Dat73z

Members-

Posts

851 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Dat73z

-

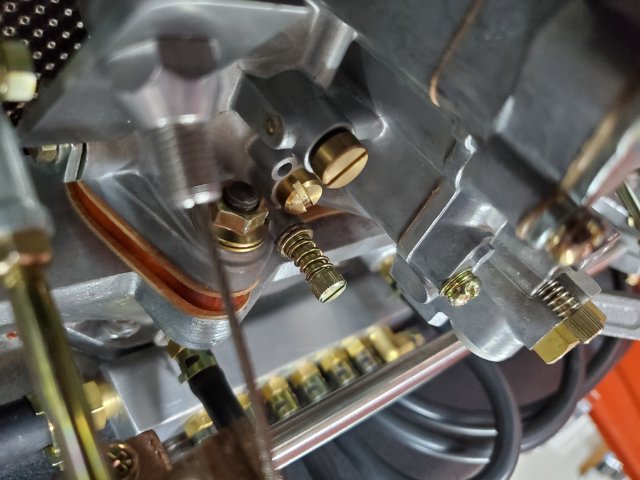

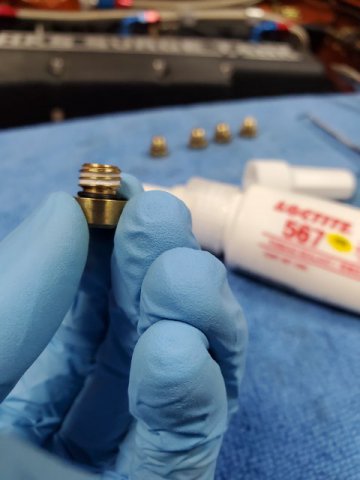

Tonight I saw what looked like light fuel staining near where the cold start mechanisms would be so I went ahead and sealed the caps with loctite. Getting pretty burned out with work this week, but I've been trying to stay true to 10-15mins and 1 thing per day. Hopefully I can get down my list of items to resolve by Nov.

-

This afternoon after work I drove over to my machinists shop to get his opinion. He took a look and started throwing out squish #s, shoulder, and other measurements in thousands of an inch then let me know the work is possible. So I'll take some measurements of exactly where the grooves should be cut then head back over on Saturday to get the idle mix screws machined. Also, after my drive today, the extra tension on the cup washers seems to have helped but there's still an even smaller puddle of fuel on some but not all of the carbs now after boosting around.

-

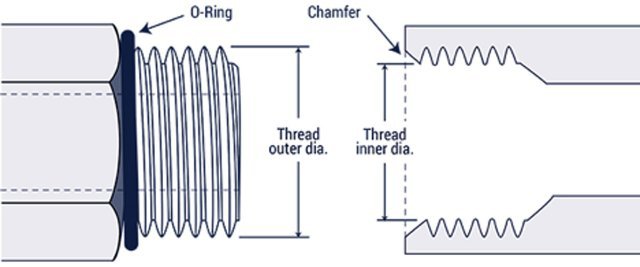

So I think the ultimate solution may be to cut some oring grooves in the threads of the IMSs and seal them that way, like on motorcycle or other carbs. I don't have machining capabilities in my garage, but I'm considering getting a tabletop lathe or something. Or just call my machinist who is down the street. If anyone else has any ideas, let me know.

-

Noodling on this a bit more, I wonder if it would be worthwhile to cut a chamfer at the start of the IMS threads and resize the oring to assist in sealing. Currently IMS surface is flat, the oring dimensions are constrained by the cup washer, pressure is counteracted by the spring tension on the cup washer which I'm playing with shimming now. Almost decades ago, I recall studying oring and squish design in engineering school. I think it may be time to dust some of that off and take a more scientific approach to sealing these carbs under boost. I'd hate to be boosting somewhere and have an engine fire.

-

After more boosting last night still found some fuel leaks by the IMSs. I'm trying shimming the washers above the orings to increase spring tension. Otherwise I'm running out of ideas. The IMSs don't really need adjustment once they're dialed in, but depending on altitude/ambient conditions they may. So a non permanent solution would be preferable.

-

One thing I noticed on my drive last night was a slight rattle coming from under the car. Upon further inspection, I think it may be one of the ebrake hangers. When I redid all of the fuel and brake lines in stainless hardline earlier this year, I routed everything with the suspension at full droop and thus the springs for the ebrake cables were at a different angle. A minor detail that I overlooked. I'm going to try wrapping the section of hardline later tonight in a piece of fuel line or something to keep the spring from rattling on it.

