-

Posts

351 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Metro

-

I don't believe TS can do anything with logs aside create them as Matt mentioned. MLV is mostly free, if you want to use the VE Analyzer and other advanced features such as scatter plots, you'll want to buy it. I think the longer it's installed, the more it nags you to register, but it's a small annoyance.

-

I understand that, basically what I was trying to say, MS2 is broken. It doesn't react the way it should react. With MS1, I can flood the engine with a ridiculous amount of fuel and it just sorta starts to smell funny. With MS2, the RPMs drop so much it nearly dies. The only thing I can do is make it worse by adjusting settings. When it comes to tuning idle, I go for lowest Kpa and call it good. The only thing the AFR target table is doing right now is providing guidelines for VE Analyzer.

-

Unfortunately, I've done that. I've pushed the injectors up to 4ms PW and it still misfires and stumbles. That puts the AFR down to around 10-11, but on MS2 going that low almost makes the engine die. Whereas on MS1, it can idle that rich without much of an issue.

-

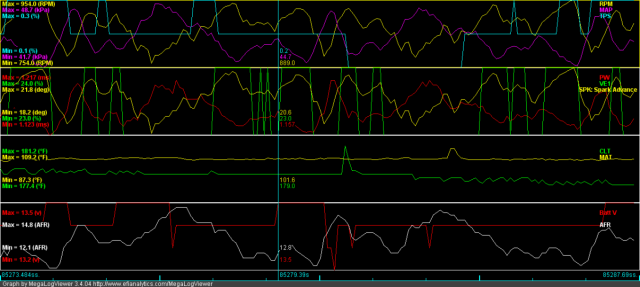

That's pretty much what I was doing over the weekend. Driving the car around on MS1, seeing how well it can be tuned with just speed-density. So far, it actually looks somewhat promising, but I know fine tuning it is going to be an issue without going blended. It would be really nice to have the 16x16 tables and 12x12 AFR table from MS2 along with MAF support, but I just don't think I can fix what's wrong with it. I've adjusted every single setting I could think of for fuel and spark and nothing helps. Granted, I still haven't tried what Sam recommended the other day with the 240cc injectors and disabled AFR-targets, but I just can't see that fixing it. It's just going lean and missing for some reason.

-

Your tooth log looks pretty similar to mine. I didn't count all the marks in the log, but the sections I did count look correct with 34 short and a tall 35th. Obviously it's reading some teeth better than others, but the tall one is important. If it were reading wrong, you'll end up with multiple tall teeth in a row. Short of using an oscilloscope you need to try what I said for tweaking the pots. I can never remember which does what, but one acts like a noise filter and one affects the shape of the signal. Reset both and you want to mess with the one in the middle of the board. Rev the piss out of the engine and adjust half a turn at a time until it stops cutting out. If you run out of adjustment, then you'll want to investigate other things or get someone with a scope to help you.

-

I've messed with a lot of different rpm inputs over the years and if your sensor or pots are out of adjustment, it definitely can feel like a rev limiter. Although it will usually show up in the logs as a jagged rpm signal when it happens. Or in the case of my 6-1 flywheel setup, when the VR sensor couldn't read above 5500rpm, it would just drop a few hundred rpms in the log. The engine would still be accelerating making the car buck and all sorts of unpleasant things. I've always had to mess with the pots a little bit when using a new sensor. Just reset, rev it up, adjust, and repeat. Hopefully that's all it is.

-

I started a thread on the MS forums, maybe they can help. One of the other things I did was to fix the EasyTherm values for the Ford IAT. I accidentally grabbed the Celsius values instead of the Fahrenheit. With that fixed I was able to get the PW in the same range as MS2. MS1 would cutout and die at 1.3ms, which makes sense to me with a 1.2ms opening time. I'm seriously beginning to question why I'm bothering with MS2, but I don't want to admit defeat yet. At least with MS1, I can move the car out of the driveway, if necessary. Also it sounds pretty cool, which was kind of the whole point of this venture.

-

I think you're right about that and I suppose it's worth investigating. Although it didn't have much of an affect on the 450cc injectors.

-

I'm using a V3 board. While I have an '81 280zx's resistor pack to play with if I wanted. The thing is, I've tried using high impedance injectors with PWM disabled (240cc GSXR injectors), with no luck either. When I said I was messing with the injectors the other night, I basically was changing every parameter on the injector page on at a time. There's always the chance it's spark related, but those settings seemed to copy over fairly well. Also if it were off, I would think the car wouldn't run and the timing is spot on every single time I check it.

-

Wonderful, there's no way I can tune around this on MS2. It would be simpler to try and use the MS1 with blended tables.

