Dat73z

Members-

Posts

851 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Dat73z

-

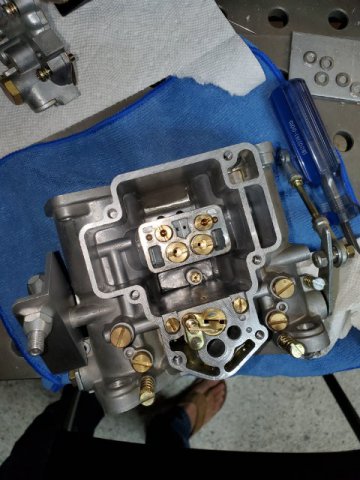

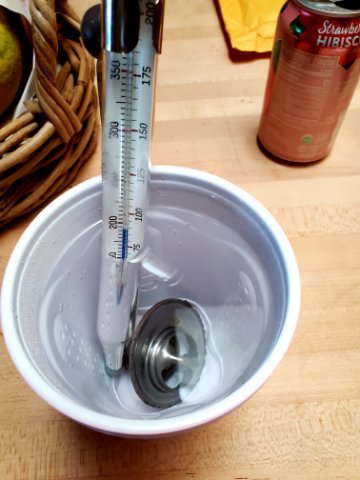

Out of time this morning but I got one carb fully cleaned and back together. Just some quick reference shots of how much loctite 567 I used for sealing. Since I'm still waiting for some jets I'm going to let these fully cure out for 2 days or so before letting them see fuel. However long it takes for my jets to come in.

-

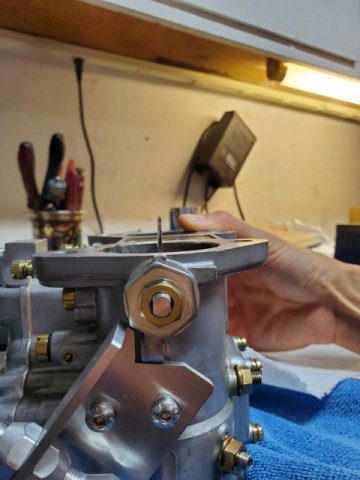

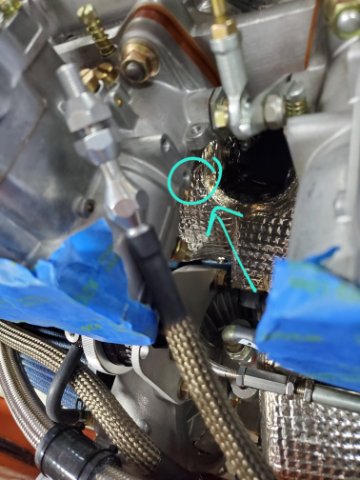

This morning I took a closer look at the carbs. Other than the side mounting areas where it was evident loctite 567 got by, everything looks as it should for a couple hours on the dyno and a few hundred street miles. Just needs some cleanup. Also as a reference for anyone doing this, the locking studs and nuts can also weep a bit of fuel as seen in the pic below. I'm going to seal these as well with a more careful application of loctite 567. I think all sidedraft dcoe style carbs would slightly leak in these areas under boost given the retaining design. Now I get to do this 3x. The joys of triple carbs/itbs...

-

Today my wife and I decided to check out car week by Laguna Seca and Carmel. Lots of amazing cars out there and builds. When I got back in I decided to get back into the build. After driving around for a bit more I still have the imbalance so I pulled off carb #2 which had the largest imbalance pictured above. With the way I set up my fuel system, heat shield, and throttle cable the carbs come off in a matter of minutes. If there is a bent shaft or butterfly I'm not seeing it. It seems there's a bunch of gunk in the barrels of what looks like loctite 567 from sealing the side ports where fuel was leaking. I'm going to clean out the barrels and manifold with carb cleaner, check for leaks, and see if things get back in balance. Edit: thinking about it more I really should get everything white glove clean. I'm glad I sealed the carbs but it's apparent they were in fact leaking badly from the factory at those side threaded areas since the casting there is paper thin and loctite 567 made it into the bores. Out of time to tonight but I'll get an early start on it tom AM

-

I drove the car around quite a bit yesterday evening. Things are running much better. Lots of horn honks and waves, hopefully I can meet more local Datsun people again soon. Unfortunately it seems I may have tweaked the throttle shafts a bit when setting up WOT or something. The carbs were easily balancing before across all cylinders but now on carbs 2 and 3 I get a bit of difference across the barrels on the same carb. I checked the plate positions up top and they are in-line across all the first progression holes. I swapped the plugs for fresh ones and will investigate further. The last time I had to deal with this was on a set of well used triple webers which I ended up rebuilding with new shafts/plates. Hopefully it doesn't get to that point but I've gone through all this before on sidedrafts so nothing new just annoying.

