-

Posts

2941 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

Search for EDIS

Yeeeuuuup.

That's not a flame is it?

-

SOME sort of induction work really MUST be done for any real performance anyhow.. 38mm intake runners just aren't enough!

Not picking on you but... if the OE manifolds had 38mm runners, this thread wouldn't exist. An N42's runners are under 32mm! The runnners shown in the above manifold are 1.5", or 38.1mm.

While I'm happy with the results, and its still way early in the game, I have no reason to go larger on a street duty motor.

-

Playing with numbers....

Bone stock L28e makes a devastating 48 Hp per liter.

Installing a Braap head, header and exhuast, re-tuning the L-Jet, while retaining the stock cam/stock intake, nets you loosely 68Hp/liter... for a 40% gain. Not bad. I've seen these very results time and again from a Braap head. Further, the LJet is still manageable becuase the torque curve, while higher, still has the same overall shape. The exception is at the top, where the 'brick wall' is now more defined. The intake manifold is done. 200hp is approaching the limit on an untouched OE EFI manifold.

For Rebello's hot street engines, again loosely speaking, 98+Hp/L is the norm... for an *additional* gain of 44%. This is with a serious cam, peekier, noisier, and harder on the valvtrain, coupled with a real induction system, and turning more RPM. This is a fairly nasty motor, whereas the first 40% feels like a refinement of stock... broad power and silky smooth.

Yeasterday I was talking to Rebello about a specific cam, and coincidentally, Dave had just finished up dyno testing a Braap head. I'm not at liberty to disclose the numbers but lets just say I commited to one about 5 minutes after I got off the phone. Which leads to.... In the end, its *still* about the head. The induction/exhaust and cam is what make it work. Its the woman that makes the dress, not the contrary.

Keeping it in perspective... at a whopping 48hp/L, almost anything has the pontential to improve the power.

What an aftermarket intake manifold will normally do for an L-series is allow the engine to breath at higher rpm. RPM is where HP lives. And if its a good manifold, it won't cost you much bottom end grunt... *that's* the tricky part.

-

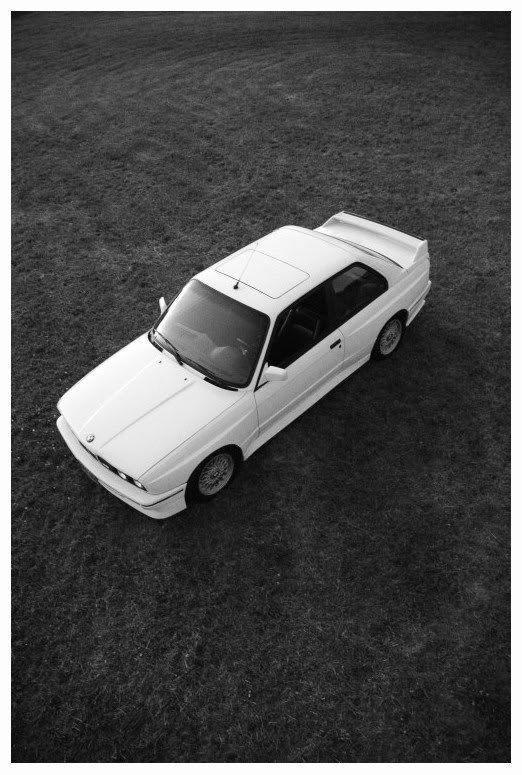

Video of stand-off injectors, BMW M3 (S14)...

-

Judgement day is just around the corner... July 14th is scheduled dyno day for the above manifold.

-

I am curious that the intake filter is inside the engine compartment where it will take in warm air. Is the benefit of cold air offset by it having to pass through a few feet of tubing?

You are correct, a better option would be a cold air intake. There are a couple reasons this car was done this way. If you'll notice, the engine compartment has been completely smoothed and painted. The removal of the AFM leaves an unattractive bracket. Due to time constraints and this car being a show car first, it was done this way, in part to hide the bracket (sits directly under the filter). Next winter's project is to relocate the battery, remove all excess bracketry, and re-spray the compartment.

