-

Posts

351 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Metro

-

The '81 CAS and wheel are only good for firing a single coil. The CAS sensor is made up of three VR sensors and it does some sort of voodoo to turn that into a digital signal that is compatible with the later optical distributor. For lack of a better term, it's a dumb signal. It will just let the ECU know it's 60 degrees (or so) BTDC, it doesn't allow any sort of reference to the crank's position. Without that information MS can't fire the other coils. I'm not sure about the internal workings of the CAS and what it expects to see vs what it will output. I don't think you can just turn the wheel into a 30-1 and have the controller inside the CAS understand what it's reading. But, I've never tried, so who knows. The trigger wheel DIYautotune sells basically does that for the optical distributor.

-

I just spent the last week working on my dash (was suppose to only take 1-2 days, that was really optimistic). My dash was pretty far gone, cracks every 10 inches, and I ran out of the SEM bumper repair epoxy on the second crack, so I just used JB Qwik weld for the rest. It seems like they cure to about the same hardness but the SEM bumper coating is definitely easier to sand. My dash had split on either side of the middle gauges and there was about 1" missing. I put some tape across the bottom and used Great Stuff to fill in the missing sections. I carved and feathered it back and sealed it with epoxy. This was my second go at filling the cracks. The first time around I didn't put anything over the top of the new foam aside from glazing putty and I found that the new foam expands much more than the dash so I had lots of high spots when the dash was warmed up. Sealing it with epoxy seems to have completely fixed that. I didn't think of drilling out the cracks, that would have been a great idea.. I was really unimpressed with the SEM texture coating, it didn't really give much of a texture and it was kind of a pain to keep it consistent. I went for a Duplicolor Bedliner, not exactly the same stuff as BitchinZ used, I think it was the cheaper version. It's high build so it gave a nice texture and filled in all of the scratches from sanding. I topped it with the SEM Trim Black and it looks really, really good. I was kind of in a rush to get my Z back on the road, so I didn't do some things as nicely as I should. I'll probably have to revisit this in the future to fix a few things, but for a few days and $40, it looks a thousand times better than it ever did.

-

Well you can try that, but it might not be enough and could cause phasing problems with your rotor and cap. You should really make sure it's in the normal position and then figure out your trigger angle from there.

-

You'll want to move the dial around until the timing mark lines up with 0°. If your dial isn't on 0, then you'll need to adjust your trigger angle until it reads 0 on your gun and on the pulley.

-

You should use fixed angle, it will completely bypass the spark map settings and use whatever degree you type in for all RPMs/Kpa. I've never tried using an advance as low as 0 degrees, MS might act strangely (I have no idea), I would suggest using a fixed angle of 10 degrees to test. Anyway, if you did enter 0 and your timing light is showing 41 degrees, that means you are 41 degrees advanced (trigger angle is off by 41 degrees). It should be showing 0°, according to your settings. To fix this, you would have to set your trigger angle to 9°, so something is wrong. Set your fixed angle to 10 and try again. Also you might want to check your distributor. I never had access to a 82/83 distributor (I had an 81), but if the distributor can be rotated make sure it's close to the middle.

-

The trigger angle is how many degrees BTDC when the optical sensor in the distributor gets a pulse. So when the ECU sees the signal it knows the engine will be at TDC in X degrees (set by trigger angle). With MS you need a trigger angle at least 10° more than the maximum advance you plan to run because the ECU needs time to calculate the firing angle. With a 60° trigger angle you will be able to run 50° degrees of advance, far more than you'll need. We throw around 60° as the trigger angle because that's roughly where the L28et sensor sits (81 CAS or Optical in the dizzy). The older VR distributor needs a very different trigger angle due to how it was constructed. Now your trigger angle will most likely NOT be 60°. To get the exact trigger angle, you'll do what calpoly-z said. Using the Fixed Angle on the Spark Settings page to lock your timing to a specified degree (10 for example) and check it with a timing light while cranking. Change your trigger angle to until you get 10° exactly.

