BJSZED

Members-

Posts

135 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by BJSZED

-

I think the Sniper is for 250 hp plus.....if you do it, make a thread. Almost went that option as well. Also, a better option than the fuel command center is the Rob MC Powersurge, no float or wonky vent set-up....it's fed the same with a low pressure pump. Some guys are gutting the command center float and setting it up like the Rob MC unit.

-

I changed my descriptions to compressed, less confusion. I don't think a 280z would be any different as far as shaft length changes, as in getting longer under compression. I believe the basic design is the same other than the strut assembly length. On the 240z the half shafts are really close to fully compressed at full droop, probably not much more than an 1/8" play left. I was pretty worried about it until my friend showed me the light ! Could possibly be an issue if lifting the left rear wheel on a road course with the extra side pressure on the other wheel or the weight of the diff moving on the mustache bar bushings....dunno ?

-

With the left halfshaft bolted in place at the wheel side and the suspension at full droop, there is little play when bolting the left inner side up. When the suspension is compressed there is more play on the inner side when bolting them up. Anyone having a hard time getting them in should compress the suspension slightly and in they go. I was quite worried about it and was going to run the suspension through full travel without the spring but my drag racing buddy came over and showed me how the shaft length got longer as the suspension went up. There is a thread somewhere on here in which someone ran the suspension without a spring and shaft length was shortest at full droop and got longer the more the suspension was compressed.

-

I went through this last winter. Replaced R180 with R200 in 240z. I had halfshafts from both and they measured exactly the same, compressed and extended. Ended up using the R180 halfshafts as they were in better shape. Had read about the binding issue so that was thoroughly checked out and halfshafts were compressed most at full droop. The halfshafts got longer as the suspension compessed. No issues driving.

-

Thanks Enzo, Also, I ran mine last summer without swapping the fuel regulator from the throttle body to the FCC center. It ran well regardless but our 400 hp units are designed to run at 43 psi and the FCC regulator is 58 psi. The instructions from fitech are to swap the regulators so the 43 psi is in the FCC center. This way the fuel trim wont be compensating for the increased pressure. For someone running without the FCC this doesn't apply as the 43 psi throttle body regulator will function as designed because of the return from throttle body being hooked up. I found most helpful info on facebook fitech owners groups. You gotta get her fired up ! I'm dying to get mine out again but my wife has me doing house reno's instead. Told her she has just until the end of April !

-

Sorry, if I wasn't clear in my post but the core is leaking. It's not out but is leaking. The blower motor box is out and have seen the leak with my boroscope. Thanks for your input.

-

I haven't pulled my heater core out yet but it's leaking. While I do this I'm going to change the heater valve and hoses. My question is, should I get an aftermarket core and valve or stick with OEM? I'm keeping the car long term and don't want to pull it again. Is a factory new unit the way to go, seeing it's been sitting in a warehouse since the 70's and would the seals be dried up in the new valve if it's been sitting around on a warehouse shelf for the same time? I haven't had much luck with getting rad's worked on so prefer new as opposed to fixing what I have. thanks, and any input appreciated.

-

That's the way the coolant passage casting is....mine was like that and didn't even have enough aluminum for the threads all the way in. Seal the threads with a good sealant and don't overtighten.

-

You can get the felpro seals at rockauto.com much cheaper

-

You said the head was gone over. If the valves were removed, were the same seals re-used? If so, they are likely damaged , just a thought? Vacuum is highest under deceleration, sucks the oil past the seals.

-

Any updates ? I've been checking on Auszcar but thought I would harass you here for us North Americans. Interested in how your plenum divider in the Clifford manifold worked out. Did it improve low end torque? I would think the delayed secondary's would be an improvement as well.

