Dat73z

Members-

Posts

851 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Dat73z

-

@240Z Turbo apologies I missed your Q on timing. The 123 ignition has a MAP sensor. I pull roughly 1 degree of timing per psi of boost and target 20 all in at 1 bar. I can also control vacuum advance off throttle through the MAP. It was smooth all the way to 7k+ and also through the dynamic driving range before the mechanical failure (crank pulley walking off). This time I never got to redline as I was retuning for the off throttle lean surge before the electrical failure. Edit: I am also assuming the lean surge was caused by overadvancing under vacuum as pulling 3 or 5 degrees of timing resulted in AFRs dropping from 17 lean to 14 before the electrical fire. I added the timing because unknown to me the crank pulley was walking off and resulting in losing timing and shooting fire when unloading the motor. But that was the last data point I got before the car went down yesterday.

-

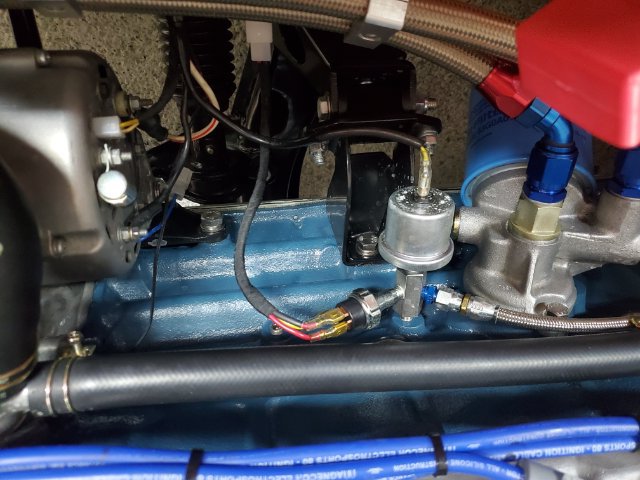

@240Z Turbo here is the configuration. The fuse which is a 30amp didn't blow. I want to say I used 12 gauge for the subharness. Maybe the original wiring was only rated to 20 amps. Not sure, I just need a solid day for this car in particular to really dig into it but my schedule just sucks for building cars for which this is one of a few vehicle projects I have going on concurrently.

-

@240Z Turbo Basically I an using an oil pressure sensor to trigger a relay to provide 12v direct from the battery to the fuel pump green wire in the harness. The 12v relay harness I made is perfectly fine, but downstream from the connector the 50 year old OE wiring is all melted. @DuffyMahoney yeah, a valve adjust and pulling the carbs apart again is in order.

