-

Posts

1070 -

Joined

-

Last visited

-

Days Won

32

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by A to Z

-

UPDATE: Thanks. S30World has a few new gas tanks for sale on eBay. I just ordered one. it has the extra ports so, ill just weld them closed.....I am going to have the seams welded and possibly powdercoat the tank. Pricy, but this Z is a keeper and I don't want to have to keep dealing with fuel leaks....I'm tired of it! Also got some new rubber pads for the top to go with it.

- 1 reply

-

- 1

-

-

I have been dealing with a somewhat on-going issue with the gas tank in my 72 240Z. the seam where the top and bottom parts of the tank meet has been a source of a leak. I had previously used JB Weld "Steelstick" to seal it, and it worked.....for a bit,... then the leaks came back. So, in reading online about ways to fix it, in car, I found out that POR-15 makes a sealer that comes in a tube that is supossedly a permanenet fix for a fuel leak. it is one tube that you squeeze out, and it costs 30-35 bucks! At any rate, I climbed under the car, and with a hammer and a screwdriver...1-2 wacks and the old JB weld "glob" came off (see pics). I then wiped down the area with some denatured alcohol and a rag, and then laid in the sealeant and then used a finger to smooth it out and then made sure it covered the seam and the edge and iunderneath. As they advised me, I used rubber gloves to do it, as this stuff apparently doesn't like to come off....pretty cool to finish the job, peel the glvoes off and have clean hands and no scrubbing! I have had this gas tank out, and blocked off ports and switched the fuel system over to a basic one overflow hose up and over to a breather at the end, eliminating the fumes tank that used to be in the quarter panel. It's a good tank, clean insdie and all....but the seam right at the front edge was leaking. Crossed fingers this fixes it. See pics!

-

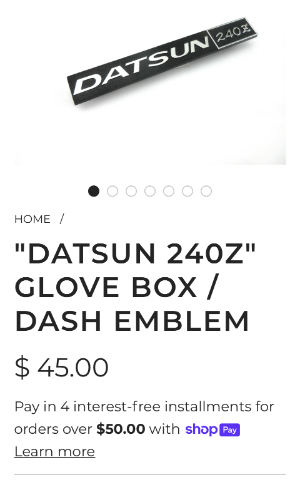

Today I worked on the glove box door. After wiping it down and masking it off, I sprayed it with the same paint, the SEM interior paint in "Landau Black". I removed the original badge and will reaplce it with a new one I found at JDM-car-parts.com. Once it is here it will be all finished off, but I have a few pics to show the result. I also found out that you have to be careful when cleaning, as I cleaned off the vinyl "carbon fiber" decal portion next to the door with denatured alcohol, and it screwed up the decal, so I had to redo the decal and do a little touch up around it....some decals can handle stuff like denatured alcohol and others obviously can't, so water on these I have! See pics attached.

-

Stock early "A" cam, early cam towers and Yoes oil spray bar so you are on external cam oiling. Have the head completely ported out. Add boost. No reason not to have nice reliability and driveability for the 90% of the time you are driving around not spooled up. Trust me....in time you are going to get tired of cruising in 2nd gear around town, to keep the turbo spooled. I've been there.

-

anyone have any ideas for the glove box door?

-

I have ignored the lower part of my dash basically since I have had my 240Z, and I have one small circle crack, just a bit smaller than a dime, and so in thinking of ways to deal with that, I came up with this. I went online and bought a small roll of carbon fiber looking vinyl on Amazon, I figured I will make 2 panels for each side of the lower dash. I started with a tape off and a couple thin coats of SEM Laundau BLack to get the color back, then I made the patterns by taping the area, drawing out each panel and carefully taking the tape off and then sticking each piece to the vinyl and cutting them out and then installed them. This opens up a wide range of idea for you guys, and you could easily use leather and other fabrics. See pics below:

-

Today was completion day! 3 years and 27 days of "restoration". It AGED me. I worked through the winters with little to no heat, bundled up choking on body filler dust, changing out the roof skin to eliminate the sunroof, to replacing interior, to complete custom big bore stroker engine building, swap from auto to manual trans, 4:11 K case rear end, you name it. Wouldn't do it again.....plowed through just so I could have an OLD one, a '72 240Z instead of a 280Z. Whew. this is a walk around in the one car garage I built it in, with one 120V electrical socket. It proves you CAN do it if you just jump in and go! Enjoy! click below to watch video: V1.MOV

-

07-13-2024 UPDATE PROJECT COMPLETE 16 June 2021 to 13 July 2024, that is 3 years and 27 days. Today was wash and cleanup day. I finished all that was on the punch list. With the flares being FRP (fiberglass reinforced plastic) I tried, and found out that caranauba wax works even better than Armor All on the flares. Nice and shiny. The big one was the door jambs. As the pics show, it's now good to go. I can't believe she is really done. Took a few pics of the day, but this is it as far as the build. She's done.

