Dat73z

Members-

Posts

851 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Dat73z

-

-

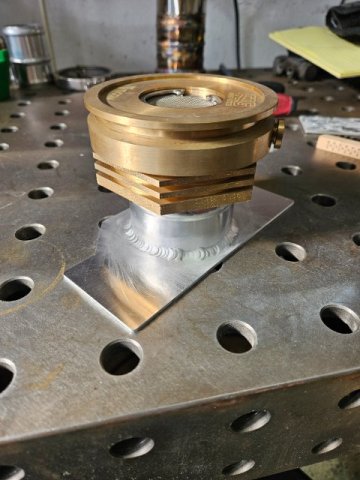

Heater Lines: For the heater lines I evaluated several options including AN, HS-79, and other fitting types. Ultimately I wanted more of an OE spec aesthetic so I purchased the following bulkhead fittings from Vintage Air: O-Ring Bulkhead Heater Fittings For 5/8 Inch Hose - Straight NO 10 Hose Fitting (34215-VUG) 90-Degree O-Ring Heater Fitting for 5/8-Inch Hose (121018) I decided to run the OEM 240z heater hoses cut at the firewall and found that the bulkhead fittings were just slightly too long. So I cut them back to the base of the second hose rib from the top and bead rolled the tube right below the 3rd hose rib from the top to securely grip the hose. When installed on the firewall it really gives an OE aesthetic, especially running the trimmed OEM hoses. More details to follow.

-

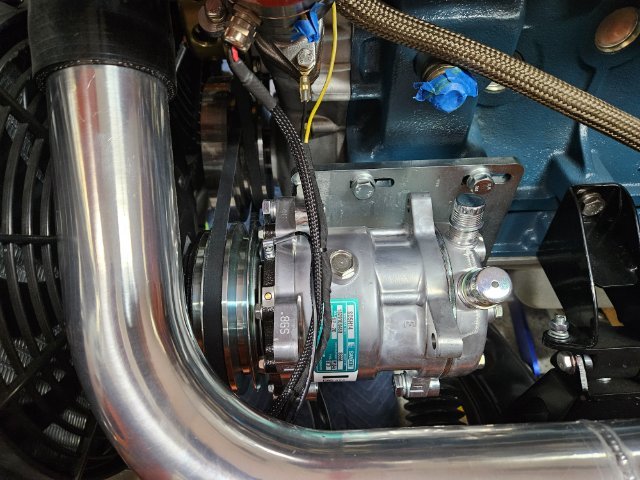

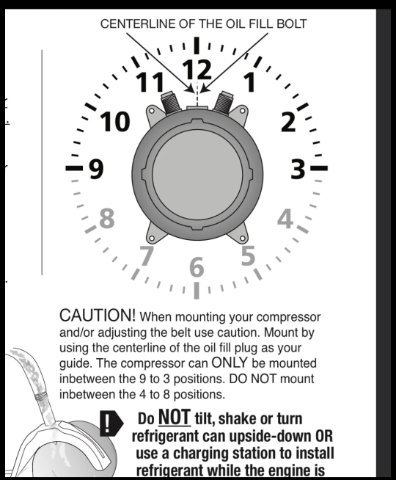

Compressor: For the compressor I'm using a Sanden SD 508 Compressor Double V-groove pulley Standard Finish (04808-VUA). Nowadays you can also get an electric compressor and mount it anywhere, but I decided to stay mechanical. There are dozens of Sanden SD 508 compressor configurations you can order, including rear fitting exits, and even custom machined rear caps. I especially liked the version where the charge ports for the high and low side were directly on the back plate but could not use that on my setup. I chose the standard top exit for packaging considerations as the turbo sits behind the compressor and I wanted to have the space directly behind to run a 4-5inch pipe from the turbo inlet turning down to the steering rack/front swaybar area of the splash pan to pick up cooler filtered air from under the engine bay. The compressor itself can be clocked, and the rear plate can be removed and clocked as well if needed so long as the centerline of the oil fill bolt does not exceed the 9:00 or 3:00 positions. I chose to clock around 9:00 to clear my intercooler charge piping and new ignition coil location. The mounting bracket is a ZSM Custom unit (a very quality piece, thanks to Zach) which I modified by milling the slots further to push the compressor back to clear my dual spals and engage the first row of the compressor dual row pulley (mating to Rebello spec BHJ dual row damper on F54 block). I have conveyed this information to ZSM Custom as well for future brackets. There are also several other bracket and fabrication options available but I decided not to go with any of those. I'll get some updated photos up of the final configuration later.