-

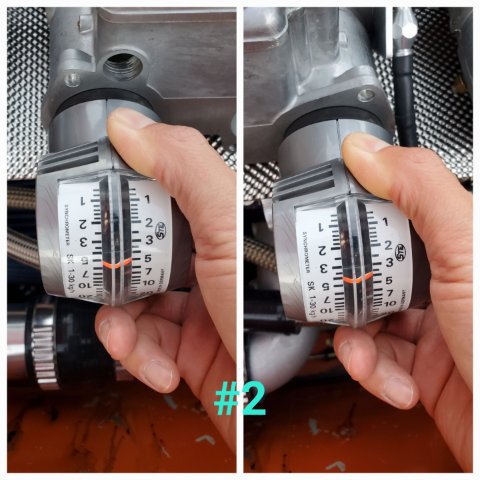

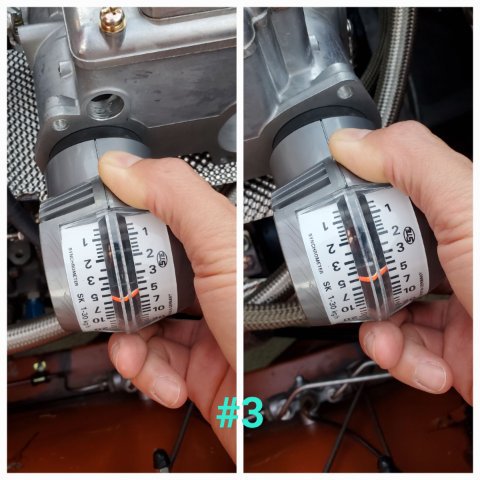

@DuffyMahoney no air bleeds on the OER dcoes, the throttle plates are close with the tap test but slightly imbalanced on the motor. The cammed 3.2 stroker is lumpy and gets off the line fine so the slight imbalance isn't too annoying but since I'm doing the work I may as well try and get it right. Next time I have them off I'll need to reset all of them like new butterflies and plates then test with a vacuum or something. Attached are pics from earlier in the build of the flows. @DuffyMahoney @Zetsaz my ammeter started going crazy when this was all going down but I traced one melted wire to the fuel pump circuit which I'm still using the factory wiring from the dash to the tank. I used an in tank efi walbro 255 which ramps up the pressure under boost so I guess that is one issue and maybe the original wiring couldn't take it. What's interesting is the relay subharness I made to serve that load looks perfectly fine. Another one of my buddies had the same issue a while back, where he put in an electronic fuel pump and it toasted his original harness. Another issue I see is all of the wires are loomed together so I assume a few wires going out could take out other wires they're taped up against. I think I just need to pull the interior later today or this weekend if I have time and start unlooming the harness and assess what I'm really working with as the harnesses on this car look pretty 50+ yr old original. If I can I'd like to upgrade the main power wire to take a 100+amp alternator and like @Zetsaz said just run a voltmeter and get rid of the high current wires into the cabin.

-

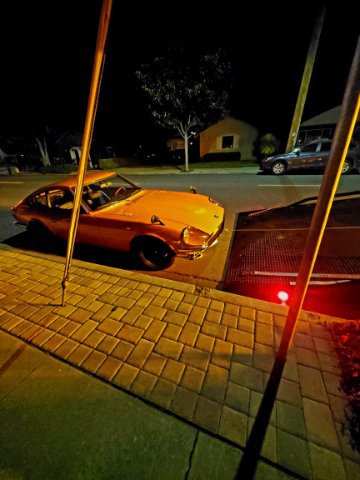

While I was waiting for a tow my buddy told me I should wrap or paint my car blue and call it Devil Z because it's cursed, and I tend to agree. Since this turbo s30z pursuit I've had a slew of crazy ups and downs in life but I need to keep moving forward. As I was getting into boost at high speed I saw the fire and smoke billowing out from under the dash. After the tow home I inspected the area and saw that the original dash harness has melted through the factory tape loom in many areas. It seems the firewall forward is fine but everything is suspect at this point. So I think the strategy will be to start by disassembling the dash and see the full extent of the damage. Worst case a few of my buddies have fully rewired s30zs so that is an option, but watching them do it did not look like a fun process.

-

So I went to fill the gas with some fresh 91 and to test the reduced timing out. Things were going great and the car was running smoother than before. On the way home I was going into boost and the ignition started cutting out. Then a crazy electrical fire started under my dash that extinguished itself. I ended up pushing the car across an 8 lane 60mph expressway during Bay Area rush hour traffic which was crazy and coasted downhill into a residential neighborhood to wait for a tow. I feel like I really can't catch a break, but I guess rewiring the car is the next step in this build.

-

@DuffyMahoney all 6 runners are ganged together and provide the signal to the distributor, BOV, and boost controller. I'm not sure I follow your Q on the throttle plates, the spacing is set by the Mikuni Short Runner. Heres an overhead view of how I have it all laid out.

-

Mechanical TDC looked good and at idle I was around 15btdc so I dialed it back to 13btdc which will also hopefully drop my idle rpm back down to 1000. Plugs also looked good and the bottom of the engine remains bone dry. So after some research I believe I'm experiencing lean surging due to over advancing in vacuum. Afrs get into the 17s off throttle under vacuum and I don't recall what they were before but not in lean into the 17s. When I was losing timing due to the crank pulley walking off I was getting fireballs out the exhaust when unloading the motor or on quick on/off boost transitions like between shifts, so I dialed in more vacuum advance to counteract that. I pulled out 3 degrees of advance to start and see what that does. Other than 3 month old fuel I'm not sure where else to look next. Pulling the carbs off again would be a last resort but I guess I'll shake it down more tomorrow.

-

This evening I got things mostly reassembled and took the car out for a shakedown drive. The alignment is slightly out now which was expected. I should probably order some new tires and book an alignment, but I'm wondering if it's worth it to wait for my new wheels to be finished. The tune is also slightly out. I had it silky smooth before the car went down and now it's jerking off throttle under vacuum and the idle is slightly high at 1.1k rpms or so. So I'll start by rechecking the timing and ensuring mechanical tdc is set correctly to the distributor.

