-

Posts

1103 -

Joined

-

Last visited

-

Days Won

40

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by A to Z

-

03-03-2026 ATLAS Z UPDATE: Fuel system. I got 90% of it done. I just need some parts to finish. Evil Energy equipment. I love this stuff.

-

-

03-01-2026 ATLAS Z UPDATE: Switched gears a bit, I decided to take a break from the trans tunnel and work on small stuff that has been waiting. I pulled out the 4" X 4" aluminum L backet plate I had, and measured and cut it to fit in front of the radiator, then cut out a portion to keep from inhibiting air flow to the intercooler! After I got that installed, I grabbed all the oil fittings and oil lines, and ran the oil line frm the filter boss to port#4 to help oil the 4,5,6 cylinder main bearings a bit, ran the turbo supply line and turbo drain line and installed everything, about 95% done on that. Then I installed the oil catch can and line and will go back and tie the line up later and finish the loop on the top fitting for that. Yeah I know it's gold....it what he had left....I will probably paint it blue. Before calling it a day, I mounted my electrical panel plate to the passenger floor plate or as Skillard calls it a heel plate. Then I just plain old ran out of daylight. PICS

-

02-28-2026 ATLAS Z UPDATE: I repainted the interior trim that goes behind the headliner with the landau Black SEM interior paint again and it looks like new, then I went around with some Locktite 567 and thread sealed the water, oil and boost sensors and ran them in and tightened them up...wiped off the excess..Then I started on the bracket for my gas pedal. There are 3 bolts above the gas pedal I will use to hold the bracket, and I am using 1/4" thick steel to hold it firm. It will need to be welded. Then the big job of hte day, then the trans tunnel isntall. Several trips of putting it in, deciding what to do, and then cutting strips of 18 ga. sheet metal, drilling holes, and self tapping TEK screwing it together. I have it about 90% done. I did it so that the majority was done before it was permanently installed in the car....that way I could cut off the screws and give it a last touch up of paint. I started running out of equipment and parts and had to do a couple other small things before stopping, taking a shower and running to the hardware store before they closed.... to God willing do more on it tomorrow. PICS:

-

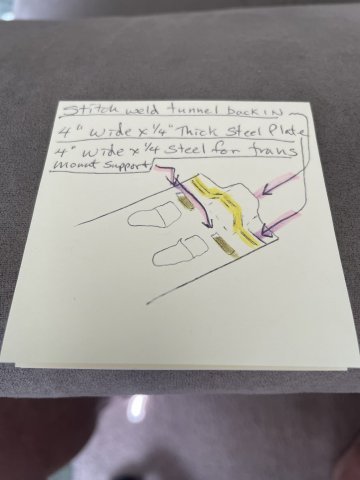

02-26-2026 ATLAS Z UPDATE: Today I got my rollbar and rear strut brace back from the powdercoater as well as the tunnel I dropped off to sandblast. The rubber is still on there, but this yucky sticky layer of honey look goos (glue) is gone. I also picked up my trans mount, he welded it up and added gussets on both sides out of 1/4" plate. I painted the back side quickly before I ran out of paint. Ready for the next day in the garage! P.S. self tapping screws and sheet metal (18 ga) here and ready to built it back, then the welder will stitch weld it and weld the plates over the top and over on both sides to the door jambs. 1/4" thick, 4 inch wide plate. Car will be overbuilt int his area like I did with the radiator support. 350-400 horsepower you really have to, even with the reinforced floor I have.

-

incrdibly nice work. Keep it up! can't see the flange on the turbo header....you hid it!

-

was able to make the template for the back of the throttle.....will bolt right to a raised area right there with 3 threaded holes. good luck!

-

02-21-2026 ATLAS Z UPDATE: I made the template for the electronic, "drive by wire" throttle, and then started bolting together the parts of my Skillard rear deck flooring. I sits about 2 inches up from the hatch floor. There are some pieces that are missing, so I went as far as I could with that this time, and then I jumped on getting a transmission mount built. I used a 6" steel square piece as a spacer, since I have such a large space to fill up. I have it 90% done, I will have it welded up and a couple gussets cut and welded in, and then either powdercoat it or paint. Lastly, I started cutting on the old trans tunnel, and figuring out what I need to get as far as some 18 ga steel to cut and form in there. I will end up screwing it together and then the mobile welder can stitch weld it together, and fully weld then the plate that goes across, but that work didn't happen today....it was COLD and I got tired of my feet being numb. PICS:

