immense. The turbo spooling and BOV venting at lifts and shifts bouncing off the trees is really visceral. I think I need to find some way to record video from inside the car but I've attached a vid below of the cold start this AM and a snap from the drive. 20220930_063504.mp4

-

Technically I get today off from work but I still need to do a few things later. So this AM I'm going to go for a scenic drive into the mountains and keep shaking the car down. I was fueling up yesterday and I'm basically paying $7/gal for 91 here in CA. It's been getting ridiculous. Since fuel cost is so high I'm going to swing by my local race fuel station which is conveniently located at the start of the drive, and see how much some 100 octane is nowadays.

-

Tonight I went for a nice long drive. The pandemic is definitely over, traffic around where I live is terrible. All the time. But on the plus side, the car is running and driving the best it has to date. No more oil and fuel leaks, boost holding consistent at 10psi, and it pulls "turbine smooth" to redline. This weekend I want to find a way to check for boost leaks and try some 7 range plugs. I'll also be picking up some 67.5 pilot jets to try out, which are 1/2 step richer based on my tuning notes below. I'll also need to see if I can pick up my 250 needle and seats sometime soon. I'm currently using BR8ES plugs gapped to 0.028". Some tuning notes: I'm idling at ~11AFRs. The idle circuit carries the car from 11AFRs to mid 12s at boost onset 2.5k rpms. By 3k rpms depending on load and gear, I touch high 12s/low 13 AFRs and the mains start to tip in. When the mains tip in, the turbo is reaching peak boost and afrs are high 10s/low 11s by 4k rpms and peak torque. By redline at 7k rpms AFRs are mid-11s. I'm going to try 1/2 step richer on the pilot circuit. Maybe pull just a bit of fuel with larger airs past peak torque. And of course larger needle and seats as the motor just drinks fuel on boost into 4th and 5th gear WOT.

-

Yeah @rossmanthe nostalgia is strong! I was digging through a box in the shed and realized I never sold it. Last night I replaced the oil pressure switch. It was an interesting failure, oil leaking around where the plastic base for the contacts crimps around the metal body. Apparently this is common. I think I will need to eventually reroute eveything and move the sensors off the engine and onto the chassis. But that will be a project for another day. This morning I did a quick inspection around the fuel system. After 1k miles I'm gaining more confidence in the car/build. Lots of seemingly random new build teething issues but I think I have them mostly all sorted out. I realized I forgot to install an anti-rollover valve on my vent. So I'll need to order one from Pegasus or another vendor.

-

Tonight I found an old MBC from another project so I temp installed it. Boost threshold has dropped maybe 3-500rpms and I regained the 1-2psi drop I was getting across the system. So now I'm back at 10psi. My electronic boost controller has been driving around in circles on the east coast for weeks so I'm not hopeful it will be here anytime soon. When the engine cools off I plan to install the replacement oil pressure switch.

-

Managed to swap the plugs and get a quick inspection in this AM before heading out. Carbs are still bone dry, no signs of leaks. This past few weeks of sealing seem to have worked. Probably need to start cleaning, things are getting dusty now that I'm racking up the miles.

-

After sleeping on it I put the HKS BOV back on this AM. I'm confident I could tune around the Tial BOV but I'm down to 4 weeks and still waiting on parts. Rejetting and test driving to bring the afr curves back in would take me a couple weeks with my schedule. So the Tial BOV is getting shelved for now. Later today my replacement oil pressure switch should come in so I'll replace that and resolve the oil leak.

-

I was curious so I quickly pulled the plugs to take a look. As I suspected, the Tial is lettings things go pig rich. I had the tune dialed in with the HKs BOV to a light charcoal afr ring, and light grey on the insulators. With the Tial BOV, the plugs are all black from running rich. Not what I was expecting but I'm learning as I go. I guess triple blowthrough turbo is sensitive to the BOV choice, and the setup needs to be tuned as a whole.

