-

Posts

779 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Lazeum

-

Don't forget to crank with no sparks Once you've checked oil pourring, you should remove the cam and spray some air in it to make sure everything is clean before you start the engine again. I would also remove the oil pump and inspect it carefully inside out. Same goes for your rockers, I would check the pad wear on them (especially the one from the blueish lobes). Your oil looks new but what about the filter? (99% of chance that question is dumb) Good luck with the issue, I'd got the same issue with a Braap's head and Rebello cam. I found it when a rocker broke and spread metal pieces everywhere in my engine

-

73' 240Z sway bar bolts

Lazeum replied to New-to-240z's topic in Brakes, Wheels, Suspension and Chassis

Check the grade as well. Don't take the first bolts you'll find without checking this point; Grade 5 or 8 in SAE standard or class 8.8 or 10.9 for ISO. There isn't much load on those bolts but it's better to do it right the first time Bolts btw are M8 x 1.25 x 20, you will also need a "Grower" washer per bolt (the spring type) -

rear spindle pin removal

Lazeum replied to nissun1's topic in Brakes, Wheels, Suspension and Chassis

@Nissun1 Did you just mill some material off? @Leon You are right it might make the job easier or I would say impossible to fit an extra washer with the joint being so tight. Poly seems very hard but with high load you can see it being deformed a lot so some pretention might be made with a purpose. I also believe if you mill one side without compensating the material removed, you'll change fore/aft wheel position back to the other one. It might not be a good thing for alignement to proceed this way. -

It means you have to shoot in between. In your example: => (16+21)/2 =18.5 Make sure to use the appropriate units, in your case: Either 18.5 Nm or 1.85 kg-m (=> (1.6+2.1)/2 ) or 13.5 ft-lb (=> (12+15)/2 )

-

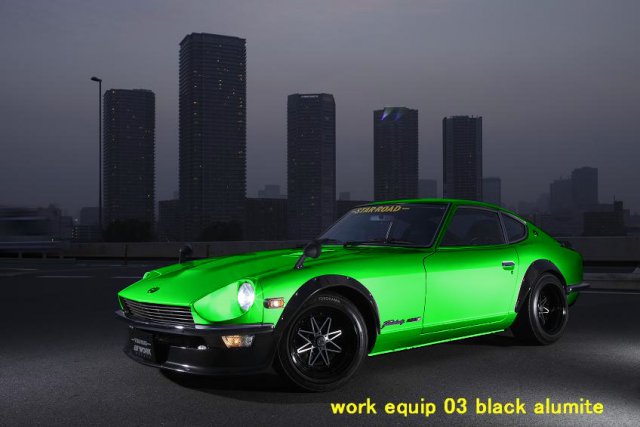

Because I had nothing better to do I hope at least you'll like it. You should check Big Phil's car if you'd like to see one... => There isn't only Photoshop, you should check Gimp or paint.net. Those are good softs.

-

rear spindle pin removal

Lazeum replied to nissun1's topic in Brakes, Wheels, Suspension and Chassis

Good job Time to sand parts and rebuild with new parts & bushings -

rear spindle pin removal

Lazeum replied to nissun1's topic in Brakes, Wheels, Suspension and Chassis

I've pulled the spindle last week and I've made the same mistake; I've cut a piece of the knuckle . Moreover, I had to use a press and an oxy-acetylene torch to press it out, the heat and the load deformed even more the knuckle. I have 3 options now: - to file some material to bring everything back even and use some washers to compensate - to use a lathe to get inserts and weld them instead of washers. - to get a new knuckle I plan to go with the 1st option since defects are not so severe. Good luck with your project! -

l28 w/ triples average mpg??

