-

Posts

1396 -

Joined

-

Last visited

-

Days Won

24

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by jhm

-

It's called a power shunt. When it's wired correctly, it has 2 two-prong plugs going into it. One of the plugs is wired with thick 12-gauge wire, and the other is wired with much thinner (maybe 18 gauge?) wire. Given that it's probably carrying 60-90 amps, I would remove it or ensure that it's wired correctly. You can find MANY threads on this subject in the "Ignition and Electrical" sub-forum. The unit's primary purpose (if not the only purpose) is to bleed off enough current from the car's main power leads (the thick wires) to operate the ammeter in your dash. Neither the gauge nor your dash harness are designed to handle the full load of the main power leads. Later cars came with voltmeters (vs ammeters) and did not have the power shunt, if I recall correctly. Guys wishing to convert their ammeter setup to a voltmeter setup are able to remove the power shunt. r/jhm

-

datsfast- "Boring" nothing...that's a nice, clean, factory-looking installation!!

-

Hey all- Had some free time on my hands so I decided to fab up a simple heat shield for my master cylinder and master-vac (also protects the brake warning switch). Used thin-gauge galvanized sheet steel from Lowes, coated with a layer of Thermo-Tec 2000 deg heat shield. Cheap, easy, and relatively effective. r/jhm

-

Does anybody know what part this is?

jhm replied to datsun280zx's topic in Trouble Shooting / General Engine

What year and model is the car? -

Yeah....good idea to call them. They often have lots of stuff that doesn't appear on their website. Good luck!

-

Thrustnut- Have you tried Z Specialties yet? http://www.datsunstore.com/index.php/cPath/37_267 Great folks to deal with, and I've always had good luck with them for these little stock and repro parts. Good luck and happy motoring. jhm

-

Hoov- Did you say "rectal scanner" or "retina scanner"???

-

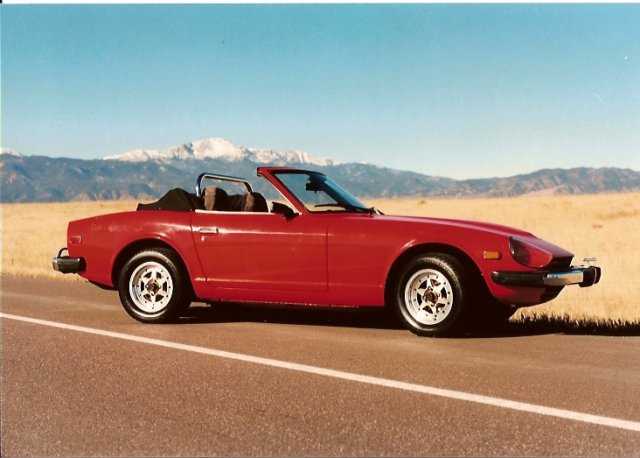

Barfife- I'm digging your ragtop Z! I think the S30's have such natural lines that they make great convertibles. Nice ride! Here's my '75 that I converted a few years ago when I was living in SoCal, then brought her with me when I moved to CO. Used a Fiat convertible frame with a custom black canvas top for the conversion. My daily driver for 3 years until I traded her for a Euro-spec Porsche 928S. jhm

-

Guys- Check out: http://www.atlanticz.ca/zclub/techtips/electrical.htm or: http://www.xenons30.com/reference.html Should contain everything you need (and more!) r/jhm

-

How does everyone get air cleaners under the hood?

jhm replied to FiveSeventyZee's topic in Gen I & II Chevy V8 Tech Board

570- Check out this thread...may have the info you're looking for. http://forums.hybridz.org/showthread.php?t=144958&highlight=vote+scarab+air+filter jhm -

Nothing special....standard automotive bulb. Here's another shot (from below, looking straight up at the light).