-

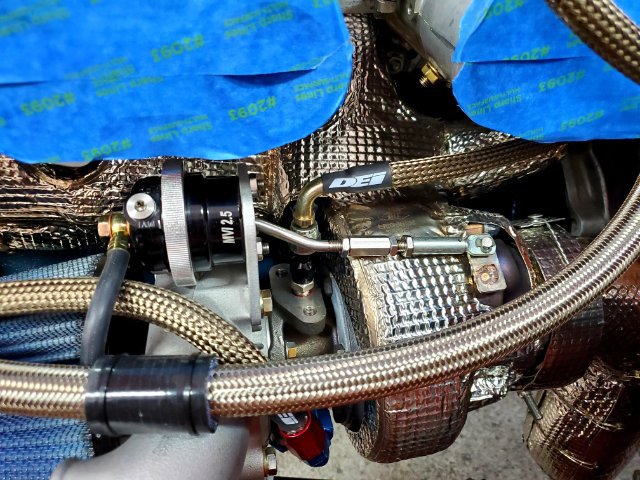

I went on a nice, long test drive after lunch. The car is running cooler and the heatshield is effective enough where the bottom of the carb feels just warm instead of boiling hot after high speed running. I can feel the coolant siphoning through the turbo coolant lines after shutdown as well. It seems everything is working much better so I'll keep shaking things down tonight.

-

I get today off but as with most days off things get busy... I got up early and was able to get everything fully reassembled before heading out. Going to change the oil/filter and start bleeding the cooling system hopefully hit the road in the PM or evening if things don't get too busy.

-

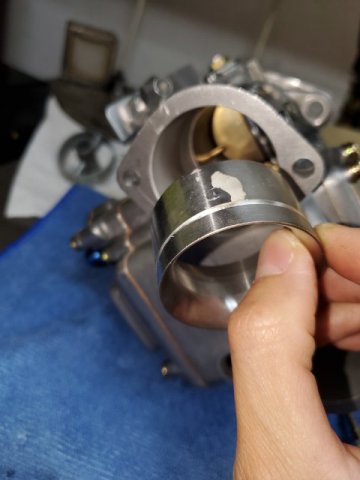

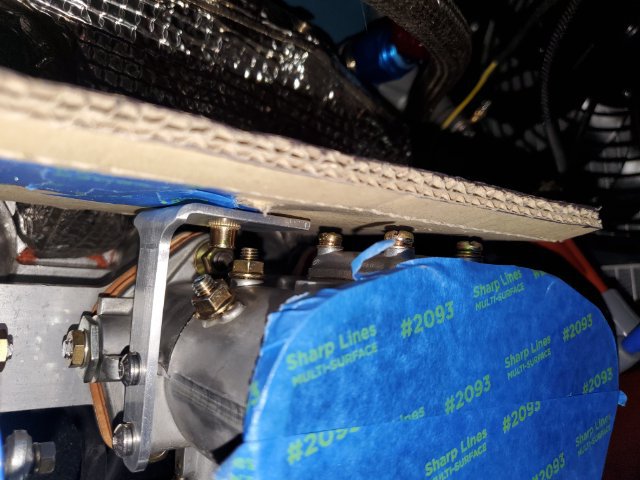

This evening I'm starting in on sealing the carbs and final assembly to hit the road again tomorrow. A critical element is sealing the carbs at the side mounting areas. I think my Mikuni 44s had these same casting areas but my Webers did not. On the OER 47s all 3 of my carbs leak fuel on the lower threaded hole due to how thin the casting is in that area. Lots of fine detail work now but it needs to get done.

-

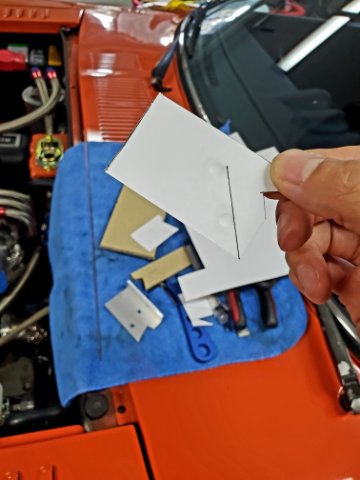

And a quick reference picture from a lower side elevation. The geometry for the additional pieces looks like they will be tricky and I want to minimize gaps. I think the strategy will be to start with one large paper template as to produce the pieces from single sheets and design the folds such that they overlap. Mounting such that the additional shields don't rattle will be challenging as well so I'll need to carefully think through the bracketry for that.