-

02-19-2026. ATLAS Z UPDATE. I trial fit the rollbar and rear tower brace, and then dropped them off to be sandblasted and re-powdercoated in "polished aluminum" which is what I had my bellhousing done in. Then I worked more on the dash, I still need to wire it, but I got all the gauges in, the dash plaque in....for the dash plaque I had to build up the back, as the hole makes it DEEP.......cardboard stacked up to the right height and glue, then silicone caulk to hold the badge on, looks pretty good I think. a 280 dash but the plaque says 260Z.....so pretty rare sight in the USA. So, you can now see how the dash will look in the car God willing. I also ordered the skillard lower piece that goes from the center down to the console and also serves as a stereo block off plate. I will be painting it matching gloss black hammertone finish, and the console floor will be that color as well. The gauges didn't go in totally as easy as the install makes it sound....I had to get inventive. Not too bad. PICS:

-

02-18-2026 ATLAS Z UPDATE: picked up my 1/4" thick steel plate for making the transmission mount, set out my seat belts for cleaning, and my rear strut tower brace from Apex and a Autopower Street rollbar from Motorsport Auto have arrived. So, I will decide what color I want to powdercoat stuff (gloss black of "polished aluminum") , and keep pressing forward. Will be COLD for a few days, so any work done will be indoor stuff. PICS:

-

ATLAS Z: Sometimes, it's easier to remove the obstruction to get stuff in, then re-isntall and mod as necessary. As mentioned, I am reinforcing the tunnel and floor with a 4 inch wide steel plate from one side to the other, welded in at the door jamb on both sides, welded across the floor, up and over the tunnel, one solid weld. steel is 1.4" thick. Add a massive amount of reinforcement for the power level. When I re-welded my radiator support I did the same thing....took the time to reinforce it and make it stronger than before.......same concept your body uses when you break bone, it repairs larger and thicker. I showed the jack pick for shock value....hehe it was a last resort, and again, I didn't get UNDER it.........I had the trans on a jack all ready to go, so I just pushed it under there to it was in the well then lowered it back on to the jack stands.

-

Dash cap is on! next is gauges and center section install. run the wires so once installed the wires are right there and can be easily wired. Speedo is GPS. Speedhut gauges. Made in USA, cost is like sending a kid to college

-

02-15-2026 ATLAS Z UPDATE: Started off pulling the plugs, putting the transmission in neutral and putting a wrench on the crank balancer. I wanted to ensure it turns over easily and thus I know that the trans is together correctly. It's perfect . I then swapped the AC Delco plugs it had for some NCK Iridium plugs as recommended on the 4200wiki pag., but put a daub of anti-seize on them. the old plugs were tough to get out! Dissimilar metals and all. Then I installed the coil packs and got them sitting in their flush. I then decided to grab the wire numbering book and start separating and numbering wires and then cut them at strategic points to cut back on the number of splices needed. after that I spend quite a lot of time pulling the wires out straightening them out, only for them to snarl again, So I then used tie wraps and not fully tight but enough to hold them and then I was able to separate them, move the majority of the wires that go on the driver's side over there just laying across the bellhousing behind the engine for now. Then I took some measurements to begin the process of making a trans mount. I then went ahead and drug out the dash and center console, and by a quick trial and error was able to cut out the floor of the console, leaving a lip around the edge so I can make a metal floor to put in there with some nice finished bolts and paint the metal, probably a matching hammertone black like the dash center I did earlier. Then I took the dash, the gauges, and the cover inside and then cleaned up the dash with Lysol cleaning wipes and then took the tube of Silicone the cover come with, and having done this before I remember how to do it. You want to ensure the silicone is in the places with direct contact, around the gauge faces in the deep pockets, etc. After that, it is a process of using duct tape and pushing to get the cover on tight and then the duct tape pulled tight to hold it tight overnight. It looks funny, but one of the last pics shows how I grabbed whatever was around with some weight to it to put on the top to assist the tape. Tomorrow I can pull the tape off and it will be ready for gauges, God willing. PICS:

-

I don't really want to. I want to make this work. Thanks.

-

Anyone have any experience getting a custom driveshaft with CV joints? That is the way forward for me.

-

steeper driveshaft angle. U joints will have a short life. Oh well!

-

02-14-2026 Happy Valentines Day! Today I got the transmission in. Took a long time. I left the pilot bearing in the freezer overnight, and I was able to tap it in easy. After I installed the clutch and made sure to use the ARP lube on the bolts, I started prepping the trans tunnel. I had to cut off the factory trans ears and grind them smooth and gave them a quick coat of paint. Then the hard part started. After trying and trying, I realized the trans tunnel just wasn't going to let it happen.....so I started cutting it out from the firewall back about a foot or so, then more and more..... little at a time, as I needed the room. I did keep the pieces cut out, As I will cut and modify and have a mobile welder come and weld them back in AND while here weld a thick steel flat plate about 3-4 inches wide the trans area and passenger floors to add more reinforcement for the power level of the engine. I was able to use a floor jack and level the engine up, and now you can see in some of the pics, what it looks like level.....yeah, dusty but you can still see it. My center console will be modded with the center floor cut out leaving a small ledge on both sides so I can make a custom aluminum floor. The shifter mechanism will be left fully exposed, I love look. It makes the shifter throws SO SHORT! So, big day. All in, now need a trans mount underneath that will bolt through the floor into plates to hold it, the reinforcement plates across, and eventual console mod. I got VERY dirty! Cheers! PICS:

-

License plate light from Amazon arrived. mount and tie in and the electric for the back half of the car shell is done. fuel system still will have to be finished.

