-

Posts

2941 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

Driveshaft...

I was a bit surprised to find the slip yoke of the original 510 driveshaft fits the SR transmission. Just a matter of having it shortened and freshened up. Final length ended up being 35 5/8", centerline of front U-joint to back of pinion flange.

-

Uh, yeah. Why is that every time someone asks about a specific engine swap, 11 people tell him he should be using something else? Can we ease up on that a bit, pretty please?

-

Hahaha Ride a cafe 500cc two stroke across the country....that I would give you props for.

Yeah, 'prolly kill an ordinary man

-

Actually, I was thinking how much fun it would be to ride to NC

-

Ugghhhh If you were closer I would buy it from you right now!

I'd be happy to deliver it for you, for a nominal fee of course

-

According to Wiki, early Ecotec's were iron, and the Ecotec II's were alum...

http://en.wikipedia.org/wiki/GM_Family_II_engine

...hmmm...

-

the iron block leads me to believe its not an ECOTEC

That was my first thought. He posted two different blocks, though. This block is alum...

...still, the architecture is 'off'.

-

Center Line Radius

-

I can't say with any certainty, but those don't look anything like an Ecotec.

-

Fuel Supply...

I spent a great deal of time deliberating on what I wanted, verses what was realistic. In the end, I chose to 'git R done'. I adapted a Z31 fuel sump/baffle inside the stock 510 tank, along with a Walbro 255lp in-tank pump. What a noisy bugger! It's triple isolated and still obnoxious. Within the car, its only noticeable while idling, but open the trunk and people scatter for 3 blocks.

New 5/16" SS fuel lines provide the supply & return duties, along with a firewall mounted '96 Q45 fuel filter.

While I was at it, I inverted the fuel sender in anticipation of using VDO gauges (opposite read). More on that later.

I haven't run the car low enough on fuel to have an opinion on the Z31 baffle. Time will tell.

-

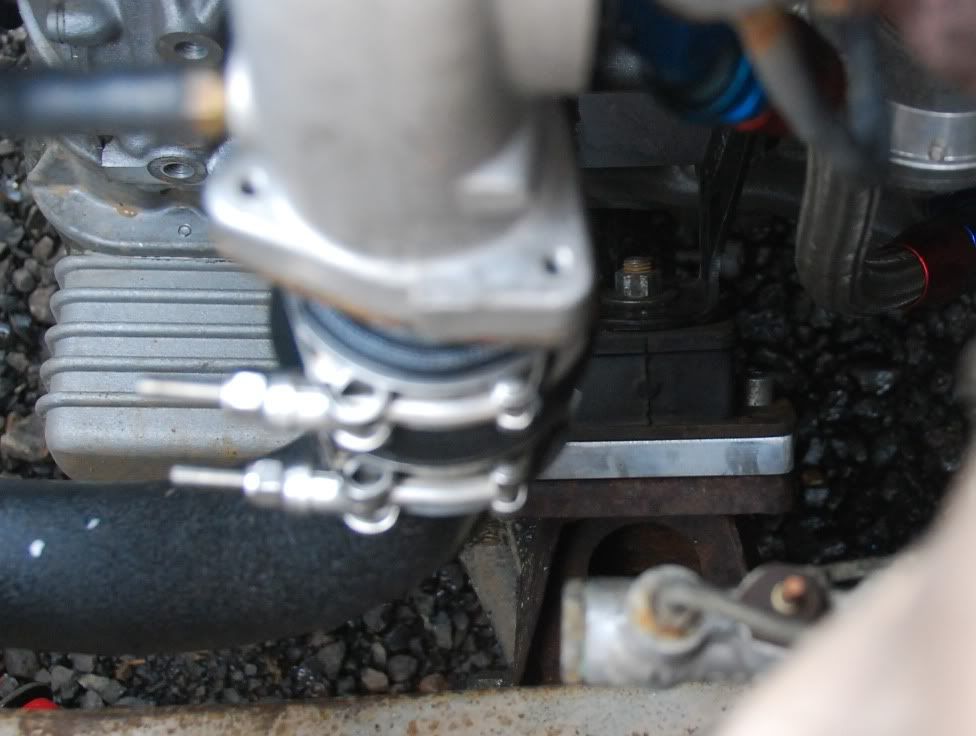

Mechanically, this was a pretty low effort swap... most everything had been previously installed in a 510, I wasn't attempting anything fancy, and the SR fits so naturally.

