-

Posts

13742 -

Joined

-

Last visited

-

Days Won

67

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JMortensen

-

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

Don't worry, you weren't "The Source"... Maybe it was that the side loading from ours being a strut suspension was so much greater than the side loading from the spring winding up, that it just wasn't worth it to spend that much money to reduce the side load by such a small amount. I can't remember. Maybe The Source will pipe up... Cary??? -

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

They don't work on struts. -

My thoughts: 3/4" is larger than necessary for the front LCA. I haven't found threaded square stock. I think people are taking a piece of 1/2 or 3/4" plate steel, drilling a hole and tapping it. Easy enough to do. The guy who did my round tubing found a size that was tight enough that it had to be hammered into the cut end of the control arm. He then turned down a threaded tube end and welded that into the end of the arm for a 5/8" rod end. If you do it that way you don't have to cut the control arm open, but you do have to turn the tube end to fit in the smaller diameter tube. Make your control arms at least as long as stock. I mean with the rod end threaded ALL the way in, it should be as long as stock. This will give you more room to add negative camber with the arms. The TC rods with the inner tie rod are a fine idea. What I don't get is how they threaded the tie rod into the end of the TC rod. It kinda looks like maybe they cut the TC rod after the J end, then welded on a tube with internal threads and that's what the tie rod screws into. Looks very similar to what BRE used on their 510's back in the early 70s.

-

Well let's just let the thread roll on. I keep reading it and I keep reading that he's being sarcastic and saying that the two idiots in their garage with some bathroom scales are wrong and that GM wouldn't have spent billions of dollars in vain. That's how I read it the first time, that's how I read it now... In any event, if anyone else would like to share some more proof one way or the other, that would be helpful.

-

You know, I have another thought on this issue. The passenger side axle should have A LOT of free play in it. It isn't nearly as tight as the driver's side as I recall. So I don't think that this issue you're having necessarily has to do with the CV's bottoming. I'm beginning to think it has to do with the Quaife. Back about 10 years ago I used to autox with a guy who installed a Quaife in his MG Midget autoxer and immediately started breaking axles. The problem is that if one wheel comes off the ground all the power immediately shoots to the axle on that side and it spins it up really fast. Unlike a clutch style LSD or even a VLSD, on the Quaife this happens almost instantaneously. Then when the tire comes down... BANG! Shock loading the axle snaps it. He went back to a CLSD after about 5 axles and never broke another one. When I first heard about the Quaife for a Z, I asked on the IZCC list if anyone had broken a stub axle, and sure enough there were several people that had already broken parts. I think this may be what is happening to you, and I only think this because I'm pretty sure that passenger side CV has a ton of slack compared to the driver's side. If that assumption is wrong and both CV's are basically bottomed, then ignore this post. But if I'm right, then that Quaife may be the problem. John Coffey (who I believe also broke a stub axle with the Quaife in his Z) had his sent to a diff shop where they preloaded the gears inside to prevent it from free spinning like that when one tire comes up, and as a side benefit that allso helps with inside wheel spin on high g turns. On your car with billet stubs, I'm thinking that maybe the weak point in the system is the CV joint.

-

I think you've got adjustable control arms right? How about lengthening them?

-

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

Yeah, just a little progress to report. Ron and Paul machined my tube ends. Just got them on Saturday. I'm going to have to get back out to the garage and get them installed. I've got some issues with that installation, but I'll post my potential problems on the other thread so as not to jack this one. -

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

Well in Ron's case, since he's not really talking about reinventing the wheel here (or are you Ron?), he could use the expandable link behind the diff to change toe, and rod ends and monoballs for the pivots. Nothing lost in terms of strength, nothing gained in terms of difficulty in adjusting toe. For a "relatively stock" suspension I think this is a pretty good way to go. If someone is going to change it to the point where NOTHING fits anymore and every part has to be made, then I'd start looking at other ways to get this done, and I certainly wouldn't rule out getting rid of the struts and going SLA. If you decide on going with SLA suspension, then that is fine too. I don't think you'll find too many people arguing that this is a bad move. Cary, I'm not saying that what you did is "bad". I just don't see the advantage of it vs what I did as far as the toe adjustment is concerned. I definitely see an advantage to lengthening the control arms and the strength of the frame where the control arm bolts up and the rest of it. But with the toe adjustment setup in particular it appears to me that comparing the two, the arm on your setup looks weaker. Maybe it's not weak enough to be an issue, you certainly know better than I do. I'm not saying mine is the only way either. I'm just saying that of the examples we're looking at, so far I prefer mine. -

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

Well in the interest of making the car as stiction free as possible, it seems that it's very easy to avoid this additional side load on the strut, so why not avoid it? If you're building your own control arm, is there any advantage to building it this way vs the other? I would look at building the maximum stiffness and minimum friction if I were making a control arm. -

That looks like more of a Japanese styling accent than a good place to put the cooler. Ever seen those Japanese cars with the oil cooler lines that go out the grill to a cooler mounted on the front bumper? That seems like what we've got here, form over function. I wouldn't put it there on a race car because it hangs down too low for one and it's very exposed to any minute impacts in the rear for two.

