-

Posts

46 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Rob240z

-

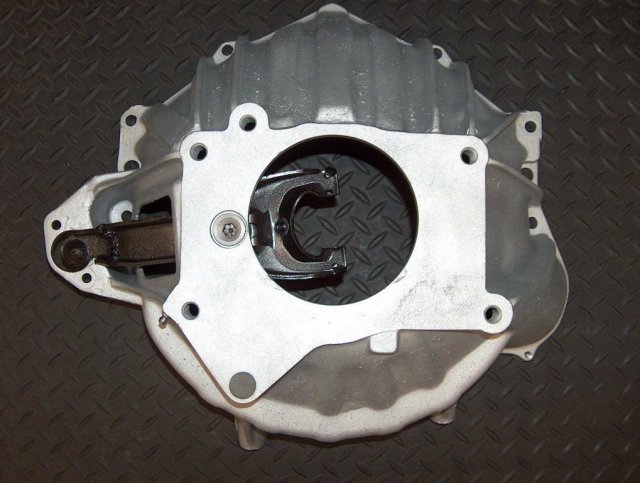

I have 2 transmissions I need to sell. Sold my 240z early this summer. Bought a Porsche 928 and I have a bunch of Z parts I need to put up for sale soon to make some space. One is a 240sx transmission that has been mated to a 280z front half / bell housing. Hasn't been used since the conversion was done. Bought from a member on here. It's supposed to be in good working condition. I have the early 240z driveshaft that is the correct length too. I'd sell it for $400 with driveshaft. I also have a Nissan T5 transmission with the correct driveshaft for sale too. This came out of a good running/driving 280zxt that was parted out due to rot. I know the previous owner well that parts out a lot of rotten Z's. The top cover was removed to inspect the transmission. It seems to be in good shape, but I'm not an expert. Due to this having been opened up and will need a little assembly I'd let it go for $200 with driveshaft. I'm in Jamestown, RI. Probably 5.5-6 hours from you.

-

1 Dark heather hoodie XXL 1 Black t-shirt XXL Zip 02835

-

Hi cnwayland, I have a E31 that came out of my 71 240z when I did a v8 swap last year. The head is complete and still attached to the block on an engine stand. It didn't leak at all and was in a good running car, I just wanted to swap in a v8. The head, cam, valves is stock, but the previous owner said the valve seats were changed a few years before I bought the car in 1999. Engine had about 75,000 miles on before it came out. If you can't work things out with Zantech get in touch. Take care, Rob

-

LT1 T56 clutch will not disengage fully

Rob240z replied to rayaapp2's topic in Gen I & II Chevy V8 Tech Board

About a year ago I was having the same problem with my car. I was able to max out the slave throw at first, but within a few days it started not wanting to fully disengage again when I was away from home. Within a few more miles it wouldn't disengage at all. After I had the car towed home I pulled the transmission and clutch. One of the springs in the clutch hub broke and came out. The spring lodged itself between the center of the flywheel and clutch. It never sounded like anything broke. There was no weird noises. I resurfaced the flywheel and put in a new clutch and it has been fine since. That was my experience, yours might or might not be the same. It could also be the clutch fork pivot. A bad throwout bearing will usually make noise when you push the clutch pedal down, but the clutch fork might have come out of it's place where connected to the throwout bearing. Once you completely rule out the hydraulics as a possible problem you need to drop the transmission and inspect everything. Good luck. -

OBX Differential Inspection and Installation

Rob240z replied to TrumpetRhapsody's topic in Drivetrain

I did a very similar thing when I installed the obx in my car. This is the thread on here that describes how I got them in without taking the diff apart. I did it with the diff installed in the car. http://forums.hybridz.org/topic/114145-what-happens-if-you-dont-install-retaining-clips-for-280zxt-cv-axles/ -

CV half-shaft swaps in 2014 any less expensive alternatives?

