-

Posts

2986 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by z-ya

-

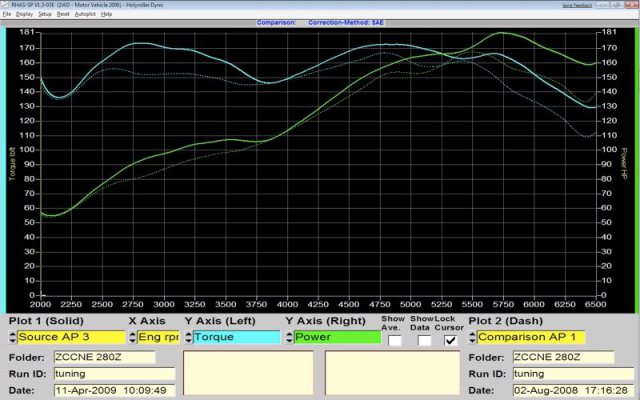

Here is another one: - L28 with flat top pistons - Mild cam (460/280) - No head work - Header, 2.5" exhaust - Dual throttle bodies with SU manifold - Megasquirt with EDIS ignition The dotted plot was with a stock 280Z intake manifold. So about 11HP gain with the dual throttle body setup.

-

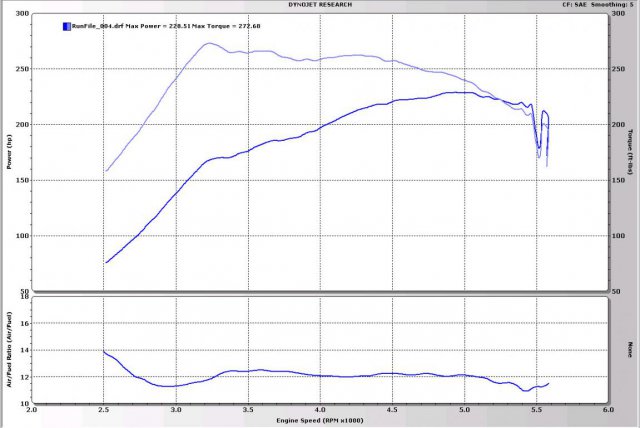

It has a fully programmable ECU. I tuned it at all load/RPM points on the fuel map. I also tuned the ignition timing across the entire RPM and load range. Also used was an aftermarket FPR and a Bosch fuel pump. You can see where it hits full boost on the dyno plot (hint, 3250RPM).

-

Here is the first iteration of my turbo car: - Stock L28ET long block with stock hydraulic cam and lifters - Stock turbo - Frount mounted Spearco intercooler - Wolf 3D EMS with direct fire ignition (RX7 coil packs) - Custom 2.5" down pipe with 2.5" exhaust and Borla turbo muffler - 12psi boost Attached dynoplot tells the rest of the story.

-

Very nice looking design.

-

I'm in the process of restoring my silver 72'. I went with YZ280 flares in the rear, and subtle Z front fenders. I want the car to still look like a Z. I'm not a fan of the Ferrari style gas doors, and filling the tank through the hatch is not what I want. I am running the stock 240Z tank, with a modified 280Z steel filler neck. Still got some more shaping a finish sanding to do. https://lh3.googleusercontent.com/GPPpC_oicx-j021-GFuE_EoxCdEuSixETOzItJsbHRU=w1538-h866-no https://lh3.googleusercontent.com/HpYKyiAyXcJy3o6gYfL9KL7DbNGyj2EMbPhCosveLzU=w1538-h866-no https://lh3.googleusercontent.com/EbMSye5o-GgwRwZvFVkSIgpVttMNR-HK1wjFwkedgkY=w1538-h866-no https://lh3.googleusercontent.com/YgDQu59nSTt2HtRXZs4t6mi3HDEd2p5Mxxtzq_dfLk0=w1538-h866-no

-

The adjustment plate on the distributor is upside down.

-

Techno Toy Tuning Strut Brace

z-ya replied to dreco's topic in Brakes, Wheels, Suspension and Chassis

What I've done is similar to what John mentioned. If you look inside where the wiper motor is, you will see that there is an area on the firewall where the "floor" under the wiper motor, and vertical braces all meet. I welded in 3/16" plate over that area that ties all of that together. Then I welded tabs to the plate. The strut bars will have clevis ends that will attach to the tabs. -

Did you check that the timing tab on the timing cover lines with TDC mark on the damper when the engine is at TDC on cylinder #1? Just bolting the tab on the cover doesn't ensure this. You can use a piston stop to find exactly TDC. As far as the timing adjustment, you may need to drop the oil pump and rotate the distributor shaft to get the timing adjustment correct. Are you using a locked L28 distributor? You need to set the static timing. Rotate the engine so that that it is in the middle of the timing adjustment range you would like. So if you would like to adjust between 20 and 30 degrees, put the engine at 25. Then rotate the distributor so that it is in the middle of the adjustment range. Pull the distributor cap and verify that the rotor is pointing at the #1 plug wire in the cap. If it isn't, then you need to drop the oil pump and rotate the shaft in the correct direction. You don't need to drop the pump all the way, just far enough that you can rotate the distributor shaft with a set of needle nose. You may have to do this a couple times before you get the rotor close. Then pull the rotor and look at the reluctor wheel, it should be aligned to the mag pickup. If not, then adjust the distributor so that it does. The start the engine and check the timing with a light and adjust dynamically.