-

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

Alright, that number is lower than I expected, but even so, if you were assembling the suspension and you had to push with 111 lbs of force to get the strut into the top mount, would that be a problem? It would certainly be a problem for me... -

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

The spindle is in front of the strut. It is basically centered in the 5.5" between the two attachment points. The strut shaft is ENTIRELY behind the two attachment points. So I think you're right that the force is lessened, but it is not in line like your diagram shows. As to your other point, I think realistically none of these parts is so rigid that they can't flex. I think the control arm would flex first, then the strut housing itself. -

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

Badly worded on my part. I think it was Cary and jt1 that bent the J bar. I think I'm in the process of building a car serious enough... I agree with you that the situation in back isn't the same. My fear is that this situation in the back is WORSE than the TC rod situation up front. Can't someone with some math skill (this precludes me) figure out what the actual loading would be? The length of my sectioned strut from the gland nut to the bottom of the cast iron housing is 15.5", add about 3" from the bottom of the strut to the rod end. So say 18.5" tall. Then the strut itself has ~5.5" length from front to back and we know this is 90 degrees from the strut tube. Since the strut is mounted entirely behind the attachment point in back, then you should have the full 5.5" of lever from where the pivot is at the front rod end to the end of the strut tube the way I see it. So lets say you can do 3 g's in bump (I think that might be low, but let's just use it as an example). If you have a 2000 lb Z with equal corner weights, that is going to be 500 lbs x 3 g's or 1500 lbs on the end of that 5.5" lever. What kind of pressure to the rear is that going to get you at the top of the strut? Anyone smart enough to figure that out? -

Similar story, I'm 31 and will celebrate my 10th wedding aniversary next April. We dated for almost 5 years before we got married too. While everyone will tell you that you shouldn't tie yourself down at such a young age and all that crap, the other side of the story is don't throw away a relationship that you're happy in because society wants you to wait until your 30s to get serious. Bastaad525 has a similar tale of young married bliss. We are the exceptions to the rule, that's for sure, but that doesn't mean that you can't get it right at a young age. Congrats.

-

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

You might be right, the clevis isn't my first choice here, but even so, you'd use one in a TC rod where the entire force of the braking is trying to snap the thing in half? Cary and I think it was jt1 have talked about BENDING the J Bar that was attached to the clevis. Haven't yet heard anyone talk about breaking a clevis. I think they're pretty strong. Maybe not as strong as a full control arm. But again, I think the weak point is the span and not the rod end or the clevis. Cary used an aluminum turnbuckle. That's the part that I'd be worried about. -

The fluid is too thick, and it usually has metal in it. A fuel pump has a flow rate far too high, and can't take the trash in the oil. It wouldn't last very long at all.

-

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

Take a closer look. That is a CLEVIS on the inboard pivot of the adjuster, not a rod end. So that looks a lot like my first drawing. [ proud of myself ] No bending going on with the clevis, because you just loosen the bolt, adjust the toe, then cinch the bolt down again and now the toe adjusting link DOES provide strength to the the control arm, and does take some of the F/A loading... -

looking for a roll cage

JMortensen replied to 74zorro's topic in Brakes, Wheels, Suspension and Chassis

I'm moving this to the Brakes, Wheels, Suspension, and Chassis forum as I have yet to see a Chevy V8 roll cage. Please post in the forum that relates to what the post is about in the future. You might also try SEARCHING the BWSC forum. I can tell you for sure that there are HUNDREDS of posts about roll cages. -

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

That's with soft bushings in place. When you remove all the rubber from the suspension then you have to start worrying about loads a lot differently, because there is no give anymore. With no bushings, pushing on the strut does nothing except side load the strut shaft. Yes it would. The two of you guys could probably do up a SLA suspension setup fairly easily too... -

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

Well the struts are angled in, so that would at least reduce the side load while cornering. We know that the side loads in cornering are still VERY significant, and that's why strut tower bars and all that make such a huge difference. The load in this case would be perpenicular to the strut's fore/aft plane, so there isn't much you can do to offset that loading, other than securing the strut on both sides. So in this case what would be really dangerous would be a big dip in the road, or a "G out" as we mountain bikers refer to them. That would tend to really side load the strut, and I would think (but I don't know) that you could get a heck of a lot more verical g's out of a Z than you can lateral g's. I don't know if this makes any sense, but it's almost like mounting the strut in single shear with a bearing on the one mount. So all of the load goes through the strut shaft. In cornering, the load goes through the control arm to the frame, and only some of it goes through the shaft of the strut itself. That's my uneducated view anyway. I'm headed out the door, it's going to be interesting to see what's in here when I get back... -

Rear suspension design. Looking for opinions.

JMortensen replied to RTz's topic in Brakes, Wheels, Suspension and Chassis

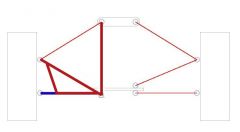

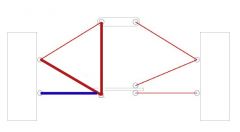

I think there is more to be concerned with than just the strength of the toe link. By having pivots on BOTH ENDS, the toe adjuster will allow for the rear part of the control arm to move independently of the front part. The only thing stopping the strut assembly from tilting up in the back when viewed from the side is going to be the strut shaft itself, and side loading the shaft is not a good idea. All the stiction reduction is pointless if you introduce a bunch of side load on the strut itself. I think you could lessen the side load on the strut by attaching the toe adjuster to the rest of the control arm. Here's an idea of what I mean: The problem then becomes that the link for the toe adjuster is so long. That's an awfully big lever, and I think it might tear the arm apart sooner rather than later. What would be better would be something like this: This ties the front and rear parts of the control arm together, and then has a smaller turnbuckle with a pivot only on the outside end. But if you just want ease of adjustability, why not just use an adjustable end like AZC or MM has on their arms? Or the toe adjusting link like poor mans toe adjuster: http://forums.hybridz.org/showthread.php?t=89111