Dat73z

Members-

Posts

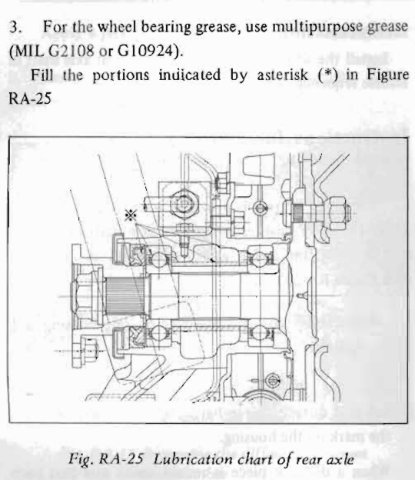

851 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Dat73z

-

Finished the transmission pull tonight and everything looks good so far. I'll take my time and paint mark everything on disassembly, as to ensure I reassemble the clutch pack and multi-plates in the same order and direction it is currently in. The tiny oil weep I noticed before is more visible now as well so I'll investigate and see if I can fix it while I'm in there.

-

Finally getting back into the build after the holidays. It's been a really rainy and cold winter so far this year and due to other projects I haven't really been motivated to finish the s30. This evening I somewhat organized the area and am going to start back in on the trans pull now. It seems my flywheel bolts won't be shipped until 01/06 so I'll have some time to work on other deferred items as well.

-

A musician's therapist (The $300 Z)

Dat73z replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

I lowered my tial on the bracket by clearancing the cast compressor housing and lowering the bracket. It gained me 1/8" but I could've probably gone for more. Otherwise I had also considered fabbing a new bracket but I had too many other things going on at that time. Your project looks great though, keep at it! -

-

Today I finished reassembling and retorquing both axles. I pulled out what I considered excess grease and used new ZX locknuts. I also recalibrated my new precision instruments wrench to click off around 195 or so at 200 indicated. I guess you can't even trust new US made out of the box tools anymore. This weekend I'll finish pulling the trans and get that sorted, a week or two ago I ordered new OE thin flywheel bolts which have yet to show up. I had considered arp flywheel hardware, but I didn't want to get into machining bolts etc. like I did with the crank pulley. This next few weeks I need to start ordering some bodywork supplies as well and figure out how to keep all the grinding dust out of my house.

-

Just a light update, I've been working on the car this past couple of days and am considering tearing it back down to a shell again for a full repaint. It's something that has been bothering me since the past decade of owning and building this s30. This car is a high mileage survivor but mostly rust free. I am capable of doing any metal/body/paintwork but due to my current life situation I'd need to either pay someone to paint the car or rent a booth and paint it myself. I think the strategy here is to get the car one the road again in a couple of weeks then start metal/paintworking the body. Mainly with kids on the horizon this is one project I just want to get "done" as I know it won't as there are just too many vehicle and other projects I've been wrapping up along with this one.

-

Merry Christmas! Today my OSG clutch tool made it back from my buddy. So when the holidays simmer down I'm wrap up the trans pull and redo all the clutch pack and flywheel fasteners. This is to ensure the vibrations from the harmonic balancer walking off didn't loosen anything.

-

Things are finally slowing down for the year. I just received a NOS NSK bearing for the rear so I'll dust off my press and get that sorted today. I had considered seeing if I could save the seal and reuse the bearing but decided to just spend the $40. Also heard back from my friend that he finally finished his swap and will be mailing my OS Giken clutch tool back so hopefully that comes in before the new year. Time is limited this next week as I got another car back up recently and am dealing with the registration and all of that but I'm coming back around to the s30 here and there.

-

So I researched this extensively a while back. You want to get a hose made specifically for the temps and fluid, in this case hot oil. It's at low pressure and you need to ensure there is no restriction. Gates and a bunch of other co's offer off the shelf solutions to this, and I'd recommend you get the same hose rated and used for oil coolers.

-

https://www.yoesheadporting.com/

-

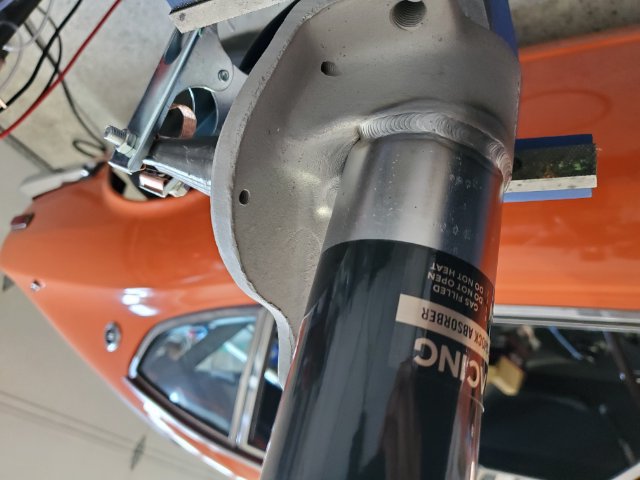

So I slapped out the stub axle and as I suspected, the outboard bearing seal has failed, blown outwards. I'm glad I decided not to just check the torque and send it. This is a new one on me. Did I overpack with grease? Brake boosting/launching causing excessive pressure? Burnouts? If anyone has any ideas let me know. I guess I have a week to research while I wait for new bearings/ZX nuts

-

This AM I disassembled the DS rear. It looks like the axles are fine with no leaks. I rebuilt them last winter so only a couple K mi boosted on everything. The DS inboard side looked fine, some red grease there but I believe that was from assembly. It was definitely leaking on the outboard side into the disk brake and wheel. I think what I should do next is disassemble the strut and inspect. Press the stub axle out and all that. I seem to recall the outboard side bearing had a factory seal on it so since I'm already this deep into it I figure it would be good to make sure it didn't pop out or something especially since the PS side is dry and fine.