Rob240z replied to gvincent's topic in Drivetrain

I converted my 240z to 280zxt cv axles last winter following this write up. http://www.zhome.com/rnt/FordPower/HalfShaft.html With an R200 already in a 240z all you need is 280zxt cv axles, 280zxt companion flanges, R200 differential front pinion grease seal (75mm O.D. X 40mm I.D.), 2 - 280zx stub axle lock nuts, and 12 new nuts, bolts and washers for the half shaft to companion flange. Overall it was an easy conversion. I paid $125 for the cv axles, $80 for the companion flanges, and $12 for the stub axle nuts. I don't remember the cost of the pinion seal or hardware, but it wasn't very much. I haven't had any binding at all. Overall I think this is the cheapest way to do it. I have a mild 327 chevy making about 325 hp, torque unknown, just a fun street car. Haven't had any problems. -

I still have a brand new Spec 3+ clutch I never installed sitting on a shelf in my garage. I was building a 3 liter L-engine, but swapped it for a Chevy 327 and installed that instead. I had the fidanza flywheel too, but I already sold that. If your interested PM me. Thanks, Rob

-

The clutch fork angle should work fine. Which T5 bell housing you are using would make a difference though. The camaro t5 bell housing mounts the transmission at an angle. The transmission won't sit level like a T10 normally would. I'm not sure if that would be a problem or not. My engine uses the old Hooker mounts. They are just like the scarab mounts. I did flip them around though which sets them back a little more than the normal scarab location. The side mount shifter on the t10 is in front of the shifter hole. I'm using a rear offset shifter (about 4") to make it come up in the correct spot.

-

-

Hi Han, I have a Super T10 behind a 327 in my car with a hydraulic setup. I'm using an old truck bell housing and clutch fork, s10 blazer slave cylinder, and a 13/16" clutch master cylinder (not sure what it's from). The Super t10 has a 26 spline input shaft so I'm using the clutch kit for 88 camaro with a 305. It is a 10.4" clutch. I'm replacing the ST10 with a WC T5 this winter to gain overdrive though. Rob

-

That is a beautiful car. I'm sorry that I can't answer your question, but I have one too. Does anyone know what side mirrors those are on the green car? Thanks, Rob

-

Bassett Racing Wheels

Rob240z replied to 9/73-E31-260z's topic in Brakes, Wheels, Suspension and Chassis

I like the look of nascar style wheels on classic cars too. Here's a picture of a really cool s30 with rims like that. I'm not sure what brand they are though. sstp-1304-01+shokuji-jtin-car-show+datsun-240z by Rob Olejniczak, on Flickr -

Most won't, but I thought somebody here might be interested in this. It is a Kameari R200 3.154 Ring & Pinion Set. It is for sale on a Yahoo Japan auction. It has a buy it now of about $1000. These are pretty rare. I was thinking of buying one, but went with a 5-speed transmission instead. http://page23.auctions.yahoo.co.jp/jp/auction/o8814403 Rob

-

As long you pick the right cam to take advantage of it the yes. Your putting a head on that flows more, but not doing what is needed to allow it to. Raising your rpm to 8000 would take advantage of it. Or an offset ground crank would too. Both would be even better. For example, Let's say the head flows 15% better than stock. You should try to get 15% more air through it. Choice 1: increase rpm from 7000 to 8050. 7000x1.15=8050 Choice 2: increase displacement from 2.8L to 3.22L 2.8x1.15=3.22 Any combination of the 2 or many other things can effect it too. That is the very simplified explanation. Most would prefer the stroker for a torque friendly street car would be my guess. I personally like the way a high rpm L-engine sounds and drives. But the more reserved side of me might go stroker if I had to choose 1 or the other. 7500rpm 3.0L sounds just perfect though.

