-

Posts

319 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Xander

-

Can't get my cam sproket back on, what I'm I doing wrong!?

Xander replied to a topic in Nissan L6 Forum

I don't know if this is going to help but i recently had to reinstall my head 4 times because of head gasket problems. When removing the head first put the crank in TDC. You did that right? I used a wooden wedge rammed down between the chain to keep the chain and fixed and to keep the tensioner from falling out. then this is the way I put it all back together again. torque down the head. Put sprocket back on cam and tighten the sprocket bolt hand tight. The sprocket is now crooked on the camshaft. Remove the wooden wedge. the chain tensioner will now pull the chain tight. I now use a big screwdriver and lever the sprocket into place. I just put the screwdriver thru a hole in the sprocket and the tip on a cam tower. This way I lever the sprocket upwards and voila it is on. At least thats how I did it 4 times now. This will also make it possible to slighty rotate the camshaft to line everything up properly. Hope this helps. I'm sorry if my english is a bit lousy but these things are hard to explain in words. -

We don't get much UFC on Dutch television. But The K-1 fights are very popular. I believe that the of the last 10 championships 8 were won by a dutch guy. I think Ernesto Hoost is My alltime favorite. That guy has the best low kick ever. He is also a very smart and friendly guy. I don't know if you get that tv quiz "the weakest link"? He came in second place.

-

Seeing that the #5 cylinder is closest to the turbo inlet it has more to do with the temperature than fuel mixture IMHO. I do not see how the #5 cylinder can get much more air than the rest of them. But than agian I flunked fluid dynamics in school

-

I think the problem with high compression turbos is the fact that no one has enough self control to NOT up the boost. Because of the higher CR there is a lot less room for error. I am now at 7 psi and the car drives good, but I already have the feeling that it is slower than yesterday. You get used to speed so easily. To help me resist the urge to up the boost I have now removed my HKS EVC boost controler. and another point is that the first 2 headgaskets were of a poor quality. One was a Rolls brand and the other a Rock brand. I was warned that I should not use these headgaskets on a turbo, but I installed them anyway. Lesson learned I guess. I'm now in the proccess of building my own Dyno. I already have a wideband oxygen sensor so when Get it all running I can do the real tuning of this thing. I'll let you guys know how much horses it will produce. (or if I blow another headgasket).

-

It is possible that I win the title for highest compression on a turbo engine here on Hybridz. I am currently at aproximately 1:9,7. I have a F54 block, slightly shaved P90 head. flattop pistons with a 2 cc squish pad on top. The pistons are .5 mm above the deck. Here's a picture of the pistons installed: at first it assembled the lot with some crappy headgasket. This blew out within a week. So I installed another crappy headgasket . 2 days later I blew that one. Installed a felpro. When torqueing the head something was stuck in between the head and the gasket. That destroyed the felpro. So I am now at headgasket No 4. I am now driving around with a new nissan headgasket and ARP studs. The boost is limited to 7 psi. The drivability is great. I can quite easilly drive of in 3rd gear. and it picks up nicely from 1200 rpm. But I will probably never reach my 300 hp goal. the good part about all this is that I can now swap a head gasket within 2 hours .

-

12 volts over a 1 k resistance will be only about 12 mA. 12 mA @ 12 volts is 144 mW. So 250 mW (1/4 watt) is fine for the resistor. A typical hall switch can sink 100mA. So there is no problem there. I think It's amazing how much you learn by building your own megasquirt. Zya

-

That's The problem with a lot of us megasquirters. There is always room for improvement. So no one is willing to post there settings. And I feel the same way. It's crazy but I feel like showing your maps is like showing something really personal. Because I am stil improving and working on them. But I will probably never be finished tweeking the tables. So I'm gonna get over it and post my maps anyway. people can learn from bad maps aswell. This is the map that I have been running with my HIGH compression turbo. I destroyed 2 (cheapo) headgaskets with these settings. So I don't advice anyone to copy them. My .msq file is attached EDIT: I can't attache .msq file so here is a link instead. http://members.chello.nl/x.worrell/files/megasquirt.msq

-

hmm... miscalculated my CR. am now at 1:11 with turbo!

Xander replied to Xander's topic in Turbo / Supercharger

thanks guys for your info but get this. I AM STUPID!!! I miscalculated the volume of the squishpad by a factor of 10. I am "only" at about 1:9.7. stil very high for a turbo block. I was amazed at the low end performance and now I know why . I am stil going to try this CR with a mild 7 psi of boost. I think with a good gasket and the ARP studs it should hold. And if not I will just sell it as a high compression NA block. And build me a regular dished piston turbo block. Is there a better way to break in the headgasket? I nomally just slap it on and retorque it after a good heat cycle. -

hmm... miscalculated my CR. am now at 1:11 with turbo!

Xander posted a topic in Turbo / Supercharger

Recently I have build an engine for my turbo project. I have a f54 block with a p90 head. The pistons are flattop but they have a squish pad on top. Now I never thought that would be a problem but just now I used this calculator http://www.csgnetwork.com/compcalc.html and came up with a ratio of about 1:11. This is on a turbo car with 7 PSI of boost. The car drives great but I already had to replace the headgasket twice . they where cheap gasket though. I am now going to install a felpro with ARP studs. I hope this will hold at least 10 psi. I am using an intercooler. Using a roaddyno I guesstimated I am currently at 214hp@5600 and 224lbsft @4100. both measured at the wheels. I would like to acheive 300 hp at the crank. Should I sell this block as a high compression NA block and build a regular block or shall I just hope and see if the block will hold 10 psi. choices, choices. -

You could go to the junkyard and get them of a pontiac fiero. 4 or 6 cilinder doesn't mater. get the air temp sensor from the filterbox and the watersensor from the block. You can also use the TPS, although that would take a little modifying. If you get the sensors don't forget to cut of the connectors also. I am 100% sure that these are the right ones because I have been using them for 2 years now. good luck.