-

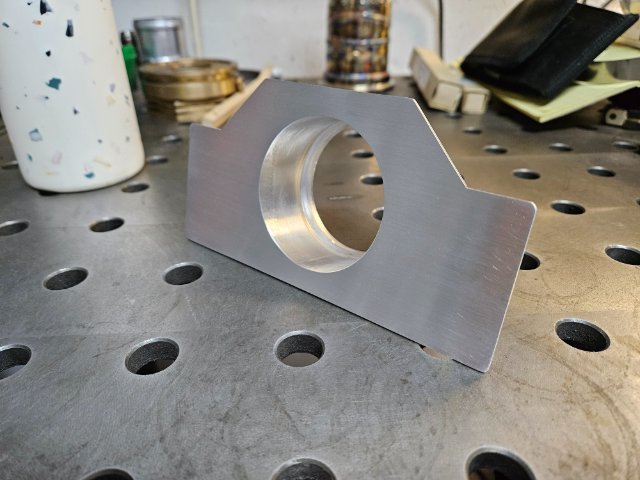

Center Vent: Nowadays you can 3d print anything, but I wanted to use what I had on hand. And what I had on hand was scrap AL plate and 2.5" intercooler tubing. I tig welded the two components together and flattened the flange with a sanding block due to minor warpage from welding. Note that I found it's better to weld the plate to the tubing first before cutting the hole due to warpage.

-

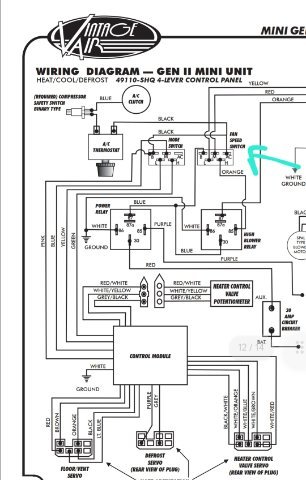

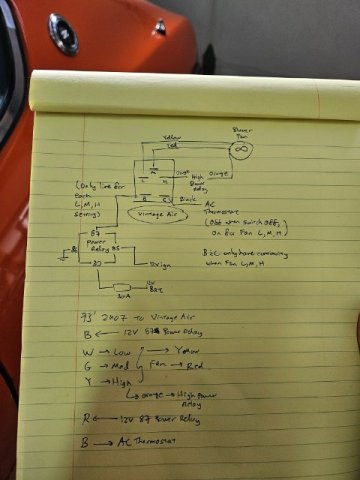

Fan Switch: I've mapped out the wiring and what I found was the vintage air switch has 5 terminals: 12v power, Fan L, Fan M, Fan H, and 12v switched only with Fan on to AC thermostat switch then onto the compressor clutch. The OE blower switch for my 73 at least has 6 terminals: Black (probably former ground) which is switched with Fan L, Fan M, Fan H, and a Red (formerly Blower 12v) + Blue wire (I believe unused in OE harness but for AC power) which is switched only with Fan on. So to go from 5 wire vintage air to 6 wire OE, I would split the vintage air 12v relayed switch power between the OE switch Black and Red wires (to power the fan and kick on the compressor clutch only when Fan on). Will update with better wiring drawing later unless someone else wants to help out.

