-

Posts

3916 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by cygnusx1

-

-

can i grind a hair off my wilwood calipers??

cygnusx1 replied to 240hoke's topic in Brakes, Wheels, Suspension and Chassis

Hmm I run the AZ Kit with 16x7 Panasports from MSA...not sure 100% of the offset but it's not zero. There is no rubbing on my 280Z. -

Last weekend I raced on a four man team 6 hour enduro Kart-race. I became spoiled by the handling of those Birel carts. Compared to the karts, my Z pushes. Many folks have told me that my Z's front bar is too large and I now feel the same way. Is there a way to "loosen" the bar by grinding a flat along it's length until I acheive the desired effect? or is it easier to just buy and try? Is there another way to reduce push asides from sway bars and spring rates? Tire pressures maybe. I don't have camber adjustment. My tires are wearing PERFECTLY even all around right now in mixed curvy road and track day driving. BTW we placed 5th on 12 teams in the enduro. It was our first time out. What a blast!!!!

-

question about hose diameter and boost controller

cygnusx1 replied to a topic in Turbo / Supercharger

...everything above and maybe a stiffer hose. I am using heavy wall black rubber vacuum hose about 1/4" ID. Like I said before I get imperceptible boost spike but I have a bigger turbo that spins up slower. However, I remember having no spike problems with the stock turbo either. It's all about the reaction time of the wastegate actuator to the boost pressure at the source. Maybe exhaust back pressure could make the wastegate open more slowly too? I am not an expert on this one though. -

http://www.streetfire.net will host car videos for free right here > http://videos.streetfire.net/Upload/Upload.uplx

-

I reference my Grainger valve from the compressor housing about 2" back from the outlet. Thumper, you explained my longer spring idea correctly. I should have said longer, softer spring. Yes Bast, in my case I use a T body for the grainger valve. If the ball opens up to the level of the outlet leg of the T, it could block some flow or become a restriction. In summary, just be aware of where the ball can go inside the valve body so that it doesnt block any flow in the open position. EDIT Sometimes it's too easy to overlook the obvious....is your actuator free to move freely and is the diaphram in perfect working order. Actuator rod alignment...etc.

-

This may be off topic slightly...but do any of you guys play Day of Defeat? It is a great, simple, $19 PC game based on WW2 weapons. I play it online and have grown to love some of the Axis and Allies guns and rifles. I don't have any guns but after playing DOD, I want a few of them. Most of the weapons you are discussing are in the game and are modeled very well.

-

Put the grainger valve as close as you can to the turbo and the actuator. Use a longer spring and smaller ball so the ball has more room to "get out of the way" and let the pressure get to the actuator more quickly. Put a short little stick ( I used a shiskebob stick ) inside the spring as a limiter so that the ball can't "top out" and restrict the passage of air. I get NO spike with my grainger valve even at 14 psi with a bigger turbo.

-

Umm this is as boring as a drag video...even more boring maybe. It's me running the straight at Watkins Glen a few passes around at the ZCCA. Sorry the vid is boring but there weren't many good vantage points to tape from. We will have to wait for the official 2005 ZCCA DVD to come out. At least it sounds good. For now... http://videos.streetfire.net/Player.aspx?fileid=46101CF4-9FAD-40C9-B425-43B4AD71475E&term=280z&p=0

-

I am running about 2-3 degrees + advanced over the stock 1983 factory spec. I run 14psi and got off the dyno with no ping to about 5500 rpm after tweaking the FMU to get it "right and safe". Sorry I cant be more specific with the numbers, it's late and I don't remember the stock timing for the '83 Turbo. I do know it's advanced initially over the other older years. The 2-3 degrees + made a huge difference in low end, off boost, torque.