Lazeum replied to jimmyjones000's topic in S30 Series - 240z, 260z, 280z

Tony, My first guess with lean pop would be to act on the idle mixture. Am I right? Since it occurs with throttle closed how could some people believe the main jet would solve their problem? I would also tend to play with idle jet if playing with the screw won't help much or make the idle runs very rich. Regarding your comments on main jet being way too big, I think you also need to put into consideration the head & the venturi size. I was running 140 on my stock N42 head with low timing (28 total to avoid knock; flat tops & stock N42 with mild cam was not a good combo) & 40DCOE w/ 32mm venturis. AFR were around 12.5/13.0 at WOT, engine was very healthy. When I have swapped the N42 to a P79 port/polished by Braap with Rebello street cam, I had to go down on main jet down to 125 (what I had in stock) and AFR was around 10.0/11.0. I came to the conclusion new head was flowing way more air, vacuum in carbs was way higher. I believe there are 2 ways of fixing this: smaller main (110? - far away from the rule of thumb: Main = 4 x venturi's size ) & bigger venturis. Bottom line is my engine combo is out breathing my current carb setup, venturis size has to go up (34mm?). Same goes for your story, 45 DCOE might have too big venturis for the engine you've seen. So they've compensated "lack" of vacuum with big jets. Your engine is most likely flowing way more air. -

Strenght is not the only concern. Torque to tighten bolt & their class are linked. You can surely use stronger bolts but torque has to follow. If you take a stronger bolt, torque to make sure nut/bolt won't get loose would have to be higher to stress the thread enough to make sure it still does work. Since the first debate I've purchased a full set of bolts for my Z; I had to order them thru a bolt specialist (the only one I've found, here in Europe with the correct size, pitch, lenght, etc), then I had to find a plating company, make sure they would degas the bolts after the plating to remove H2 to avoid bolts to become brittle, etc. not so easy, it took me tenth of hours to get it.

-

I've got the unisync but I ended up using the hose technic. People "who know" (what they think) were amazed by the smoothness of my idle. They were all asking for the shop who tuned my carbs to get theirs tuned up as good "He might be good since he tuned 3 of them whereas 2 are already a pain" - this is the comment that came back the most.... People don't know (and I believe I know just a very little). btw, Unisync does not fit also in between my carbs & the shock tower making it very difficult to use anyhow.

-

Check this thread out, there's already tons of info in it. Check out also on Amazon and get some books: Weber Carburetors Weber Tuning Manual

-

I'll be curious to know as well. I haven't seen Paul or Tony reacting to this, I'm quite surprised Regarding the tuning, I understand now, we never have enough money for our little car... Were you also recording EGR during the tuning sessions? I'll be curious to see how they look like (not to provide my non-existent expertise but more to see how it looks like)

-

First, I love your build & the info being shared There's a lot of stuffs to learn. Regarding the lash pad, I would be concerned. if it has been broken this way, somehow you had side loads where you're not supposed to. Could it be the spring seat tilted a little? If not, I would look for something that could have created some rocker rotation back to Z axis: free lash on the lifter, cam profile or rocker pad not flat (can it be even possible?) Regarding AFR, can you please comment? I do my tuning on open road with a wideband & my dyno butt, I'm usually targetting for a baseline AFR of 12.5. Yours deviates from it, does the dyno show better results with such levels? Could the torque drop at 5500 be caused by rich AFR? same goes for lean AFR at 6500rpm? I'm curious since you're doing it with much more appropriate tool than me I'm also thinking it might not be tuned completely yet...

-

Sirpents 260Z / C32 AMG Powered RS30 - Australia

Lazeum replied to Sirpent's topic in S30 Series - 240z, 260z, 280z

Very nice job! I'll be following your work also along the way. It's very interesting & entaintaining! Please! don't stop -

Going Triple Webers!...and you can't talk me out of it.

Lazeum replied to studioti's topic in Nissan L6 Forum

I think the choice of cam & carb have to be done together. I have a port/polish P79 head from Braap with flat tops & Rebello street cam and it flows too well now for my 40DCOE-18 with 32mm chokes. I run out of air at 5000rpm but it could be adjusted with larger chokes. tuning is also awkward, my engine requires small main jets around 110-115 whereas previous stock N42 head with Scheinder stg II cam was running well with 140. You have to think about the behavior you want on your car. Mine pushes very hard at low rpm and it's very fun to drive on small roads. As stated before, it has to be tweaked to be efficient until red line around 6000rpm where my cam should still be efficient. Regarding fuel pump, I was running my mech pump at first but I found out very quickly it couldn't keep up. Electrical one is definitely a big plus: higher flow, carbs will be primed easily before you try to start the car. I have a carter unit so far but it is crazy loud (i think something is wrong with mine since you can read good comments about it and the noise it makes), I'll try a Red Facet pump next. Regarding driveability with Weber, it is linked with the fact vaccum from distributor is removed (you have then way less advance than required at low rpm / low load), it could be fixed with electronic ignition (EDIS + Megajolt for instance). If you change cam, you'll have also to think about timing, this is where you can get power from your setup. For that matter, I run a mallory unilite distributor, you can tune it but it is not super user friendly. -