-

Everything Dave is saying makes perfect sense. For a naturally aspirated engine, increasing displacement and/or rpms will need a head that flows more air to take advantage of that. Making your head flow more than you need isn't necessary. It will probably have some positive effect, but not nearly as much as also increasing displacement and rpms. I decided on max rpms of 7000 for my build, but In my case I wanted the increase in head flow so I could decrease the boost pressure relative to flow. Forcing more air through it would be easier. For the headwork your getting, and staying NA, I would rev the engine higher and/or increase displacement. Otherwise it would be a lot of money spent for the head with not much gain. The head will be so much more capable than what you are trying to flow through it.

-

OBX Differential Inspection and Installation

Rob240z replied to TrumpetRhapsody's topic in Drivetrain

I can confirm what Jon just said. I put an obx in this summer and the backlash was not right. At the time I didn't have the shims to adjust it, but if I switched the shims to the opposite side it was pretty close, but not within specs. I put a couple hundred miles on it like that and it was whining pretty badly. I'm about to take it back out and shim it correctly this time. Hopefully I didn't damage anything. Maybe someone will read this and not make the same mistake I did. I wouldn't normally do something like that, but it was only a couple days to zcon and I didn't want to miss it. Rob -

Thanks guys. I posted it sold just a little bit ago. I'll see if they close it soon, if not I'll PM a moderator.

-

I've just sold an item in the Parts for sale section. The instructions are to then close/hide the ad. How do I do that? I see other threads locked when the item sells, but can't figure out how to do it. I have used the search, but didn't find an answer. I'm sure it is something obvious I'm just not seeing. Thanks, Rob

-

Hey Tony, Sorry for the confusion about the welds. I just meant that if I was in his situation and one of my welds failed I would feel even worse. I was implying it wasn't because he built it pourly. It looked like he did a great job. It just seems like he got really unlucky. Shit happens, even to the best of us.

-

Wow! I've been following this build for a while. I would have never thought something like that would happen. You would think a fire extinguisher would be stronger. Why do you think it happened? There must have been a lot of pressure in there. Hey, at least your welds held up.

-

Hopefully this will help you some as an example of a street build I did in the past. This is the results of the street port work Rebello had done on my build. Rebello P90 Head Flow Stats by Rob Olejniczak, on Flickr This is the breakdown of costs of my build from Rebello. Rob O0001 by Rob Olejniczak, on Flickr This shows calculations to get to exactly the 8:1 compression ratio I requested. for exactly for a supercharged l-engine. Rebello Engine Notes by Rob Olejniczak, on Flickr Before I did my build I did a lot of research on who to use. I'm on the east coast and was reluctant to pay for shipping back and forth to the other coast. I eventually called Dave and talked to him about what I wanted out of my build. I took his advice on what was needed and what wasn't for my particular build. With his reputation I trusted that he knew much more than I did about an L-engine and when he said things like, l24 rods will be plenty strong for my build, I listened. He took the time to explain why. When he sent me over the whole quote it was a little more than I wanted to pay. That wasn't because he wasn't expensive though. I went through the whole list of items on the quote and frankly, each item was priced very fairly. It was actually a good deal. He was the cheapest I could find for JE pistons as well as other items. It was more than I estimated, because I was forgetting a few things. I ended up calling him back a week later and moving forward. In the end, he was great to work with and was very professional. He finished the build when he said he would. That is rare. I even got an education on things like tensile strength in relation to rods and that a rods strength needs to be higher for high rpm engines, but not necessarily for high horsepower boosted motors. My plan was to redline my engine at 7000 rpm. He said stock rods would be plenty strong beyond that. I felt just like you about only having to do this once the right way. I wanted a long lasting reliable engine. In my mind that meant overbuilding it. Dave saved me some money in that respect, by not using aftermarket rods, because the l24 rods were stronger than my particular build needed and would work great. I'm not trying to push you to use Rebello. I'm happy I did, but I would just suggest using a very reputable engine builder. Talk to each one and see who you are the most comfortable with. I'm sure the other recommended guys would probably do a great job too. Just don't try to save a couple bucks on someone that doesn't have a great reputation. In the end, they never cost less. Just pay a little more and end up happy in the end with a high quality build. Someone like Rebello is expensive compared to a junkyard turbo swap, but apples to apples he really is a great deal. I've heard the same about Braap and John Coffee and I believe it. I've heard Bryan Blake does great work too, he just younger and hasn't been around as long. That wouldn't stop me from using him though. The key is, I haven't heard anything negative about any of their work. Why take a risk when you don't have too with a builder who has had any negative feedback at all. Good luck with your research and build. It sounds like it will be a cool project.

