-

Posts

1077 -

Joined

-

Last visited

-

Days Won

34

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by A to Z

-

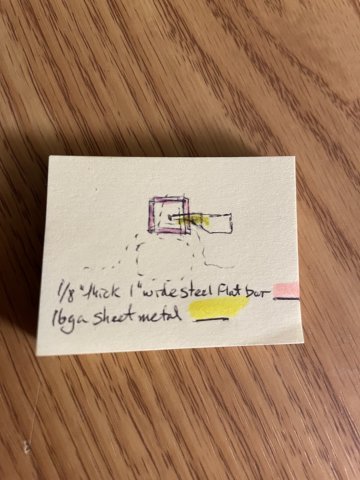

I appreciate your concern. No one else even asked about it. As I stated, the strut tower is going to be reinforced. the amount cut didn't completely cut it, and hasn't changed the ride height or anything, but will be addressed before leaving the garage. I have a guy I know and he is a mobile welder. He welded my coilovers, so with some thick plate and some sheet metal, he can come in from under the fender and build bracing and close it up. Will be perfectly safe and actually strong once done. The closeness to the brake master cylinder, I have worked on, and I will be putting a layer of high-temp insulation between them as a safety precaution, cut to fit, and is rated to 2400F. Attached is a drawing I have made. The welder is an active drag racer and his input will of course be taken to make it stronger that it was being just thick sheet metal spot welded together with bends from Yokohama. It will be stronger than it was. Even though it is just a cruiser, I wouldn't leave it weakened. It will be better than before.

-

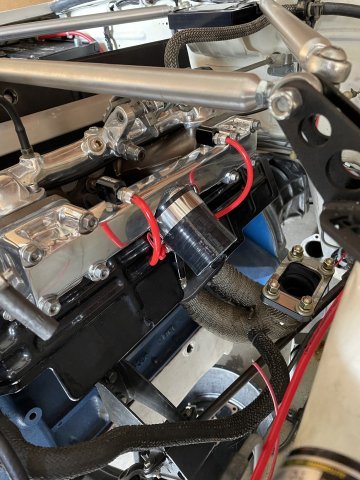

12-07-2024 Turbo Project Update. Pearl Harbor Day. REMEMBER. Boy, today was a L O N G one. I started by porting the waste gate my hot side/turbine housing. I used white lithium grease to mark it, and then went out porting it until I was at a spot where I needed to leave enough for the foot to seal. then I got ready to clock the wheels, so that my oil drain would be right at the bottom and oil feed at the top. This is when the trouble started. My turbine would not bolt up to the J pipe. there was no room. So, I made a big mistake. I ASSUMED the T3 housing would be the same as the original RayJay housing....not even close. So, a decision had to be made....make a new J pipe or make all of this work I have done to install it...work. I went ahead and started cutting the inner fender to get the turbo to fit. unbelievable trial and error, fit, refit back and forth, after what seemed forever I was able to the put the turbo on, get it clocked. I ported out the oil drain hardware, as I have read that the 10AN kit that is sold tends to be just a hair to small and the oil can't drain fast enough, and will back up in the turbo. So, as the pics below show, I was able to get all of them ported out, and I assembled the drain line with thread sealant, installed it and then dropped the turbo back on. So, with 10-15% of the turbo in the wheel well now, and more needing to be cut, especially into the strut housing, I had to think it over, and I decided, I can have the mobile welder come over and weld up and reinforce the strut tower and all will be well....I also came up with a way to have the carb come back "in" completely to the engine compartment on an angle, and will sit right behind my snow performance water methanol pump, and the coil and electrical. It really took a along time to get the complete turbo in, I had to grind on the turbine housing and the brake master cylinder to get it to fit, and then a bit more so I was able to get the turbo blanket on as best as I could for now. I will get some high temp insulation to put between by brake lines and the turb as soon as I can. So, crisis averted. And when it is done, I will have it all cleaned up and will look very presentable. Pics follow. Cheers!

