-

Posts

629 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by beermanpete

-

The charging system in my 280Z is not working.

beermanpete replied to 4.6StangRage's topic in S30 Series - 240z, 260z, 280z

The missing "L" connection won't keep the charging system from working but it does explain why the charge light is not lit. All year models show this wire in the service manual but the 74 and 75 don't have the light so maybe the regulator is from a 74 or 75? In your first post you said the replacement regulator is used but working. How do you know it is working? You never clearly stated that you full-fielded the alternator. Did you actually do this? If so, what was the result? -

The charging system in my 280Z is not working.

beermanpete replied to 4.6StangRage's topic in S30 Series - 240z, 260z, 280z

The brightness of the test light will indicate (to some extent) the voltage present at the field winding. If the battery voltage is only 12 volts as you said the field current should be maximum which means the voltage on the field should be essentially the same as the battery voltage an the test lamp will be bright. Since the test lamp is dim it suggests the regulator is not supplying enough current to the field winding. Which wire is missing from the connector? -

The only wheel alignment provided by the factory is toe. If the alignment is off there are worn or bent parts. Check the other bearings and pivots in the steering system to be sure there is not high friction somewhere that is over-powering the self-centering forces of the caster. The steering column has 3 bearings that are easily ignored. The steering rack might need attention. There are bearings in the upper spring seats that might need service. Lastly, the strut/shock itself could be stiff for some reason but this would likely be accompanied by stiff suspension movement.

-

I agree with Jon. I will add (for clarity) that you need to ensure there is free-play between the brake handle and the master cylinder. Check the adjustment. If the handle is heavy and its own weight is pushing it in the applied direction it might be be self-applying. Add a return spring if necessary to ensure the brake does not self-apply.

-

The charging system in my 280Z is not working.

beermanpete replied to 4.6StangRage's topic in S30 Series - 240z, 260z, 280z

The charge light is not connected to the field circuit. It is connected across the "Ig" and "L" terminals on the regulator. The "Ig" terminal is at battery voltage (+12) when the car is on. The "L" terminal is grounded through the regulator when there is no alternator output. As soon as the alternator output is above a set threshold a relay in the regulator opens and breaks the ground path and the light will go out. You need to test the alternator separately from the regulator by "full-fielding" it. This is simply disconnecting the regulator and connecting the "F" terminal directly to the battery. If the alternator is working correctly the output current should be very close to the rating in the manual (60 amps at 5000 RPM). The battery voltage will rise quickly to well above 15 volts so be careful and do not run the engine long while performing this test. If the output current and voltage do not rise as expected the alternator is bad. Make sure the main output wire and ground are properly connected and is good condition and make sure the V-belt is in good condition, adjusted correctly, and not soaked in oil. I learned the hard way once that an oil leak can cause the belt to slip and prevent proper charging. The VAT-40 you mentioned in your first post can do the full-field test. Having access to the VAT-40 is a luxury. Use it to your best advantage. -

Bypassing the stock proportioning valve will increase the rear brake pressure. Based on all the comments above it will not be enough however. To solve your problem you need different rear brakes. A larger diameter rotor and/or a larger caliper piston diameter. Another possible solution would be converting to a dual master cylinder setup so you can use a smaller diameter master for the rear.

-

My experience of the factory gauge is about the same. The accuracy is ok but the response time is very slow. Your high volume pump is making more pressure at idle than the stock pump does in our car. I suspect you will have 70 pounds by about 2200 RPM or so. It seems the oil pressure is ok. I doubt your oil leak is being cause by too much oil pressure.

-

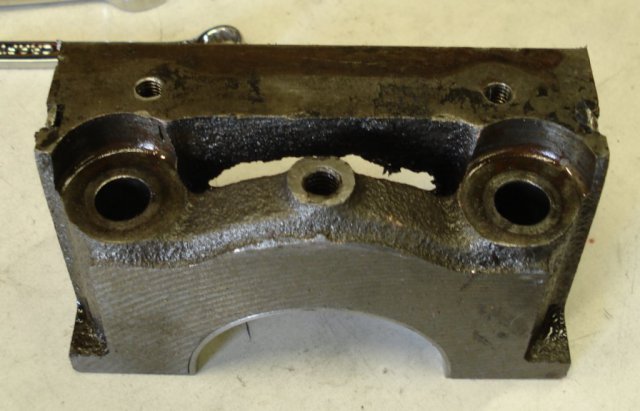

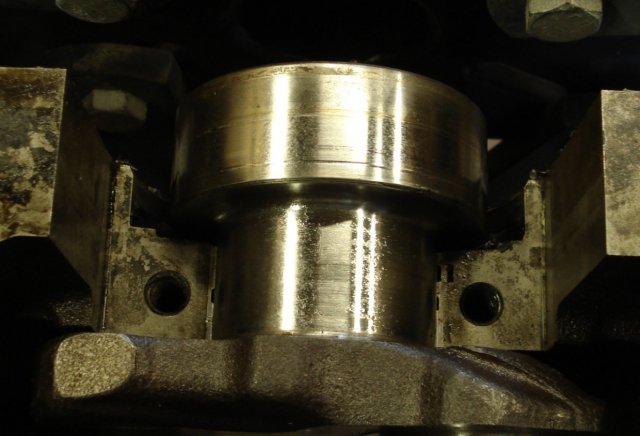

The oil pressure is generated by the pump not the relief valve. The pump relief valve only determines the maximum pressure. The valve is normally closed and does nothing. When (if) the oil pressure rises to the valve's operating point the valve opens to prevent any rise in pressrue beyond this point. When you get the mechanical pressure gauge installed watch the oil pressure as you rev the engine. It should rise somewhat linearly with engine speed until the bypass valve opens. Increasing the engine speed beyond this point should not increase the oil pressure. When the engine (oil) is cold the oil pressure will be higher at idle than when the oil is hot. If you are using heavy oil (i.e. 20W-50) the oil pressure will be higher than with light oil (i.e. 5W-30) at low engine speeds. Regardless of oil viscosity, temperature, or engine speed the pressure should never be higher than the operating point of the releif valve. Here are a few picuters of the rear main bearing cap and crankshaft. You can see the somewhat crescent shaped slot where the oil returns back to the sump. Note the wear on the crackshaft where the seal runs. The Speedi Sleeve should take care of this type of problem.