-

Rebello will offset grind a l28 crank for about $200. With the bore size you are planning that would put it right around 3 liters, maybe just over. If your already balancing the rotating assembly you might as we have it offset ground. $200 is cheap for the gain in displacement.

-

Just clamp in a straight piece of pipe where your muffler is now to see how it sounds. If you do go straight pipes post up another video, I'd like to hear how it sounds too. I think your car would be plenty loud for me, but I do really like the sound of straight pipe cars in general. I just don't like to draw to much attention when driving around, especially from the police.

-

Handcrafted is what pays my bills. In almost all instances I would rather have something that is handcrafted over something made in a factory. The quality and attention to detail is much higher. An almost 40 year old 2+2 isn't something the general public would think is safe to drive kids around in. It is so far away from modern safety standards. My point is that if someone is willing to drive there kids around in the old 2+2, then if the conversion is done correctly, it shouldn't be any different from a safety comparison. Comparing the conversion to a modern car is no contest. The modern car will obviously be safer. I wouldn't do something like this to use a a daily driver that I regularly drive my kids around in. That is what my wife's car is for. She get's the nice, new car. It would mainly be the same as it is now, my fair weather toy. Bringing my kids to a local car show down the street in the 240z a few times a year, and a handful of similar type drives a year is something I could live with.

-

I agree that you would need proper seat belts and anchors as well. I personally wouldn't consider doing this if it wasn't done correctly. The original pictures of the aftermarket seat Plata posted probably were ok back in the 70's when most people didn't wear seat belts, smoked with their kids in the car, and even rode around in pickup beds. Today is different though. Just driving a classic car is taking more risk than a new car, from a crash impact perspective, but we all do it. I don't see how a converted car like we are discussing would be any more unsafe than a factory 2+2 if done correctly. The back seat would just be smaller. For some people like myself that would be preferred over an extended squared off roof line just to fit larger seats. I don't need space for adults. I prefer how Porsche didn't butcher the look of there cars for a back seat, they just made the seat smaller. It was no secret that it was only for very small people. Although they screwed that up with the new Panamera. It's direct competitor, the Aston Martin Rapide is a better approach to a modern 2+2 in my opinion. The head room for the rear passengers might be a little lower, but they didn't make the back of the car ugly and kept the signature styling of their cars. I had a Porsche 928 that had very small back seats that could still fit a booster child seat. It took a while to find one that fit, but I did. I added rear seats to my work van for the same reason. I need to pick my kids up every once in a while and it only came with 2 seats. I probably could have just bought a passenger van and stripped almost everything out. Instead I inspected what the differences in the passenger vans and cargo vans were and then welded reinforcing steal at all the anchor points in the floor and upper seat belt roof point just like the factory did. Actually, I even made it a little thicker for piece of mind. I sourced seats that exactly matched my front bucket seats and people that see it think it came like that from the factory. My biggest issue with the back seats in passenger vans is they are all benches except in some conversion vans. I needed a clear path down the middle so I could load long lumber inside. I can fit 12' boards in my configuration. Overall, my thinking is that cars are designed to appeal to as many people as possible. They were not designed for every individuals needs or wants. If I want something that isn't or wasn't available, I just make it myself. I would think that is a common thought process on this forum. Safety is always an important part of the process and there is no reason this can't be done that way.