-

It looks like whoever did the work, did a decent job. You can unshroud more, but keep in mind that the largest bore gasket you can get is round 89mm, so have one on hand before doing anything. You don't want to unshroud into the gasket sealing area. My suggestion would be to unshroud to a Felpro gasket, which I believe is around 87mm. This way you can run inexpensive gaskets. I have two E31 heads, one an original Bob Sharp, another a reproduction I had done. Both require the use of an 89 mm MLS gasket. You can see the build I did here: http://forums.hybridz.org/topic/96584-road-race-enduro-l28-engine-build/page-8

-

Turbo distributor to MSD 6A installation help!

z-ya replied to Logoleaf's topic in Ignition and Electrical

I did this a while back. Check the modified MSD schematic I posted: http://forums.hybridz.org/topic/97010-280zxt-distributor-with-progammable-msd/?hl=6al2 -

Techno Toy Tuning Strut Brace

z-ya replied to dreco's topic in Brakes, Wheels, Suspension and Chassis

Most all of these style strut braces do nothing but add weight anyway. The spherical bearing can move around, which completely defeats the purpose. A completely welded solution would be a lot better, but the adjustability make it easy fit to any car. What I have done on my recent build is to weld 3/16" steel tabs to the shock towers and firewall (with reinforcing plates), and used clevis rod ends that fit snug onto the tabs. Still not as good as welding, but certainly better than a spherical bearing. -

This swap was done by Ron Tyler in the past. It is not an easy swap for sure. He was able to pull it off. http://forums.hybridz.org/topic/79806-rt260-bmw-m-powered/page-2?hl=tyler&do=findComment&comment=854198

-

Techno Toy Tuning Strut Brace

z-ya replied to dreco's topic in Brakes, Wheels, Suspension and Chassis

The only problem with this approach, is that there isn't a lot of meat to the hood latch bracket. And there isn't a lot of support coming from the firewall in that area. It certainly looks cool though. It's the only way to do it completely bolt on, without drilling. We built this brace a few years ago, and as you can see the box steel fits between the hood latch mount and the rain gutter. It's a tight fit, and the whole thing gets sandwiched together with two bolts. Better than the T3 solution, but still not ideal. -

We have a bunch of panels, quarters, and wheel arches in fiberglass. All NOS. Limited quantities. Let me know what you need.

-

Nice work. A great solution for racers too. Most sanctioning bodies require steel between the cell and the passenger compartment.

-

It's hydro-locking, except with gas instead of water. Pull the plugs out, the cylinders are probably filled with gas. What There must be a leak somewhere in the carbs and gas is flowing into the cylinders. Are they they the stock flat top carbs? Check you oil, it probably has a lot of gas in it.

-

Looking good Jon. Get some primer on that puppy! Did you Dzus the rear flares on? Any pics? Thanks Pete

-

I have one that I bought new and ran for 5 years, so it is still flexible. I'll take$40 plus shipping. You should be able to get the rivets from Nissan.

- 6 replies

-

- Wiring Harness Cover

- Rivets

-

(and 2 more)

Tagged with:

-

Most machine shops charge per hour for the cylinder honing machine. The bigger the bore the longer it takes.

-

As far as I can tell, they only make one hub for the L6 that has a V-belt pulley. The other has no accessory drive at all. Here are more pics: It's being mounted on the engine dyno today.

-

I agree with NewZed. If the o-ring grooves are not correct, then the head will compress against the o-ring before the gasket fire ring. The o-ring should sit just outside the fire ring, not on top of it.

-

Sorry for the delay. Been traveling a lot for work. It's buried in my attic. I just need to find time to get up there.

-

Most NA 280ZXs came with 3.9:1 R200s. You are better off just swapping the whole unit.

-

When you put it back together, set the rear main seal so that it doesn't ride in the groove in the crank. I would say it was rebuilt at one point due to the punch marks on the main caps. Those are Nissan OEM pistons (P79). Check all the piston sizes are the same. I remember one engine I rebuilt had one oversized piston in it. Probably a dealer repair as it was an OEM piston. Not sure what the combustion chamber volume is on an MN47, but your CR might be too high.