I hate to say this, but for me the answer is probably no. Not because I don't think it's worth it (I do), but for my moderately-built N/A L28 it's unlikely I would gain enough benefit to justify the cost.I might argue that, depending on where your 'at' right now. If you are currently injected and using an OE manifold, you'll notice power dropping off pretty seriously by 5500 rpm. The manifold is the leading contributor. Runners are *tiny*. Even on a bone stock L28, this manifold would wake up the top end. A couple 'gotcha's'... you will need some sort of programmable EMS as the factory L-jet would be 'lost'. Valves *will* float with stock springs. Right now, this motor, with a mild cam and matching springs, is pulling to 7300rpm... where its beginning to float valves. This manifold wants to spin! See where I'm going with this?... the issue will become one of mechanical limitations. If you address those, even on a stock cam and head, I believe there is plenty of room to justify a manifold upgrade.

Just my dos pesos.

-

I can't speak for Justin, but there is a possibility that I will make a few, with some minor cosmetic and performance enhancements.

Here's the catch... they won't be inexpensive. To be profitable, $1200 to $1300 is looking like a realistic figure. Still game?

-

As the manifold is setup will the throttle bodies bolt as they did on the original manifolds?

As Justin has it drawn, its wide open for any type of flange.

I built a Ford Crown Vic. flange, at 65mm. Bolts on in a similar fashion to OE (vertically oriented throttle shaft, though)....

Keep in mind, one of the things that make this manifold work is the TB size. Not from a CFM perspective, rather an emphasis on a smooth transition from the TB to the inner walls of the plenum.

-

With Wolf V4, the only option was hard cutting fuel.

Wolf V500 is a bit more refined. The primary choices are Hard Cut Fuel, Hard Cut Ignition, Both, or soft cutting ignition.

The soft cut can be tuned and staged with a hard cut.

For example, you can cut '4 in 8', cutting every second event. '6 in 8' would be approaching a hard cut, and '1 in 8' the opposite.

-

It's too bad you're going to sell it

I'm leaving up to the Divine. I have listed it pretty steep... maybe it won't sell. The downside is, if I keep it, it will hinder my Datsun development.

beautiful car

Thank you.

the first generation M3 is one of my favorite cars.

Its one of my favorites as well. Its a terrific handling car AND a realistic daily driver. Tough combination to beat.

-

Even putting the regulator in the back is an issue unless you're willing to run one looong vac line back there - doable though I guess, maybe a hard line?

I may have missed it, but somehow I was under the assumption you were going to use an aftermarket ECU? A vacuum line to the regulator is not mandatory. There are benefits but, most often, its not a *requirement*... depends on the specific 'build'.

On a forced induction motor this is a must as pressure has to increase with boost or you'll run it lean.

Not with a standalone (and factored in up front).

You could tune around this but you'll end up running out of injector more quickly

Yup... if you don't plan in advance, but it sounds like you're the kind of guy to do just that.

- it's a headache tuning around stuff like this to say the least.

Not really.

unlike the super rich condition I had to fight down low with teeny tiny injector duties

Resolution helps. I've run monster injectors on small engines. With the right EMS, its realistic.

Took it to the track and it knocked like mad and had all sorts of issues going down the track no matter how much fuel I put into the tune.

Because thats not the right answer

Where are you right now? You're down to physical fuel delivery, correct? This is a small hurdle. Tell us more about your objectives and maybe the collective wisdom of HZ will save the day

-

From what I have seen paintless dent removal works best on large shallow dents not small, sharp ones..

It would seem that way. However, the occasions I've used it, were in fact, sharply focused dents, less than .125" dia.

In reality, I suppose it depends on the guy doing the work... just like anything else.

-

Without seeing, its hard to say, but it sounds resonable. I've had great success with paintless dent removal.

-

I jumped the green to green yellow as is shown in the lower diagram, and the blinkers work great!!

Great!

The first is simple, but what is floor temp?

For catalytic equipped cars.

The second is how many switches do I have going to the 'brake' light that's in the speedo pod? I figured the two brake level switches at the master cylinder, but are there more? Even with the fluid level switches removed and turned upside down (so the floats would be reading 'full' ) the light still stays on.

Check the switch at the E-brake handle.

-

This 280zt has A/C... http://home.comcast.net/~jgkurz/z/album/index.html

He's a member here... jgkurz. PM him if you have any questions.

