-

Posts

13742 -

Joined

-

Last visited

-

Days Won

67

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JMortensen

-

I agree with Todd. By the sounds of it they're pretty dialed. One thing I wanted to try was different emulsion tubes. The Mikunis don't have all the different options like the Webers do, and pretty much every runs the OA, but there are the OBs and the 8s to try. IIRC the 8s were supposed to be a "street" setup so I was thinking of trying them on the hunch that they might do better on the transition. Never got to it though.

-

CV joint circ clips stub axle

JMortensen replied to zgeezer's topic in Brakes, Wheels, Suspension and Chassis

You need to swap the inner CV joint from the driver's to the passenger's side and vice versa. If you look at them off of the car one is about 3/8" longer than the other. -

That's not what I was talking about. If he has 280ZXT axles, I've never heard of them coming apart, with the exception of Jay Hitchcock's car, and he had custom axles made too short.

-

You know, some people have reported hearing weird clunks and stuff like that before the stub axle comes apart.

-

His axle has springs in it, so it won't jiggle like a Z31T axle. He'd need to pull very hard. The springs look like valve springs and at full droop you'd be at the shortest axle length, so it's not going to be as easy as a Z31T by any stretch.

-

Yesterday was a false alarm, for the record. Just a few more questions before you go Mike. I read that GRM article too. What materials did he suggest making a diffuser from? Did he say anything about needing CFD or tunnels or any other extravagant methodology to make one? How did he compare the Vette diffuser to the Civic diffuser that looked like it was built in a garage? Most importantly, is the author right because he is an expert, or is the guy at the windtunnel right because he is an expert?

-

I'm surprised that you're HEARING the CV bind and suspect that you might be hearing something else. Loose gland nut maybe? The 280ZX CV's are different and kind of a PITA to take apart and put back together, you have to cut the boots off as they're crimped on from the factory. I know some people have cut through the metal band and then clamped the boot to the housing, but it's not a tight fit so it would probably rely on the force of the clamp to not leak. They also have both ends floating. The outer moves maybe 1.5" and the inner an inch or so, and they have springs to extend the shaft. To test for bind you should be able to jack the back of the car up and try to slide the CV shaft left and right. If it moves, then it isn't bound. EDIT--flipping the cage on the Z31T axles gains you about 1/8", FWIW.

-

Maintaining brakes DURING a race.

JMortensen replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

If you're going to try and do more track days before you do the brake upgrade, you might look into this. It requires quite a bit of plumbing, but it wouldn't be a bad thing to have on a big brake system either. http://www.dpiracingproducts.com/dpi-sure-stop-i/ -