-

I have 17x8 +17mm (245/45/17), 17x9 +17mm (275/40/17) Roh Snypers on my car and I think they would fit an unflared Z with coilovers. I picked them up as part of a group-by with some Supra guys about 8 years ago. The offset wasn't what I wanted, but the size and price fit, so I bought them and used spacers to fill out the flares. I'm pretty sure I have some photos with them on my car before I cut the fenders, I'll post them when I find them. Eventually I'd like to get away from the spacers and pick up some RBRs or something similar with the correct offset.

-

I never attempted to use the 4pin with the stock ECCS, but I would imagine it gets wired up the same as if using Megasquirt. B = Switched 12v (o-ring connector from coil (+) to spade on the HEI should do it) C = Coil Ground G = Signal from ECU W = Ground The HEI module grounds the coil through the casing with the mounting screws. You might want to run an extra lead off of that to make sure the module is getting a nice and solid ground. Moby's MS diagram

-

I didn't use the VCM and ditched the 280zx's intake manifold altogether in favor of the manifold off of my 280z. For a fast idle, I reused the idle valve from my 280z. It needs 12 volts supplied to it when the ignition is on. As the bi-metal valve heats up, it closes the port and drops your idle. Or you can just ignore both and you might have to crack the throttle a bit to start it when it's cold, but hey it's almost summer and that's a winter problem, right?

-

Direct replacement for the Nissan ECCS? Probably not.. I'm not really sure what sort of signal the ECCS wants. But if you're using Megasquirt, you don't have to run wasted spark/multiple coils with a decoder wheel. I ran a single coil with the stock '81 distributor and wheel decoder without any problems. You'll still want to enter the Trigger Positions for the other coils but just leave them disabled in the spark outputs. I was using a 6-1 flywheel based wheel for a while (like in the MS FAQ), but getting the sensor threaded in and out was a constant pain in the ass. A few weeks I stripped the threads on the aluminum sensor and said screw it all and created the 30-1 wheel.

-

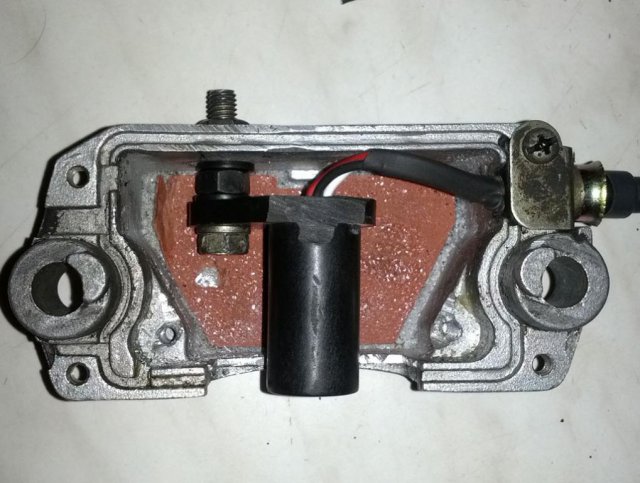

If you have an 81 pulley with the toothed wheel and the CAS sensor and brackets, it is incredibly easy to turn it into a 30-1 wheel. I did pretty much what the OP did, ground off two teeth for every tooth and then an extra for the missing tooth. What tooth is used for the gap really doesn't matter, when you plug the info into the spreadsheet it spits out all the correct information you need. The important thing is to line your sensor up with a tooth and record that number. With the motor at TDC the missing tooth is #0 and you count backwards (counterclockwise) to find the tooth number for your sensor. In my case, I decided to reuse the mounting bracket for the original CAS. I gutted the CAS and bolted up a Hamlin hall sensor that DIYautotune sells. Acetone will dissolve the goop inside and then just chisel out the circuitry and magnets. So now you have a very sturdy and adjustable bracket for the new hall sensor. Supply 12v to the sensor and wire up MS as VR and you're good to go. Lock your timing at 10 degrees and adjust your crank angle until it lines up. Really the hardest part about doing this is removing the crank pulley. When it's off make sure the key on the snout is pointing straight up and make a note of which timing mark corresponds to TDC. There's two marks on the wheel, one is used for TDC at the timing degree marks and the other, I have no idea, but it appears to point at the CAS.

