-

Posts

2986 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by z-ya

-

No problem putting a P79 on an N42 block, or an E88 on an F54. I believe that the Felpro head gaskets have all of the possible coolant holes, so there shouldn't be an issue with holes getting blocked off. It is always a good idea to confirm when doing assembly. The Felpro oil pan and cam cover gaskets are the best IMO.

-

NIce! I'll be making one for sure.

-

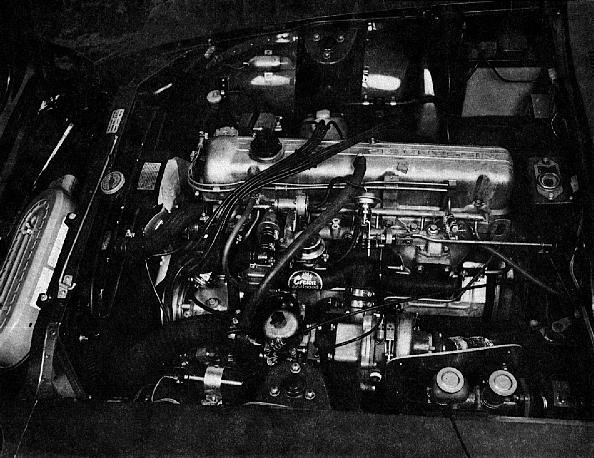

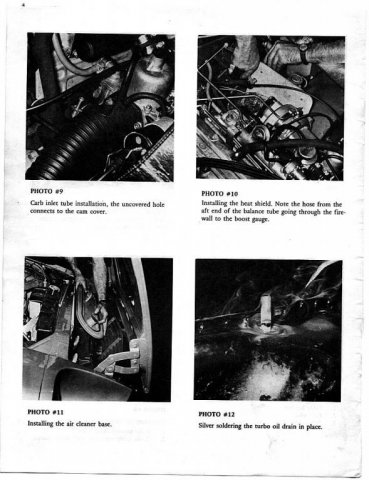

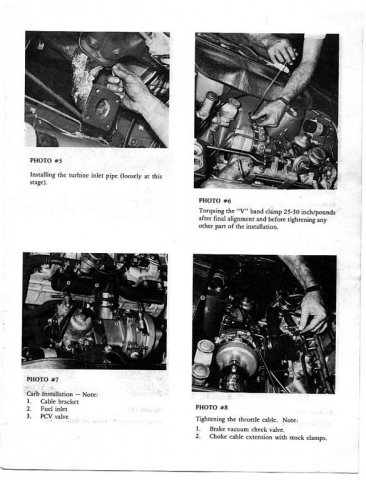

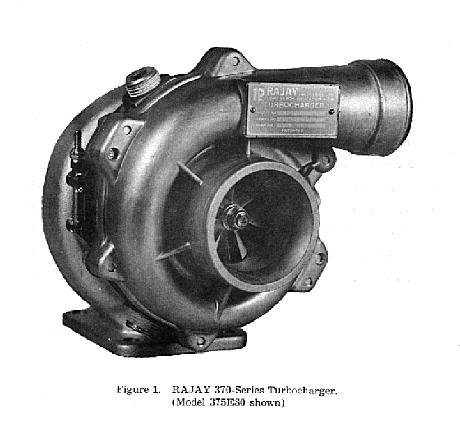

When I orginally got my 240Z, it had the Crown kit on it. Modified in a similar way with ethanol injection. It's a Rajay turbo, which you can probably still get parts for. I could not get more than 5PSI boost without serious detonation on my setup. It was the original L24 with an E88 head and flat tops. If you have flat top pistons, a good swap would be a P90 head, which will lower the CR, and be less prone to detonation. Some sort of intercooling would also help. I had two float bowls on the single SU to get more fuel capacity near the carburetor. The needle was what ever came with the kit. I've attached pages from the Crown installation manual. The last photo is of my Z. I long ago replaced this setup with an L28ET, and I have never looked back. I'm now working on a new L28ET engine for the same car. Pete

-

Bumping this. I am starting to think about this again. From what I read there is no issues having the throttlebody upstream of the IC, as long as the IC plumbing is short. I am thinking that I would weld partitions between the runners where the IC meets the intake manifold. I'm thinking that this would simulate longer runners. Ideas, thoughts?

-

Looks like a turbo block that someone put an N42 head on. Should be a decent setup for NA. CR should be around 8.5:1

-

If they are junk, and fail, you will end up with an expensive boat anchor, that is why . The only reason to run non stock rods is if you are running the engine at high RPMs for long periods of time (over 7k). The Nissan OEM ones are good most most all applications except extreme road race or turbo applications. The best rods are Carrillo, but for $300 each, they should be. This is what we run in in the L28 road race engine.