We used to have races in France with those cars. We call them "Formule France". Their name somewhere else might be different. It was a tubular chassis with Hayabusa GSXR1300 engine (500kg for 180hp). Cars are sliding a lot because there isn't any diff in the rear axle. Looks like a lot of fun to drive

-

I loved it I've seen others with Datsuns but not this one. Some scenes are quite funny

-

Are you blowing fuses when you try your low beams? I have issue with lights as well some time ago. It was a turn signal lamp that was messing up the whole system (modified to be Euro legal ;I took the ground of the side marker as ground for position lights located in the headlight housing. When I was turning my headlights on, the fuse was blowing before the lights starts to work. My advice, would to open your headlight system by removing all your lamps & reinstall them one by one, check your system until the problem you're encountering happens again. It could help you to spot the issue. then you'll have to find the reason (bad ground, bad lamp - even if it still works, bad cable, bad fuse, etc.)

-

Suspension Bolts - Inventory

Lazeum replied to Lazeum's topic in Brakes, Wheels, Suspension and Chassis

Just to let you know, I've found a source locally to source parts Thanks to your help. We've made a group buy in France and I'm waiting for 477 bolts, 350 nuts & 800 washers to come. All my charts are in French so far to share info with shops but I will surely translated them to share it here with HBZ community, even if most of the info are already here. -

I like this topic a lot! tons of info to learn (and understand...) Regarding the tau layer, I believe some can also used this technique to vaporize the fuel mix. With our "out-dated" fuel injection system (as opposed to new direct injection systems), to have fuel mix going against hot valve & runners can also help. They take some energy out of the mechanical parts, temperature of the mix goes up, liquid mix becomes gases so mixture would be much easier to burn afterwards... Condensation on hot runners is lowered compared to cold one. This is one of the reason why engine when cold needs more gas than when hot. Flow discussions on the side, what would be the effect of a polished runner on tau layer? Can we consider the less, the better? I believe we wan the least possible close to the throttle and some at the back of the valves. Regarding flow, can the valve seat be also design to create some "shape" in the flow such as a swirl. Same remark for valve back face, we could have also grinded them in order to create some kind of swirl. Since it is not done, I guess there's a reason: is Flow > Swirl for max power?

-

Suspension Bolts - Inventory

Lazeum replied to Lazeum's topic in Brakes, Wheels, Suspension and Chassis

there is some slight differences but quite sure 99% should be similar. It would be good to compare with somebody who might have done the job on other s30 platform. I know that nuts for R180 (M12x1.25 nut) are different compared to R200 (M14x1.50 nut) -

Suspension Bolts - Inventory

Lazeum replied to Lazeum's topic in Brakes, Wheels, Suspension and Chassis

That's a big job to do too I only wonder if purchasing bolts from Nissan would make sense, they might be the most expensive option to replace hardware... -

Suspension Bolts - Inventory

Lazeum replied to Lazeum's topic in Brakes, Wheels, Suspension and Chassis

I did not expect such a good document! Congrats for the file!!! It would be very helpful to me (and hopefully to others!) Thanks a lot!!! -

I'm currently in the process of disassembling everything in my car to review the suspension (rust removal, poly bushings, etc.) I'm trying to list every bolts required to find a source able to provide me new hardware. No supplier today proposed bolts for s30 the way I need: Grade 10.9, correct dimension (obviously), fine pitch, zinc plated I also need self locking nuts (with the last thread crushed) If you have the list of hardware required for the rear side, I'll be glad to get it since the rear is not done yet on mine The list below is for One side only, every quantity has to be multiply by 2 for the whole car. Everything is obviously in millimeter.

-

I kind of agree with the picture size The best way to resize pictures to me is to use MS Office Picture Manager from MS, it is provided with MS Office suite. You can open a picture from a folder, plot all the pictures from the directory at once with the icon below "File" as you'd do with MS Powerpoint. Then you select them all => Image/Resize You just have to save them all afterwards (and obviously you would have saved original pictures before doing so) Quality isn't that great but for forum purpose, it is most of the time ok.