-

Posts

357 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Snailed

-

My first steps went something like this; -get it running -do donuts -weigh the car -weigh the q45 suspension -remove engine and start stripping it -cringe at all the body filler and rust -try to sell parts

-

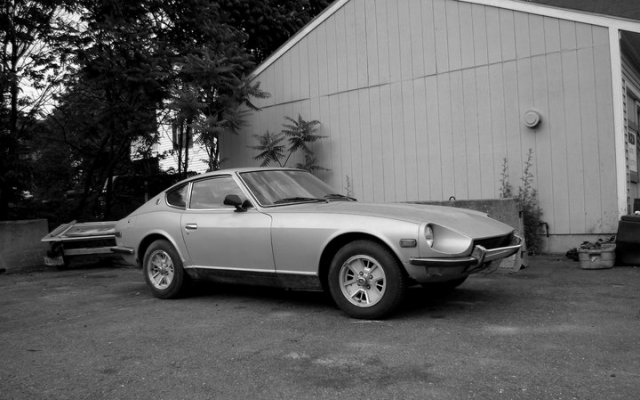

I think it's time to document my project. The car is a '71 240Z with 71k miles on it. It has spent it's whole life in the North East and has the rust and shoddy repairs to prove it. My plan is to do a semi-professional restoration and modify things as I go. It will sit very low, but I plan on setting up the suspension so that it has pretty good geometry since I would like it to handle at least as good as my other projects. The rear suspension will be from a '95ish Q45 and the front will likely end up being some mongrel I cobble together but is still undecided. I have started reinforcing the body as I begin to repair the rust in hopes of making it a little more rigid without adding too much weight. The goal is to be under 2500lbs and have at least 400hp at the wheels. Here is what I collected for parts so far; 240Z 5 lug 300zx hubs q45 rear subframe with diff and shafts 17x10 wheels that are somewhat light poly bushings for steering rack and coupler Recaro seats Cabin vents from some GM car Now on with the pictures to get this up to date -

-

Lots of old guys use motor oil (or other oil mixes) and from the cars I have cut apart, it works very well too and is probably better for metal that already has a little bit of surface rust since it will penetrate much deeper than the waxes or rust converters. Whatever you can do to keep oxygen off the metal and not create voids will work.

-

Any problems with S13 type suspension?

Snailed replied to ComicArtist's topic in Brakes, Wheels, Suspension and Chassis

I wouldn't feel comfortable taking corners knowing those little shock shafts are all that is keeping the top of wheel from flopping over...at least not with sticky tires. Did you see how big the stock struts are in comparison? There's a reason I bet. -

Designing the "perfect" suspension setup

Snailed replied to iBang's topic in Brakes, Wheels, Suspension and Chassis

The weight of the narrowed Q45 setup with R200 will be about 25lbs heavier then the S30 stuff with comparable disc brakes. I have weighed both setups and will have final numbers once I buy rotors and get shorter shafts. John, I understand what you mean about the diff and shafts not being part of the suspension but if you look at the whole package (which is really what it comes down to) the 240/skyline/q45 stuff is FAR cheaper as a whole setup. My goals are similar to the original poster, that's why I posted in this thread. I want to have a nearly bullet proof rearend and suspension. A stock 240 with LSD would do the job fine for 400-500whp a stock S30 would not. Getting an R200 into an S30 could easily eat up $300 (right?) and you still have weak stub shafts, weak axle shafts, little brakes, 4 lug hubs and poor geometry if you want the car to sit a lot lower than stock. I know it's a lot more than $300. I'm curious honestly, what does all the good stuff cost to handle big tq #s, stop fast and not have the camber heading positive once the control arm is past horizontal? I bet it's over 2 grand excluding rear coilovers since both setups get those usually. I don't have the $ to get all that stuff, but I do have the use of a fab/restoration shop and the skills to make it work properly. I know this is a touchy subject on here because so many have had success with upgrading the stock layout. I think that's great and I'm not trying to convince anyone otherwise, just sharing what I am doing on my car to get what I want out of it. Ibang, I won't be spending a dime on bushings or colorful arms anytime soon. The factory eccentric bolts work great if you have stock geometry (LCAs not pointing at the ground like your average "slammed 240") So the only real cost is coilovers which I would buy for either setup so I don't see that as anything additional. -

