-

Posts

311 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by PMC raceengines

-

New Cam and Rockers - odd looking at 500+ miles

PMC raceengines replied to inline6's topic in Nissan L6 Forum

Sorry to say this but that happend about 3 minets after you started the engine , i have seen it so many times on the engine dyno , heat from oil problem did it , and there is only one fix remove and replace rockers and cam start again , i have seen a cam do it on the bench before it was started because it was dry and was picking up when turned over setting up the rockers . -

OK when the chain changes it path after leaving the guide , its to far , the chain must not rub across the top of the guide

-

i think Datsun did ok with the guides lol the best hp engine we have built still uses guides , there simple and they work and there cheep . The only time the gear set works well is when the head and or block has been shaved to far for the guide to work the way it should ,

-

Magnaflow 3in no power loss over no pipe , and sounds nicer , not a fan of twin pipes but saying that i have not tested many small motors to know ,

-

Back on topic hears the front of the 3.4 with EWP not my thing but he wanted one, also he wanted gears not guides , so some changes to my norm but we will see how they work on the dyno .

-

At the shop we made a new front for the TC head , with built in oil ways and drysump pump with a water pump that will be driven of the cam belt thought id show the world ....

-

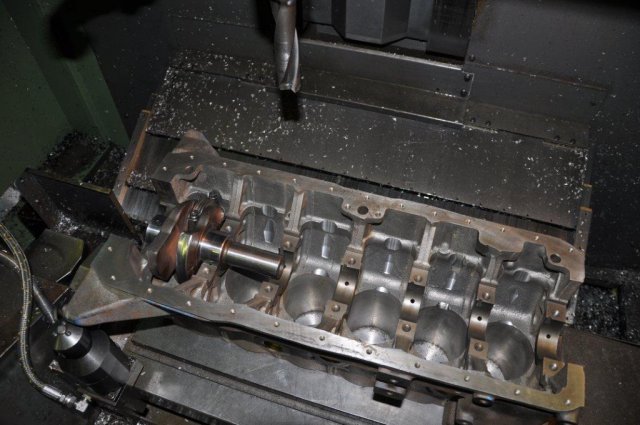

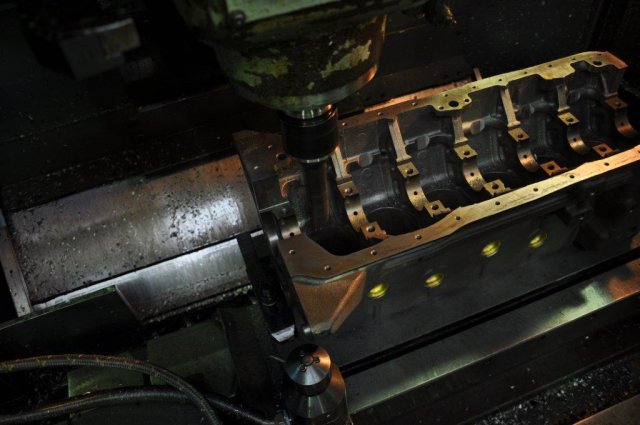

By the way the pics are a 96mm stroke with honda rod ...

-

I do my engines with a mill now and i leave at least 1.2mm , i also made a crank and rod with the big stroke to check , so i did not have to fit the good crank in a dirty block ,

-

Do not drill the rods ,,,, repeat DO NOT . There is no need to oil the bore , there is lots off oil splash from the crank . i run many rods with no oil hole in L motors ,

-

126hp per L over 2hp per cube

-

You realy need a 89mm bore as the valves are so close to bore , also you realy need some cams the stock NA KA cams are just to small to work well , You need a crank gear , and a sr20 chain , we make the crank gear there hard to come buy , you need to weld the top of the timing cover to line up to the KA cover , its not very hard if you have some skills ,then all you need to do is block the oil drain on the back of the head , and your away , also build a set of pistons to get the comp where it need to be

-

-

-

HAHA LZ is a works twin cam . the z block and head came in 18 20 22 24 hear , we build the z24 up to 2.6 with a billet crank and run the KA head on it , makes big power and torque , we make it belt drive like a bda ford looks great

-

I build them in L18 L20 L22 l23 and 2.6 they make great power , with a 2L and GTX3076r they make 350kwatw at 20psi but you will make great power with the zed head we built the z18t to 300kw many times , great little motor

-

-

The problem with the LD block is its bore is only 84mm so when you bore it it goes to water at 87mm you need to go to 91 to run a normal liners thats 89mm bore , so its not a easy job , i have tryed , when we first tryed the big strokers , also the head bolts are 12mm , so you need to drill out the head , its not that easy if it was everyone would be doing it lol

-

Even Datsun liked light parts , for there works engines 250g , and 10,000 for 4 rods even drilled the cam buckets to make them lighter , make your parts light and go fast

-

Yes like the OS 3L rb 26 but you can never get the bore out to 89 like that , 86 no prob , but then the 2 valve head dont work , need that big bore for air flow around the inlet , i did a FJ 20 like that out to 2.5 worked ok but it was very hard to keep together under big boost The 3.6 is just a torque monster and was built just to be difrent, cost was not part of the build , the bloke that has it wanted somthing no one else has , its just like art you pay for it because you like it or just want it , it dont have to make sence ,

-

We run a 10mm plate on the top of the block and run the ring pack down the piston , there is just no more room 3.6 is as far as they go . hope you can get to the shop Tony will be nice to cach up

-

We have a 3.6 kit as well i have built 2 now , but we make the block taller so we can run a longer rod , COST lots only for the hard core Z man that loves the L motor ,. As for the cost off my motors there dear , there not for every one , i dont care, there built to a very high standard and they go like they should , I have more work than i can do , this year im booked out already so im not trying to sell any parts or engines .

-

Yes we have a kit , comes with 89mm stroke crank , H beem rods , custom forged pistons , and a custom flywheel . Also has bearings , price is $6500 , aus dollers. We like to use the P90 head , but we can make the piston sute any head , we just need the CCs of the head and need to know cam spec for valve pockets , As far as i know we are the only 3.35 kit out there .

-

The 3.3 makes 300ftlb @5100 and makes 360hp engine @7600 with 50mm webers , engine takes about 70 hours to build , we have a race version with billet crank and A beem rods and light valves and injection this revs to 9000 , costs a shed lode more lol

-

After 450hp at the wheels with a rb30 you have no hope of tracktion , the last one i did, i droped boost down to 12 that was as low as it would go , it was still 300kw atw fryed the wheels any gear lol at 18psi it was 417kw lol and it was not safe at any speed , the car will be faster at 10psi .. the clutch has no chance with your motor , the torque from the 3L is way past that twin plate , there ok in 2L sr but not for your engine , the last 3026 i built with a 66 wheel turbo made 540kw on E85 atw . 3 plate clutch is a must for you with this combo

-

i never mod or change the water pump , they work just fine , the work i have done to the head fixes all cooling problems , all my parts are for the race guys out there and are just not needed for the stock style engines out there .