Starting with the mounts...

Motor mounts consisted of 1/2" spacers. Yup, that's it. I machined 1/2" aluminum spacers and used the stock L-series rubber isolators. With the spacers, the SR bolts up to the stock cross-member. Well... kind of. The issue is not the mounts, so much as the cross-member itself. The SR being a front sump, created a bit of interference. This has been addressed in several different ways, but I chose to cut out the front biased offset and weld in a 'straight' replacement. I think a single 2" round tube would have been sufficient for any normal loads imposed, but I like to be able to jack the car up by the cross-member. This led to using 2"x1" box tube, one situated vertically, and the other horizontally. This seems to be plenty stout as jacking produces no visible deflection.

The transmission mount is a modified stocker. It ain't pretty, but its stout. I cut out the center, welded in a 2"x1" box tube (horizontally) and drilled a single hole through the center. I used a GM transmission isolator, which fits the SR tranny nicely (Energy Suspension part# 3-1108G).

-

But the water will warm up though, becoming a lot less effective

So do air/air intercoolers. As TonyD would say, it's system capacitance that you're after.

-

Grim, the water is not consumed, just circulated.

-

-

Trust me, if you don't get some cheaply made ones, you don't ned a clamp for them. My teacher passed around a peice from his super-modified to the class and no one was able to get the fitting out, they're on there for good. So if you're gonna use it on something you're gonna take apart, add extra to it because you're gonna have to cut the hose to get it off and you want that extra length of hose so you can slip it back on instead of buying a whole new hose.

How many of you simulated crashes?

If you need to take it apart, you did something wrong.

-

Cool beans. Keep us posted!

-

If I'm off base, I know I will hear about it;)

You are;-)

-

I kinda covered it above. In the Formula 1 world everything in the combustion process is optimized to the point that any bore size over 98mm doesn't produce any more power (IMP) and reduces thermal efficiency (more fuel, not more power). The reason is that there isn't enough time (10,000 to 18,000 rpm) for the flame front to complete its job if it has to travel through a larger combustion chamber. NASCAR ran into similar issues with their 10,000+ rpm engines. More fuel but not much (if any) more power.

This also translates into lower rpms if the combustion process is highly optimized and is true for very large diesel engines (MTU and MAN).

That makes sense, John. But the advantage is because the 12 makes more efficient use of the bore/stroke combination, not because there are more frequent firing pulses. That's my take, anyhow.

-

Ken, What's the KA-T going into?

-

Happy Birthday!

-

Just to clarify... the Nissan water temp sensor uses the same connector as the injectors discussed above.

-

Yes.

I find GM's are generally more plentiful, though. Some Subaru's came with them as well.

-

i just need to know does it matter what wire goes on what pole on the sensor or does it not matter just as long as it makes a circuit?

Nope. Not polarity sensitive.

and also i cant find the thread that talks about what cars have the good connectors (the squeeze kind) so if any one knows off the top of their head what car has those that would be great as i am going to the j-yard tommorow

Most GM cars have what your looking for.

-

I don't see this as a big deal. Remove quill shaft. Cut handle off long Chinese screwdriver. Chuck up in drill motor. Switch to reverse. Insert molested driver into oil pump. Spin until shop floor is covered in oil

Just say'n... if your concerned, pump it out.

510 (Bart), SR20DET powered w/BMW suspension

in Other vehicles

Posted · Edited by RTz

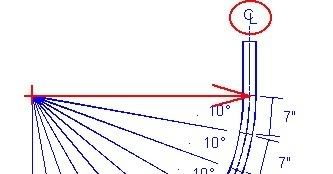

Steering...

Normally, the crosslink is a minor issue with an SR swap. There is some interference with the NVH braces at the back of the oil pan. The usual methods are to machine down the braces, or use a modified crosslink. However, with the above motor mounts, the engine sits a little higher than 'normal'. The only contact is right at full lock, the centerlink *barley* touches the lower bellhousing bolts. It's causing no trouble... just one of those things that whispers in the back of your mind "ya know Ron, rack & pinion would solve that problem"...