-

This is a great idea, especially for folks with shaved rear ends! Nobody wants that ’68 Chevy pickup behind you plowing into your rear end because he didn’t see your brake lights. I put a similar system on my car as Cygnus’, but used these LED lights from Harbor Freight vs the PC lights he used. Got the lights at my local store on sale for $7.99 each: http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=98408 They definitely make the car more visible when braking, and add a little bling at the same time. Enjoy, and happy motoring. Drax- If you use the PC lights, I wouldn’t recommend bending them double…..but it would be easy to mount two strips side-by-side to create a double row (same goes for the Harbor Freight lights I used). John

-

All- Here’s a great alternative for your interior dome lamp. They’re available from most RV parts suppliers, but I got mine from CarParts.com for $13: http://www.carparts.com/autoparts/Product/Pr-p_Product.CATENTRY_ID:2003343/c-10618/Nty-1/p-2003343/Ntx-mode+matchallpartial/N-10618/tf-Browse/s-10401/Ntk-AllTextSearchGroup?Ntt=aircraft+style+interior+light They come in multiple styles, are available in black or silver brushed aluminum, and the light fixture swivels 360 deg. So if your dome lamp has crapped out, or just gone plain missing over the years (like mine had), and you don’t want to fork out the cash for an original-style replacement unit; you may want consider this nifty alternative. jhm

-

Glad you got it working, Dave. Next week I'll be putting in a putting in a third brake light like you did -- that was a great idea (and cheap...I always like cheap!)

-

Well, after owning the car a year, I finally decided to get my clock working (since I was already into the dash chasing dash harness electrical gremlins). From what I've read, these old clocks on the S30's are amazingly robust -- even after 35 years of hard use. They often freeze up if the car has sat for a long time with a dead battery or the battery disconnected. Most can be coaxed into life again, with a little cleaning up and lubricant. Use a small amount of very light-weight oil on the gears and spinning mechanism. Ensure all parts are able to move freely. And, as I found out, there are two screw pins that provide the mounting platform for the spring/counterweight mechanism (which is basically the motor for the clock). These two screw pins may need to be adjusted to get your clock working....they need to be just tight enough to hold the spring/counterweight mechanism securely, but not so tight that they impede free movement of the mechanism. Now my clock is working again and keeping perfect time. It's amazing how much the little things in life mean! jhm

-

280z headlights & turn signals not working

jhm replied to jakeoster's topic in Trouble Shooting / General Engine

Jake- I'm guessing that your grounds are all good since you hotwired the lights and they worked for you. If not, bad grounds are always a problem with the lights....fortunately bad grounds are easily fixed. WRT the turn signals, could be your flasher's crapped out. It's under the dash on driver's side, just to the left of your left knee. There's two there...one for the hazards and one for the turn signals. I just replaced mine -- $2.99 for a new one from Pep Boys. Headlights could be the combo switch maybe? Have you removed your steering column cover and checked the switch leads and connections? Good luck and be sure to post your results! jhm P.S. I've been watching your build thread for a while now....car looks like it's coming together really nicely. Great job with the engine swap! -

Slo Mo- Go for it! I've got a 350 from a '78 C-10 in my 260....runs great and reliable as a brick. Yeah, the stock HP ain't awesome, but it's pretty darn torquey. I've spruced mine up with headers, Edelbrock Performer intake, Holley 600, and Moroso super HEI. May eventually add a cam, but it runs great for now. Good luck and be sure to post your results. jhm

-

Gauging Interest in OEM style BEEFY differential mounts

jhm replied to lumberjackj's topic in Drivetrain

RM- I'll take it!! Already sent you PM. Thx. jhm -

Engine won't fire with key in "Start" position

jhm replied to jhm's topic in Ignition and Electrical

For anyone that's interested, it turned out to be a bad ignition switch. I tested the unit, and determined that the ignition wasn't getting power while the switch was in the "Start" position. The attached schematic was quite helpful -- I believe it applies to all S30s and 130s, since MSA carries the same ignition switch (electrical portion) part number for years 70-83. I was able to get a replacement unit (used) from Z Car Source for $16....only needed the electrical portion of the switch, not the keyed part. Strange that my switch decided to crap out at same time as my fusible links....don't know if there's a connection there somehow. -