-

So I was able to call TiALSport earlier today, and I'm glad I did. Their tech support is super helpful and actually has experience with boosted applications, and also blowthrough turbo configurations. I'm going to go with the QRJ with the 1.5lb spring. Due to the configurability of the QRJ, they're made on an as-ordered basis. So hopefully there won't be a long lead time for that, but I have another month and a half or so before my dyno date to get it in and installed.

-

After my drive tonight I noticed some small puddles of fuel around the progression/IMS areas again. Fuel leaks sketch me out, so I decided it was time to stop playing games and get these sealed. I cleaned the ports off again, changed orings and sealed the threads with loctite 567. With the progression ports sealed, the only other area the fuel could be coming from are the IMSs. I'll do some more shakedown tomorrow and see if the leaks have been resolved.

-

Had a quick break today and called Greddy tech support. It doesn't sound like the type FV valve will work but to be honest it wasn't a very helpful conversation. So tomorrow if I get a chance I'll give Tial a call. I had one of their big Q series valves maybe a decade ago and recall it was tunable via spring pressure to manifold vacuum.

-

It seems Synapse Engineering Inc. may be out of business which is unfortunate as I wanted to use their Synchronic BOV. I see they have some BOVs on Ebay but I'm not a fan of purchasing new parts with no support. Their phone number is disconnected, and their company info lists as permanently closed/owe taxes. So the search continues for a BOV which can quickly/fully vent under all boost conditions. I think the Greddy Type FV2 may fit the bill but I need to do more research. It's been difficult to actually find good data. Interestingly, most information I've found on BOVs online are not performance oriented, but people asking how to make their turbos flutter like mine is doing.

-

Today my orings came in so I fit them up. I have several sizes to play with so I'll try a few and figure out which one seals once the rain lets up. I haven't gone further with the tuning as I figured everything needs to be absolutely sealed before pressing forward.

-

Hey thanks @rossman, really appreciate the pics. I think your setup looks clean. I saw another Z recently that had a vintage air setup installed by a professional shop and their install didn't look as nice as yours fwiw

-

Since I'm now waiting for parts to resolve some issues, I've been reviewing vintage footage of these types of setups. This is the best reference footage I've seen so far, I think they must've used microphones in the engine bay because to audio is so clear. The seamless transitions on/off boost are what I need to tune for. Transitioning on boost through the dynamic range is really smooth, but due to my BOV flutter I get a rich spike at lift if I'm only partially spooled below 7/8psi or so. Hopefully the parts come in soon, but it seems everything is delayed nowadays.

-

Investigated the progression port covers a bit more. The orings are some obscure metric size. I don't quite have the right sizes (too large or small) so I'll measure them out a bit later today and order an inbetween size to try for a bit more squish but not too much.

-

@LooseRocks there are themostatic plates, but when I disassembled and restored the ZXT oil cooler plate I was under the impression that there is a thermostat built in. Not sure what the best approach here is as it's overcooling on the street even obscured but I think it should work out well for 20min WOT boosting sessions on the track. Unfortunately I still found some smaller puddles of fuel at the carbs. It is certainly less than before. I'm thinking it may be the progression port covers as the orings in there are some tiny metric size. I think I'm going to see if I can find some suitably sized replacements or maybe try some sort of sealing washers. I could easily loctite them and have 100% seal, but that would leave residue and possibly be a pita to remove for service.

-

I put another 30 miles on the car this PM. In 78F weather obscuring the oil cooler by 2/3rds let my oil temps get up to 168 or so over the course of an hour or so on and off the boost, and in stop and go Fri Bay Area traffic. It still drops like a rock when moving but not like it did before. An unintended consequence is my water temps seemed to be slightly higher for this kind of weather, maybe 210. So I think if I'm going to be stuck in traffic during a heat wave like driving through LA or SoCal I need to ensure there is no obstruction at all.

-

Had a few mins this AM so I partially obscured the oil cooler with some cardboard. Clearances are so tight I could barely wedge a piece large enough to obscure the cooler by maybe 2/3rds. With temps dropping into the 50s in the AM now, I'm getting significant oil overcooling issues. The highest temp I've seen was 180sF oil temp at the pan on a record 107F day sitting in traffic after boosting. Hopefully this doesn't block the airflow coming out of the IC too much.