-

Today over lunch I ran the engine up to operating temp and went for a drive NA. Had some issues with the 2.5 needle and seats again so went back and recalibrated everything again- hopefully this will not be a recurring theme. The balance between all 3 carbs was pretty close to where it was last spring with some minor adjustment. As I remembered, carb 2 has some slight imbalance issues due to overextending the linkage when I was setting WOT with my wife at the pedal (oops). I will fix that next season when I have the carbs back off for the next service. I'll let the car cool this afternoon and hopefully this evening I'll get the surge tank back on and be boosting again tomorrow.

-

Since I went for a short drive yesterday evening this AM I performed a quick inspection for leaks. Everything seems bone dry. I'm hoping later today maybe over lunch I can heat cycle out the car. I've been running into timing issues where it's either too early or too late to fire up the car and run it for a few fan cycles since it's so loud.

-

Unfortunately my schedule has been getting crazy this week but I needed to move the car so I set the float heights to 28mm (spec is 29...for slightly earlier tip in) and the engine fired right up after the 2nd crank. I noticed the 2.5 needle and seats are much more sensitive to adjustment than the 1.8s but I got them dialed in. It seems to be running smoother than it was and sounds healthier. But it's been a few months so I don't fully recall. If I have time this PM I would like to burp the cooling system and heat cycle everything but we'll see how the rest of the day pans out. 20230207_161111.mp4

-

This AM I started back in on the carbs. It seems the initial pressure wave when triggering the fuel pump on causes the float bowls to slightly overfill. Then at steady state they maintain level. Or at least that is what I think I'm observing. I believe with the greater seating area of the 2.5 versus 1.8 needle and seat, more force is required to open but I'm not sure about closing force. Either way, these are fairly standard parts and everything was working fine with the 1.8s so I'll play with it more later today as this is the last thing required for a running and driving car.

-

@calZ they are all poly and spherical bearings. This evening I hung the exhaust and finished checking the torque on everything. I then torqued the lug nuts and proceeded to crank for oil and fuel pressure. It seems I need to reset my float heights after the needle and seat swap as some fuel was overflowing into the AVs on carb #3. I'm out of time for tonight but tomorrow I'll fire it up and heat cycle everything. Burp the cooling system, check carb sync, recheck the torque on all the vbands, let it cool then put the surge tank back on for boosting.

-

So after going through the suspension I found a few fasteners loose that I know for sure I had torqued multiple times in the past. Nothing safety related but just random things like the fuel filler plate and others. One thing I've been struggling with this build is random fasteners seems to be vibrating loose over a few thousand miles. I never had these problems for years of hard driving before building around the turbo stroker. I think I need to start drilling and safety wiring everything, along with checking torque on everything every few k miles.

-

Today I started by writing down what I did over the last few months to rebaseline what needs to be done next and also for tuning. I realize I need to go through and write down all my jet settings again as my memory is foggy at this point: 1. 40 -> 45 pump jets 2. 1.8 -> 2.5 needles and seats 3. Cut and reweld hot side charge pipe 4. 170 -> 160 tstat, modify tstat housing 5. New BHJ dual row damper + 10.9 bolt 6. Uprated inconel wastegate hardware 7. New valve cover gasket 8. New front and rear main seals 9. Uprate all boost control lines 4mm -> 6mm 10. Poly trans mount 11. Bead roll cold side charge pipe 12. 275 short rear swift springs + helpers 13. T3 camber top hats 14. New flywheel and PP hardware, new pilot bushing 15. New rear DS wheel bearing, repack and retorqure both rear stubs with new ZX nuts 16. Engine filter, oil, trans fluid, coolant Still left to do: 1. Brace midpipe 2. Finish barreling wheels for 245s 3. Meth injection 4. AC 5. Accusump

-

Thanks @DuffyMahoney. It's been a journey for sure. This afternoon I fully reassembled the driveline and filled the trans with some Amsoil 75w-90. I was going to mount the exhaust but it started raining so I decided to put the car back down and torque down all the suspension again. No sense in rushing at this point as the car's been down for 2 months and basically had the suspension, driveline, brakes and turbo fully serviced along with some upgrades. The plan is to hit everything with a wrench one last time and shake down the car over this week if the rain lets up.