-

-

They are Rota RB 17x9.5 rear, and 17x8.5 front.. I don't remember the offset. I am running 2.75 ARP studs all around with 1.5" spacers in the rear, and .75" in the front. I'll take some pics tonight.

-

Yes, I got the car back on the ground. Gas tank, differential are in. Brakes are operational. I'm moving in 6 weeks, and my goal was to have the car as a roller by then. So far going to plan. I'd like to get the windshield, dash, and doors on before I move. I'll post more pics shortly.

-

IF they put an internally oiled cam in, and just put bolts in the spray bar mounting holes, the oil feed holes will still be open. You need to either swap the cam towers from an L28, or make some block off plates for the oil holes. Motorsport has them too. NJ has a pretty active club, with lots of knowledgeable Z owners: http://www.njzclub.com/

-

Did you replace the throwout bearing and collar? There are a few different collars out there, and if you put a new one in there without the proper offset, you will have the problem you describe. Been there, done that....

-

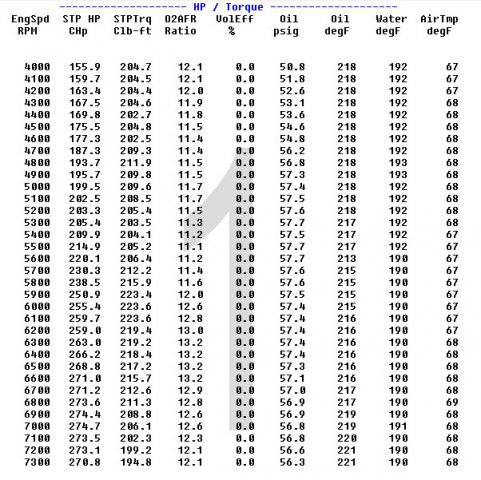

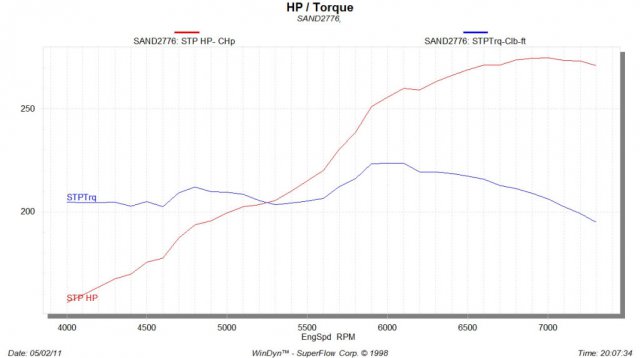

Pulled like crazy from 4000 to 7200

-

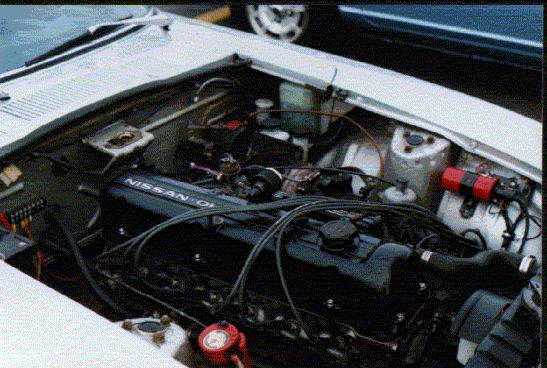

Here is a race motor I built a few years ago. Unfortunately it had a crack somewhere in the block that when the coolant temperature exceeded around 180F, caused the radiator to overflow, eventually pumping all of the coolant out of the system. Here are the specs: - F54 block 1mm overbore - Bob Sharp prepped E31 head, shaved, 37cc chambers, too many mods to list - Custom Isky cam - Cosworth pistons, 12cc dome - Carrillo 133mm rods - 13.5:1 CR - Fully balanced - Mikuni 44mm phh taper bored to 50mm Dyno was a Superflow engine dyno. http://i160.photobucket.com/albums/t177/psanders240/clubcar/th_VIDEO0004.mp4

-

As usual Derek, amazing work, and the attention to detail is quite impressive.

-

-

Silvermine Motors rear stage 4 kit install

z-ya replied to Mrtsunami20's topic in Brakes, Wheels, Suspension and Chassis

I tried to install mine last night, and all went well until bolting the calipers on. The e-brake cable bracket points directly at the CV companion flange and hit it. I see from your photos Mrtsunami20 that the bracket point straight up. id you have to swap any of the e-brake brackets? -

The air dam fit perfect, but on my car I had to build up the door gaps. The subtle z fenders are really race fenders. No internal support (I bonded stock steel supports in mine). And then you have cutout the head light holes. I understand that fiberglass parts are no where near the quality of OEM. But I have a set of aftermarket fiberglass fenders that are amazing in quality, and fit great. So it is possible.