-

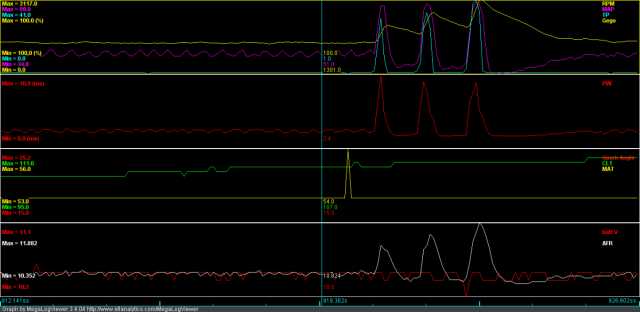

After spending a lot of time trying to tweak the fuel injector settings to no avail on Friday, today I dug out my original MS unit. It has nothing done to it, aside from a few things I did to butcher it years ago, but last time I put it away it was in perfect working order. So I modded it for wasted spark, loaded my December 2013 settings and plugged it in. On the first attempt, it started and died two seconds later, but it was sounding nice. The second attempt I gave it some throttle and it roared to life. It's running extremely rich, but it was buzzing steadily at whatever rpm I held it at. And damn, it revs up quick! I was holding it around 1100rpm with a 3.5ms PW and around 11:1. I reflashed MS with with EasyTherm to fix my IAT sensor. I used the values listed in TunerStudio's MS2 config. Either it didn't work or I reflashed the ECU with the wrong file because it's reading negative temperatures in the log file. So with that, I tried plugging my MS2 chip into the old board and it was back to missing and shaking. So there has to be something wrong with my MS2 settings (injectors?) or that chip is bad, which seems extremely unlikely. The settings I'm using for my 450cc DSM injectors came from the injector thread on this forum and from forum posts on the MS Extra site. Now I know my injector settings for MS1 are spot on, but the settings completely changed between versions. I suppose I should datalog the MS2 chip on the old board and compare. I noticed there's almost no noise on the MS1 log, but nothing has changed in regards to the grounding with the harness. 2014-06-28_21.30.28_MS1.zip

-

The MS2 software supports sequential injection, at this point it has nearly the same code as MS3. The problem is with the hardware. MS2 only supports 4 injector channels (which probably conflict with other outputs I'm using). Not to mention to get that, I would need to add extra injector drivers and another VR input circuit for a cam sensor. I haven't looked into it too much right now, so I'm not exactly sure. The MS3 hardware has many programmable inputs and outputs so it doesn't require any modification.

-

Yeah, just because something worked in the past, doesn't mean it's working now. I think I need to throw out what I thought I knew and start over. It seems like it was working alright at one point, so I need to debug it until I find where it went wrong. I'm not sure if MS2 has that feature, but I'll look for it.

-

Looking at your log the two things that seem unusual - your idle kpa is really high and not once do you ever trigger acceleration enrichment. If you really are cracking the throttle, then your TPS needs to be recalibrated, BADLY. It's reading -3% open when you're idling. The lack of AE should make it difficult to rev up quickly, but it should hold steady once in place. Also, wait until the engine is fully up to temperature before trying to tune or diagnose anything.

-

The jiggle test didn't have any noticeable effect. Now here's something interesting. I found the data log of the very first time I fired it up using MS1 and my old config. No wonder I was so optimistic back then. There was no special setup, no balancing, or vacuum log, I just bolted the manifold on and fired it up. The manifold definitely wasn't sealing though. It was night and I could see it spit fireballs where the manifold met the head. The only unusual thing in the log would be the alternator. I don't remember why, but it clearly wasn't charging. After this test, I rewired the coil outputs to use the SPR instead of the IAC outputs and did the boost control mod. So this gives me some new things to look at. try to raise the idle up to get the PW around 2ms disconnect the alternator - could be the source of my noise problem check the wiring check the board for bad solder joints 2013-12-21_20.48.29 fixed timing.zip

-

@tony While I like your idea, damn that seems like a mess to clean up after. But if I get desperate enough.. @sam I've done the carb cleaner thing and that's how I ultimately discovered my manifold wasn't flat. The engine would rev up and even out when I sprayed around runner 1 & 2. I haven't been able to find any other leaks since I fixed the others. In the second data log I tried revving it up and holding it around 1500rpm and it still seemed a bit problematic. I'm not sure I have enough idle adjustment to get them much higher than 900rpm, I would have to crack the throttle. The ITBs are attached fairly securely. I can barely move when I've tried wiggling them, but I haven't tried it with the engine running. I suppose I could try it and do it again with the pushrods disconnected. It seems like there could be some problems there.