Wife is on a monitor for a couple hours. Past this point I'm just going to back off and throw some money at you guys. http://forums.hybridz.org/topic/55913-windtunnel-testing-the-datsun-s-30-z/ Me: I know you guys were keen on blocking the open space between the air dam and the rad core support. Was there any attempt on any of the cars to seal the top of the core support to the underside of the hood? You: Jon M., We didn't test any advanced airboxed. We tried to stick mostly with basic stuff. You again: Well lets backtrack to the other comment you made for a second... You're worried about an extravigant sheetmetal box for the radiator, but you missed the whole section on how the radiator only needs 2X4 inches of space to stay cool... That sheetmetal "box" is probably effective at doing that, but probably isn't as big of an aerodynamic aid as you might think, so you have to think in different terms there. Me: I'm not sure you're getting the point of the box. It isn't only there to limit the amount of air coming into the radiator. That is it's less important purpose. It's more important purpose is to eliminate the pressure from the underside of the hood. And this ties in with the other question as well, about sealing the core support to the hood. If you have positive pressure inside the nose of the car and have not sealed the core support to the hood, then presumably just as the air can go down underneath the airdam under the car, the air can also go OVER the rad core support and through the holes in the core support as well. This will increase the amount of pressure under the hood. If one were to do the box structure and seal the hood to the grill area so that all the air that went into the box went through the radiator, then you'd get a couple of benefits. You guys already showed that cutting down the amount of air is beneficial. In addition though, you'd cut down the size of the pressurized area in the front of the car. In fact, you could probably get negative pressure in the front hood area above the box. Negative pressure under the hood, coupled with the pressure of the air being diverted over the hood = more downforce, and that's why you see so many race cars using that type of radiator duct. If memory serves I think preith has this type of setup on his car, with a sealed box and a much smaller inlet hole for the radiator. Here is a link that describes what I'm talking about from a circle track magazine: http://www.circletra...ch_definitions/ The magazine article has some flaws, but the article estimates a 180 lb downforce gain from this type of box. It also talks about using a wide airdam to suck air out of the fenderwells. You: Jon, No. Not according to Bob Smith. His comments were that you're going to get air packed in under the hood... There's no getting around it. Sealing off the nose of the car in general, like Roddy Sugg's car does, is an effective way to deal with the area at the mouth of the car. Look at the test data for #28, along with the other data for closing off the grill in other tests... Also, remember, air is exiting the radiator/fan assembly at 15mph. You're travelling a lot faster than that (we hope) and what does that create? An area for air to pack up and create lift. Forego the whole "Aerodynamic downforce" theory of yours for a moment and think about just closing off that gaping hole in the front of the Zcar, known affectionately as the "grill". Do that, provide minimal feeding for air, and then funnel that air to your radiator however you wish, via ducts, tuning, sheetmetal/plastic radiator box, or whatever. Just remember that the air isn't travelling any faster than that, which means the larger that opening, the more air is getting caught there... and remember the first lesson we passed on from our friend Bob Smith. What happens at the very front of the car will impact everything else along the way... Total package, JM. Total Package! Me: I think I'll have to disagree with Bob on that point then. I don't think you'd see so many race cars from so many different classes doing the same thing if there were no point. The opening to the box I'm suggesting could be whatever size you want to get a very small frontal opening. This is very similar to the point you guys proved about sealing the air dam to the core support. That prevents air from spilling out UNDER the radiator. The box prevents air from spilling out OVER the radiator and through the holes in the core support. And if you have a LOT less air in the engine compartment you might just make a low(er) pressure area under the hood, which translates to more downforce. You: I won't debate "IF" a box would have worked, since it wasn't tried. But Bob Smith has tested hundreds of cars, and his insite was amazing. All these boxes on these cars could very well be tested, or could very well be something people "Think" is a good idea. Until we test them, I'm listening to the man that does this stuff for a living. he wasn't wrong pretty much every recommendation he made... choice is yours to trust a pro. I am.

-

I've got bigger fish to fry today guys, should have a new baby here in a couple hours. Suffice it to say that I'm in no position to demand anything of you, and that you're in position to ignore me if you so choose. I only persist because I think you're wrong, just like I thought the wind tunnel operator was wrong that splitters and rad ducts don't work on Z cars. I will donate if given the opportunity, and I will read through the numbers after the fact like a kid on Christmas morning.

-

So am I correct in asserting that the reason you are so virulently opposed to the flat bottom idea is that plain old flat bottoms with plain old diffusers don't work? That seems to be the only line of reasoning to answer Chris's question. In Competition Car Aero McBeath used CFD on a NASCAR model to simulate a flat pan under the engine and cabin. No diffuser, no wing, not even a splitter. Just flat panels starting at the nose and continuing under the engine and cabin on an otherwise non-optimized car. Panels stop at the rear suspension. Result: 6.5% increase in downforce, 1% reduction in drag. McBeath also said in an email to me that I should panel as much of the underside of my Z car as possible, even if I could only get the engine compartment done. The email is in my splitter/airdam thread if you're interested. In Race Car Aero Katz examines a 1991 RX7 GTO car with flat floor and simple 6 degree diffuser and says that the published L/D for the car was -.3 to -.4, which is much better than anything that went through the wind tunnel last time. He also says that with a little more attention to detail and room to maneuver with an open ruleset it probably could have generated -1. In looking at this book again, it must be where I got the idea for the diffuser fed with a duct opening in front of the rear tires, as he describes air rolling under the RX7 and increasing the performance of the diffuser. Damn. I really thought I came up with that myself. He didn't describe fences on a flat bottom to make a venturi though. I think that one is an original... I've read other books on aero, but these are the ones I own and can check right now, but so far I'm 2 for 2 in general principle. Obviously I can't make you do anything and I don't want to, but your irritation with my line of reasoning doesn't seem to be an appropriate response to the way I'm approaching the subject and doesn't really fit with anything I've read re: aerodynamics.