-

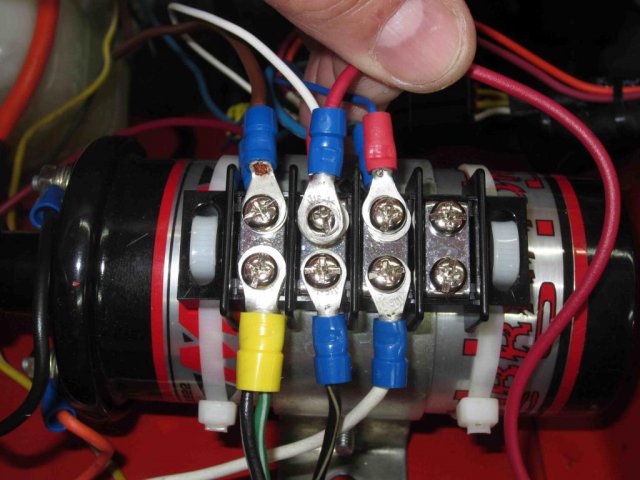

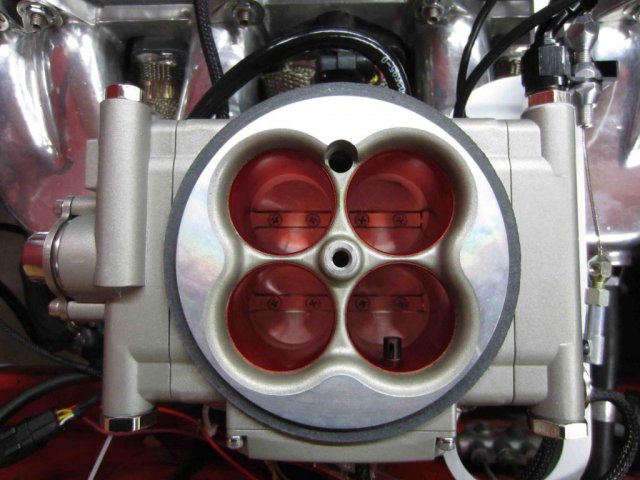

Enzo, The rear throttle plates should open 90 degrees ( mine do ) but more importantly they should open at exactly the same time as the front blades. Fitech has had been inconsistent with their factory adjustments. The fact that your rears don't open fully probably doesn't really matter as there is more than enough cfm for our little motors but on a big ass V8 it would. Since the fuel is injected above the throttle plates, the front and rears should be perfectly in sync. My guess is your front and rears are out of sync and that can be adjusted with the secondary screw. Fitech has info on doing this on their site and it has been discussed on www.chevelles.com. The linkage itself can and sometimes needs to be adjusted as well. This out of sync operation will also hugely affect how the ported vacuum circuit works as it is tapped above the rear throttle plates. I believe you are running manifold vacuum to your dizzy so that wont matter in your case. Again, very happy with the operation of the fitech but like just about everything else in the automotive aftermarket, tweaking is commonly required. Brent

-

Thanks Enzo, That's pretty much what I was going to do when making the phenolic spacer, form it out the back like you did to shield the IAC. Probably should have a shield of Aluminum there too. I was checking out the kits Chickenman was referring to from Jegs and Summit but if I can find some flat Aluminum I could make my own. My engine runs cool and haven't had any heat soak or similar issues but I really want to protect the IAC. I also briefly considered turning the throttle body 90 degrees since all throttle blades open at the same time, there wouldn't be an issue with the dual plenum. The throttle cable would run straight from the firewall but I would have had to modify the intake stud hole position or the throttle body. Shield is more simple and less permanent but it would have looked better turned 90 degrees.

-

Thanks, I can't have one that's too thick so I ordered some 12" x 12" sheets on ebay in 5 mm and 10 mm. The quality is good (used same before for fuel pump spacer) and its large enough for mistakes. I'm going to shape it so it sticks out the back of the throttle body to shield the IAC valve. If it cracks over the IAC then plan B will be stainless or aluminum shield or a combo with the phenolic spacer. I don't know what's worse, waiting for spring or waiting for something from china post. Also, got the Nissan OEM, Aisin made thermostat you suggested and what a difference from the Stant. Very accurate opening temps ( on the stove ) and larger opening diameter.

-

Beauty is in the eye of the beholder...definitely A for effort and for trying something new. Maybe in a safari type car ?

-

Holy crap, that's horrible. What about rigging up a garden hose with some kind of adapter and reverse flushing from the thermostat housing (thermostat removed). You could flush everything from the head out the hole in the front case from the removed water pump. After that's done, you could flush again from the block drain towards the removed pump. Don't be surprised if the head gasket leaks when you're all done, or shortly thereafter.