-

I was just tossing in my two cents. I just replaced the head gasket on my L28et after experiencing similar issues. Car ran well, the AFRs were good, and the oil was clean, but it would occasionally puff some white smoke/steam at idle. After pulling the head off, the metal ring on the #1 cylinder was cracked down by the water jacket and oil passage. It wasn't a catastrophic failure, like you would think it would be, just enough to cause problems. I never bothered looking at my exhaust manifold, but I think they were all nice and carboned up. You can try looking in the plug holes and see it there's anything unusual. My #1 cylinder had some wet goop on top of the piston (and that plug).

-

I used an 81 harness so I have no idea what those 8 pin connectors are for. Mine only had a 6 pin connector where the coil harness plugged into. Out past the grommet, it had another 8 pin plug for the resistor pack, all red wires going in and out of it. The second big plug looks like the main power plug for your 280z. Off the top of my head I would say the green-blue wire powers your fuel pump, the white-black or white-red might supply power when the key is turned on. This plug should be used to turn on the 280zx's main relay and the blue/green wire should be connected to the fuel pump relay output.

-

That's definitely not a nissan 5 speed, it must be the t-5. I think you might need the driveshaft that came with it or a custom one made to use it in your S30. Not sure if it's worth the effort, you might want to do some research and decide for yourself. $500 bucks for the whole package seems nice though.

-

White exhaust, clean ports, and white plugs; sounds like a blown HG.

-

Seems like to me, using EDIS these days is increasing your complexity, not decreasing it. With EDIS you're relying on it to decode the wheel signal and then output that signal to MS (which uses the same circuitry as if it were decoding the wheel itself). If the VR input circuitry goes wonky, MS won't have an RPM signal and it won't run regardless of the limp mode built into the EDIS unit (no fueling). Back in the day when MS couldn't decode wheels (or not as well) using the EDIS for wasted spark was a great option. I kind of see it as a relic these days especially with introduction of MS2 and MS3. Just my two cents, I never spent much time researching EDIS, it might have other inherent advantages I'm not aware of. But that's an interesting setup you'll have, I hope the flywheel method works for you.

-

Why do you want to use EDIS, unless you're not using Megasquirt? But as for you're question, believe me when I say I'm not an expert at this, but I think it might work. EDIS is just looking for a 36-1 signal, I don't think it would matter too much where it came from. I'm not sure what the technical term is, but VR sensors just send an AC frequency, the controller just needs to sense the pulses. The one thing you would need to check is the trigger angle that the EDIS control unit expects. If you go this route, you would definitely need to build in some sort of adjustment to slide the pickup to set the trigger angle. I'm not sure of the exact part number of the sensor I'm using, it's stainless steel and I think it's a 5/8th thread by about 4" long. I did manage to find a marine parts website that sold it a while back and it was about $100, but I can't seem to find it again. If I were you I'd just buy a threaded VR sensor from DigiKey and try that.

-

It really doesn't take much to make the connection. Just make sure it's solid and in place before it's powered up. If you really want to be sure, you could ohm the left and ride side of the jumper pins and see if your jumper wire is making a connection. Also make sure whatever adapter you're using is set to 9600 baud, I think MS2 uses a higher rate. If you want to see exactly what's going on when you try to boot, you'll need to get hyperterminal and then you can follow DIYautotune's guide here.

-

Oh man I forgot all about this post, I never did get the CAS figured out, but I did fix the problem with the 76 NA VR distributor. Apparently they work off a really low trigger angle, I think it was around 15 degrees. I had to tweak the VR mounting plate inside the distributor to get the right angle for MS to use. If I remember correctly, with a low trigger angle like that MS goes into next cylinder mode and it figures it out from there. Don't ask me why I could run a trigger angle of 115 degrees with the HEI module, but the VB921/BIP373 would only work with a low angle.. I have a tendency to kill flies with sledgehammers, I was having a different problem and I decided to go with a flywheel trigger. I followed the excellent guide by X64v in the FAQ section. I'm using a Caterpillar VR gear tooth sensor instead of a hall sensor (used what I had on hand). I was running a single coil with a wheel decoder for a little over a year now. Just recently I've gone to a wasted spark setup using a GM DIS coils. I gutted the DIS control board and wired up 3 BIP373s inside to control spark. In the past I had problems when I tried mounting an ignitor on the MS board, so this keeps everything clean and separate.