-

Haven't had much time to work on the build this past week but I decided to purchase a new precision instruments 250ftlb beam style torque wrench to check the rear stub axle torque since I saw grease leaking from the driver's side rear. In the past I'd use my 150ftlb torque wrench and give it a bit more after it clicked off. I usually dropped off my old torque wrench to get calibrated locally maybe every year or two. Today I decided to weld up a quick test stand so I could check the calibration in my garage and save some time and money. My old 150 torque wrench clicked off around 145ftfbs when set to 150 so it'll need some minor adjustment. For some reason the new made in usa precision instruments beam torque wrench was reading 10-20+ftlbs low at this range and maybe 10-15 ftlbs low at 80. Maybe it got bumped a bit in shipping, I'm not sure but I'll set the calibration a bit later today and get back into the build

-

From what I've heard and seen from local vintage Porsche guys, if you're going to pay someone it's a lot cheaper to send it out of state. Apparently Idaho has some great body and paint shops. With the way the world has been going this past few years, the discount is probably less but even with transport I wouldn't be surprised if you save more than a few K over paying someone legitimate in SoCal to do it. On my fairly straight and mostly rust free but tired car I've been quoted 10-20k+ locally in the Bay Area CA with me doing a lot of the disassembly and of course all of the reassembly. Basically scuff and spray with some minor bodywork.

-

Still waiting on parts so tonight I got the rear end mostly back together and adjusted the ride height to my preferred spec. I noticed that some bearing grease was leaking on the outboard side of the stub axles into my disk brakes. I have never seen this before and I've redone the rear end with new bearings twice on this car. But I was also brake boosting and a bunch of other stress test stuff when I was tuning before the car went down. So I'm going to check the torque on the stub axle nuts this weekend, I believe to 200ftlbs or so.

-

Just a quick pic of my hot side charge piping in case it moves. There is easily 1/4" clearance between everything now before contact. I'd like to do HD weld-in clamps but I didn't like how they were 1-200$ each so maybe someday if I get serious on this car

-

@Zetsaz it's awesome how many random and interesting people you meet and the stories we get from these cars. Hope we can meet up someday and hang out 👍 Tonight I started back in on this project. I need to organize and clean. After all the travel and funeral stuff to be honest I was pretty down and got heavy into overworking again along with all the other family commitments in life. So I'm going to get back into this, one thing per day until it's done again, starting with cleaning my space. My buddy let me know he ran into some issues with his swap so I won't get my OS Giken clutch tool back until maybe next week. But plenty to do before then.

-

@Zetsaz np and yeah the suspension was a decision I made like 10yrs back when I built the car for the first time/3 lol. With the options on the market now I'm tempted to get something with a threaded shock body so I can preload the suspension independent of ride height but I also have a few other vehicles so I'm trying not to light too much money on fire with this one. The funny thing is I actually welded up a set of s30 BCs for my buddy not too long ago, the coilovers are pretty nice

-

@Zetsaz I belive it's 1/16 high temp non-adhesive backed silicone sheet. I don't recall where I got it from but any industrial supplier, amazon, ebay etc. should have some form of it. Yes punch the holes for the screws and cut a small circle in the center to slip over the shifter area. I started to swap over the springs from the eibach to swift along with the pillow ball camber top hats. It seems to be doing what I need the suspension changes to do, providing camber adjustment, more clearance, and also preventing spring pop out at droop.

-

@rossman yeah I've been doing a bunch of reading since last night. Everyone has opinions everywhere. I think I need to call one of the companies that mass produces them and talk to a materials guy, just to get the final word on what they've seen work on turbo setups. Been busy getting ready to travel today, but my shorter rear springs and helpers came in. I thought I ordered Hyperco springs like they use in Nascar but apparently I got Swift springs. When I get back I'll get them on.

-

Got all of the trans bolts loosened and everything cleared out. Unfortunately I'm out of time this weekend, so I'll pull the trans next week. It may also be a good time to refabricate the entry for my muffler to clear 245+ tires. I think I have just enough scrap in the cut pile to make that happen.

-

Thanks @rossman that is what I was thinking as well but I believe the nuts are copper coated for corrosion protection and not fully copper, they are these from atp http://www.atpturbo.com/mm5/merchant.mvc?Screen=PROD&Product_Code=MIA-FST-031&Category_Code=FST I think I'll order some inconel studs and take a look at which locknuts to use, perhaps the stainless variety you indicated. This morning I'm going to pull the driveshaft and the heat shielding from the turbo. Don't have much time as I need to fly out for a funeral later today but no rush at this point as I'll probably be waiting for parts again for another week. One minor annoyance with my current setup is with the short nose q45 r200, I need to drop the diff xmember to drop the driveshaft.

-

After some further research, I think I should probably order some inconel m8x1.25 studs since I'll already have this all apart. I don't want to order the same hardware and run into the same issue down the line. I guess I'll sleep on it and decide tomorrow.

-

Got everything mostly disassembled and came to find my ATP wastegate housing has come loose, likely from the extreme heat cycling but maybe also because my downpipe is not braced. I'll have to disassemble the heat shielding and inspect. I recall I had used nordlock washers, copper locking nuts and studs. 20221202_190416.mp4

-

Managed to get the trans mostly prepped to pull maybe tonight or tomorrow. Had some people ask me for detail pictures about the 240sx trans swap in the late s30 over time so maybe this may be helpful for someone. For the shifter area if you are redoing your fuel and brake lines and decide to keep it all in the tunnel, you will want to add some bends in the line to clearance for serviceability. Also make a custom shift bezel boot from silicone sheet.