-

I bought my Z 1-1/2 years ago....barely was able to buy it from the guy. He had backed out on a previous deal with cash in hand. I have since improved the car and asked if he was interested in seeing it. Response was " outta sight, outta mind ". Poor bastard, he sold the car thinking he was going to buy a boat for the family and it never happened. I'm going to the grave with this car. I bought it just before pricing got really crazy.

-

in fact go to the 2nd page in this sub forum

-

If you check back a few months, there was a thread about those very seats.

-

When I needed a phenolic fuel pump spacer and couldn't order one, I ordered a small sheet of the stuff off ebay. Was cheap but took forever to get from china, lol. Maybe I will try to get another sheet of the stuff, could possibly make the throttle body spacer stick further out the back under the IAC. Thanks for all the suggestions, will definately order an OEM thermostat. And yes, the current one is Stant. Appreciate your time.

-

The manifold doesn't really get that hot or the throttle body. The headers are coated and the primary sections just under the manifold are wrapped. I run a 180 thermostat and actually was thinking of running 190 instead. The previous owner ran a 195 thermostat with the L26. I just run the car May until the first salt. At the end of the season, on the highway the temperatures would drop to 150 with ambient temps about 50f. I plan on checking fitech's temp sensor which I read can read too low. It's in the thermostat housing. My concern is really the IAC valve as it sits just above the header pipes. I strapped an extra wad under the valve which seems to have worked but I may make an aluminum or stainless shield like you suggest but just under the IAC valve. Not into a big heat shield unless it proves necessary. System works great, basically like oem injection and once I get the timing dialed in will be perfect. Fitech offers timing control but not this model with the smaller injectors and the system is not upgradable. Also, if is there is a general guide to what the L28 likes for A/F ratio's. The system is disconnected now but I believe I have it set for 14.7 idle, 15.0 cruise and 12.7 full throttle. Like I said no dyno's around here so looking for L28 generalizations.

-

I believe he bought that car from the states approx. a year ago for somewhere in the $1000.00 to $3000.00 range.....read about it maybe on ontariozcar.com. The picture on the trailer is from when he brought it back.

-

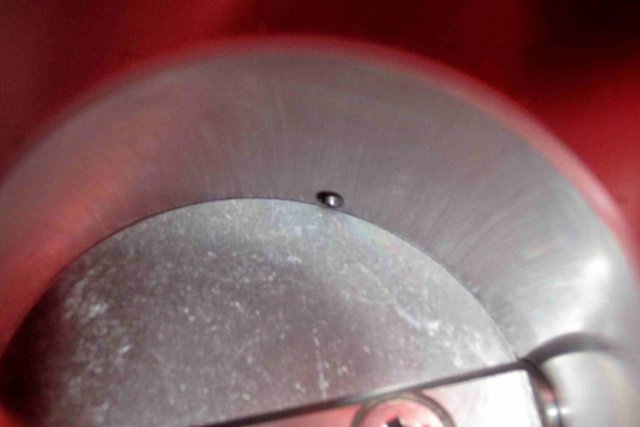

Thanks for the suggestion. Is there a minimum distance? That was more of a temporary way of isolating my MSD box while testing. That way I could easily return to running solely off the dizzy although I was thinking of keeping something similar in case of MSD failure. It's pretty much just the wire connections that are normally just behind the stock coil with the exception of a tach adapter while running the MSD box. One other thing I was considering is removing the header wrap under the intake manifold. The original Bob Sharp manifold had coolant piped into and out of the area just under the plenum. The AZC manifold has the extra aluminum there but is not drilled..pic attached. Would there be any benefit to more heat in the intake and throttle body? It wouldn't suffer any heat issues like a carb and should take care of any pooling issues while the engine is stone cold? I have protected the IAC motor by a strapped up wad of header wrap directly under the IAC as figured heat on that motor was not good long term. Maybe an aluminum heat shield under the IAC motor would have been better but the wad of header wrap was quick.