-

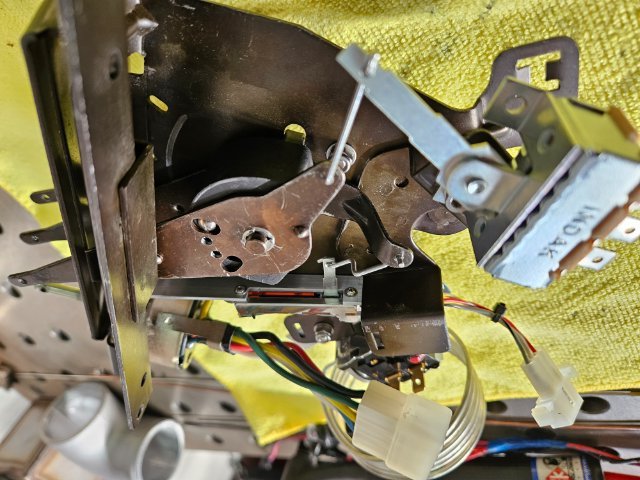

Starting a Vintage Air Gen II Mini install thread. Specifically this is going into my HybridZ, a 1973 240z which is a triple carb blowthrough turbocharged L running a FMIC, oil cooler, and retaining the stock hood springs and front valence. Factory dash, radio, and gauge mounting. Nissan Versa EPS. Wizard cooling AL rad with dual Spal fans. The same concepts would apply for any Z install, but packaging considerations may differ. Each post will focus on a specific aspect so hopefully it'll be easier to digest for the DIYer. I'll attempt to edit and add more details over time. Controls: What I found researching is most either discard their OEM controls, or perform a partial retrofit where some OE levers are used, OE lever throws may be incorrect, and it seems everyone modifies their OE housing to accept an aftermarket blower switch. I wanted retain the full look and feel of the OEM HVAC controls including the OE blower switch and levers + lever throws. It's important to note that the Vintage Air unit I selected uses 4 switches. I also included the Vintage Air part #'s used as applicable: 1. Fan (Off, Low, Med, High) - Rotary (OEM Switch Used) 2. AC Thermostat (Off -> Cold) - Linear (11088-VUT) 3. Heater Temp (Off -> Hot) - Linear (11212-SUA) 4. Mode (Defrost, Upper Vents, Lower Vents, Upper/Lower Bi-Level) - Linear (11430-VUS) For functionality and less to remember in the car what I'm going for is when all levers are to the right AC Thermostat is Off, heater is Hot, Vents are Upper/Lower Bi-Level. When all levers are to the left AC Thermostat is On, heater is Off, Vents are Defrost. So basically all left Cold, all right Hot. Note that the wires on the Mode switch can easily be moved around for any custom order of control, but it's important to get the mounting orientation of the AC Thermostat (bimetal thermostat) and Heater (potentiometer) correct to where you want them. I used 1/16" AL and SS tig wire for the linkage rods. For the Mode select I added 2 detent positions for a total of 4 including the factory 2 (chamfer the new holes a bit where the bearing rides for positive engagement and smooth disengagement). For the AC Thermostat I added an overtravel stop on the left/off position as I noticed even the OE lever would overtravel and crack the hvac control panel on almost every panel I've inspected so consider that an improvement over stock 50 years later 😆. For the bracketry I used some Home Depot scrap AL L stock I had left over from my wife's garden. I'll get those dimensions later. In the videos everything is dry with no grease so while things are already smooth with no binding they will get much better on final assembly. My plan is to black zinc coat everything but the issue I am having now is finding someone local in the Bay Area CA who will do zinc black chromate for larger parts. So perhaps I will run it patina as I'd rather not paint and have the sliding/friction areas gum up the grease. Pictures attached detail the arrangement, clearances, and function. 20241109_092059.mp4 Controls.mp4

-

Replying to FAQ's - Dat73z

Dat73z replied to NewZed's topic in Brakes, Wheels, Suspension and Chassis

I am using tig as that is all I currently have available but mig would work as well with small wire. The key with the tig is to focus the arc on the cast yoke, a light dab of filler, wash the bead onto the cap then immediately get out of it and force cool. Another option could be to plate in like below and perhaps there are already washers of the correct 15mm size out there. Welding caps is apparently very common for the 4x4 guys, and they do it on high speed applications like driveshafts/axles. Worst case I already know it's easily serviceable as I had to get the poor quality joint out. I'm really hoping this bearing will last another 50 years like the original 😂 but we will see. -

Replying to FAQ's - Dat73z

Dat73z replied to NewZed's topic in Brakes, Wheels, Suspension and Chassis

Thanks @NewZed. Didn't realize that was a thing. Updated my post per your suggestion. -

