-

Posts

5399 -

Joined

-

Last visited

-

Days Won

58

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by RebekahsZ

-

My tire recommendation depends on the usage, and I want to give you really specific advice. Are you street driving, autocrossing or drag racing (or trying to do everything with one tire)? What rim specs do you have?

-

Stock Car Mafia's '78 280z LS2 Build

RebekahsZ replied to Stock Car Mafia's topic in S30 Series - 240z, 260z, 280z

I don't think it matters which way your wire it. If you can use a weatherpack connector, you can switch the wires if you get it wrong. -

Please help me buy my garage lifts

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

I looked at that. Can't argue with how nice it looks and how much open floor space it preserves-and I LOVE how low that lift is. But, you can't park under it to create more car storage space. Take a look at your z-car's belly and tell me you want to support the car like that? That tile floor will be hell with a rolling stool or creaper. Or a transmission jack. Glad he used black grout in preparation for oil spills. My wife would like it, but not me. -

Please help me buy my garage lifts

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

That's why I'm getting both styles. I helped a buddy reduce his S30s toe-in from 3/8" to 1/16" today because he was eating a front tire. It took us a couple hours what with checking baseline camber and toe, removing some coil spring wedges, measuring again, inspecting the front end wear components, then setting it correct, then checking again after a test drive. I'd like to reduce the time involved in that exercise as I wind up doing it a lot. I think a developing crack in my slab may determine where my 2-post goes. Problem with that scissors jack is that I don't want to lift by my floor pans, and you can't store a car underneath them AND on top of them-that is an awesome setup for the right car. Good idea about having jack points made where the roll cage hits the floor, but I think that will be BEHIND the CG of the car, especially if I pull the engine and transmission with the car off the ground (one of the reasons for wanting a lift). I dropped my rear subframe once with jackstands too far back and the car tried to flip over on its nose-I grabbed the back bumper and screamed till my wife woke up and put something in the trunk to balance the car. When you autocross, track day, drag race and landspeed race, and drive to work (when it ain't broke), you do a lot of setup changes. I do wish I had the bad dog frame rails-they will go on the next z for sure. Greg Smith sells Atlas lifts-the arms really sag a lot on their 2-post lifts and they don't offer (that I could find) a low profile lift. The Atlas 4-post is much narrower than the one I'm getting, which requires you to collapse your mirrors before you park underneath it. Not centering for-aft is what is called an asymmetric lift. It simply lets you open the doors while the car is on the lift. Everybody I have asked insisted that I get an asymmetric. I have also ordered a couple of tall jackstands-one for each end after the car is in the air. 2-posts look scary by their nature. I took a good video today of a stock Z's bumpsteer (actually compression steer). I will post that once I go thru the video loading exercise. -

I have 5 actual CLSDs and one open diff that was sold to me as an LSD. Guess which one was my first purchase? Guess which one didn't get the cover removed prior to purchase, cause it had a finned cover and I trusted the seller? It's not a big deal to remove the cover and take a damn picture.

-

LS/T56/240z Project Mentor Wanted

RebekahsZ replied to RebekahsZ's topic in S30 Series - 240z, 260z, 280z

I have the front crossmember slotted and most of the parts here to put the front end together. Just a matter of making time. Have ordered a couple of lifts for the new garage-one of which is an alignment lift. Hoping to use that when the front suspension is put back together. Don't know how long the lag will be between ordering the lifts and having them installed and ready. Have bothered Rockland Standard Gear a bunch trying to learn about their custom-ratio T56 Magnum-they dont have a good way to make 6th gear a .75-ish ratio, so it looks like I'm staying with my current transmission. I'm gonna be going with a 3.18 rearend ratio to take the car to 200mph. Between that diff ratio and an S1 sequential shifter, dollar per dollar, it will be a break-even with getting a T56 Magnum, and perhaps less work, I was just really hoping to come up with a clutchless transmission. I'm pretty sure all those Liberty, G-force and Jerico trannies use external shifter linkage, and I'd really like to stay with a top-loader style for simplicity/reliability. I may be the first guy to buy one of the S1 Sequentials (really just a vertical gate shifter), but I don't want to bother them until I have the funds to commit. I may still waste some time talking to Liberty about face-plating for my spare tranny. Edit: looks like a 3 week lag time on the order due to the size of the package (the lift, not mine). Time to go review my aircompressor advice thread and start working on that. Then all the big items are done. -

Thanks! Absolutely incredible!

-

Please help me buy my garage lifts

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

Suggestions? -

Spitz-how do you power the alternator with the electric water pump?