-

This weekend ran away from me but I'm starting back in on the build now. Where I left off I had reassembled the turbo with all new hardware and safety wired all of the inconel shielding back into place, replaced the RMS, and reassembled the clutch pack also with all new hardware. I think the objective this morning will be to shove the trans and driveshaft back in. If I have time this PM I'd like to rehang the exhaust.

-

And one more shot of the turbofans on the turbo build. The front brake clearance with spacers will be the limiting factor here. If I was running smaller or stock brakes then there would be a lot more options. Otherwise 16x8.5-9 will fit easily on the rears or 245 or wider tires with the suspension modifications. I want to run everything square so I can rotate tires

-

Today ran away from me somehow but I'm starting back in on the build now. My wheel faces arrived in from Japan so I started measuring for the barrels. I'll need to get with my builder on Monday to figure out some particulars on the hardware dimensions as everything is tight with the big brakes. I had already swapped in shorter springs earlier in the build thread and camber hats to run 245s with no flares. Since I need more data to proceed I'm getting back into the turbo assembly tonight. I'm really hoping I can get through that soon as it's literally just bolting things together after that.

-

@Zetsazthe flywheel tool is a lisle 23800, I got it new on Amazon for like $30 delivered. The seal tool my buddy designed (this is actually v3, I have all 3 of his prototypes lol). I could give you his contact info if you're on IG not sure if he's selling them but I can vouch his stuff is really quality/high resolution. I posted some pics earlier in the build but it was pretty apparent by the way the oil was being flung out from the flywheel when I took it off that the RMS was for sure leaking so i replaced it. Check the side seals too. But it's kind of annoying cause you don't know for sure if it's all fixed until it's all back together and running lol

-

It's a long weekend for me, and all of my parts are now finally in. So I kicked it off by installing my new OE Nissan RMS with the tool my buddy designed and printed for me. It's a really great tool to aid in the perfect install. I'm going to see if I can get the car completely reassembled this weekend, a few things per day should do it. Tonight I'll see about finishing up the turbo hot side.

-

@240zturbo nice projects. Are the downpipe hardware exposed on all of them? I've seen people mention on roadracing forums to not run a turbo blanket or shielding over the hardware, I've been wondering if that could be an issue. It was a nice weekend and since I'm still waiting on parts for reassembly I decided to pick up some tools for next week. A set of 3d printed L seal install tools from my buddy and a flywheel holding tool so I can stop asking my wife/neighbors/buddies for help at random hours.

-

@240zturbo just to keep it simple and in one post, in my research there are ultimately 5 things seem to solve all turbo hardware failure issues: 1. Upsizing hardware to M10 2. Inconel or high temp alloys 3. Some form of mechanical locking hardware 4. Do not overtorque materials to yield 5. Don't trap heat in Edit: added 5 but again since this is a carb setup everything is conpromise

-

Tonight I test fit the rest of the stage 8 and modified hardware to the inconel shielding. Things don't fit as well as they used to, mostly due to the hardware on the stage 8 being larger. Since the inconel shielding is just two layers of inconel with a ceramic layer sandwiched inbetween, I'll just bend the shielding a bit to hug nicer before the final safety wiring. Debatably, Ive read online that inconel shielding and turbo blankets trap heat in allowing turbo hardware to heat higher and longer than they would exposed to free air resulting in high temp creep for the hardware. But since I drive this car on the street I'm hoping to find a compromise since I've found through this build that carbs and ethanol fuel in bowls above the turbo really benefit from the shielding. If it was a pure track machine I'd lean towards no shielding around the hardware at all for reliability since the carb radiant heat issues start coming up in stop and go traffic only. Edit: Just to document this and perhaps only those that have run these setups know (which is the point of documenting this build thread since I've never seen this info out there...) but one thing I've found is when you're boosting, the atomization of the fuel and charge air cause the carbs to get ice cold to the touch. So even when you've parked and heat soaked to where the carbs have boiled over/fuel had completely evaporated and you will literally burn skin touching the carbs...after the first mile or so of boosting the carbs get ice cold and can have condensation building outside of them depending on ambient weather conditions. These are details I wanted to document here I've never found researching these setups.