-

Posts

1629 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by olie05

-

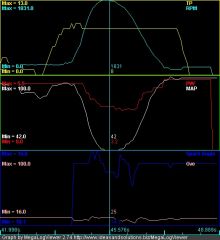

As the title says, the car will fire up but will not stay running. The setup is: MSNSE 029v V2.2 board HEI 4pin module driving coil 12v to coil, with proper pull up resistors on module and distributor n/a 280z basically stock (electrically) with turbo distributor and 240sx TB Here is a screen capture of the datalog of what I am talking about: Hooked up a timing light and it looks like i'm getting consistant spark... I'm thinking it has something to do with the fueling...

-

As the title says, what is the minimum operating voltage on an 83 Turbo Distributor? My experience so far: -turning distributor by hand with 12v going to it, injectors click, rpm shows up on laptop. -cranking the engine with ignition module unplugged, no rpm on laptop, and nothing at the injectors. This tells me i have my pullup resistor wired correctly, injectors work, and judging by the gunshot sound down my exhaust , the ignition module is wired up correctly.

-

what are your plans for this car? It almost looks beyond repair... *almost*

-

ha. I found a very good source that lists the wiring for any o2 sensor connector... thankyou NGK: click here for pdf

-

They say it has a 9000rpm redline. Doesn't that contradict what everyone has experienced with L-series cranks? -or- is this problem cured by the overly priced kameari billet fully counterweighted crankshaft?

-

Wouldn't it be more effective to have the roll hoop braces go directly to the strut towers, rather than the bar that joins the strut towers? I bet the guys at classiczcar.com are cringing at what you are doing to #248

-

From the megamanual: I'm with the first paragraph on this one.

-

I made the mistake of getting a 4 wire o2 sensor from a 92 or maybe 93 ford thunderbird at the JY. I'm pretty sure it was a v8 and I pulled the passengers side pre-cat one. I am confused as to which wires are the heater wires and which wires are the signal wires. The colors I have on the hanress are: gray with yellow stripe gray with red stripe Black with green stripe tan with orange stripe can someone please tell me what these do?

-

I don't think it would be very practical to have the engine that far back... Sure you could change your steering rack without a problem, or even service it without having to remove it, but what if you ever have to take your valve covers off? It makes simple things like removing a spark plug a difficult task. On example, minivans. The back cylinders on a v6 caravan requires removal of the intake manifold to change the spark plugs. That is just ridiculous.

-

Its can't be a grounding issue because as of now I have the headlights to be common grounded. In other words, I only have one ground per light. Since the low beams work just fine, it's either going to be a voltage drop somewhere in the power wire, or a bad bulb. I have never heard of a bulb going bad and still working though.

-

Got my z in austin, drove it back to houston (190miles) with a u-joint with LOTS of slop, and 5 cyl. For the full story with some creative effort click on the picture of my car below and then click on the other picture of my car. (lots of pictures I suppose)

-

I recently rewired my ghetto 2-switches-in-the-console-for-headlights to work with the stock switches for headlights/hibeams. Along the way I discovered a problem. I noticed that if I follow the wiring diagram on my car, my "high beams" are significantly lower in brightness than my Low beams. I verified the issue with beam pattern. On low beams there is a distinct cut off line, along with a brighter beam, however on High beams, there is a wide beam pattern that is very dim. Note: The bulbs are three prong, common, hi, lo. I wired the bulbs to be 12v positive on the hi and lo, and grounded the common. The factory does it the oposite, where the lights get the power from the common, and the hi, lo are switched to ground. Could that be part of the problem? As far as I know, light bulbs work exactly the same if you run the current the other way. -Oliver

-

There is a plastic open element GM iat sensor. I came upon it in the intake pipe of an early 90's Buick. Seems like this would be the most accurate solution, regardless of placement. (and without having to find the curve on the Audi one.) Note:not my picture, just hosted on HZ for posterity.

-

Looks like fun! are those the two guys from sez who couldn't launch their bikes?

-

Aviation racing, autocross style and some whirly-bird aerobatics

olie05 replied to BRAAP's topic in Non Tech Board

Wow... never seen a helicopter do stuff like that. (i can barely get the heli off the ground and landed in one piece in flight sim!) -

yes. They sell this at craft stores... I know because my Design I project was a ping pong-golf ball sorter, which happened to have 2 rows of UV cold cathode tubes powered by a small 12v battery. We painted everything we could with flourescent markers and flourescent paint... This could have promising results for the z dash.

-

did you know fer is actually spelled "FOR"? who would have thought...

-

Awsome fix for your stock differential mount. PICS!

olie05 replied to proxlamus©'s topic in Drivetrain

strong epoxy is to be read as "infinitely strong epoxy" -

Awsome fix for your stock differential mount. PICS!

olie05 replied to proxlamus©'s topic in Drivetrain

The problem with the stock mount is that the two pieces tend to separate under acceleration. Filling the void of rubber with anything other than a strong epoxy would do nothing to keep the diff from moving up under accel. -

Thanks to those who took the time to write novels for posts Seriously, the wisdom/opinions is appreciated and thats why this is the only forum I participate in! So what I am hearing is: I need a closed chamber head (knew that) I should probably use a lower CR (knew that as well) I need to switch to programmable EFI I need to revise the stock timing map (duh thats the title of the thread) and one thing I did not know is that porting the manifold will actually make a difference in performance without first porting the head. JM, to answer your question, I was pinging under heavy load, and it caused a headgasket to fail. No, I am not running "several" head gaskets, rather I wanted to imply that I did not want to have to be replacing headgaskets in the future. I have one week between summer session and fall semester... the plan is to become a social hermit and devote that entire week to: 1. porting my intake manifold to accept the 60mm TB and opening up the runners 2. installing megasquirt.

-

I suppose I left out a few details about my engine. I have 10.3:1 static CR and I have been driving around with that for a while. I had to retard the timing *slightly* to make sure I didn't blow head gaskets under heavy acceleration. Now that the cam is in the engine runs WAY better than it did on 10.3:1 and the stock computer, in the top end. Oh yeah Z-YA... i have the little coolant fuel trimmer

-

I just came back from a 4hr road trip. This was the first road trip I have been on with the cam. I noticed no difference in this cam and the other one in highway mileage. I am only getting poor mileage in city driving. Wouldn't it be pointless to open up the intake manifold runners without opening up the intake ports first?

-

I recently put a bigger cam in my daily. It is a crane 272/282 split duration with .480" lift. The problem is that I lost most of my low end putting-around-town power and it has killed my around town mileage. The one thing I can adjust (as of now until I go with megasquirt) Is the ignition timing. What would be a good initial number to run? I seem to think that giving it more advance will give me a better around town car, but the question is how much? thoughts? -Oliver