-

Please help me buy my garage lifts

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

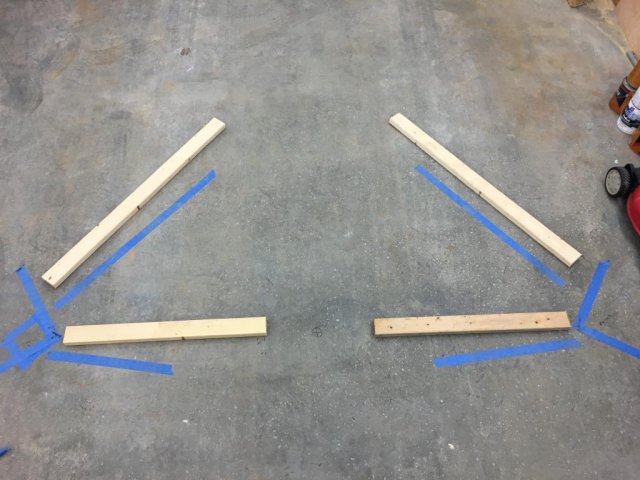

All taped out. Have called a vendor and he is emailing me a proposal. I spent a lot of time today practicing backing in and pulling out the trailer. Lemme tell ya, if you ever build a garage, do yourself a favor and put a 12' wide door on the side where you plan to park your car hauler trailer-its a bear (sic) trying to get a 103" wide trailer thru a 120" opening while making a 90-degree turn backwards off the street. An auto tranny on the truck would help too. I had my friend come over with his F150 extended cab to ensure that I could work on the largest vehicle I could imagine-I won't be able to park that under the 4-post, but it fits on top of the 4-post and on the 2-post. We moved the 2 post a little deeper into the garage based on that. I have my only buddy within 2 hours, that has a running S30,coming over next weekend to see how it fits. Checked my truck and trailer on both sides and it's good. The 4 post lift placement is pretty simple; its the 2-post that is more difficult. The toughest issue to figure out is where to locate the lifting pads on the S30 chassis when using the 2-post. If I locate the 2-post columns in the WIDE setting as is required to let the trailer back between the posts, there is barely enough reach on the lifting arms to get on the frame rails at the TC box if I fully utilize the asymmetric setting and swing the front arms as shown below. That will allow me to just barely reach the seatbelt boxes with the rear lift arms, fully utilizing the asymmetric property of the lift. The lift pads are supposed to be a 3". How do you guys feel about using the pinch seam on the rocker panel for lift pad placement? -

Please help me buy my garage lifts

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

The lifting capacity of each lift is reduced as the wheelbase of the vehicle decreases. The capacity of the HD7500-BLX (tall boat lift) is reduced to between 3,000# (95" wheelbase) and 1,875# (80" wheelbase), so for our 90" wheelbase S30 cars, the max capacity is 2842#. I'm sorry; I'm just not comfortable with that. So, that reduces my 4-post lift options to either the HD-9AE alignment lift (127" width, 70" rise) or the HD-9XW (110" width, 82" rise). I sure wish they would mix columns and runways! If I apply the same math to a 9000# lift, I get between 4500# and 2250#. If I run the numbers for 90" wheelbase, that allows me 4263# capacity. Argh! After long deliberation, my lead choice for the 4-post lift is again the HD-9AE. I get the best width and the alignment features. I lose lift rise. We went out and measured our Honda Odyssey: if I take the cross bars off the rooftop luggage rack, it will fit under the 70" lift that the HD-9AE offers. My lowered S10 tow vehicle is only 56" tall. So the wider lift will allow me to whip into the garage faster with less concern about knocking a mirror off. If I ever go to a full-size tow vehicle, it looks like it will need the lowering treatment too. If I can design a dolly system that will fit my trailer axles and go in-between the current tires, I will be able to get the car-hauler up onto the 4-post lift, something that would not be possible with the higher-lifting, but narrower HD-9XW. I will tape the foot plates out tomorrow on the floor of the garage to finalize that decision. Oh yeah, the alignment lift loading height is 6-1/2", so I'm ordering the longer 48" ramps, and may have to have them extended even more to get the car up there without ripping an airdam off. I would SO like to be able to get the car up there with the 3" airdam clearance I am aligning my suspension around. Now, onto the 2-post lift: EVERYBODY to the man, has told me to get an ASYMMETRIC 2-post lift. Bendpak's smallest asymmetric lift is a 10k unit. Since we like to lower our cars, I'm gonna get the low-profile series. That yields the XPR-10A-LP model 2-post lift. The drive thru width of that lift in the wide configuration with the arms down is only 102", and my car hauler trailer is right at 103" wide (argh!) But, if I raise the arms up and out of the way, the drive-thru clearance goes up to 112", so the trailer can go in just fine. I'm taping it all out tomorrow. I may even use some 2X4s to model the columns out in the garage so that I can verify that the two lifts won't be all up on top of each other, limiting door opening, walking around, etc. It is, after all, only a 30'W X 36'D garage. After that, its price and shipping comparison. Maybe I'll have something ordered in the next week. I have part of Monday off, so who knows? Thanks for everybody's input and for putting up with my indecision. It's a lot of dang money and fulfillment of a life-long dream. All this to work on a car that I paid $900 for 27 years ago! -