-

@rossman I may need to go down that path as well. I only know one other person locally who has a high HP stroker L turbo and they recommended running no hood lol. That's not an option for me but I've been running with my hood cracked this entire time to evacuate the rising hot air off the turbo...I may need to go vented hood as you suggested but I also have some concepts in my mind for forced airflow via ducted fans using something like this https://www.revotec.com/acatalog/Hose-Adapters-1.html This AM I started measuring out the other pieces of the multi piece heatshield concept. I think I want to attempt to box in the turbo hot side in the teal and provide additional shielding for the fuel lines in the orange. I think this will come later after I get back on the road this weekend as I want to get back to tuning first

-

It's been another busy week but I got the center section of the heatshield done. I didn't take too many pictures as I've had limited time this week but rest assured working the material was a massive pita. I'm just waiting on some grub screws which should come in tomorrow. Everything will come off one more time to acetone wipe off the sharpie marks and gas. Then I will seal all the hardware to the carbs with loctite 567 to prevent fuel leaks under boost. Fortunately I get Friday off so I'll dedicate that day to driving and shaking down the revised setup. I'm hoping all of these cooling and heat shielding upgrades have improved the turbo heat situation.

-

I had maybe 30 mins tonight so I installed the riv nuts on the heat shield brackets. Hopefully tomorrow evening I can start transferring the pattern to the heatshield material.

-

Simplest solution is to find a used crank vent in good condition with the specific outlets you need as they changed over the years. I've never had good luck reusing them (or finding them in good condition) after removing as it's an interference fit, but you may be able to reswage them if you have or can make the tooling. Instead I just found some SS tube which seemed to be a good interference fit and welded on an AN fitting.

-

Just a couple of detail shots showing the clearances, maybe it can be helpful to someone doing something similar. Things are tight with the additional turbo complexity but manageable. Note the radiused edges in the brackets and choice of smooth head hardware was also to prevent the vacuum and other lines running close to not get snagged or cut.

-

Tonight I had an hour or so and was able to fabricate the 2nd heatshield bracket. The heat shield mounts to carbs 1 and 3. I'm planning to inset some rivnuts at the bracket bottoms to ease assembly in the car but want to do some final mockup with the surge tank first just to be sure of the positioning before transferring the design to the heatshield material. Out of time this weekend but hopefully I can get this wrapped up over the next week.

-

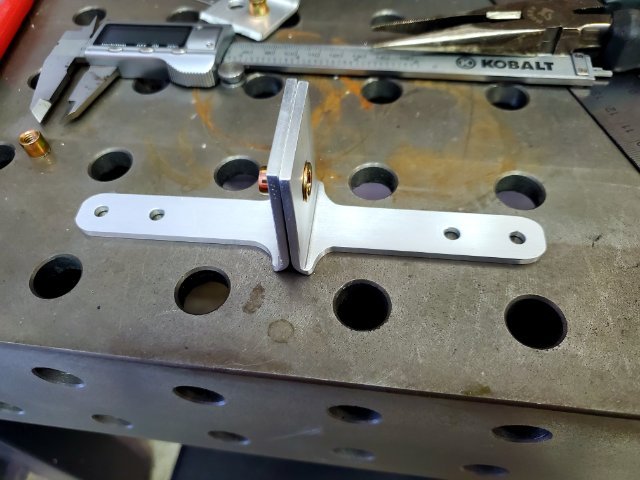

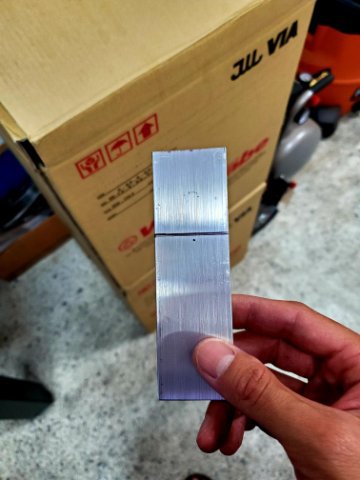

This morning I worked the prototype bracket a bit more. Clearances are tight but I think it's about right. Most inportantly I want the carbs to maintain an air gap. Hopefully I get get a good start on the rear bracket this AM before I need to head out for the day.