-

as far as I know it is a stock cam. But in europe stock NA 280zx's came with a flattop p90 combo. So maybe it is a stock NA cam. I did not rev it higher because the engine is freshly rebuild. I will see what is there to gain when I have a couple more miles on the clock.

-

Here is a picture of why I can spin my rear tires in 5th gear. This stuff always happens when I want to go for a test drive. I'm Sliding all over the place. I am lucky that my front airdam isn't on yet or it would have been damaged allready. But Still, my roaddyno came up with this graph when it was still dry: not bad since I am only running it at 7 psi for now. I am now slowly going to raise the boost and get it on a dyno to program the upper end. I didn't want to rev it to hard since the engine has just been rebuild.

-

Those cherry brand sensors are nice. If I would have known about them before then I would have bought one of those instead. They have a magnetic version also. So I could replace the one I have got in the future.

-

Yeah I can't wait to get the new fet driver so I can fix my idle . about the manifold. It usually takes 8 to 10 weeks for ground shipping to europe. So it is due anytime now. I'll let you know when it arives.

-

Tony, At dinner time in paris I was pretty wasted from having not enough sleep. I was just sitting there and listening to you and frank yapping about all kinds of stuff. All I can say now is that the trigger in the flywheel works. If I look at the timing with my timing light it is rock solid. No fluctuation at all. I have another problem though. With all the soldering in the megasuirt unit lately I must have damaged the FET driver. One channel is not giving off a signal. I now routed the signal from channel A to both FETs. This works but I can now only set the injection to simultanious and not alternating. I would rather set it to 2 squirts alternating. But new parts have been ordered including a couple of new FETs so for now it will have to do.

-

the ms unit needs a puls before every ignition event. So that's three per engine revolution.

-

the engine is now in the car and my megasquirt system is registering 200 rpm when cranking. So the system works sofar. I still have to test is at high rpm. Hopefully tomorow (tuesday) I will start the engine for the first time. And frank. getting dirty is not a problem with these engines since the flywheel is totally closed off from road dirt. And the sensor can easilly be removed for cleaning. And come to think of it, even the flywheel magnets can be cleaned if you take out the starter.

-

I'll let you know this week. The engine is not finished yet. I still need to do the fuel system.

-

yep, the magnets are distributed evenly around the flywheel at 120 degrees. With one magnet at 60 degrees before TDC. I first thought I had marked the location of the first magnet wrongly. Because I turned the flywheel 60 degrees advance instead of retarded. I felt very luck to have caught this error in time. In the end it turns out that it doesn't matter, because the magnets are evenly spaced at 120 degrees. If one magnet is 60 degrees after TDC then the next one is at 60 degrees before TDC.

-

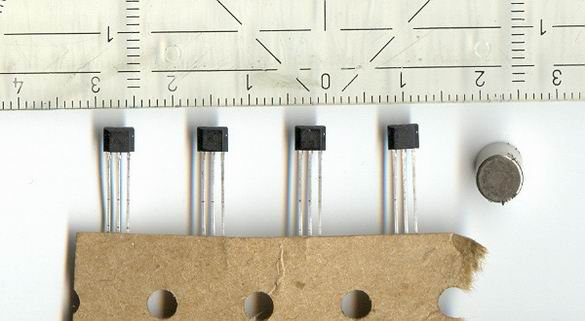

there doesn't seem to be much interest in this thread but I'm gonna post anyway. This is the hall effect switch with the wires attached. The left wire is +12 volts, the middle wire is ground and the right wires is a free floating wire until the senor "sees" a magnet. Then the right wire will be connected to ground. This is the finished sensor. I drilled a hole through a M16 brass bolt. The sensor is bonded in place with a 2 part epoxy resin. the rear is sealed with a regular sealant. three magnets are drilled and bonded into the flywheel. The first is located 60 degrees before TDC. The rest are at 120 deg interfalls. This is where I mounted the sensor. At first I wanted to mount it at the opposite side of the starter, but I was afraid of the heat from the exhaust so went for this location instead. It is well protect behind the oil pan. And the good news is. It actually works!!!

-

http://www.hksusa.com/faq/?ID=1647 here are some installation instructions on HKS boost controllers.

-

Hi all, I am in the proces of rebuilding my L28ET for my 260Z. I have been running this car on MS&S for a year now and it ran perfectly. On This new engine I will be triggering the MS&S unit from three magnets in the flywheel. The hall sensor will be mounted on the plate in between the block and the trans on the opposite side of the starter. I will be posting pictures of the finish item but for now here is a picture of the hall switches and a magnet. the measurements are in centimeters. This is the same method that SDS uses to trigger there system. If you look close at a picture of one of there pickup plates you can actualy see the hallsensor glued to it.

-

clean it out with water and before you weld it hold a match to one of the openings (I am not kidding here). The little fuel that might still be there will just burn away. And NO it will not explode. I have done this lots of times. It's better to have a controlled burn than having it suprise you when you start welding. PS: I still have all my eyebrows too

-

Now I am not a regular poster but I just had to share this one. http://www.seriouswheels.com/top-2005-Ford-Shelby-GR1-Concept-Aluminum-Body.htm Now that is a beauty.