-

Tonight I installed the Tial BOV and went for a nice long drive. Unfortunately there was a lot of traffic, but that was good to test the setup on and off boost, at the transitions which is what I'm attempting to correct. At idle the Tial BOV is bypassing as expected, and snaps shut as vacuum apporaches 0. Starting is easier, and so is driving off boost. Also there is 0 flutter, and the fuel pressure does not hang. Every blowoff sounds like a sigh and gets sharper as the boost builds. However, on the transitions the HKS valve is much better. Shifting between gears on the HKS valve, boost builds back almost instantaneously. It honestly feels like an EFI-like response. On the Tial valve, there is just a momentary hesitation and the afr gauge reads pig rich then the boost builds back up. So an interesting result but I'm out of time today to continue testing. AFRs across the board changed slightly so maybe I need to jet down the idle circuit a bit with the Tial valve to pull a bit of fuel. I also didn't get to test higher speeds/rpms.

-

Today my Tial BOV came in so tonight when I get a break I'll install it and see if the transient rich spike issues I get go away. The Tial BOV should bypass with vacuum which my HKS SSQV BOV does not always do.

-

Some tuning notes from the past weekend. Investigating the high load high rpm region of the setup, I start to lean out a bit into 4th and the engine is still pulling hard and fast to redline. This is something I'm saving for the dyno for obvious reasons, but I've unmasked some fuel issues there although I probably won't be doing too many WOT 4th and 5th gear pulls on a regular basis. The OERs come with 180 needle and seats. After exchanging notes with my friend, I'm going to swap out to 250 needle and seats to meet the fuel demand of the motor. I think I'm running the float bowls dry into 4th. Unfortunately I couldn't find the OER parts but apparently the Mikuni phh needle and seats fit so those should be in shortly.

-

After boosting around and cleaning off the area it is apparent my new oil pressure switch is leaking oil around the base where the plastic attaches to the metal. I think I may relocate the switch off the block and onto the chassis to help it last a bit longer. I've been eyeing an accusump system for a while now. Contemplating if I should just do everything at once and rebuild the oil system on that side of the engine.

-

This morning I went for a nice long drive, mixed between in city and high speed with lots of boost throughout. The carbs are bone dry which is great but I just noticed another issue. Looks like a small oil leak at the oil pressure senter/turbo feed branch. So I'll investigate further and repair when I get back later today.

-

This morning I repaired the alternator tensioner. I cleaned off the bolt from my bolt bin, put a few drops of blue loctite on the threads just in case and torqued everything to spec. Whenever I do a build I always put a wrench on everything twice so I'm confident that bolt was torqued. Still not sure what happened but Im I'm going to do another undercarriage inspection later today and put a wrench on everything again for a 3rd time. Still waiting on parts this next week so I'm going to drive the car daily as much as I can to keep shaking things down and tuning. Still minor issues creeping up here and there, but nothing major. Biggest ones which have been resolved so far were rebuilding the cooling system, fixing the fuel leaks, and the alternator tensioner.

-

Earlier today I heard my alternator belt squeeling a bit at startup. I didn't think much of it as I figured it probably just needed more tension. So it turns out, the rattling noise I was hearing which I thought was an ebrake spring was likely my alternator tensioner heim joint slapping against the alternator pulley fan. This is a new one on me, have never lost this bolt before on any L series.

-

Today got crazy busy but I managed to get the oring grooves cut. I went boosting around for a while and the carbs are now bone dry around 8psi of boost. Hopefully it stays that way, getting a bit burned out chasing minor issues. The true test will be when I turn the boost up.

-

Parts I ordered a couple weeks ago are starting to trickle in. One thing I have learned this past few years is call for lead times before you order anything. Due to supply chain I think the longest I've waited for parts was 8 or 9 months. Hopefully my new BOV and boost controller come in next week. Some other items are backordered for 6+ months so won't make it in time for the dyno. Later today I'm going to try to get my IMS screws machined.