-

Did you use the Subtle Z fenders? Mine were a bitch to get to fit right. Huge amount of work.

-

-

Thanks Guys. John Washington did most of the gas door work, but I had to do quite a bit of modification to get the hinge to work right, and for everything to line up. I think this was the first one that he did. Yes, I painted it myself in my garage. The third car I have done, and by no means perfect. Some orange peel needs sanding, and I got something under the clear in one spot, Won't be noticeable in the sun. The color is custom, but it is based on the original 902, but slightly brighter with more metal flake. The gap in the fender well will either be glassed in, or steel inner fenders. Haven't decided yet. The whole undercarriage is getting bedliner. One other note, the Subtle Z fenders didn't fit my car very well. They really are more "race" fenders. There is no internal reinforcement. So I bonded steel ones from a set of old stock fenders. I used the Fusor bonding adhesive for the rear quarters and anywhere else I had to bond glass to steel. This is the third project I have used it on. Expensive, but good stuff. Pete

-

-

Try this: https://goo.gl/photos/dhHAgVGDfbP2V6yq9

-

If you click in the link, you will see the photos. Just worked for me. I am using the stock door hinge. Where the hinge mounts was not offset correctly for the door opening, so I bonded a block of wood in there and then glassed over it. On the back side of the hinge I cut the stock capture nuts, and then bonded that plat to the back. On the door, I bonded the hinge using 2 ton epoxy, and then glassed over that. This made the door thicker and a lot stronger. So far I see no signs of cracking, but it only has surfacer on it now. Did you have Z-Trix make the stock gas door?

-

I did! I'll post more soon

-

Starting to look like a car again: https://lh3.googleusercontent.com/ExtqM9STM7lHj1h17-aLsszYAxmxnbsqkRlYitvlIYOwWU0HRLa6tyEjbtuApLI65DhvNVxOValFsLu63aySya9NXZPbPhF8v-aoBlt-s4VgS7QqzvLw32EtvF13gImLCT8R4PQW9S8AkRabkAiEWB_PgRkSxGmRNiF0qhc2aSPBuuXWTtVg-ME42mNBeJPVbU8wd9iMqAMHMH-q_iqF9llpekedxOhEJCBkr4vC6Zz1p70iYGl9OndZTcy5gOLgkLDmQf03JGlIABhVirIW1cxGiiQUhj54nv12CDlCUzKEDsJ-vh05JrDUpFFFAbqLOhD8OmZYuLv4iQwIsYl3HpOK-kwD0eeSmA2ybmxerFwZo3r-p-q3YRGHKVqZ3494WUrN0MkTmrjAd3uoAJiF5-a3hemgQmVEsNEYugdkacEJNarITf4Bft7oZjItna6eoNAqDvFwMLJE6COeImSXLeX89z_pGI7S_IL92wp6cYaEyJJ8GF29FowvzcodKDUfzEZta6uTUZNtTyrMvfvKNOZiqotOfsKnlIEF6Nc_z0Q=w1639-h922-no https://lh3.googleusercontent.com/TARDxqID9LP8uZDXq3_ZGnJMk7QKz95VfEMw8z0s_NPS8NEIQorqaUsjyu1DTi6Ka76DFgDktyXPI15z5nD4o1gNnL2_ahjm0Yo3WL35CEktnsZKIy8AU3mUBuTLghgXfUkdIcViNBzf20rJPxDA2sOEGvRmmy_87LRfjI8s6HaraCvJ9MEwnb9pL_AAsxURIDd9sXwsmnTIisy2uwdOK8Ugq3wEAhBK1I0AoHCBkZD9gNmWK28D7f6exH6Iv91Squ0oK-3vSdAxlf82DUablN8oJ3ZJFuEzfFCTwB4u0Y6dpqeqX8eECKYsueQFz5YAJptXpG8Iszqktx1MisliHxAIuarNpjeUF2SR2gJjZL8jKatFsOUGxEUPeFaZZx2_UP5Zn97ndPOWhado_Pc3dLnF2JATb7awvQQwgH-xm0YdIxF744nx_vH1bsilVFmUEXA1yySkPu6qPmOFlyRcmT9pzFCbovRdfSvlZBoWvEj1yG3rT3-IhW40_Gs8oOmBLnK5S87sQLvcoPAwDwpcbk5hoZhV0Br7bfF1l41vRFE=w1639-h922-no