-

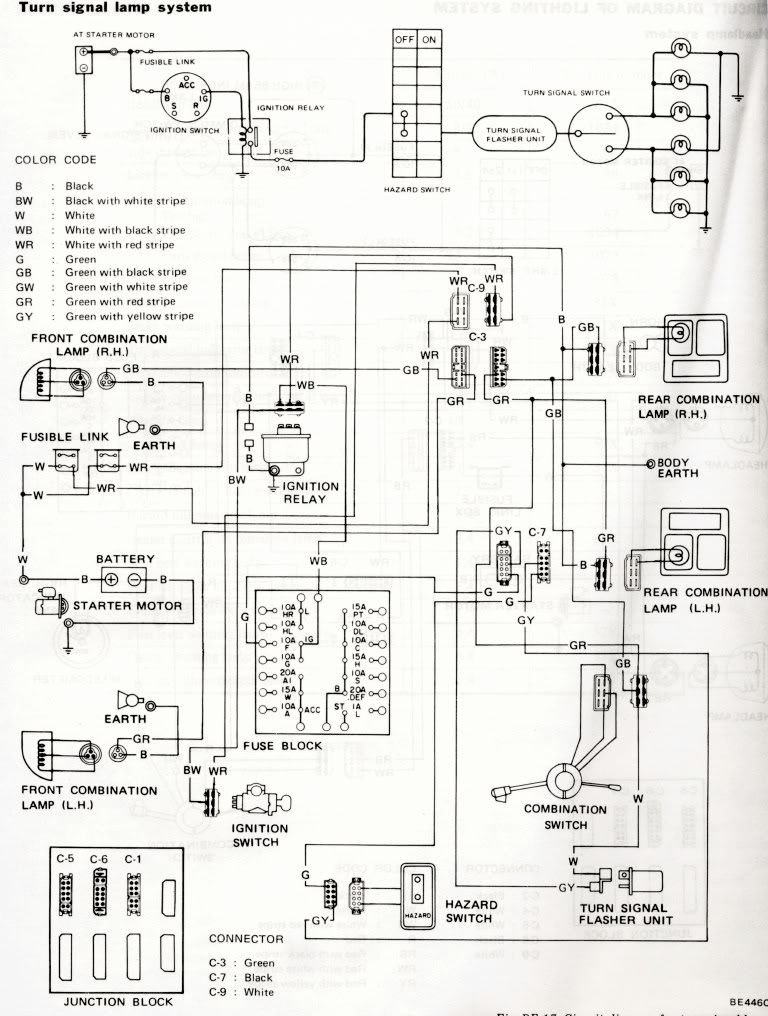

Correct me if I'm wrong, but according to the top of the diagram I should be getting power to the flasher unit whenever the hazards are off, right?

Yes... with key on, hazards off, the GY wire at the flasher should be 'hot'.

-

Below is a schematic of '78 turn signals. Notice that power distribution is separate from the Hazards (two separate fuses and flashers).

Turn signal power is routed through the hazard switch (so the hazards can interrupt turn signals). Then through the flasher. Then the combination switch, and out to the bulbs. I would start at the fuse, and follow the above path.

There are no relays in this system. The only thing you should hear is the flasher.

-

Its time to sell the BMW. Last night I took a couple of final pictures, for the ad. and sentiment...

.

.

.

.

-

You guys always entertain.

You guys always entertain....You mean like clowns in a circus???

OTM: Your prices just went up.

-

Ron,

Ferraris are RED- Ford emblem is… blue…

Hot chics wear RED dresses,

Monica Lewinsky wore BLUE.

Monica Lewinsky wore BLUE.

Coke-a Cola over Pepsi.

Killians RED over Pabst BLUE ribbon

...Hell is RED too...

-

See what I mean?!?!?!

-

Dear SuperDan,

I respectfully ask you to revoke Braap's Admin status. He's impossible these day's... won't talk to me, and when he does, its COLD. Spouts off "Red vs. Blue" and "Your either with us or against us". I had a talk with his wife to see if she's noticed any change.... she say's he wakes up in the middle of the night, sweeting and shouting "BAN HIM". I'm really concerned.

Sincerely, Ron

-

Pile?.. I have no pile... my junk is spread OUT....

-

A few adjustments to my new home...

L28 custom intake flange

in Nissan L6 Forum

Posted

Nice.

I can only imagine:biggrin: Have you posted pictures of it yet?