-

What's the real possibility for rebuilding New Orleans?

cygnusx1 replied to dr_hunt's topic in Non Tech Board

Here are my two cents. For STRICTLY historic/memorial/industrial reasons, a part of it should be rebuilt in it's original location. TO all the people that lost their homes, Greater-New Orleans (residential) should be built in a new location that would be not within reach of a 200year storm surge. -Rebuild the dykes. -Build a tourist/entertainment/memorial/industrial ONLY area in the original location. -Create a Greater New Orleans for all the displaced residents in a "safer" nearby location. It's a tough proposition but it can and should be done. With this plan, you end up with all the original industrial benefits of that geographic location, a place to remember, a place to vacation, and no permanent residents to lose. This country is rapidly heading towards becoming an entertainment, services, and R&D country. This plan would fit the bill nicely. -

I had an early 90's civic 3-door that was a sub-base model. It had NO letters on the hatch...not DX or EX or SI. It had NOTHING but the basics. No intermittent wipers, no rear wiper, manual locks and windows, 4speed. Pleather seats, no center console...I could lift a rear tire off the ground by grabbing under the rear wheel well and I only weighed about 150. It had 60HP at the flywheel. I got 41mpg regularly. I want it back!!!! Im going shopping. Love the skinny pig!

-

About to order a ACT 6 puck clutch and pressure plate.. need some help

cygnusx1 replied to proxlamus©'s topic in Drivetrain

Look at my sig. The instructor at Watkins Glen called my clutch a "Nascar" clutch I'm not sure what he meant but that can't be good. -

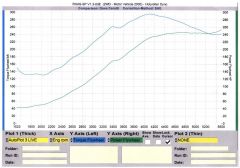

Wow, all those rumors about low end torque from V8's is true!! lol. That is ALOT of area under the curve. It must fly! Bast, I wonder if that little dip in the power curves is when the EFI maxes out the AFM and goes into open loop operation....hmmm amazing that we have an EFI system that has been around so long yet nobody seems to know the finer details of it's operation.

-

Nice car. Glad you got it sorted out.

-

This is from the Dynapack at 2005 ZCCA. It says flywheel but it is actually measured at the rear axle.

-

-

I love it!!! Welcome to boostaholics anonymous Its always the same story, 7psi for now, 10 later, intercooler, then 14 then.... Congrats on a job well done.

-

I have the HP/T curves sheet but I am waiting for holyrollerdyno to post my results on their site. It should also include the AF curve as well in a downloadable format. Did anyone else Dyno at ZCCA? What were the results compared to what you expected or from other dynos? Incedentally, many people suggested that I turn the boost down for the track event so I put it at about 12psi from 14. The car ran poorly at 12psi. It bogged a bit and missed a bit I guess because the BEGI is not a perfect fuel compensation device and did not manage the change in boost very well. I set it back to 14psi on the last track session and it woke up again. Sorry for the puffs of black smoke out there on the track...

-

Thanks to the ZCCA Convention, Giles and his wife of http://www.holyrollerdyno.com I was able to finally quantify what my butt dyno has been telling me. I filled out the prediction sheet prior to testing and I guessed 250HP and 300ft-lbs at the wheels. First pull brought some ping so I fattened the mix with the FMU. The second pull brought lots of Black smoke and low power so I leaned it a bit. The third pull gave an AF curve that started out marginallly rich and ended on the limit of lean around 5300rpm. It produced 258HP and nearly 300ft-lbs on 14psi boost. I was pleased considering it's stock '83 FI, electronics, internals, and 110,000 miles. Yehaww I made it to ZCCA, hot lapped Watkins Glen, and made it home with not a glitch. There were some AWESOME machines at the ZCCA but that's for another post......with pics and vids....

-

Project: Silver Bullet LS1 240Z Photos posted

cygnusx1 replied to qwik240z's topic in Gen III & IV Chevy V8Z Tech Board

Looks AWESOME. I can't wait to see it and hear it next week. See you there. -

If we post it here a hybridZ I think we should get a discount from Valvoline for the free exposure!! LOL

-

Mad dori dori camber!#@$

cygnusx1 replied to Forrest's topic in Brakes, Wheels, Suspension and Chassis

Looks awesome...even better when you can see it. Touched up photo attached. -

280ZX Turbo CV Shafts in a 280Z R200 rear. When I get under the car rock the car forward and back in gear, the right side CV shaft thrusts in-and-out of the side of the diff about 1/16" and makes a clunk noise. What could be the cause? The left one does not move in-out at all. I tried snapping the CV into the diff again and it snaps in OK.