-

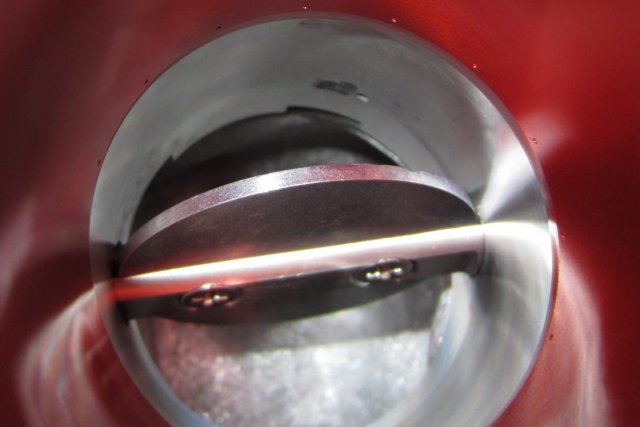

Good Morning fellow HybridZ members ! I have been a member here for a little while now and have educated myself with all the astounding contributions from this community. I can't imagine all the work in the detailed threads and builds. Unfortunately I don't have the same skill set or patience for taking pictures or video of all the steps along the way but will still try to contribute. I will warn you I take to long to explain things. Can you tell ? History: Picked up a 72 240z with a rebuilt stock L26 running round top SU's about 1-1/2 years ago. Loved the car, always wanted one and it ran ok when warm, terrible when cold. The previous owner looked after the car cosmetically but his mechanical skills were limited so I knew things could be much improved. I also researched and wanted to do the easy and common driveline swaps so I found an 81 280ZX to harvest the 3.90 R200 and close ratio 5 speed from. The car was original, rusted out and had 54,000 miles. At first, I wasn't going to use the engine as the seller said it had a knock but upon inspection it had thrown one of the lash pads off due to a stuck valve from sitting so long. Anyway, I tore the head off and found perfect cylinder bores, no pitting, ring ridge etc so I figured might as well try using the L28 short block. It was original with it's flat top pistons while the L26 I had was running dished. Induction thoughts: I loved the look of the twin SU's but they were going to need work, although they were apparently rebuilt and properly adjusted. Now, right or wrong I didn't want to be dickin around with two carbs so my plans were to replace the intake and carbs with 4 barrel. For me this was best, can be adjusted and maintained easier and I'm a function over form guy. I researched and decided that the manifold to use was from Arizona Z car. It was dual plenum and would provide more usable torque for the street and would also go with the recommended Holley 390 carb. A buddy of mine is a very talented, long time drag racer and he offered to work on the intake for me. I didn't really think it would be required for a street car but his theory was that there could be some free horsepower in there and a few extra horsepower is a few extra horsepower. He went about smoothing the ports but did the most work in the plenum. The plenum divider was thinned and much time was spent carving the plenum transition to the runners. Sorry, but these are the only pics I have. Much more work was done and making a thread was never a thought at that point. Cylinder head: Originally I was going to use the L26 so I had decided to rebuilt the 72 E88 head. Whitehead performance did the work and confirmed that I had the early E-88 with the closed chambers. They also confirmed that the original brass seats needed replacing with steel and I decided to replace all valves with the larger size used on the L28 engines. The head needed some aluminum repair but otherwise was in exceptional shape. I was panicky and conflicted when I decided to use the L28 F54 block as compression might be too high. And after much research and confirmation with whiteheads decided it would be ok. And if it wasn't, I would just use the L26 block. When I got the head back my buddy again offered his services. He smoothed the ports and bowls and did some other voodoo for another potential horsepower or two. Awesome guy! Also, a mild cam from webcam and new OEM rockers were installed. Start up and experience with Holley: Everything went so well. I had expected some issues but the engine roared to life and after a couple mixture and idle setting she was running like a champ. Decided, to take it around the block without the hood on to see how the 5 speed and rear end worked. I was taking it really easy but could tell things were much improved. My drag racing buddy asked what I thought and my response was " I think she really wants to go ". I was taking it so easy that my busy body neighbor comes over and asks me "what"s the matter with it, it doesn't seem to be running right" Guess he never heard a performance cam before. Anyway, the next day as I was backing out of the driveway the same guys coming over again so I was a little more aggressive and left him standing in a cloud of tire smoke as I'm driving up the road watching from the rearview mirror as the smoke rolls over him . It's one of the funniest things I've ever done and laughed about it for days and the 150 ft black marks are still there. Guess it was running ok after all eh, lol. Timing was set conservatively at 12 degrees