-

280z 1jz track build from a pile of parts

A to Z replied to flatout's topic in S30 Series - 240z, 260z, 280z

dedicated track car with this one seems like such a waste. I would hope you could get some plates on it and race it and drive it on the street. Turning out way too nice to relegate it to the track only. AWESOME! So glad to hear that. -

280z 1jz track build from a pile of parts

A to Z replied to flatout's topic in S30 Series - 240z, 260z, 280z

dedicated track car with this one seems like such a waste. I would hope you could get some plates on it and race it and drive it on the street. Turning out way too nice to relegate it to the track only. -

02-11-2026 ATLAS Z update: I got back half of the car all wired in except for a license plate light I am waiting for it to arrive. pretty cool LED unit I found on Amazon for 8 bucks. Got the headlights almost in. I always have a problem with this job. I had to break out the angle grinder and mod to get the driver's in....unsure so far far with the passenger one. Strange..... it REALLY fought me. I also got the 10AN line between my main filter and pump in, so it is ready for installation. PTFE lines take some work.

-

-

02-08-2026 UPDATE. Today I completed further work on the fuel system. It is on a sheet of metal that will be hung from the ceiling down on all thread to where the pumps are horizontal facing the floor and a tad bit lower that the fuel cell outlet so gravity flow will be good. I then took all of my interior panels I have out except he center console, and cleaned them up and painted them with SEM interior paint....Landau Black....which was referred to me years ago and really is a perfect shade and everything for these old Z cars. After they had dried, I quickly installed them a little bit, not fully, but enough for them to be in place, and then finished leveling up my fuel cell and bolted it all down. I am having some problems with the pilot bearing for the trans.....it appears I will need a sleeve or perhaps a bearing with a larger O.D. as the ATLAS, never came with a manual trans, and the well for the pilot bearing is roughly twice that of the bearing I have here that I strangely was told to use. So, I am working that problem out. I also went and installed the door handles and door locks, a bit more work in the doors, and they will be ready to be sealed up. Also got the lock mechanism into the hatch lid, but none of the rest of it. I painted the seat brackets on the floor in anticipation of a rather soon to come re-entry of the seats, which are fully reupholstered. PICS:

-

02-06-2026. ATLAS Z update: my FabBot 4 inch back relocated shifter for my AR5 came in today. Very nice billet construction. Doesn't appear to need a gasket and it came with nice socket head bolts. Also got my RAM clutch pedal adjuster. This allows you to adjust where your clutch pedal takes up or if it takes up too high, this will allow you to adjust it so it takes up where you want it to. This is for hydraulic throw out bearing setups that are in the bellhousing. PICS:

-

02-05-2026. ATLAS Z UPDATE. I got up early and got on the road. I went to Junkyard Jenny's in Ft. Lupton, about 110 miles one way and bought a R200 rear out of a 1978 280Z manual trans that she got in. Less than 100K original miles and she inspected it and said it is VERY nice inside. So, I got the diff, the mustache bar, and the front mounting parts. I ordered a new gasket rom Eric at Z Car Depot, and will paint it up and install later....after the trans is in. then teh driveshaft . It's an open diff with 3:54 gears! Exactly what I wanted. I ASSUMED my late 74 came with an R200, but when I looked under there, a greasy R180 stared back at me! . If you are in the Colorado springs area and want a free R180 let me know. I took my Wilwood clutch master.....I got from Godzilla Raceworks, and masked it off, wiped it down with alcohol and applied several thin coats of silver engine paint. Why? to match the brake master and the color palette in the engine bay. You will also notice I used stainless fittings to get the hookup for the clutch line that I brought in from the cabin to the master nice and clean. On the brake side, I got the Master mounted up to my adaptor plate I finished yesterday and mounted it up requiring me to remove the clutch and brake pedals, move the clevis point on the brakes up 1 inch for a better pedal ratio as I eliminated the brake booster (I did this on my 240Z, so it was quick and easy). Once I got everything bolted up, I was able to adjust my brake pedal height, but ran out of time and daylight for the clutch side. I need to get a replacement locknut for the clutch master rod as I cant find the one it had.....and then use the Speedway threaded clevis and pin, which is larger diameter, and that is why I pulled the pedal and drilled it out. In the pics, you can see I achieved the clean install I wanted. I loosened the clamps holding the master cylinders and moved them, etc. little things to make it look even cleaner. I will plug the remaining "slop" in the holes drilled and paint with a Q tip to finish it off, but I have kept the shaved firewall. Yeah, I am happy. Not too bad for a big bumper 260Z.