-

The reason to do it is to see what the results are before you go and redesign your whole car. If the effect is good enough, it might be motivation to go for it and really make that sort of change on your car. Have you ever heard of Simon McBeath? He does the Aerobytes column for Race Car Engineering and wrote Competition Car Aerodynamics and Competition Car Downforce, and he tries stuff on the fly in the tunnel all the time. I've never seen him test a whole floor that was plywood, but he makes parts from cardboard, wood, etc and tapes them to the car to test in the tunnel. Seen articles where he modifies fenders with cardboard, blocks off grill openings and ducts with cardboard, cut holes in fenders with a cutoff wheel, carboard extensions on diffusers, etc. He has done that kind for years, check out some of the old back issues of RCE and you'll see what I'm talking about. He also does CFD and has a company that manufactures wings. I remember Hot Rod Magazine did a LSR car and they had all kinds of crap taped all over it, including the airdam and the hood scoop. After optimizing in the tunnel and then actually mounting the parts, it ended up going 250+ mph and they were able to get the Cd from something like .5 to .22 on their late 60's Camaro. Halfassing it in the wind tunnel makes sense because you can see what works before you put the time and effort into making it permanent. That's the beauty of the wind tunnel. I'm just making suggestions, and it seems like there is a lot of pushback and I'm not understanding why. FWIW though, I've seen flat floors on cars that weren't designed for them and it's not as impossible as you're making it out to be, especially with as much ground clearance as you have. Chris Rado's AWD Scion comes to mind. It had a dropped panel that was probably 4" lower than the floor to avoid all the drivetrain crap underneath the car, and to get the floor down to where it would actually do some good. You or anyone else could fairly easily attach plywood to the bottom of the car to create a flat floor, test it, then take it off and have maybe a few extra nutserts in the chassis or something like that. That's the beauty of the tunnel. It doesn't have to be "right", it just has to be there, and this piece would be easy because it is flat. Anyone could make a flat panel the right shape in 1/2 hour with a jigsaw, then it needs only to be mounted it in the most rudimentary fashion to the car. Do a very simple diffuser, just a 7* angle and see what happens. As to the applicability of this idea to your car, it appears to me that you have plenty of room to drop a floor down to 2 or 3 inches off the ground. If you ran droop limiters you might even have enough clearance to go under all the suspension arms. The windspeed in the tunnel is 80mph as I recall, so I don't think you're likely to be developing huge amounts of downforce.

-

Has anyone tried the Speedway LS1 header kit?

JMortensen replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

With pre-bent tubes that header is going to come out a certain way. Looks like it's intended for a "classic truck" so I would expect that if you just welded it up you'd have the collectors scraping on the ground. I think if you're going to do a longtube header you're going to have to make it fit a Z, not use a kit (unless the kit is for a Z). -

I'm finding this very hard to believe in light of all the actual racecars that use flat bottoms. I would suggest that if there is a controversy, this would be easily proven one way or the other in the tunnel. I was kind of hoping that you would have a flat bottom since I think you're the most likely person to do it, but since it's just a wind tunnel the bottom doesn't have to actually be attached to the car, or at least not very well. I could see mocking it up with a couple pieces of plywood clamped to the rockers or screwed to nutserts installed on the frame rails or something like that, and if like I said in the other thread, the flat bottom was dropped below whatever hangs down then you could do a nice flat surface all the way back. Once you saw the effect, then maybe you'd know whether it was worth it to do all the mods to your car. I think the big obstacle is exhaust and side pipes is the answer to that. After that it should be relatively easy. BTW, with regards to the C6, have you seen hemipanter's Vette? Pretty badass: http://www.hemipanter.se/#Corvette Nordic Supercar

-

You might check out Coffey's dual master conversion kit. IIRC it gets rid of the booster and allows you to bolt dual masters straight in. Then you could use a real balance bar instead of a prop valve. Not sure if he's still doing them, but that was a really slick solution. I saw you had R4S pads on your car at the track. Not a good choice for stock calipers. I punched a hole in the pad at a track day. The lining got so hot it left the pad and then the caliper piston pushed straight through like a hole punch. You'd probably be OK with R4 pads on stock calipers, if you could keep the fluid from boiling, that will be your next hassle if you choose to stay with stock. Fluid boiling is fun, as you can lose the brakes all at once with no warning. Going bigger just allows for a larger heat sink and you can run harder without having to worry about all this crap. With your car it's a good idea.