-

07-06-2024 UPDATE. More flare fitting. I ended up having to trim the front lower valence on the ends.....taking them in 3/8 to 1/2 inches, and then cleanup to make them look nice. I also had one rear tire that was dragging really good on it's flare that I had to work on. Success is finishing it, with no rubbing going on, and everything looking good. I also interior painted a spot that was in need of it. The list of to do's is getting very short now. PICS.

-

06-29-2024 UPDATE: Today I finished getting the wheels on, with the center caps installed.....I had to drill a small hole in the front wheels , tap the holes, and use 8/32 screws to ensure the covers don't come off of the front wheels. Then I armor alled and dressed them up and went for a drive, and heard a lot of grinding, so there will be further adjustments made on the flares. Becasue my driver's side door stop on the hinge broke, I added door stops. These are leather ones with chrome brackets I found online which are made for a 1936 chevy pickup! see attached pics, they work well! This post is pic heavy. But, pics are attached.

-

06-22-2024 UPDATE. Long and Busy day! This morning I took my wheels down to Big O Tires, on Austin Bluffs here in colorado springs, and got the tires mounted and balanced, I then got them home and the very long and tedious process of getting the wheels swapped out, to include ride height adjustments and some flare modifications so that the car doesn't look like it is sitting on top of the wheels, but that the wheels are tucked in looking proper. I managed to get all the wheels on, however, there will be a tad bit of work on the front flares in a spot where the tire wants to rub on turning, but otherwise it is complete! The center caps had no way of sticking to hte centers, So I used good 3M VHB tape and got them installed. I noticed that upon closer inspection the center cap paltess are held on by an actual BBS device! In the pictures you can see the roughly 2 inch higher profile the new 17" wheels have, so yep....every side had to be raised and then adjusted backand forth to get it right. Along with flare modifications to let the car sit down on the wheels. TIRED! See attachment pics!

-

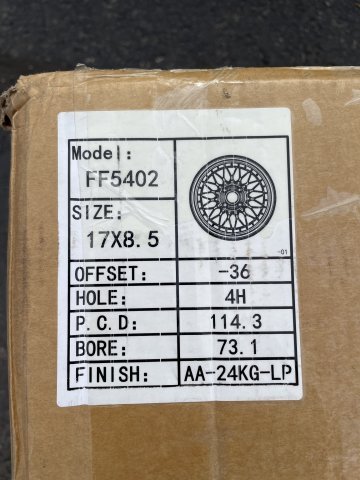

Well, my 17" wheels arrived today. (2) 17X8.5, (2) 17x9; -36 offset. Tires are Riken 225/245 45ZR17. Center caps are about 1/8" thick, like a poker chip with the "Z" etched in and painted. As I have mentioned before, I bought these from a company in China, had them custom made....these are Forged. Can't beat the price, quality is VERY good.

-

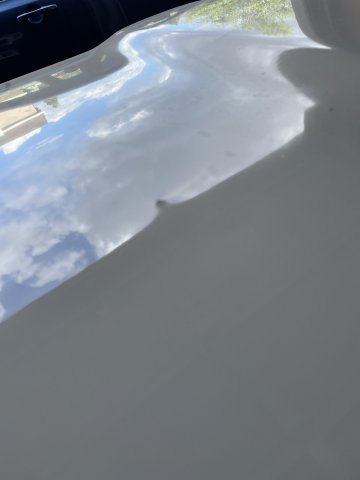

06-14-2024 UPDATE: Hood pins are done. I wet sanded the touch up areas with 2000 grit sandpaper and got them to where they are smooth and decent, then polished it by hand with Meguires 205 and then a coat of Mcguires Gold paste wax (pure caranauba wax) I took several pictuers to show that the hood pins are not obtrusive at all and blend in nicely with the whole thing. See attached pics. Cheers!