-

There surprisingly isn't a lot of blowthrough dcoe info for datsuns, although there were plenty of off the shelf kits developed for our cars through the decades. Maybe this thread can serve as a goldmine of info for that. After reading all sorts of blowthrough rotary and v8 forums posts ranging from all out drag cars to street and road racing I'm going to see if I can keep the FPR reference at the top hat to see positive pressure only and attempt to resolve the low boost vent/response issue with a normally open BOV. So off boost, the triples should respond as I've tuned them NA, which is a very small portion of the dynamic driving range, but the one which is used the most on the street. At WOT and if I actually get on the boost, my current SSQV BOV fully vents and all is good. But at low boost settings it flutters which sounds cool but leaves some residual pressure in the floats causing enrichment until the engine burns it all off. I've placed and order for the new BOV so hopefully it comes in before my dyno day.

-

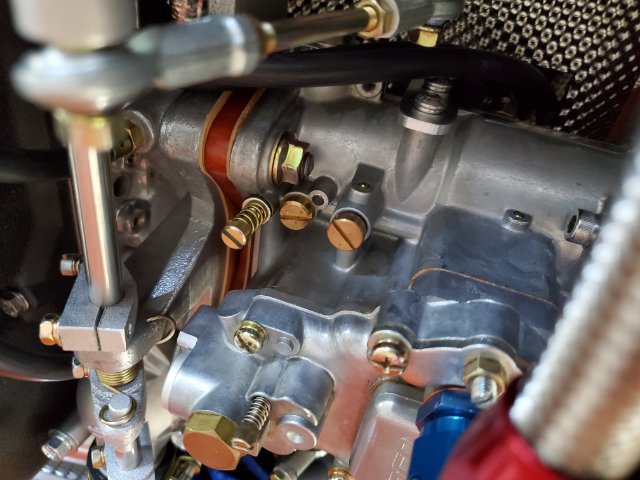

Things got really busy but I was able to spend maybe 10 mins today working on the car. I installed the cup washers and orings then reset the needles to my baseline. Technically I get tomorrow off but I'm working through the weekend too. Hoping I can squeeze a couple hrs in to try using the Gunson to get the idles dialed before heading out on Saturday...just a bunch of little projects which all take time.

-

Tonight I went for a short drive and met with the Datsun Europe people who were really cool. Have been meeting with lots of random people lately I think because JCCS recently wrapped up. It seems the orings on the idle mix screws are working at low boost at least. Tomorrow when the cup washers come in I'm going to try using a Gunson colortune to adjust the idle mix for each cylinder. I tried the listening/lean-rich extremes approach but the car is just too loud so I've been adjusting based on plug color. Of course this is a very iterative and subjective process. Hopefully the Gunson tool will work better.

-

As a temporary stopgap I've installed orings and washers I had around. I ordered the cup washers and to my surprise they'll be here tomorrow so I'll put those on when they get in, I thought it would take a few days to a week. I need to recalibrate my idle mixture screws anyways for each cylinder so the timing is good.

-

I didn't have too much time last night to work on this but upon visial inspection my OER carbs lack the cup washers and orings on the idle mixture screws. I know my last set of weber DCOEs I rebuilt had them. I don't recall if my Mikuni 44s had them. At this point, I think the idle mixture screws and progression port covers are the only areas which I haven't taken a close look at sealing. Fortunately I don't need to remove the carbs again to seal these areas. Everything else seems to be well sealed. So I'll order some cup washers for the idle mix screws and hopefully that will help seal those areas on boost. I also have some ideas if that doesn't work. When boosting through dcoe carbs it is apparent that is a lot of fine attention to detail is required to ensure they are adequately sealed. I've seen some pictures of blowthrough setups where these details weren't addressed and it's apparent from the fuel staining that the carbs were just run with fuel and boost leaks.

-

Went for more shakedown boosting tonight and caught some more fuel leaks. Perhaps from the idle screws or progression port covers on all 3 carbs. They've been bone dry for weeks so its curious it all happened tonight. I'm going to change the o-rings, clean up the area and check again on my drive tomorrow. This weekend I will take the car for a few hour high speed shakdown and visit some friends in the East Bay.

-

3.2 stroker turbo. I could get more out of it, but it's blowthrough. Have a thread in the turbo section of the build so far

-

I'm running a Q45 R200 SN 3.54 rear end. I think our #s are similar though, at 9PSI on Rebello's dyno my engine made 370HP @ 6k rpms, and 370 trq around 4k rpms. I've spun the R compounds in 2nd and going into 3rd. Our driving styles are different, I'm setting my car up for street and occasional HPDE targeting 3-400whp/trq. At 8psi or so I'm happy with the car as-is since I mostly like to go cruising with friends.