-

I used to experience what you mentioned when I had the FPR mounted by the fuel filter on the passenger fender. This put it about 4-5 feet away from the rail. I had this same VDO gauge mounted on the fuel rail and would bounce around 10-15psi as the injectors fired. I think I was able to tune around it, it wasn't much of an issue. Now I've moved the FPR to the end of the rail and the gauge barely moves at all. The FPR is getting the same vacuum signal as MS - it's attached to the end of vacuum log. I've also removed the vacuum line from the FPR numerous times and it hasn't had any noticeable effect. I might be able to get my hands on some quality fluid filled gauges to test with, we'll see. For whatever reason, I've never been able to get it to idle smoothly with alternating, I've always gone with 2 squirts and batch fired. For many other reasons, I'm wishing I splurged and got an MS3 instead of the MS2 chip. It would be great to go full sequential without having to add a bunch of drivers. Maybe next fall when I have time to rewire everything. Also I just wanted to toss out, thanks for all the ideas guys. This is pretty much my hail mary attempt at finding a solution. I've been screwing around with this for about two months now.

-

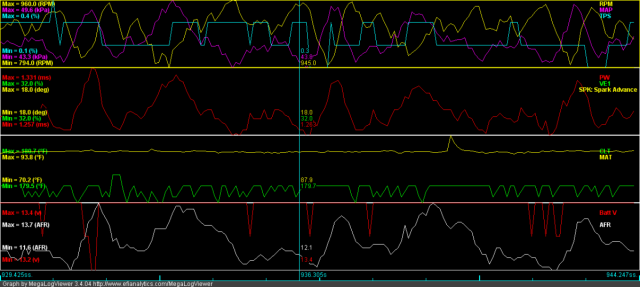

@tony MS2 and MS3 have a cold idle advance table and I was thinking of using it in lieu of an IAC. The problem I have is, the vacuum port on the TBs are only 1/8th of an inch. Playing around with it, I can only move the idle by about 150rpm at the most. Of course, it might all change once it's idling properly. @sam Turning off include afr targets was a good catch, that should not have been enabled right now. Turning that off, I had to up my VE values slightly, but ultimately it's still exhibiting the same problem. I honestly haven't paid much attention to the AFR table as I thought it should have been disabled along with EGO. The load range is from my old MS1 configuration and using a 60mm TB on an N47 manifold. I was hoping to use MAFload for the axis at some point. I think my injectors run fine down around 1ms, if I wasn't clear before I've been running MS1 since 2006 with the same injectors. My old config used 2 squirts and the VE value was down somewhere near 25 in the table. Unfortunately I'm having difficulties with finding an old log, but I'm confident I didn't have problems running these injectors around 1ms. The only thing I was unclear on when going from MS1 to MS2 was the Injector PWM period(us), so I left it at the default "50". I should also point out the GSXR injectors are half the size, so the idle PW was around 3ms, same problems. I also just went out and tried running it 1 squirt and that didn't help any. I have been following your thread too Sam, that's why I was a little concerned with the placement on mine. @madkaw Early on when I was having problems keeping it in one bin, I tried pretty much everything MS recommended. First I tried using a fuel filter to dampen the pulse, no change. Then I inserted a restrictor from the GSXR map line, nada. Then I tried all together and still didn't see any change. So in conclusion with my weak cam, I don't see any need for MAP tricks to help smooth it out. If not for the RPM going all over the place, it would only fluctuate 1-3kpa or about the same as it did when running a single TB. I haven't tried removing it from the equation yet, it hadn't really crossed my mind. I really want to think there's vacuum leaks or the manifold is leaking exhaust gas into the intake ports, but I just don't see any of the signs of it doing any of these things as I had in the past. As far as I can tell, it's fine and yet it still idles terribly. I went out a attempted to datalog some higher rpms and I definitely have a noise issue that I'll need to sort out. I used to ground MS to the intake manifold, but I can't with this manifold. Instead, I ran a heavy lead out from the cylinder head to a spot on the fender and bolted all my grounds together on there. Obviously that isn't working very well or MS2 is a lot pickier than MS1. 2014-06-23_18.28.24.zip

