-

Posts

2943 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Posts posted by RTz

-

-

Could you run it as a v16? With w/e ecu is needed. Or is it you have to run them with a ecu each?

A single competent EMS, with careful planning, could conceivably run both simultaneously. However, there's no doubt you'd get better results with two separate systems, especially if you choose a lower end EMS.

-

Twin flathead's showed up at the Portland Historic's a couple years ago....

.

.

-

Wolf over MegaSquirt?

Yep, Wolf

-

Did you see the part about the Dyno and then the Track with regards to the Air horn Length protruding into the Plenum causeing different Fuel requirements per cylinder? Cylinders #4, 3, 2, 1 needed 7%, 5%, and 3% different fueling than #1?

Sure did. If the correction was in random order, I would have thought along the lines of plenum wall proximity, but the correction being sequential, sounds more like protrusion. Reinforces my beliefs on velocity stacks... without due testing, protruding velocity stacks may work against you.

P.S. I like his stand on actual track tuning. Mindful datalogging, with subsequent dyno tuning, have produced negligible gains in my experience.

-

Believe it or not, Braap's a pretty nice fellow. What he's trying to say is that you have a LOT of reading to do... feel free to help yourself and, though we do stray, try to be mindful of the thread topic.

-

Gave me a couple things to ponder, and confirmed a few others... thanks for sharing

-

There is a definate step where the stock manifold meets his head (manifold is obviously smaller) it may be something like 1mm all the way 'round if memory serves.

Tony,

Do you feel there are any positive anti-reversion effects in that scenario?

-

You should be ashamed of yourself.

-

Clearly, some advice in this thread is lacking wisdom.

-

...you can see allot of thought and work was put into it not the welding though

jk Ron

jk Ron No need to kid... you're right. That weldor has been 'removed from the project'

-

As far as a solid drawing, if thats what impresses you, then WOW. I am certified in mastercam, as well as solidworks, so solid drawings are EASY.

C'mon Brian, thats not what he said.

I am curious though, your flanges look to be around 1" thick, or so. A header flange is commonly 1/2". Since they both share the same stud & washer, how are you making up the difference in height between the two?

Ron I know your selling the complete intake however are you selling the flange alone? and the middle flange for the intake you were helping justin on?

Thanks.

Justin is putting together orders for both flanges, largely based on my own, starting at post #132... http://forums.hybridz.org/showthread.php?t=111342&page=7

-

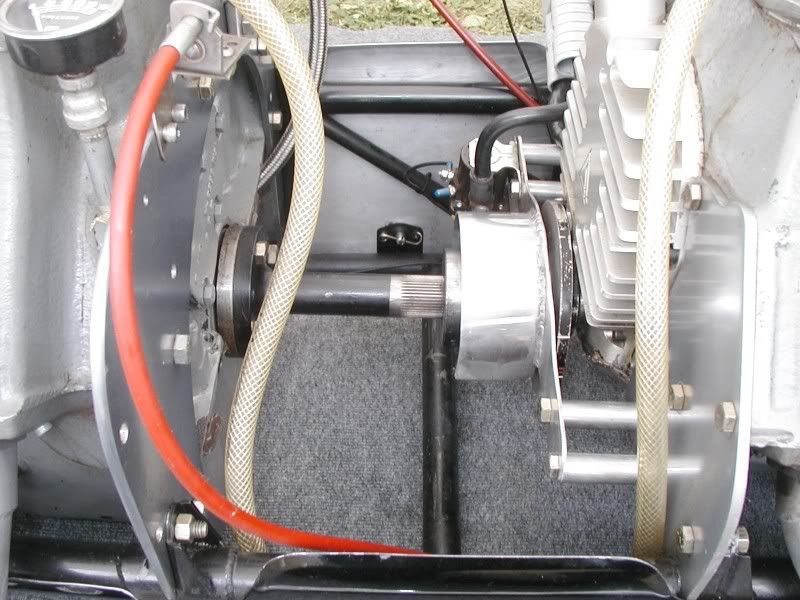

Saturday, Braap, myself, and the owner (Clint Barnts) met at TJ Wongs Performance in Vancouver, WA for some dyno tuning (Mustang Dyno). After putting in a fair amount of windshield time in this car, I was a bit surprised by the numbers. Car runs exceptionally well... a bit contradictory to the peak numbers.