-

Thanks @rossman! Someday I want to repaint it...likely not someday soon 😁 Today got busy but tonight I managed to start prototyping the heat shield brackets. My AL stash of questionable quality was dwindling so I decided to pick up some 6061 T6. It seems to work easier than what I had before but of course bending requires annealing to prevent cracking. Hopefully I can get this knocked out tomorrow as the heat shielding is the last major item to do before getting back to road tuning.

-

After tidying up a bit, I think I want to dedicate some time this weekend to finish restoring my JDM Fairlady Z grille. I positioned the cooler packaging such that the OE hood springs and grille could still be used. I think it'll give the car more finished look and hide the oil cooler lines/intercooler a bit.

-

This morning I continued working the heat shield template. I think I'm close to a final concept. Due packaging contraints and serviceability considerations, the heatshield needs to be multiple pieces. I punched a hole for the distributor/BOV vacuum lines and decided to add a relief area for the throttle cable. Unfortunately I've made an absolute mess of my garage this past week so this AM will be dedicated to cleanup.

-

What a ridiculous week, I'm glad it's the weekend. Tonight I trimmed the throttle cable wire to fit and verified WOT. The new cable is silky smooth. Hopefully it doesn't melt in this new position. I also silver soldered the end of the wire to keep it from fraying but it's been a while since I've soldered wire ends so it wasn't perfect but seems to be holding. Just a couple minor reassembly items, the heatshield, and I'm back on the road.

-

Thanks @madkaw and super clean engine bay, I've always liked how you did the valve cover airbox. Yeah it's pretty apparent especially with modern fuels the most challenging aspect of this setup is managing the immense turbo heat. Fortunately, there are many non-asbestos products available on the market now to mitigate this. I was chatting with my friend the other day and he stated the ridiculousness of it pretty well: Imagine this setup in 80's Japan...boosting down the Wangan at 300km/h...everything melting 🤣

-

Last night I was able to get the throttle cable reroute bracket prototyped. I started with a paper template and transferred the general profile to some scrap AL. The angle of approach was pretty tricky as the cable not only needed more clearance from the turbo hot side, but also had to run through a 1/4" gap between the carb heat shield and the surge tank. As with everything on this build, ridiculously tight but I made it work. I also took into consideration for the angle that the cable should be fully controlled in the bellcrank between idle and WOT. Hopefully I can get a break tonight and work on making the bracket look a bit better.

-

I pulled vacuum on the system for an hour and ensured there were no leaks then proceeded to fill. I think I'm going to bleed the car traditionally as well with a no spill funnel and the front elevated as I had the entire system apart and fully drained. So now we have rerouted and shielded turbo coolant lines, new tstat, and new wpump. I am confident the heater core branch won't be boiling anymore since the turbo is no longer hooked up there, but I'll keep monitoring for any issues with the new setup. Last major things to do are finish fabricating the throttle cable bracket and carb heat shielding. Hopefully I can get to that tomorrow. I should probably also change the oil as I'm sure I've flooded it out with gas reworking the throttle setup.

-

Tonight the turbo oil feed extension and Tstat came in so I installed them. Normally I don't like additional fittings/potential leak points but in this case I think it's worthwhile as the oil line now spaces an inch or so off the turbo hot side. I also verified both the new 170 Tstat and prior 160 Tstat were opening and closing at the proper temps. The new Tstat is some Wahler/Borg Warner unit. I'm surprised at the size difference in the opening over the former (I think) Motorad unit. Hopefully tonight I can vacuum test and fill the cooling system...then the cooling system reconfiguration will be complete.

-

240z SCCA vintage race car, restoration

Dat73z replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

That looks really good @AydinZ71. Looking forward to seeing the bodywork finished 👍 -

In reconfiguring my throttle cable last night, I was manipulating the linkages to check throw and as a result found some fuel leaks from the carbs as I was actuating the pump circuits. Not a major issue, but it seems to jive with the feedback I had received from Rebello where at higher boost levels past 10-12psi fuel would start leaking from the carbs. It seems the casting area behind these threaded ports is glass thin with the venturis sitting directly behind. I'm planning to seal up all the threaded holes with grub screws and loctite 567. It feels like there are just a lot of time consuming fine details on this build, but I'm glad I caught it now instead of a fire later.