-

Posts

351 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Metro

-

If you're using the stock 81 ECCS equipment, you have a CAS (crank angle sensor) reading a toothed wheel on the engine's pulley. As far as MS is concerned, it's a hall/optical pickup, exactly like the 82-83 optical distributor. So let's say you installed a 280zx distributor with built in ignitor. It has everything required to fire the coil (VR pickup, ignitor, etc) on its own. The problem now is that you wouldn't be able to retard the timing under boost. Then in order for the engine to run, you would need to keep using the 81 CAS in order to feed the ECCS an RPM signal. This all might work in theory, but it would be really bodged. If you're going to the trouble of installing MS, not controlling the spark when you have all the available tools to do so is just silly. Spark is like one of the simplest things to set and control with MS. As I've alluded to above, running a turbo motor with no spark control would require a lot more work than not. If your kit already has the ignitor installed, then it's literally as difficult as running a wire from the ECU to the coil. If you're building the unit yourself, it's only two more things to solder and a few jumpers. I would recommend for you to use the MS supplied ignitor, but you could keep your HEI module and use that if you really wanted. Most people struggle with getting an RPM signal and you need that in order for MS to run, spark or not. Using MS to control spark is the simpler route, in my opinion.

-

You definitely have an '81 motor. You can see the CAS with the pigtail running up from the toothed wheel on the crank pulley. I never could get the 81 cas to work properly with MS, it would idle fine but it would cut out and lose the signal above 4000rpm. It's possible I had a bad sensor, but it's something to note if you have problems. I wired mine up exactly like the optical distributor, they both output the same signal even if the 81 CAS is actually a VR sensor. If you have problems with the CAS and you're feeling adventurous, you can read about how to convert the 120 tooth wheel into a 30-1 wheel here. It will allow you to run wasted spark, if you want. You don't have to use the MS relay board, but you do need to wire in relays and fuses somewhere. I modified a Ford power distribution block with my wiring harness instead of the MS relay board. You can read about the MS relay board here. I don't know much about the relay board, but I think it just passes everything straight through to a terminal strip. I would think it has all the connections MS2 needs. One thing to note, it says you're running MS2-Extra, which is a different code base. You should always check the documentation at msextra.com before looking at main megasquirt.info website.

-

If you wired it up like in the picture, but ignoring the VR inputs and not connecting R, it probably would work as a dumb ignitor where MS controlls the dwell. I'm not sure if it's like the 4pin HEI module where it's a pulsed +5/12v signal to the ignitor. You could test it by powering the coil and ignitor, making sure everything is properly grounded, and then tapping 12v to E and see if it fires the coil. Years ago I used a 4pin HEI module with mixed results. There always was a slight miss at idle (tick.. tick.. ticktick) that drove me mad. I tried multiple different modules, new cap, rotors, plugs, and wires, always with the same result. Once I finally understood how to properly wire the VB921, I switched over to it and all my problems went away.

-

Braap talks about the stock efi and cams here. The short version: the stock efi does not play nicely with them. Megasquirt is the solution to all the problems with the stock EFI system, but I'm not really sure what you're going on about having a sensor for detecting the cam, it makes no sense. A larger cam will affect the VE and you fix that by altering your fuel VE table. MS will only care about your AFR if you tell it to. It will run in open or closed loop depending on your settings. If you allow it to run in closed loop you can set your target AFRs based on rpm/load.

-

There's no reason to use a GM HEI module (any flavor) with any MS2 build (or even MS1 on a v3+ board). The HEI modules are a leftover from when the MS hardware didn't support as many features as it does now. Not to mention you can now get a rock solid ignitor (with thermal cutoff) in the BIP373 and I personally never had any issues with using the older VB921 ignitor. All this talk about VR is mostly irrelevant though. You also are using an L28et distributor which is an optical/hall type sensor and already outputs a square wave signal that MS can use. Just wire it up as shown here.

-

What do you use in place of your fusible links?

Metro replied to ISPKI's topic in Ignition and Electrical

I spent months combing the internet for a fuse block and maxi fuse holders to use with Megasquirt with no luck. So I went to the junkyard and took a power distribution block from a Crown Victoria. It had 4 relay holders, 5 maxi fuses and about 12 regular fuses and I paid $15 for it. Just browse around until you find a car that works for you. With the Ford block, the connectors can be easily popped out of the panel by pressing in on the catch from the top. Then you can reuse the connectors or find new ones on the internet. -

On second thought, I might be leading you astray here. My ignitors aren't mounted on the MS board, they're inside a GM DIS coilpack where the GM ignitors used to be. MS just outputs a spark logic signal, not the coil grounds. I guess how you wire the output of your ignitors is up to you, if they're on SP2, 3, 4.

-

I don't use a relay board, I thought the Sx outputs were for MS2? I put the pin numbers on the image I posted for MS1.

-

Yeah just make sure the 4pin plug is wired like my picture.

-

Are you positive the 78's efi works that way? It doesn't make any sense to me and I've never heard of an oil pressure switch cut off in Z cars (75-76, and '81 280zx). If anything, if there is an oil pressure switch it would kill the relay's ground so so the relay would turn off. The ECU should control when the fuel pump turns on and off.

-

No offense dude, but buying a Chinese knock off turbo.. well yeah.. it's going to be terrible. It's too bad you can't return it due to their poor customer service though. Get eBay and Paypal involved, that should at least get a response out of them.