-

06-08-2024 UPDATE: Well, i finished up my hood pins. The reason I did this, was becasue the Tri-Bar setup from Techno Toy Tuning was making it impossible for the hood to latch, every option possible to loosen things up to get it to latch, then tighten, etc. wasn't working.....then the thing I never wanted to happen occurred, the hood release cable broke. I was able to get the hood open, and it was then that I decided to remove that horror from ever happening again, so here we are. I bought the kit on Amazon for under 10 bucks, but instead of using the large diameter scuff paltes, I used Stainless Steel Washers. I then bonded them on to the hood, and then after painting underneath, used some silicone adhesive and smoothed it out with my finger, and once dry looks great! So anyway, after finishing that, there are a lot of chips in my paint....My el-cheapo paint job seems to be very susceptible to chips. So I had to go over and over each chip several times to fill the chips in and then get it higher than the surface.....once dry and hard, I can wet sand with 1500 grit wet sandpaper smooth and then hand buff out and they will be all gone. I then pulled the Z out and cleaned and re-organized the mess formerly known as the single car garage...being a rental, no money is spent on the garage, save a few bucks today to have a spot to plug in my Mom's old stereo and I then also moved everything over to that wall and did a bit of cleanup of the area. Then took a few pics of the Z in it's cleaned up abode. Took it for a ride, about 20 or so miles, everything is still getting better and better as everything continues to seat in together. Pics attached. Cheers!

-

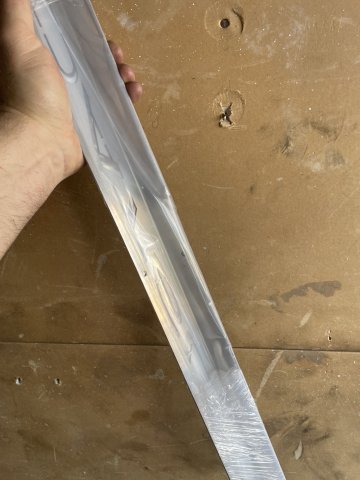

05-25-2024 UPDATE: I went ahead and prepped and installed some fuel hose breathers. When I open the gaarage I can smell fuel, so it obviously is coming from the vents. I was able to get both off to Amazon. My door sill plates from Skillard came in, and I put them on, and I managed to notice 2 little dimples I have on my hood h Techno Toy Tuning strut bar and tri bar setup. I guess it clearanced itself! Not supposed to do that, but it's already done. I tried the push button hood pins, over and over again and I just couldn't get it right, so I am going to switch and go to the old school pin and clip type. Oh! I polished the aluminum block off plates for the hood and old hood latch areas and installed. Then I started her up, she started right up and purred like a kitten. Good day! See the pics!

-

05-16-2024 UPDATE: I re-installed the door latches after a cleanup and clear coating. New mounting bolts for them as well as matching washers. I also ordered from Skillard the door sill plates in brushed stainless with "DATSUN" cut out of both. They are enroute. Couple pics, you can see I put on the new data plate I ordered off of eBay Motors. Very nice piece. I have a couple of runs I need to sand out once the paint is hard. Cheers.

-

05-11-2024 UPDATE: One of the last things on the punch list is to get the door jambs cleaned up, so I did that today. I also drained out the transmission oil as it is GLP-5 and is bad for brass syncros. I then refilled it with RedLine MT-90, which is of course synthetic, and is GL-4 rated....safe for brass internals. I also went ahead and undercoated the bottoms of my door sill plates. I will take them down to J&S Polishing to see if they can be polished, as you know they are very thin, we'll see! Pics:

-

05-01-2024 UPDATE. I recevied my "new" clock from Ron at Zclocks.com. I paid extra for a quartz movement instead of the old stuff, and I had him remove the green light filter, since my gauges are all lit with a white LED setup. Anyway, I installed it today and then covered the 2 spots on the rollbar with rollbar foam where I had removed a rear brace. I then took it for a short drive, and then went about more little this and that finishing things up. I pulled the door data plate off and the "big" job left is to restore the door jambs on both sides, so I have that to look forward to. Aside from the 17" wheels arriving and setting the suspension height for them, the car is basically done. As usual, I took a few extra pics, just to look at stuff from different angles. Cheers!