-

Top View You don't REALLY mean "RRFPR" do you? My mistake, yes, I meant a normal 1:1 FPR. The above two are basically mutually exclusive. You set your balance how? Bypass screws per barrel? CLOSE the throttles it idle and adjust your balance with the individual bypasses. Check off-idle balance separate from idle. The plates are completely closed and the idle is being set by bypass screws on the bottom of each TB. The bypass screw is just a hole in front of the TB -> screw -> exits behind the plate. The black tubing is for my vacuum log. Use water or some sort of spray. No leaks are permissible. Any present will screw with you forever. I discovered a while ago that spraying any liquid on a vacuum leak with individual runners will make a loud puffing noise. I've also been using some tubing as a stethoscope to probe around. I haven't been able to find any other vacuum leaks since my other problems. Unfortunately, the way they're attached allows for lots of potential problems. Replaced plugs several times. Long time ago I used to foul plugs like crazy, so it's a cheap test. I have probably 30 lightly used plugs in a box, waiting to be cleaned. What is idle vacuum? .. If it's jumping between four cels at idle and they all call for different fuel you will constantly be chasing it. Make all cels at idle that it jumps through identical and see if your AFR settles out. The idle is stable enough and I've setup the load cells so that's it only ever sits in one cell. So the fuel being delivered is fairly consistent (around 1.18ms), but I still get a wildly fluctuating AFR. I mentioned alpha-n because a long time ago I tried using that to keep it in one bin. In the log, it says my range was 41kpa to 48kpa and the VE was mostly limited to moving from 23 to 24. As you can see in the logs, my spark advance does move around a bit, but even with a fixed advance it still runs rough. The 450's may have had latency issues, they were also high impedance? The 450s are low-impedance and the 240cc are high impedance, they're about as different as you get, which leads me to believe I can rule out injectors. Granted, I don't know the exact opening and closing time of the GSXR injectors. The 450s are configured with settings I had been using previously with MS1. I've attached my log and current settings. I should point out the MAT is from the Ford MAF and I had it sitting on top of the radiator, then I moved it off to the side, that's why it drops like 20 degrees in the log. 2014-06-21_18.35.28.zip

-

Since my car was running so well last fall I decided it would be a fun to ruin it by building a turbo ITB setup. It's very basic using GSXR ITBs clamped on tubing with DCOE flanges on a TWM manifold. I went with the TWM as it was the shortest easily attainable manifold I could find. After many months of small successes and large failures, I discovered my "new" TWM manifold was machined unevenly, not to mention the bolt holes for the #1 carb put it 2mm out of center. That was very annoying to say the least. With a belt sander and some flat aluminum stock, I was able to get it leveled and as best I can tell, it's sealing. MS2-extra v3.3.2 L28et ("A" cam, but otherwise stock) 450cc DSM injectors (flow tested, 2.3% variance) 46mm GSXR ITBs Aeromotive RRFRP set at 37psi or so GM DIS coil packs with BIP373 ignitors inside. No idle control (yet) So my problem is that I cannot get it to idle smoothly. It will pick up, then miss and drop 150rpm and repeat. It's consistently inconsistent. My AFRs are bouncing around from like 12.5 to 14.2 as it stumbles and catches. At this point, I don't believe it has anything to do with my Megasquirt configuration, I can't help but feel it's something endemic to my setup. I haven't really attempted to tune at higher rpms, but when I do rev it up and hold it, the AFRs bounce around just like at idle. The injectors are mounted in the stock location on the GSXR ITBs, putting them about 5" from the head. I've noticed when I take the manifold off, the gasket is permeated with fuel around the intake ports. Like there's a half inch ring where the gasket is wet. I've never really worked with carbs or a wet manifold, so maybe this is normal. In general it seems like there is a substantial amount of fuel in the intake tract and I've wondering if it's just pooling and not being atomized. But it seems like everybody with DCOE style ITBs would have the same issue. For the time being I'm just running Speed-Density while trying to fix the idle. Switching over to MAF or Alpha-N doesn't help. Thus far I've: Balanced the ITBs with a carb syncrometer to 4 Kg/hour Used a caliper to set the plates to open within 0.25mm. Fixed a few small vacuum leaks I found using ether or by listening with a hose. Replaced plugs several times Readjusted the valves Fuel pressure looks good. Several compression tests, open and closed throttles, all good. Swapped in a set of GSXR 240cc (high impedance) injectors. The only thing I haven't swapped out or replaced would be the coil packs. As best as I can tell they're working fine though. I'm about ready to throw in the towel and pick up some Jenvy DCOE throttle bodies. The only thing stopping me is the fear that they will do the same thing. I'm just wondering if anyone has any ideas.

-

http://www.msextra.com/doc/general/sparkout.html

-

Those look like GM coils, which as far as I know are logic-level. Meaning MS sends a low voltage pulse to fire the coils. I notice you have them set to "going high" which is usually used for driving the coils directly with an ignitor like the BIP323. Provided you haven't damaged the coils, changing that setting might fix the fuse problem.

-

It's got an undertray without any sheared off bolts, that's got to be worth at least $10k.

-

It looks like they used a variation of that oil cooler/exchanger on just about everything in the last 10 years, but with slightly different in/out routing. It would be nice and compact, I guess you could check if the oil filter has the same threads?

-

The fuel pump flickering steadily on the board would indicate MS is pulsing the fuel pump. This is a sign of a important software misconfiguration. Like your wheel/distributor settings are wrong or you have the wrong number of squirts configured, etc. Something massive that would not let the car run because it conflicts with reality.