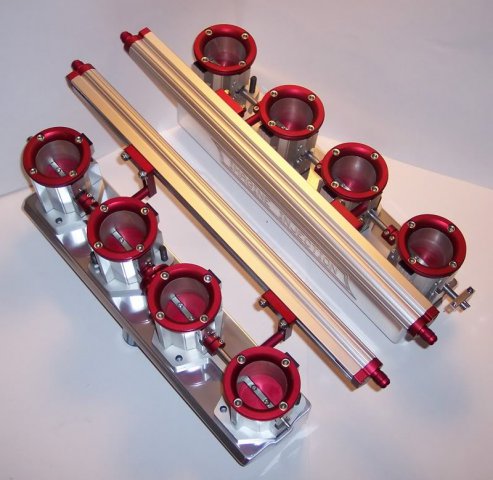

I recently bought some cheap fuel rails off eBay. The reason they were cheap I’m guessing is because they were pink ……..or purple. Not that there is anything wrong with that. The worst part about owning purple fuel rails is telling your parents you’re ***. I’m just joking. One thing you may notice is I use the correct spelling of Aluminium because I am from Australia and all you guys spell it wrong

My plan was to strip the anodizing off the rails after being inspired by a recent article in a local magazine. How hard can it be?

Grab some Draino or Drain Clean or something containing Sodium Hydroxide. Oven cleaner spray works as well, but is an aerosol and the application would be different.

I sprinkled about half of the little tube on the side of the Drain Clean bottle worth of crystals into an old oven tray. I then poured enough boiling water into the tray to completely submerge a fuel rail. If you’re only doing a few fittings you could use an old cut down soft drink bottle or something that wont melt with the hot water. Now be careful, this stuff is very dangerous and by heating it up with boiling water it is extremely bad if you get it on you or in your eyes. I performed this outside with a fan blowing any fumes away from the house.

Give the crystals in the hot water a stir to help them dissolve. Throw a pair of gloves on, grab one fuel rail and lay it in the solution. Make sure you keep an eye on what happens next as the stripping rate will depend on the concentration of sodium hydroxide in your solution. The photos were taken during the stripping of the second fuel rail, and the results were much slower than when the initial solution was fresh and hot.

After you really start noticing that most of the anodizing has gone you may wish to drop it in a bucket of water. The reason for this is the surface gets a slippery soapy coating on it from the reaction and it slows the process down. Once in the bucket of water, rub this stuff off the surface with your gloved hands and dunk it back in the tray to finish off the rest. Once fully stripped, give it a wash in the water again, rubbing the surface as before but this time let it sit in the water to release all of the chemical.

Once the anodized surface has been stripped, the aluminium is prone to oxidation like any other bare metal surface. I plan on giving my rails a coating of an aluminium de-oxidiser just before I polish them using an aluminium polish. The finish below is straight out of the bucket of water (pre-polish) so you can see it doesn't look too bad already.