-

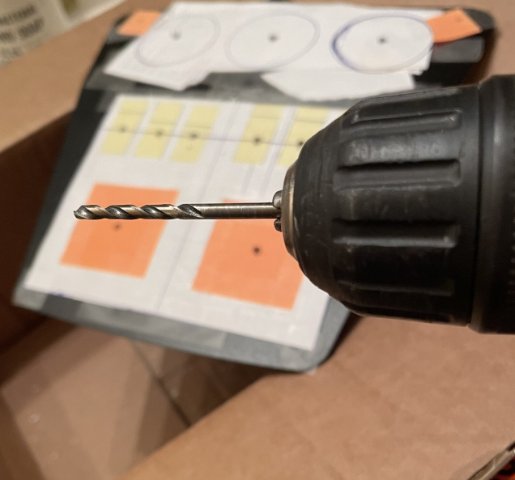

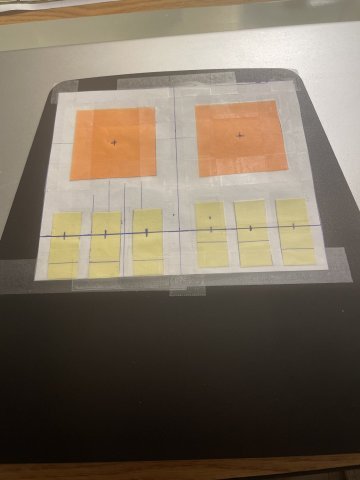

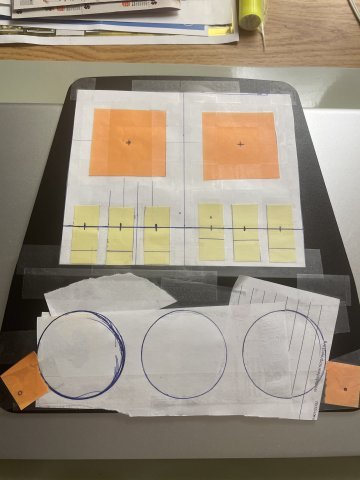

12-04-02024 Dash Center Plate Project Update: My switches came in already, So I went ahead and drilled out all the holes and mounted the switches in. I like the look with the waterproof covers that screw on. The big holes will need a little adjustment here and there but coming along pretty good! Pics follow

-

Thanks! I will do my best.

-

I decided one of the very last things I will probably do with my 240Z is replace the center dash area with a custom plate with switches and gauges. I started by getting the plate from Skillard, and made sure to spend the extra 10 bucks for the satin powder coating. Nice piece. I then went about taking measurements and figuring our just exactly how I wanted it to look, what I needed it to have and what would make it look cool. Earlier I had added 5 switches to the fuse box cover plate, and now that I am going to do this, I will move those wires up to switches, and eliminate those switches in the cover. Since that plate will now have holes, I will have to decide whether I wish to replace it with another stock piece, or cut a piece of aluminum to fit. Do any of you know someone who makes that plate? I asked Ben at Skillard and he doesn't. Anyway, I decided to go with the old fashioned toggle switches, and then in the space above it, I am going to add two 2 1/16" gauges I found online from "MaxTow".....apparently they are used by truck guys, but of all the gauges I found, they were the nicest looking .....in my mind at least. I spent some time tonight drawing out all the holes needing to be drilled on the back of the piece, and I am hoping that by going from the back out, the powdercoating will survive. I am also attaching pics of the gauges and switches I have ordered.....and another pic of the triple gauges I already bought from MilkFab....still waiting on my Knock sensor gauge to come in. Comments welcome. Cheers!

-

12-01-2024 TURBO PROJECT UPDATE. Earlier I had mounted by Water Methanol tank, but it needed clearanceing so the hood would close. I had to make a spacer to get the hood spring out of the way, and used a spot of JB Weld to hold it permanently and a tie wrap for now until it dries.....and then I was able to fiddle around, drill some more holes, and finally get it in a good place. After that, I pulled the gas pedal and drilled out the ball end and made sure my clevis fit. The clevis is from MOTION, and yes, it is expensive....but I needed it. After drilling it out, I cleaned it up with the wire wheel attachment in my electric drill and gave it a shot of flat black paint. I also got my longer oil supply line for the turbo in and got it installed...much better. While there, I drilled out the spot welds holding on the factory bracket for the throttle rods. I will paint it up and then put a polished aluminum plate over that area. I am waiting on stuff now....the turbo, that was send out for carbon seals, the carburetor, and the J&S Safeguard knock sensor and individual cylinder timing control. Well a few pics from the day. Cheers.

-

I don't really like taking her over 5000 RPM really anyway. The cam is stock, and its a stroker with all the power where I like it.... mid range. If this is going to give me that type of power, frankly I couldn't ask for more. Its a high compression engine (11.5 to 1), and this is meant to just lightly turbocharge it. I am at 6035 ft. elevation, so basically lose a point and a half on the thin air. This is a Draw through setup on an old crown turbo kit that has been updated. I have a snow performance water/methanol kit with 2 nozzles to cool it down and give it a bit more octane....and a J&S Safeguard Knock sensor with individual cylinder timing pull. It's mainly for looks and a little bit extra push....it's a cruiser.