-

The relief valve is the filter bypass. It will not have any effect on the system pressure. Did you get the mechanical gauge connected yet? I looked at the rear main bearing cap on a spare engine we have . The oil return from the seal side has a slot about 1/8" wide and 1-1/2" long to flow the oil to flow through to return to the sump. I doubt this would restrict the oil flow enough to build any pressure on the seal itself. When the seal failed did it actually pop out? A few possibilities: The sealing surface of the crankshaft could be worn. If there is a groove worn into the shaft it will shorten seal life. A burr on the crank could be cutting the seal as you install it. There are other possible leak paths at the rear of the engine. The rear main bearing cap has a seal on each side. Sealant is required in the corners of the shoulders where the main bear cap fits into the block. The factory service manual shows this on page EM-25 (1973 manual). The oil pan gasket.

-

The presence of the L28 does not necessarily mean there is any electrical differences. All of the '73 electrical parts will fit directly on the L28 block and work correctly. Because you have carbs, the fuel injection question is likely a non issue. The alternators are essentially the same up to about '78. The ignition is the variable most likely to be an issue. It is possible the car has the '73 points distibutor. If has the electronic ignition from a newer model you will have to look at the car to see how well the conversion was done.

-

Rear brakes locking up before front

beermanpete replied to zack_280's topic in Brakes, Wheels, Suspension and Chassis

Adapters are tough to find. We bought one pre-made steel line with the 3/8-24 fittings, cut one end off and swapped one of the fittings with one from a metric line. We re-flared the ends thus giving us 2 lines, each with a metric fitting at one end and an SAE fitting at the other end. -

Rear brakes locking up before front

beermanpete replied to zack_280's topic in Brakes, Wheels, Suspension and Chassis

Yes. -

Where to buy Tokico BZ3099

beermanpete replied to SUNNY Z's topic in Brakes, Wheels, Suspension and Chassis

Beta Motorsports is a Tokico dealer. http://www.betamotorsports.com/ -

Rear brakes locking up before front

beermanpete replied to zack_280's topic in Brakes, Wheels, Suspension and Chassis

What does AZC say to use? It seems they should be have already figured this out. Anyhow, I suggest option 3. -

We have the R180 from an STi as well (3.54 ratio). It does have some free play between the input and output. I don't know if it is "normal" or not but it has not failed. We have used it for several track day events now without any problems.

-

The 240SX engine has a different bolt pattern for the bell housing. Therefore, transmission from the 240SX is not a direct bolt-on to the 280Z.

-

Early 260z weight reduction. How did you do it?

beermanpete replied to brianZortiz's topic in S30 Series - 240z, 260z, 280z

Here is a list of various parts and how much they weight: http://forums.hybridz.org/index.php/topic/98733-itemized-list-of-weights-for-the-purpose-of-weight-reduction/page__p__926063__hl__%2Bweight+%2Blist__fromsearch__1#entry926063 We removed about 130 pounds from our car by replacing the seats, removing the heater system (AC had already been removed), wipers, floor mats, insulation, tar paper, headliner, and so on. Most of these items are only a few pounds each but it adds up. -

The wheel offset (or backspace) will determine if there will be a problem with rubbing on the fender. Our car is fine with 205/50-15 on 15x7 wheels with about 1 inch offset (3.5 inch backspace). With zero offset wheels (also 15x7) we have run 225/50-15 without any rubbing. The Tokico springs won't change IF it will rub, only how often. Unless you have wheels with a large offset it should be fine.

-

You said the engine was unused for a long time. The rings could be stuck due to disuse. How much have you actually driven the car (in miles)? It is possible that it will improve after driving for a while (hundreds of miles). Go beat the *%#! out of it and see if it gets better.

-

Wilwood proportioning valve

beermanpete replied to xShodaimex's topic in Brakes, Wheels, Suspension and Chassis

The Wilwood valve has 3/8" NTP and requires an adapter fitting for use with the inverted flare or the bubble flare. Our valve included adapters for 3/8" threads and 3/16" line if I recall correctly. -

Shifter Bushing Question

beermanpete replied to SoC MATADOR's topic in S30 Series - 240z, 260z, 280z

We installed the MSA short throw shifter kit in our Z. It works well and we like it. My only complaint is the shift knob the supply is very heavy and looks to modern for the Z. http://www.thezstore.com/page/TZS/PROD/PRC02A/20-1050 -

Shifter Bushing Question

beermanpete replied to SoC MATADOR's topic in S30 Series - 240z, 260z, 280z

Brass is softer than steel so it will wear faster than the steel parts. -

Shifter Bushing Question

beermanpete replied to SoC MATADOR's topic in S30 Series - 240z, 260z, 280z

We have the brass bushings as well. They work fine.