idle, 30 degrees full throttle with about another 30 degrees at cruise from vacuum advance due to using the 81 280ZX dizzy and without any pinging. Anyway, holley was great, no hesitation, instant throttle response, very happy except for the electric choke. It sucked and couldn't be adjusted to my satisfaction so I used that as a HUGE excuse to try an EFI throttle body. Finally, experience with Fitech EFI 4 barrel: Overall, everything went very well but there definitely was some issues which had to be resolved. I went with fitech's fuel commander which has a few issues that I wasn't aware of at the time. I sorted them out but there was some head scratching going on. First issue: Venting the FCC center. Fitech says it has to be vented to the tank and can be t'd into a charcoal canister line or any other vent line going to the tank. I t'd into the tank vent which runs to the two way valve which runs to the stock PCV tube coming out of the block. This should be perfect as i'm venting the FCC tank fumes into the same system that vents the gas tank....WRONG! What I was seeing was occasional A/F ratios which needed huge amounts of trim. The fitech system tunes itself but you can watch it from an included monitor. As an experiment, I installed a clear vent line from the FCC center to a clear apple juice container and took the car for a 30 minute ride. In that time the FCC vent was spewing out enough raw fuel to 3/4 fill the container...WTF supposed to be a vent not a fuel return. What was happening was that fuel was dumping into the gas tank vent line and being sucked directly into the intake manifold through the PCV system causing the crazy fuel trim ! The fix was to vent the FCC into the original fuel return line which runs back to the tank which lets the gas tank vent line function as it should from the rear vapour separator to the pcv system. 2nd issue: Was getting a momentary lean spike with momentary pinging with sudden throttle transitions from cruise or under full throttle while shifting gears and getting on and off the throttle. Never any pinging under full wide open throttle. I tried adjusting accelerator pumps shots thinking it was getting enough but that would not work no matter what I tried. Next I looked at the distributor function and hooked a mechanical vacuum gauge T'd into the distributor line and compared with what the fitech manifold vacuum was....gotcha, you pesky problem ! Basically no vacuum on the distributor line coming from the throttle body port vacuum circuit. The only time the line saw vacuum was for a split second during sudden throttle transitions as noted above. The fix would not be quick or easy. You might be thinking just put the distributor on the full manifold vacuum port and I did experiment with several versions of this. Bottom line is my engine idles best without the added vacuum advance and it worked perfect with the carb and so it should work perfect with EFI. A combination of things were causing the problem, 1. Throttle body is huge and is really meant for larger engines which means you need to almost completely close the throttle blades to get your IAC reading correct. This lowers the blades further from the port vacuum orifice. 2. Throttle blade is very thick compared to the holley which means it has to move farther to uncover the hole. 3. Fitech has the orifice too high. At approx. 6% cruise the hole is too high The fix: I first tried adjusting the secondary blades higher to the hole and closing the primary throttles lower but this resulted with too high an idle while getting IAC adjustment correct. Basically, I would have to fill the existing orifice and re-drill lower. This took a few attempts as the vaccum circuit is not drilled at 90 degrees but at an angle and had to be drilled from outside in. In the end, this worked along with thinning the throttle blade on the underside to fine tune. Port vacuum works as designed, nothing at idle and full manifold vacuum above idle. Ping on throttle transition is gone. Timing will all be fine tuned in the spring as the cars away for the winter. Anyway, a lot of work to replace an electric choke !!!!!!!!!!!!!!!!!! The system works very well, runs perfectly from cold, instant throttle response, excellent power. No dyno's where I live so will take it to the dragstrip this summer to get an idea of the HP. Sorry, for the messy engine bay, tie wraps etc. Has been a long experiment and the throttle body has been on and off about 30 times. Tried to insert photos as I went, we shall see if I screwed it up.............sorry for the rambling post. Brent