Designing the "perfect" suspension setup

Snailed replied to iBang's topic in Brakes, Wheels, Suspension and Chassis

My $.02 on the rear suspension idea - I am doing almost the same thing for my rear suspension and I think it makes a lot of sense. It's a fraction of the cost to adapt a skyline/q45/240sx rear subframe rather than build up the s30 rear suspension. I'm using a narrowed q45 so I end up with aluminum uprights and bigger output shafts on the R200 (same as skyline) and it has a VLSD already also. Adapting it to the car means you can mount it so the suspension geometry is good at whatever ride height you choose. that is not an option with stock S30 LCA pickups. It's nice to not have to use the weak s30 hubs too with a powerful engine too. Anyway, I have $300 in the setup so far and I plan to add is a set of r33 rear calipers and a couple of shortened halfshafts which will be another $300 or so. So $600 for 5lug, lsd, 2 piston calipers, strong halfshafts, light hubs and good geometry? Sounds good to me. -

I really don't agree that solution looks better than leaving the holes- but you know what they say about opinions...

-

Isn't that a sparrow tail/ZGR? It looks really good either way.

-

I have used the EZ wiring kit in a couple cars and it was nice. I prefer the mini panel that they make to the big GM style one and that's what I plan on using on my Z. The wire is very nice and fire resistant (I burned it to see) and with the mini panel I like that you can move the flashers/relay to a different spot. I have used other brands as well and the extra cost doesn't really get you much. Ron Francis or Painless stuff seems the same quality as EZ Wiring but costs 2-3x more. Forgot to add - the tech support is pretty good with EZ also. It's nice to be able to just call and ask questions.

-

That is the most rust free 240z I have ever seen pictures of. Very nice find. I guess for the street it doesn't matter but I'm pretty sure that main hoop won't pass tech for any racing class with so many degrees of bend in it. And holy crap that's a lot of water/meth to carry around. And yes winter mixes for washer fluid are 40 to 50% meth so it's the same thing less the blue coloring. I wouldn't think twice about it and I wouldn't bother with a vent either.

-

Very interesting! I can't seem to find pictures of what that bar would have looked like. Do you have any pictures you would share?

-

adjustable fuel pressure regulator

Snailed replied to siteunseen's topic in S30 Series - 240z, 260z, 280z

I have used Aeromotive regulators on about ten cars with no problems, but I have heard of them bleeding down. Seems like every brand has some bad ones out there. Can you crush the stock one of make a restrictor orifice in the return line? -

Front to Rear Track Ratio

Snailed replied to johnc's topic in Brakes, Wheels, Suspension and Chassis

Thanks -

That's sort a missleading way to say that (I think I know what you mean though) Just to clarify. The same A/R turbine housing on different frame turbos does not equal the same performance in any measure, spool, response, restriction etc. A smaller A/R in a T4 can flow better than bigger T3 A/R. I would only bother with a divided housing if you have a divided manifold with the proper cylinders feeding each volute. Otherwise, you are adding unneeded turbulance from the divider. The gains from a properly designed pulse manifold are better on other engine designs rather than the I6 but there are still gains in low to midrange RPM response, just not as prevelant as they would be with an I4. Divided housings do not help high rpm power.

-

I would cut it about 8" in from all sides so it's easy hammer. Also, cut the corners with a nice radius, maybe 2-3", this will keep warping to a minnimum.

-

nope, but I bet you could buy a shock body from them. Most companies will sell just that.

-

Autodarkening Welding Helmets - What do you recommend?

Snailed replied to BLOZ UP's topic in Fabrication / Welding

nice, I'm sure it will work well for you. Glad you didn't get one with ugly graphics on it The adjustment knob strips out on the Miller hoods I have seen break. I'm sure it's not that common though. -

Autodarkening Welding Helmets - What do you recommend?