-

Give it a shock absorber. My plan is to mount the rear of mine to the crossmember with a clevis pin setup acting as a hinge. Then the front mount will be a long bolt with a rubber bushing or two on it. If the front of the splitter hits the ground or something, it will compress the bushings but it will have a little bit of give to it, instead of being totally rigid. Then I'll use cables rather than turnbuckles for supports in the front. I figure if I go off the track it's less likely to destroy the splitter. This idea comes from tube80z.

-

Check out Dan's car (74_5.0L_Z is his username, look at his gallery). He did a roll bar and door bars without having the A pillar and halo, which is the part you're likely to hit your head on. He actually has a full tube frame front end, but you could go a little less extreme with a dash height hoop in the front and a regular hoop behind the driver, and X door bars connecting. Could go through the firewall out to the front struts if you were feeling ambitious.

-

Brainstorming Aero ideas for Windtunnel II

JMortensen replied to JMortensen's topic in Windtunnel Test Results and Analysis

Yeah, I was thinking of putting a little piece of stainless on that part, or just painting more Rustoleum over the scratches from time to time. The way mine will be set up with the tires hanging out 6" past the doors, the whole side of the car is probably going to get sandblasted. -

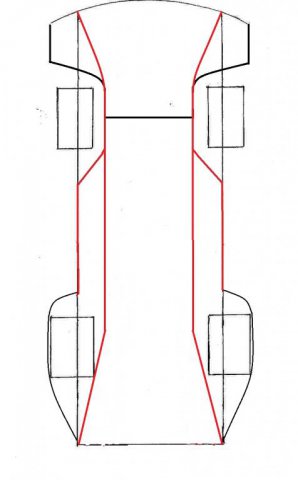

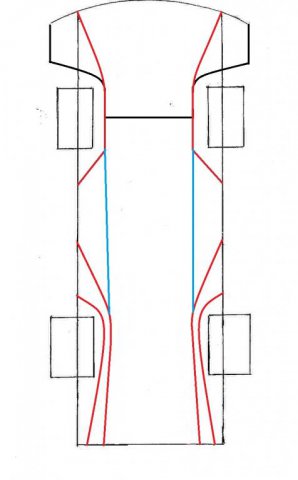

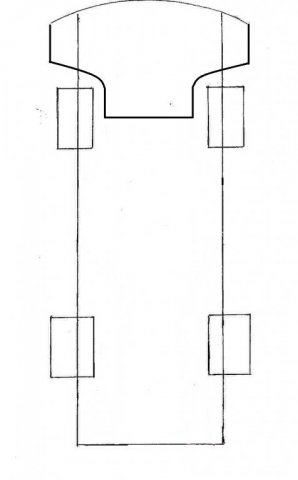

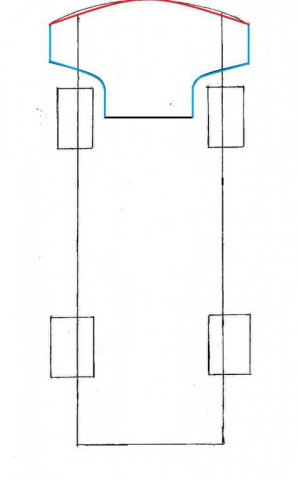

With another wind tunnel test approaching it might be helpful to throw out some ideas that the guys can test; this thread will provide a place to share those ideas. I've had a couple ideas rolling around in the back of my brain for a while, things like splitters with airdams on the leading edge, trying to increase airspeed on a flat floor, etc. All have more to do with the underside of the car. Here are my ideas: 1. Splitter with airdam on the leading edge. I think this will work better for autox types of situations where the speed differential of the air going under the splitter won't be as significant. Since the windtunnel air speeds are pretty low where you guys are going, I think this would be a good spot to test the theory. I think Cameron actually has this setup so that all he has to do is bolt it on. Not sure if he will be part of this though. This was recently tested in Race Car Engineering on a Porsche, but the airdam they used was still 3-4 inches off the ground and not surprisingly it produced worse results than the splitter alone. I'd like to see it tried with an airdam 1-2 inches off the ground. A variation would be adding dams to the sides of the splitter. This could be fairly easily tested by taping a cardboard strip to the edge of a splitter, with some triangular cardboard braces on the backside to keep it from folding under pressure. 2. Splitter with diffuser. The NASCAR COT's used a diffuser after their splitters. This diffuser was about as simple as it gets. It was just a piece of aluminum mounted at an upward angle at the end of their splitter. Their splitters were very short, and the diffusers were too. If there is room, it would be interesting to try a 12 or 18 inch long piece of cardboard at the back of the splitter, just tape to the splitter and then tilt up towards the rear. The COT had a very rough bottom so you wouldn't think that a diffuser would work, but they were talking about 80 lbs of downforce difference based on the angle of the diffuser in a video I watched. Variations on the angle of the diffuser could be checked. 