-

here are my T3/T04 Turbo specifics: Turbine Side: Turbine Trim: 74.2 Turbine A/R: 0.63 Turbine Inducer: 64.8mm Turbine Exducer: 55.8mm Turbine exhaust outlet : 79mm Turbine exhaust inlet: 44.7mm(length)/85.8mm(width) Compressor Side: Compressor Trim: 48.1 Compressor A/R: 0.5 Compressor Inducer: 52.7mm Compressor Exducer: 76mm Compressor outlet:78 mm Compressor inlet:51.5 mm

-

Hello! Since my turbo project is going well, I wanted to ask if any of you have any thoughts as to what I can expect from my T3/T04 turbo with .50 A/R 48 trim) with a .63 turbine housing (trim 74.2) on my 2.9 stroker? Since I like quick spool, I think a turbine with more vanes might be nice. Thoughts? Thanks in advance.

-

Cool writeup I found on my turbocharger: T3/T4 hybrid turbocharger assembly is created by installing a T4 compressor wheel and housing onto a T3 turbine housing wheel and center section. A T3/T4 hybrid turbocharger assembly is a compromise for engines where a T3 turbocharger is too small to reach the desired maximum horsepower but using a T4 turbocharger would create an unacceptable amount of turbo lag. The T3/T4 turbocharger is designed to be used on engines displacing 1.5L-3.0L and is typically good for around 400HP. They are also commonly used in twin turbo applications. In this case those figures would be doubled 3.2L-5.0L engines up to 800HP. Horsepower ratings are generally meant to express the turbochargers maximum airflow capability. Recommended boost pressures are 7psi(0.5 Bar) to 21psi(1.5 Bar) and boost pressures should not exceed 30psi(2 Bar). Exceeding 21psi(1.5 Bar) of boost pressure can significantly reduce a turbochargers lifespan. Generally speaking 14psi(1 Bar) is good for a 100% increase in horsepower from a naturally aspirated engine. Also factory non-turbo engines without forged internal components on high octane pump gas (91-92 octane) it is not recommended exceeding 7psi (.5 Bar) of boost. Doing so could result in damaging your engine.

-

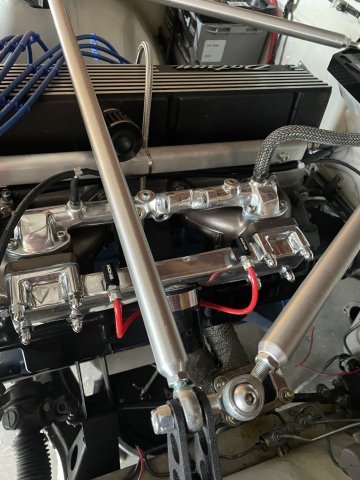

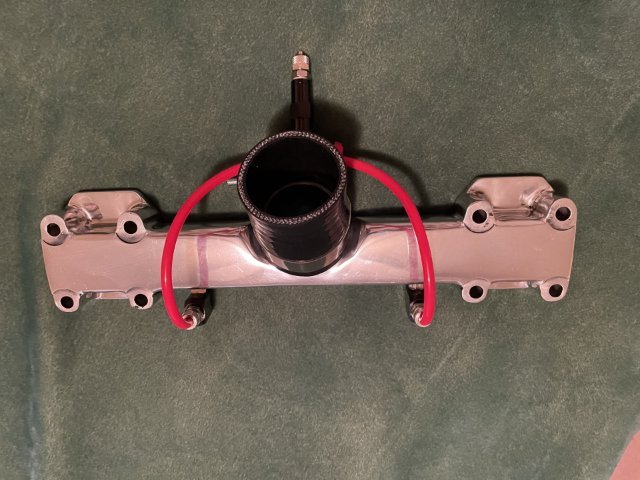

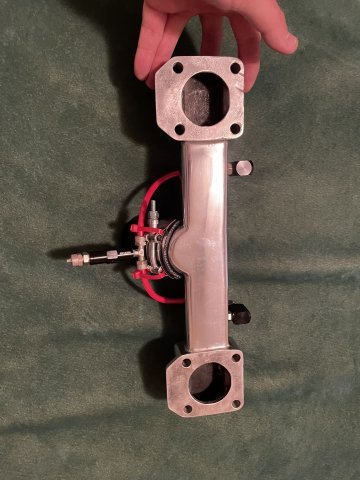

11-23-2024 TURBO PROJECT UPDATE. Hit the garage running today! Dropped the 2-1 exhaust and carburetors and prepped everything for install. I installed the Crown J pipe with a new gasket, and then installed the Crown log manifold, I then plugged the port for the second carb on my Pallnet fuel rail. Then I went ahead and installed the crown adaptor and 3 inch to 2 inch hose which goes between the carburetor and turbo inlet. I found that the hose that goes from the block to the PCV would not work with the crown intake, so I took cut a portion of the factory hose and attached a breather to it and attached it to the block. I also attached the valve cover breather using Loctite thread seal on everything. I took a break and ran to Ace Hardware and got some chrome button head screws for the manifold so it looks even better but was unable to get a plug to fill the PCV port, so I ordered one on eBay...M14x1.5 thread....so awaiting it.... stainless. Next I jumped on installing the oil supply line. Unfortunately, my oil feed line is about 8-10 inches short, if I want it to go all the way around the back. So I will look into a longer line. This line will work if I run it over the valve cover. I then added a few stickers under the hood, and mounted 2 of the 3 gauges to the Milkfab gauge plate. The 3rd gauge will be for the J*S Safeguard knock sensor which is also en-route. So, quite a bit accomplished. Pics follow. Cheers!