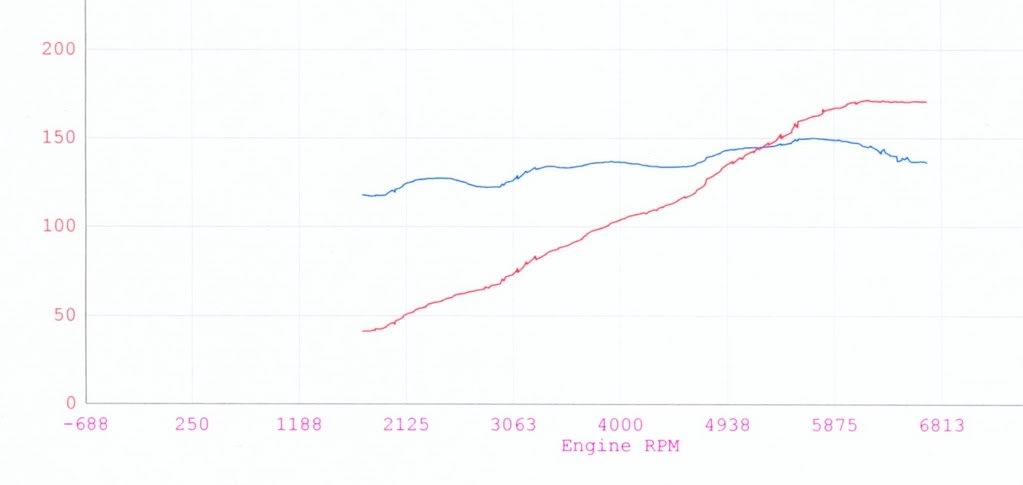

Cutting through the crap, peak wheel hp was 172@6400rpm with peak torque 150@5400 rpm....

Looking at the average power, it torque peak's at 5400rpm and still makes far more low end grunt than stock. That partly reflects the cars broad powerband and demeanor. Broad, streetable power was at the top of the list.

You'll notice a couple dips in the torque curve around 2800 and 4600rpm. The AFR's went a bit rich in the same regions. This implies that airflow is down at these points. In a nutshell, I believe this is a function of mismatched parts. Let me clarify... the headwork is pretty extensive (built by Braap), with little left for improvement, outside welding up the chambers. The intake manifold is also very aggressively sized, with liberal runners. Prior to getting it up and running, I had calculated the manifold with a torque peak around 5500rpm (which is almost exactly what we got). The cam, an Electramotive L7 grind (265@.465",) is far more docile. The headers are the larger 1 5/8" primaries, enough to support well over 300hp... attached to a smallish 2.25" exhaust system. These compromises were made to keep the car tractable enough for an everyday commute, but produce enough power to be fun when the 'itch needs scratching'. From that perspective, it was successful. However, I am confident the right cam and exhaust would amplify the peak number's substantially. The sacrifice would be drivability.

Some side notes...

Some things came to light from this session, particularly regarding heat. Not surprising is the location of the air filter, next to the radiator. It was a warm day to begin with, around 85 degrees. I was recording 160 deg. intake temps. Ouch. My best guess is that this cost us close to 7 or 8 hp. If I'm right, we would have seen ~180whp. Not bad, but still about 15 or 20hp less than I was betting on. The owner was a contributing factor in the location of the air filter. After seeing the results empirically.... lets just say, before day's end, a resolution was in the works.

The one that did surprised me a little was water temps, compression ratio, and detonation. First, the compression ratio of this engine is modest, at about 8.1 to 8.2. Never expected any detonation. Running a 160 deg. thermostat, we never got any when the water temps were 'normal'. However, even with premium fuel and low compression, we experienced SEVERE detonation once the water temps reached about 225 deg. Obviously, dialing back the timing, based on temp, 'solves' the problem, but that's not really the point. Backing into it.... we got the best numbers at 160 deg. Every consecutive run, brought temps up... and power down. Let the car cool down and the power reappeared. When we pushed much beyond 210 deg., we would get detonation, progressively worse with temp.

At 160 degrees, the car made the same power with total timing anywhere between 37 and 43 degrees. Running less than 37 cost power. With temps above 200, 40 degrees caused a power reduction.

This, in itself, is not all that surprising... the surprise is the knock propensity at such modest comp. ratios. How about all those L6's, running 10+ CR, with lackluster cooling systems? My point is this... don't discount a cool T-stat and a cooling system to back it up.... the car is receiving a Ron Davis radiator and an upgraded fan.

The other related conclusion is that this is inspiring me to install a cylinder head temp sensor near cylinder 5, as this appears to be directly related to chamber temperature. Wolf will allow additional sensors to manipulate the mapping... I will be taking advantage of that, even if for no other purpose than data logging... I think it will be interesting to see the correlation between cyl. head and water temp sensors.

In the end, this car is proof that a dyno sheet doesn't tell the whole story.

The question for me at this point is runner size. I'm of the opinion that a slightly smaller runner, say 1.4" to 1.450", wouldn't have cost us any peak power, but could in fact, bolster the low end (and quite possibly smooth out the torque curve). I need to make a decision shortly.