Snailed replied to BLOZ UP's topic in Fabrication / Welding

I like the Miller Elites quite a bit (with four sensors). They are comfortable and turn on automaticly, which is nice. The headgear is a little junky though and they are a little heavy to wear all day for me. Also the hood is a little bigger than some other ones, so if you weld in tight places it can restrict you a little. That said, I use a Speedglas for probably 8-20 hrs/week and it's very light, compact and comfortable. The only problem I ever have is an occational flash from blocking the sensors when welding in difficult places. -

question about fabricating a manifold and coatings

Snailed replied to FJ 280z's topic in Fabrication / Welding

Thin tubing, (~.065") either stainless or mild doesn't tend to last as long when you hang a turbo and exhasut off it, especially on 4 cyl motors. For starters, take a look at some 80's F1 turbo setups. They had thin manifolds (iconnel usually I think) and they would use a small tubular tripod to hang the turbo from it's CHRA and take the weight off the manifold. As long as the support can flex in the right directions (1/4" heims) it will do a good job of taking the stress off your manifold. I have fabricated turbo supports as elaborate as the F1 stuff and some, more simple designs and found it made a big difference in the longevity of the manifolds. Consider using a long flex joint in the downpipe and supporting your exhasut very well also. Another large factor in manifold durability, is getting clean, full penetration welds. If you have a crack or a pile of sugar at the root of the weld, inside the pipe, that is a huge stress riser and it won't really matter how think your tubing or pipe is, it will break there. As far as the coating goes, it will keep more heat in the steel and probably make it weaken faster. I guess the theory of coating the inside of the pipes is that the heat doesn't get in the metal to start but I have yet to cut into any exhasut part and find the inside properly coated. That's part of why high grade stainless is a good material for manifold, it doesn't conduct heat nearly as well as mild steel. Incidently, 304ss weld els (cast pipe weld fittings that many turbo manifolds are made from) are cheaper than mild steel ones. -

240z Urethane Air Dam Modification/Splitter

Snailed replied to Yorgee's topic in Fabrication / Welding

There are lots of cored products that might be good for this too. I have seen some thin aluminum sheets (~.040") bonded to foam core used for making signs. It's tough, light and very rigid. Not sure how thin you can get it, but I bet you could buy a piece from a local sign shop. Some of these look like what I saw...My link -

Coilover Conversion 280Z

Snailed replied to markglasco's topic in Brakes, Wheels, Suspension and Chassis

You need to find coilovers with a seperate preload and ride height adjsutment so the part that attaches to the spindle is not part of the actual shock body. You want steel ones, so you can weld them to the 280z parts. No one seems to want to talk about it on here, but it's probably not the best idea to take a coilover that is not designed as a strut and use it as one (S13 rears being a good example). If there is a single attachment point on the bottom of the coilover it's not designed to take pressure from the side and the shock shaft diameter is much smaller as a result. It does work, as many have done it already, but there is a reason for large diameter shock designs for a macpherson strut. -

This is all good advice. I do rust repair and panel fabrication as a job and I can pretty much count on the rust damage being at least twice as bad as it looks. Some places that rust out on the s30 are areas that you won't even know are bad until you cut off the panel covering it. Same goes for cars that have been repaired. Most body shops can shape filler pretty well so there is no way to know what they are covering up until you take it apart. On a car like a 240z it's pretty likely the paint/rust was touched up or "fixed" already.

-

What kind of AFR are you running in the ~10psi up area? A lot of people tend to run a 'safe' tune really rich and that can cause boost creep in some cases, especially with larger turbine wheels. Another thing is that with a richer charge in the chamber, the burn happens faster so what might be a conservative timing setting for 11.5:1 afr could be closer to knock at 10.0:1 AFR.

-

Triangulated 4 Link Qs

Snailed replied to OustedFairlady's topic in Brakes, Wheels, Suspension and Chassis

yeah, all heims have 360* travel in the main direction you are using them. Think about how much side to side travel poly bushings have... . Sorry I mispelled swaged tubes. Google it. You probably want 1" ones which will fit 3/4" heims. I think 12" x 1" DOM tubes are about $11 each. Also lots of people use pre tapped, aluminum hex tubing, also cheap. If you are going for big power later, think about some larger diameter DOM tubing with weld in ends. Still cheaper and lighter than stainless bar. If you figure out what lengths you need (hole to hole) we stock all this stuff and I can TIG weld them up for you and ship four tubes with eight 3/4" rod ends & jamb nuts included.