-

For just the engine and trans, that seems pretty steep. You can get a complete running 280zx for around that price or less. I paid $600 for the rusted out '81 280zx I used for my swap back in '05. Checking my local craigslist and I see a running 280zx turbo with 5speed for $1,200. That being said, if you've been watching craigslist and this is all you can find in your area, well then I guess $1000 is how much a L28et costs..

- 18 replies

-

- l28et

- l28et price

-

(and 1 more)

Tagged with:

-

I don't see anything particularly special about their kit that is specific to a Z. You could put together a kit from eBay for a lot less and come out with a lot of spare pipes and clamps. With this kit, it looks like you will still have to fab up the mounts/attachment points, which in my opinion is the hardest part. I'm not an expert by any means, but I did recently install an intercooler like I described.

-

When I picked up my $300 junker '76 280z, it had no spark and it turned out to be a broken lead on the ignition module. It's located in the passenger foot well. There's about 6 wires (mine was a CA model) with screws holding each down. I still have my ignition module in my car and have been meaning to remove it for a while now if you think yours is bad. Might also want to check the air gap for the VR pickup inside the distributor too. I would imagine If it can't sense an RPM signal it won't fire. It would have to be really bad for it not to catch the signal though.

-

I was getting wild swings just like you described (7 to 22v). First off, you'll definitely want to check your grounds like Matt said. If improving your ground doesn't help, you might want to look into the PWM mod and putting a cap (I used c30) in the boot header. What ultimately helped me was moving the BIP323 out of MS. Basically, giving the ignitor it's own ground to the motor (not going through the MS PCB). I'm not sure how your coils and their ignitors get grounded, but that might be something to look into. While my voltage still moves a bit, it only varies from .3 to .5 after doing those changes. msextra.com PWM mod thread

-

It's been a while since I've posted here or worked on my car Seems like I've always had problems with spark, either getting it out of MS or getting a RPM signal in to it. Anyway, I'm kind of wondering what my best options are for spark input and output with my current setup. I have a 81 L28et with the CAS. When I initially started using MSNS-extra I was using a locked 76 NA distributor (VR input) and using Moby's HEI 4 output setup. The car ran and worked pretty well aside from an intermittent miss which would screw up my in-dash tach signal (bounce around constantly). So in an effort to fix the miss I tried various things. First was to use the VB921 to handle spark output. Initially this worked too, but I had to use a really low trigger angle (around 20 degrees, I think) so my spark advance/control was basically nonexistent. My only other option at the time was to try and use the 81's CAS. I eventually got it running with the CAS using the same wiring setup as the optical distributor. My new problem was around 3700-4000rpm MS would lose the tach signal completely and the motor would cut out pretty bad. Fast forward to the present and I can't even set the trigger angle, spark is very inconsistent. In frustration I tried to go back to my original setup with the HEI module, but it's been a few years and I'm a little rusty at MSNS so I had problems doing that. Not to mention the whole reason I was doing this was to get a working tach signal for the dash gauge. To sum it up: 76 NA Dizzy with HEI - car was drivable, but slight and constant miss. 76 NA Dizzy with VB921 - low trigger angle, stuck at around 15 degrees max advance. 81 CAS with VB921 - motor ran, but MSNS lost rpm signal around 4000rpm So now I'm looking at something like using a Ford EDIS setup, but I really just want to get the car running with the simplest setup I can. Looking at other threads people just flat out say don't try and use the 81 CAS and for the price of an 82 optical distributor go EDIS. I'm going to do more research to find out how difficult EDIS is to setup (like installing the toothed wheel). I know I'm kind of rambling, it's what I do, but any input on my situation would be great.