Stock Car Mafia's '78 280z LS2 Build

RebekahsZ replied to Stock Car Mafia's topic in S30 Series - 240z, 260z, 280z

I'm too tired to fight the site to post pics. I just shot some pics of my setup. Send me a text asking for the pics and I will send them to ya. 256-366-4685 -

1976 280z 5.3 TR6060 Build

RebekahsZ replied to EastTnZ's topic in Gen III & IV Chevy V8Z Tech Board

Travis-good to see a 3" pipe will fit thru the passenger side mount. That's where I plan to pass my passenger side header. No down-pipe for me: it will be open exhaust, limited use only. -

Please help me buy my garage lifts

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

Bad news. Bendpak won't mix and match components for me. So, I'm looking hard at the boat lifts: HD7500-BLX (lift height to 82") or HD7500-PBX (lift height 111"). The lower lift costs about $4,000; higher lift costs over $7,000, so I'm likely not about that, plus some of the catalog photos show guy wires on the tallest lift. I sure wish the damn alignment lifts went higher than 70"! Gotta get back to cleaning the shop so I can tape-out. -

Stock Car Mafia's '78 280z LS2 Build

RebekahsZ replied to Stock Car Mafia's topic in S30 Series - 240z, 260z, 280z

I stacked them. I mounted the pump on the bottom of a flat plate, then I put a hose in a U up to the filter/regulator on the top side of the plate. The whole plate is like 8" long and about 3 inches wide. -

Stock Car Mafia's '78 280z LS2 Build

RebekahsZ replied to Stock Car Mafia's topic in S30 Series - 240z, 260z, 280z

Looks awesome! Consider having an AN fitting soldered onto the fuel rail-I've had several buddies have the push-on fuel fitting pop off and spray the motor with gas. -

Please help me buy my garage lifts

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

Great. The floor is a foot thick with 3,000 psi concrete. I designed the shop specifically for lifts. I have electrical 220 already waiting at the ceiling to power the lifts and will lay out my compressed air system once the lifts are in place. I called and talked to the little girl in Sales who said she would ask the engineers and get back to me. I asked her about combining the strengths of all three models. -

If the other guy bails on the axles, send me pics and a price. I'm interested in adding to my axle horde. Keith PS-you sold the car???? Ahhh, man! That car was a leader here. Hope it went to a good home.

-

DIY 280Z mandrel bent side exit exhaust with 3" dump

RebekahsZ replied to Smyrna388Z's topic in Exhaust

Very cool! Must be nice to have all that room inside a 280z tunnel. Couple questions? 1) Stainless or aluminized? 2) Are you going under the rocker panel or are you cutting a hole thru it to put the pipes thru? 3) Have you heard a date for ZAttack2016? That will be my deadline to have my car back on 4 wheels. I dunno if it will be aligned and drag-ready.... Keith- 13 replies

-

- Exhaust cutout

- H-pipe

-

(and 2 more)

Tagged with:

-

Please help me buy my garage lifts

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

Hmmm. I'm so thankful for the input. I really appreciate the photos too. -

Please help me buy my garage lifts

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

Awesome! I'm gonna clear out the crap in the shop and start taping this out on the floor. Tomorrow I will try to find out if they will put alignment ramps on the boat lift chassis. -

Please help me buy my garage lifts

RebekahsZ replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

I've been doing research all day. These are Bendpak product numbers: I want the heighth (to park a truck underneath) and width of the HD-7500BLX (to store the trailer up against the ceiling), and the alignment fixtures of the HD9AE (cause I can't leave my suspension alone). However, while the wide setting of the HD-7500BLX (a boat trailer lift) is wide enough to accommodate my car hauler, the narrow setting is too wide for my Z (the wheels will be half-off the ramps)! I'm gonna call Bendpak on Mon to see if they do custom assemblies. Another option is to make narrow-er track dollies to put the trailer on. I've decided I AM getting the sliding ramp jacks. -

Finned Aluminum Nissan R200 extra capacity diff cover

RebekahsZ replied to Rob L's topic in Price Check

I paid $450 for a purse for my wife this Christmas. Some guy (I'm sure he's a lovely man and a wonderful human being) named Michael Kors. Seemed like as much waste of money as a finned diff cover. Difference is, the purse got me ..... I will admit that I LOVE polished, finned aluminum. Just not enough to modify my suspension-again. On the up-side. If you pay $900 (crazy) for a CLSD, you have a finned diff cover that you can sell quickly for $300, reducing your CLSD cost to $600 (still crazy, but tolerable). The high cost of the cover represents a win-win situation. -

You may have to find a PC instead of a phone. But once you can see the menu that has forums and gallery and time flips and such: there is a spot where you can click "Donate." Follow the links from there. I asked same question a couple years ago and somebody helped me. Now, if you can tell me how to rotate photos on my new IPhone.....