-

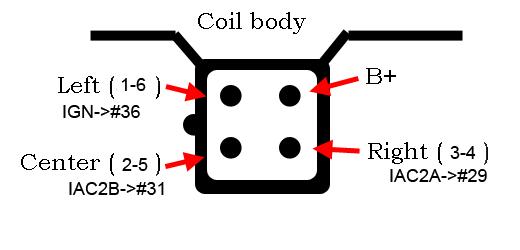

Your wheel settings look fine, but your coil wiring is still screwy. The coils should be paired 1+6, 2+5, 3+4. It looks like you have plug wires on 1+4, 2+6, 3+5. I modified DIY's picture for that coil and how yours is mounted upside down in your car, it should look like this: That's front to back ABC.

-

If you have spark, that means the ECU is at least on and it's getting an RPM signal from the CAS. If your fuel pump is running as you say and you have fuel pressure, are your injectors firing? Do you have the injector dropping resistors from the 81 harness plugged in? It's a large metal block plugged in just outside past the firewall grommet.

-

For simplicity I would run one fuse for the coils and split it off into the six wires using a junction block or something. It's all up to you though, if you think you need 6 fuses and have the room for them, have at it. I'm not really familiar with MS3x, I'm not sure if you can just use the software to run wasted spark COP. Hopefully someone from DIYautotune will chime in. I have a feeling you will have to wire them like you would for MS1/2, pairing 1+6, 2+5, 3+4 to output 1, 2, 3. There's two fuses for the injectors because there's two injector drivers. To keep everything separate, I went with two fuses when I rewired my engine recently. I ran with a single fuse before that.

-

Honestly, I think you're best off using what you have. There's no reason why it won't work unless the distributor is bad. You never mentioned what distributor you are using, I think there's two or three different VR distributors for the Z, I've only had experience using the kind found on a 75-76 280z (the ignitor and conditioner is located under the dash, not part of the distributor like they started using with the 280zx). With that distributor my trigger angle was around 15°. Normally a trigger angle that low is a bad thing, but when it's under 20° MS goes into next cylinder firing mode. Instead of calculating the firing angle for the current cylinder, it will calculate it for the next cylinder and everything works as it should. So what you should do is get out a timing light lock your timing to 10° and start adjusting the trigger angle until your timing light reads 10°. Report back here what you find and I can help you out some more. As for the DIY 36-1 wheel, it doesn't look like it would work on an L28's crank/pulley, the bolt pattern and the size of everything is just too far off. If you want a crank wheel you can see how a few of us have modified the '81 L28et's wheel for use with megasquirt here. You could also try mounting a ford EDIS 36-1 wheel on your pulley, there's various threads around here on how to do it.

-

A few years back they had a problem with the controllers, I'm not sure of the date range off the top of my head. If the manufacture date of your controller really is around two years then it should be safe from that defect. The first thing I would check if connect to it using their logging software. If it can't read or connect, then your controller is the problem. It's been years since I used it, but I think it will give you some other diagnostic information too.

-

I'm not very familiar with MS2, but I've built several MS1 v3 boards. Looking at DIY's instructions, it seems pretty simple. Just build the MS2 ecu like normal with jumpers setup for Hall/Optical and then make the few changes DIY list for controlling the spark output. You'll have a lot more to learn when you decide to go to coils and a wheel decoder. It's pretty simple to get the car running with the stock distributor and coil.

-

The standard code running on MS1 doesn't support spark control. It was added later with Megasquirt 'n Spark Extra and MS2. MS is all about flexibility, if you want to MS on a lawn mower, you might want to skip ignition control.

-

Let's recap, what is your current problem? Also post your wheel setup so we can double check it.

-

Going back a few posts, I hope you didn't just plug in the numbers I posted for my wheel. They would only work if your missing tooth was exactly the same as my wheel (highly unlikely). MS will pick up the RPM no problem since you told it's a 30-1 wheel (30 teeth, gap -1) but the spark will be all crazy because the coil firing positions are wrong.

-

Yeah the coilpack they sell is for a v6, I think it's from a Chrysler. Rewire the plugs and I think it'll run.

-

Hard to tell, but it looks like your coils are paired wrong. Should be 1+6, 2+5, 3+4. How you wire them up is up to you, but I setup A for 1+6, B for 2+5, and C for 3+4. Also note that C and B are flipped with MS. So D14 is A, D15 is C, and D16 is B.

-

Here's a direct link to the file from MSextra.com You just need to config ABC for your three coils (or just A if you're using a single coil). I would clear out the other fields. The macro needs to know the tooth number at your sensor, not where the gap is at TDC. If the gap in your wheel happens to be at your sensor, then you would use tooth 0. Your fuel pump is cycling because your ignition input/output is configured incorrectly. Once we get the wheel decoder info set properly, it should stop. I'm at work, so I can't get a screencap, but my settings are something like this: Tooth number aligned with sensor at TDC: 14 Trigger Pos A: 7 Trigger Return A: 11 Trigger Pos B: 17 Trigger Return B: 21 Trigger Pos C: 27 Trigger Return C: 1 The rest are set to 0 My trigger angle is around 56°

-

Yeah you need to set your trigger positions. Basically when the tooth A comes around it knows to fire Coil #1, and so on. Your tooth config is fubar right now If you don't have Excel, give me the tooth number that's in front of your sensor at TDC. With the motor at TDC the missing tooth is #0 and you count backwards (counterclockwise) to find the tooth number for your sensor.

-

The fuel pump cycling is usually an ignition output configuration error. What are your trigger and return positions for A, B, and C? It will vary depending on where you notched your missing tooth. I attached the spreadsheet you need to calculate it. With the trigger positions set and the sensor in the stock location, the trigger angle should be about 60° +/- 20° wheeldecoder.zip