Like many other Zs my 50+yr old staked ujoints were making some clicky play and of course there is not much good information out there. After some research online, the staked ujoints can be replaced but restaking them properly requires a special tool which is quite expensive (500$ to a few thousand). Also many shops will not touch these components for liability reasons. So what I did was I carefully ground down the stakes with a dremel tool and pressed out the old ujoints. For the new ujoints I actually had to do the job twice as I initially purchased some ujoints recommended by the classic zcar forums. What I found was the caps were so soft that they ovalled out when pressing in and caused binding in the joint. The country of manufacture were not specified on the boxes, and when I cut the joints out to redo the crosses were also soft. After many years of dealing with poor quality aftermarket parts, I should have known better and the solution I found was to purchase high quality Made in Japan Toyo joints PN ST-1540 (15mmx40mm), and when pressing these in the caps do not distort or cause binding. I believe this is an OEM part and OE supplier. Pressing the new joints in, you need to be careful and press the caps to the appropriate depth to achieve 40mm cap-to-cap, centered in the yokes on either end of the cross. Similar to what is done in the 4x4 communities I decided to tack weld where the old stakes were, 4 per joint and air cool after each tack as to not overheat the parts. I know this is much stronger than the factory arrangement as I was able to press the OEM caps past the OE stakes whereas I could not actually press out my first install attempt (before I realized the poor quality bearing issue) with a 20 ton press without exactly grinding down the spot welds for fear of bending the yoke ears (the poor quality soft caps were all kinds of mushrooming out and distorting unlike the OE hardened caps). Hopefully this helps someone. This has been on my to do list for the better part of a decade and I know from inspecting many columns and steering shafts over the years that there are a lot of worn joints out there. Edit: per suggestion from @NewZed the joints which did not work are as follows: https://www.driveshaftparts.com/index.php?route=product/product&product_id=1100 From this thread at classic Z cars: https://www.classiczcars.com/forums/topic/63434-steer-column-u-joints/?do=findComment&comment=629099 When I was researching the above joint, it seems many of the same appearance above are sold under different name brands are coming out of China, probably from the same or similar factories. Also some tips: I practiced the tacks on a few spare caps I had laying around and they blow through super easy compared to thicker driveshaft ujoint caps. So focus your torch on the cast yoke, one small dab of filler, and lightly wash the filler down onto the cap. Work quick so you put the minimum heat into the parts. I used tig as that is what I currently have available but mig with small wire may work as well. Consolidating comments to FAQ from discussion thread: Another option could be to plate in like below- I did check and 15mm washers are available. Due to the construction of the s30 steering yokes, I'd recommend washers sunk into the holes versus plating above the recessed bearing surface so the bearing is fully captive and cannot move. This will make sense if you are servicing the joints and have the parts in your hands. See picture of washers welded to yoke ears. This way per @NewZed comments the metallurgical properties of the bearing caps are not affected.

-

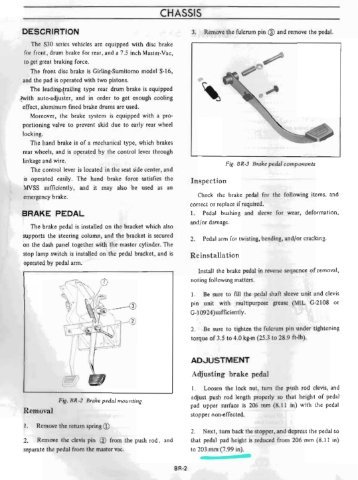

A minor point on the larger EPS systems as this information wasn't readily out there when I was researching. For the Versa unit, I clearanced the brake pedal then plated it back in for reinforcement to achieve the OE pedal position as a starting point, otherwise the pedal would need to be adjusted downwards to clear the EPS gearbox assembly. This allows a full range of adjustment and is not necessarily a negative as ime getting the stock s30 pedals closer helps me in heel toe but def something to consider in EPS options if you have a preference for pedal position.

-

A musician's therapist (The $300 Z)

Dat73z replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Yes the regular kit will fit under RKRs 15x8 +0. Here is a pic from like 10yrs ago when I was still daily driving my Z, you can see the T3 big wilwoods peeking out under the rkrs I took a bunch of pictures and measurements with rkrs and watanabe/several other wheels a couple yrs back when I decided to go ZCG due to the limitations on the t3 kit. I also ran a 1" wilwood MC but would not recommend it today as the unit leaked internally and externally so I went new OEM. Will DM you those later when I get some time to dig them up. -

A musician's therapist (The $300 Z)

Dat73z replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

The regular t3 wilwood BBK is really nice, I ran it for many years and miles under a set of 15x8 Rota RKRs which were one of the only 15s I found that would fit that setup. The watanabe 15s don't fit due to the inner barrel design. The ebrake setup where the cable pinched the rear brake pads was not the best ime and I always kept the car in gear when parked as it would sometimes roll. I almost forgot about the t3 sale. Do the hubs you got have the same offset as the OE? Nice build progress 😁 -

I tried it both ways and cutting the hole after is definitely the way to go. I used a copper heat sink as well and got some very minor warpage which I was able to lightly knock down with a sanding block. Definitely not my best work but it'll never be seen.