-

In my experience, MS has a steeper learning curve than any other EMS.... quite the opposite of the original poster's wishes.

-

I will look a little harder into the SDS system, what is your price for the one w/o ignition control?

As I mentioned, I don't sell SDS. I sell Wolf3D.

In my opinion, installing an aftermarket EMS, without ignition control, is missing the point... particularly on a turbocharged vehicle. Its similar to installing a turbo without an intercooler... it can be done, but there is so much left 'on the table'. That small step pay's big dividends.

-

The liners should be fine, the F54 is pretty rigid in my experiences.

I was referring to the liners in the exhaust ports.

So the SDS is pretty decent , Huh?

SDS works.

My point is/was, if you want it 'simple' you get it 'simple'. There is nothing extra. That's what makes it 'easy'. That is part of its beauty.

I sell a competing brand. Its not 'better', its just more flexible and capable. By nature, that makes it more complex.

There's an EMS for every person, and a person for every EMS... Choose wisely.

-

I know this is asking alot...but throw me a fastball.

If you want it simple, from every angle, then SDS deserves attention. Keep in mind, simple is synonymous with user-friendly AND plain.

Sorry for the diversion... you are running an MN47 and 18 PSI. What comp. ratio? Any problems with the liners?

-

Tread lightly, friends... I hear the keys a jangling.

-

....ahhhh a mathematical formula... so who's got the spreadsheet?

-

I've come to the conclusion, when Admins want a vacation, they just hire a new one. Braap's been holding down the fort, while the rest of 'em have been down'n a brew

...or something like that

-

Hi Brian,

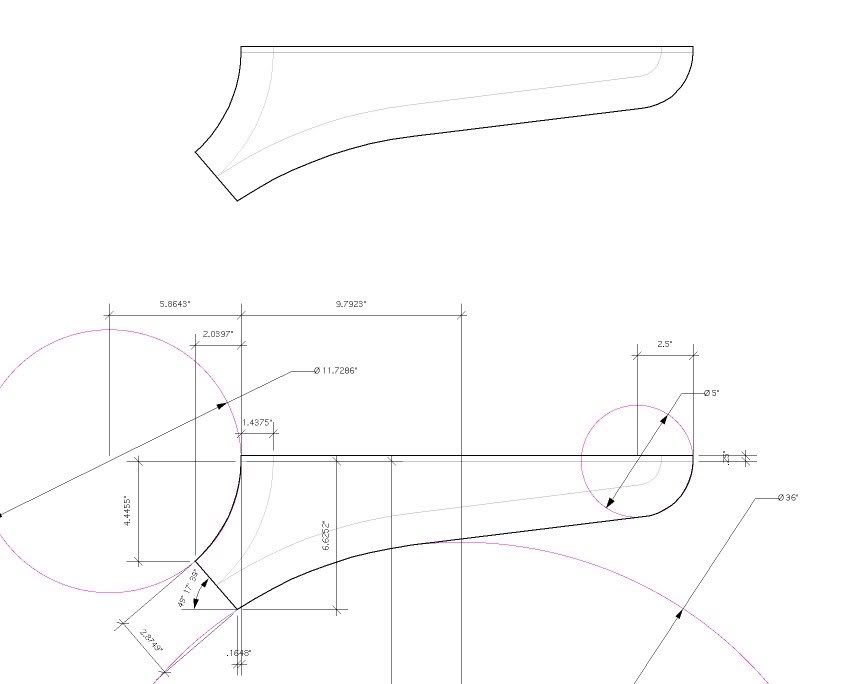

I can appreciate the work you've put into those flanges, been there myself. Your work is always top notch... not trying to discredit. Being down this path before, I have learned one or two things...

It looks like the middle of your flange doesn't have enough clearance for the header flange. Picture below illustrates that portion being above the centerline of the runners, whereas it looks like your flange is at the centerline....

.

.

Also, its a bit hard to tell by the picture, but thermostat housing clearance is suspect, as well as the area directly below the runner. I tapered my flange inboard for this reason. It may be deceiving, since my runners are a bit larger, 1.750" OD....

.

.

-

Anxious to see your talents go to work on this one. Keep us posted!

-

Sent the prints off to my CNC guru yesterday. Sadly, he's busy.... its looking like 30+ day's before I receive the buck's.

-

-

No I have not! could I have a Link to that Thinky Please?

Thought you might like that.

Thought you might like that. I've run ITB cars, speed density, making 9" idle vacuum, with that little hummer.

http://www2.towerhobbies.com/cgi-bin/wti0001p?&P=WR&I=LXCR48

Is the threads 10/32 by chance?

Without checking, I believe they are 8-32. Let me know if you need a confirmation.

Ordered a red top

in Nissan 4 Cyl Forum

Posted

Brad,

Add me to the list of 'enquiring minds'.