StealthZ- Thx for the reminder about the locks....I had forgotten about that. (Amazing how our minds blank out the unpleasant things in life!) Yeah.....in addition to the window cranks, armrests, and door-mounting clips; I had to relocate the door locks when I put the 280 door panels on my 260. This meant cutting enough metal inside the metal door frame to provide a new "channel" for the door lock rod to follow. It's all these little details that make our Z's so much fun to work on!!

-

Unfortunately, I believe the door panels between 240/260/280 are all slightly different. I installed 280 panels in my late-'74 260 and the holes for the window cranks and armrests were slightly off (you'd think they'd be the same, given the fact that my car is a LATE-'74 model!). I used 'em anyway....just had to relocate the holes about an inch or so....covered up the gaps with some black adhesive cloth tape. I also had to drill a couple new holes in the backside for the plastic clips. You can see the results in my 'Intro' thread: http://forums.hybridz.org/showthread.php?t=151406 I'm pretty sure the back panels (behind the doors) are pretty much fully interchangeable 70-78. Same goes for the rear hatch pieces. As an alternative, have you considered using any of the spray-on vinyl dyes to dye your brown panels to black? I've used Dupli-Color's Vinyl and Fabric dye with good results -- available at most auto parts stores. Good luck and happy motoring.

-

Like BRAAP said...."drop the tank!". There's really no way around it. FORTUNATELY....it really isn't that big a deal and you only need to drop the tank a few inches -- no need to completely remove the tank. First, MAKE SURE YOUR TANK IS ESSENTIALLY EMPTY. You will see the wisdom in this once you start getting into it. There's a drain plug at the bottom of your tank. You can usually drop the tank enough by simply removing the two lines in the front of the tank and the big fat filler inlet hose. Remove the two small lines first, lower the tank a couple inches to give you enough room to reach up between the tank and the fender, then remove the filler inlet hose. Lower the tank a couple more inches and you should have sufficient clearance to remove the bumper mount. While you're at it, this is a good time to replace your rubber fuel lines and fuel filter. Good luck and enjoy your new shaved-look rear valence!

-

Had the same thought when I was wiring up my circuit breakers. I would think that you'd be fine with the soldered wire ends as long as you can sufficiently tighten the terminal nuts. Might help a little if you can put lock washers on (not the single-split kind of lock washer, but the kind with dozens of little splines sticking out). Sorry if I'm not correctly describing the lock washer; it's been a long day...

-

Cooling my newly running engine

jhm replied to FiveSeventyZee's topic in Gen I & II Chevy V8 Tech Board

570- With respect to your differing hose outlet sizes, there are several places that market hose splicing kits -- JTR has a really nice kit. Or, you could fab your own. Or, you could solve your problem like I did with a radiator hose filler like this one from Summit: "http://www.summitracing.com/parts/MOR-63740/" It has the added advantage of enabling you to easily purge your cooling system of any trapped air. Hope this helps. jhm -

You may want to get an independent confirmation that the alternator is overcharging. Places like Autozone and Pep Boys provide free bench-testing for components like alternators, starters, etc. Next, you mentioned that you removed the external regulator.....but are you sure that your new alternator is internally-regulated, and if so, is it working correctly? The bench-testing I mentioned above will include testing the regulator. Finally, are your yellow and white wires large enough to carry high amps? (I think 12-gauge is the norm for the charging wire leaving the alternator.) Also, are all the connections clean and corrosion free? Finally, are you sure that there are no shorts in the system? If you answered no to any of the above, that may be the root cause of your problem. Hope this helps. Be sure to post your results and let us know how it goes. Good luck and happy motoring.