- 1 reply

-

- 1

-

-

Yes I also cut the notch and modified the brake pedal slightly for my preferred position + and plated in with 1/8 steel for reinforcement. I'd be curious about steering delay as @calZ mentioned. Self centering/wandering I wonder what alignment settings people were running. I've always been pushing a few degrees more positive caster since switching over to 225 (soon 245) RComps, enough where my front apron corners are trimmed a bit.

-

Fabricating and tig welding several AL pieces this weekend. Basically thin wall 0.080" intercooler/charge piping to thin AL maybe 14 gauge. To minimize warping would you cut the hole before or after welding? Don't need full penetration so I'll use whatever thinest filler wire I have on hand and control the heat the best I can.

-

Still waiting for parts/materials and I've been doing a bunch of fabrication work in the background. I was chatting with my machinist the other day and it's amazing how supply chain for many parts and materials still hasn't caught up to pre-covid times. One of my objectives for the build was to run AC and Power Steering, so when putting together the first iteration of the build a few years back I measured and intentionally fabricated around future component locations.

-

Fuel system is set up for carbs, as recommended by Aeromotive for carb forced induction applications. The setup is for rock solid base pressure but also maximum volume which is very important in high fueling demand FI carb applications. I haven't been posting much as life has been crazy busy but the build goes on in the background. After the trans swap I determined I could no longer use my fuel line routing so I've upsized to SS hardline -8 feed and -10 return while also upsizing the regulator and fuel pump. The fuel pump is a walbro 450LPH, which I'm planning to run single but could also go double mounted inside an in-tank surge tank with an integral Pierburg lift pump. The fittings are full flow so there is minimal restriction in the feed/return. New manifold, turbo, and other hot parts went out for shielding last month so hopefully those come back soon.

-

Following on my previous post, I had my steering column modified by TruPig Motorsports which utilizes a Nissan Versa EPS unit. With the design of this retrofit, the EPS while large is able to just fit in with the motor and control module clocked up running a cable throttle and Vintage Air Gen II Mini HVAC unit. I think it would still be possible to fit a DBW actuator back there as well. Hope this helps someone in the future, it was impossible for me to find any information on fitting an OE EPS unit (not smaller ATV/Powersports units), DBW and AC behind the s30 dash other than people mentioning it is too tight/will not fit.

-

Bumping the power steering thread. I'm curious if anyone has adapted the Prius EPS to the s30 chassis? It seems the Prius unit, being plug and play with it's standalone EPS ECU is desirable and easily adaptable to just about any vehicle. Also much more economical at ~$100 for a complete Prius junkyard unit versus the $1500+ for the aftermarket adaptations available today. Edit: Adding a link here for some of the known torque sensing EPS from cars found in junkyards today that could be good and economical candidates: https://www.therangerstation.com/tech/toyota-electric-power-steering-eps-conversion/

-

It's been a busy year but I've been making progress on the build. Since the last update I've installed a CD00A transmission, had a AL driveshaft made up, performed some retrofit modifications on the SK50s for boost/fuel control + swapped venturis, and in the final stages of the cnc intake manifold. This winter I'd like to wrap up fabrication on some new stainless fuel lines and the exhaust. If I can swing a trip down to SoCal I'll drop off the new exhaust manifold, turbo, and downpipe for inconel shielding.

-

Had to take a break for a couple of months and go on a bunch of family trips. A few left to go but long lead-time parts are trickling back in. Had my vintage SK50s fully restored by Kyusha House as the older castings are better suited for the surge tank, they look fantastic. Once I get back in from traveling will see what it'll take to get the custom intake manifold cnc'd.

-

I had a couple of hrs this morning so I stripped out the old turbo setup and started mocking up the new Vband G series and wastegate. There is a lot of fabrication work ahead and it starts with mocking up all the hard parts in the car.

-

Life got busy but I recently started working on the build again. Since the last post I've been cleaning out the garage and figuring out where things are at. All of the new suspension is on and I pulled the midpipe to begin refabrication around the new turbo setup. I also sent the vintage SK 50s out for restoration and started assembling my wheels with the 245s for more traction.

-

It has been a ridiculous month and I had to take a break from the project due to working insane hours and balancing family time, but I'm back at it again. Since the last update I wrapped up the bulk of the suspension and brakes upgrades and started tearing back into the turbo aspects. I need to fully mock up the new manifolds and turbo setups into the car before we continue with the new cnc intake manifold setup so I've started tearing everything back out again. This will also allow me to refabricate my midpipe to downpipe connection.