3. Ground effects. It's really tough to do an aero bottom on a Z because of exhaust and drivetrain clearance, but it might be possible for the guys with larger diameter wheels to do it, particularly if you have very stiff springs. I know 74_5.0L_Z is running at about 2.75" from the bottom of the front crossmember to the ground and not bottoming with spring rates in the 400s IIRC, so if you have 5 or 6 inches to the lowest hanging piece, you could drop a floor down a few inches and still not scrape. Flat bottoms are usually mandated by rules, but aren't the best option. Contoured floors are better and obviously more difficult to fabricate. 3a. Contoured floor. Splitter with diffuser into a second venturi into a rear diffuser. Basically we're talking about aping a LeMans car, mulsannescorner.com has plenty on this if someone wants to try it. 3b. Flat floor. Much easier to make is the pro here, and theoretically much better than the rough bottom with the drivetrain and exhaust hanging down. It would be awesome just to test the flat floor/diffuser setup, but I have a couple variations. The idea behind the contoured floor is that you're creating a venturi by getting the floor closer to the ground and narrowing the opening for airflow, causing the air to speed up. If you have a flat floor, what is to prevent someone from using fences on the bottom to narrow the airflow passage on the bottom of the car and get the same effect? Essentially I'm talking about more airdam material, and making a venturi shape on the bottom of the flat floor. This could be tested with aluminum 1/2 x 1/2 x 1/16 thick angle (easy to bend to shape) double sided taped to the floor and then the cardboard fences could be taped to the angle. A further variation would be to add air from in front of the rear tires to the venturi. I think there would be a decent amount of airflow to tap at that spot, particularly if there were dams pushing air out to the side of the car behind the front wheels, as I know Mike Kelly and others either have or were planning to have. All of the above can be tested pretty cheaply and easily. These drawings are not to any scale or anything, but I think they might help to conceptualize the overall ideas. Red or blue is a fence that could be tested with cardboard and actually be put on the car with airdam material (plastic lawn edging is what I would use). 4. Spoiler/wing combos. It is pretty well known that a spoiler and wing can be more effective than a spoiler or a wing alone, but I don't think there is a hard fast rule about what size spoiler makes the best result, so that could be tried, in particular testing the amount of increase in AoA on the wing before you get separation on the bottom side with and without the spoiler would be helpful. This would probably be useful only on the car that was tested, but if my car were going in there I would definitely want to do this test. 5. Front fender contour. I doubt anyone will do this, but I'd like to see a Z with the front fenders cut and folded in behind the wheel to the wheel well, imitating what you seen in Spec Racer Fords, Can Am cars, etc. It's not a new idea and we know it works, but I'd like to see what the result is. Would require cutting up a set of fenders and making a fender liner so that air didn't get past the opening and trapped in the back of the fender, but fenders could be grossly cut and cardboard used to push in behind the wheel and make a crude fender liner as well. 6. Fender top vents over the front wheels. Preferably alligator tooth style. 7. CFD. Anyone ever considered putting this money into a CFD model? Not sure how much that costs to do, but if you had a CFD model, you could test infinite variations without going back to the tunnel.

-

That's a spoiler, not a wing, so if you go searching for IMSA 3 piece wing you won't find it, but IMSA 3 piece spoiler will work.