-

11-21-2024 Turbo Project Update. I got my J pipe and down pipe back from the welder, Juggernaut Welding. He gave them 3 coats of Cerakote dark graphite powder coating, and it is good to 1800 degrees F. I went ahead and brough a bunch of little things in the house and got them done, I got the Water Methanol injection nozzles installed and the hoses installed, put the plugs in the carb adaptor and wrapped the down pipe and J pipe with header wrap. I have a turbo blanket that matches the header wrap waiting. It's starting to come together. Pics follow.

-

Turbo Guru's, T3 question(s). Please advise

A to Z replied to A to Z's topic in Turbo / Supercharger

thanks. It is at G Pop Shop. Getting Carbon Seals installed, and a possible port and wheel change for quicker spool. My redline is 5500-6000 RPM, so I am willing to sacrifice a top end I won't use for more "meat" in the mid range. -

Yeah....I have started to realize the same thing. I will let it make what it makes and provide the fuel, methanol and water it needs. the knock sensor will save it. If it wants to spool immediately, that would be exactly what I want. I don't go over 6K RPM anyway. I am going to talk to the turbo builder and see what he has for custom wheels....apparently more vanes brings earlier spool.

-

My welder also does powder coating, so I am having him powder coat the J pipe and down pipe with some graphite black colored hi temp powder. Supposedly good for 1800 degrees F. Also....G POP , who is doing the carbon seals on my turbo is going to hi temp powder coat my hot side with some 2000 degree F Titanium color powder coating, and then the compressor side is being Powder coated gold. You will see, it will all come together. also mulling over having the turbo ported and maybe a custom turbine for the hot side to spool the turbo quicker since I like my 5500-6000 RPM redline. We go forward!

-

Turbo guru's please read: I have the T3 Turboboosts M12 turbocharger I got off of eBay, and because of what I have learned on here and other pages....being a draw through setup with crown manifolds, etc., I have sent the turbo off to "G POP Shop" in Arkansas to gee carbon seals installed, and the hot side is getting their high temp coating in Titanium finish, and I am having the compressor side powder coated in gold. Since it is there, I am thinking about possibly having a custom hot side wheel put in to create a faster spool. It has journal bearings, which doesn't bother me as this is just a weekend around town toy. The Specifics of the turbo are: Compressor : Inducer 52.7mm, exducer (outer diamter) 76 Ex turbine: exducer 55.8mm, Inducer ( outer diameter) 64.8 Trim: 48.1 A/R .50 420 HP Rated. Going on to a 171 cubic inch (2859cc) inline six cylinder Any opinions on exhaust wheel sizes, etc., that will help deal with a 4000 RPM spool, outside of manifold work and larger down pipe enlarging etc. I am thinking custom wheel(s). Not sure if porting would help either. P.S. I was shocked to find out Garrett turbos are made in Shanghai, CHINA.

-

Turbo guru's please read: I have the T3 Turboboosts M12 turbocharger I got off of eBay, and because of what I have learned on here and other pages....being a draw through setup with crown manifolds, etc., I have sent the turbo off to "G POP Shop" in Arkansas to gee carbon seals installed, and the hot side is getting their high temp coating in Titanium finish, and I am having the compressor side powder coated in gold. Since it is there, I am thinking about possibly having a custom hot side wheel put in to create a faster spool. It has journal bearings, which doesn't bother me as this is just a weekend around town toy. The Specifics of the turbo are: Compressor : Inducer 52.7mm, exducer (outer diamter) 76 Ex turbine: exducer 55.8mm, Inducer ( outer diameter) 64.8 Trim: 48.1 A/R .50 420 HP Rated. Going on to a 171 cubic inch (2859cc) inline six cylinder Any opinions on exhaust wheel sizes, etc., that will help deal with a 4000 RPM spool, outside of manifold work and larger down pipe enlarging etc. I am thinking custom wheel(s). Not sure if porting would help either. P.S. I was shocked to find out Garrett turbos are made in Shanghai, CHINA.

-

$195 ish for the carbon seals installed along with a rebalancing of the turbo wheels, and a thorough checkup for the turbo. It makes my turbo just that much better. Granted its Journal bearing instead of Ball bearing, for my uses, it is fine. On a Draw through Turbo, the vacuum created by the carb being in front of the turbo, tends to cause turbos to leak oil by pulling oil through the seals and burning it, leaving a blue smoke cloud behind you when driving along. This alleviates that.